Why High Efficiency Fryers Are the Secret Sauce for Food Truck Success

Why High Efficiency Fryers Are Game-Changers for Food Truck Operations

High efficiency fryers are commercial deep fryers designed to use significantly less energy and oil than standard models, delivering faster cooking times and better food quality. They achieve 30-35% better energy efficiency through advanced heat transfer systems, superior insulation, and smart controls that reduce waste.

Key features include advanced heat exchanger designs, better frypot insulation, automatic filtration, and ENERGY STAR certification, which requires at least 50% efficiency for gas models and 80% for electric.

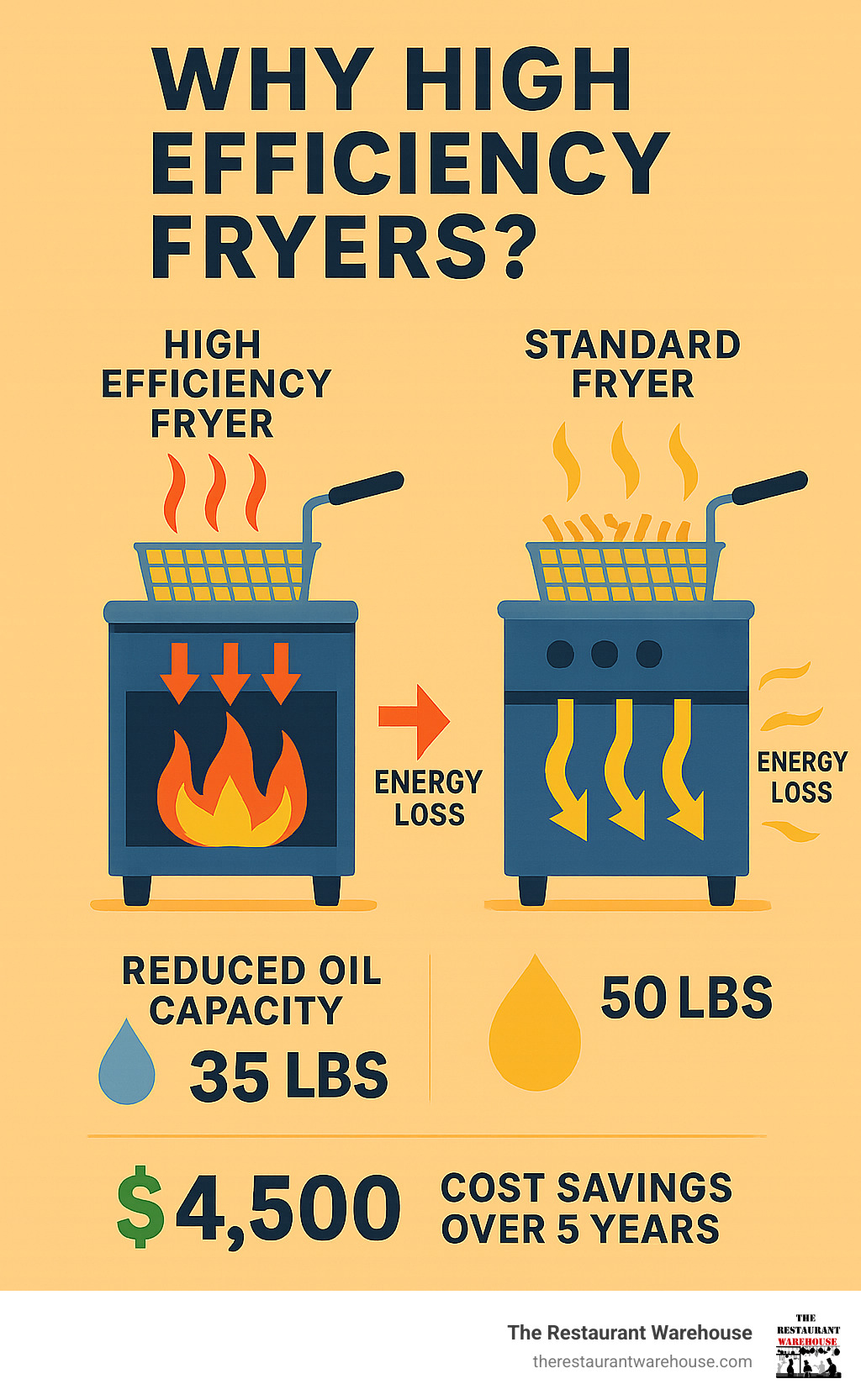

For food truck operators, this translates to real savings. ENERGY STAR certified gas fryers save about $410 annually ($4,500 lifetime), while electric models save $260 per year ($2,600 lifetime). In the tight margins and space constraints of a food truck, standard fryers waste expensive propane or limited generator power.

As one industry expert noted: "When all the costs to operate a restaurant fryer are taken into account, the high-efficiency fryer is often the least expensive choice." This is especially true for mobile kitchens where fuel costs and consistent food quality directly impact your bottom line.

Must-know high efficiency fryers terms:

What Are High-Efficiency Fryers and Why Do They Matter for Your Truck?

With a standard fryer, you're not just cooking food—you're heating up your truck and watching propane costs rise. High efficiency fryers are designed to squeeze maximum performance out of every BTU. They optimize energy transfer, so more heat goes directly into the oil instead of escaping into your kitchen. The result is faster cook times, lower utility bills, and consistently crispy food.

ENERGY STAR certified models can be 30-35% more energy efficient than standard fryers, putting real money back in your pocket. For a deeper dive, check out our Commercial Fryer Guide.

The Key Differences from Standard Models

The magic behind high efficiency fryers is solid engineering. The heat exchanger design is a major upgrade. Instead of basic tubes, these models use systems that provide more surface area for heat transfer, sometimes using infrared burners to push cooking efficiency beyond 60% for gas units.

Superior insulation around the frypot dramatically reduces standby heat loss when the fryer is idle. Advanced controls maintain oil temperature with precision, often featuring digital controls and programmable cycles to eliminate guesswork. Finally, their fast recovery time means the oil temperature bounces back quickly after adding frozen food, keeping your line moving during busy periods.

To earn ENERGY STAR certification, fryers must meet strict standards: minimum 50% cooking efficiency for gas models and 80% for electric models. Our Fryer Comparison Guide breaks down what to look for.

Why Your Food Truck Needs an Upgrade

In a food truck, every inch and dollar counts, making high efficiency fryers essential for profitability.

- Space & Comfort: Standard fryers generate excess heat, turning your truck into a sauna. High-efficiency models keep heat in the oil, creating a more comfortable workspace.

- Fuel Costs: An inefficient fryer burns through expensive propane. Reducing energy consumption by 30-60% directly slashes these costs.

- Food Quality: Inconsistent temperatures in standard fryers lead to greasy food. High-efficiency fryers maintain precise temperatures for a perfectly crispy product every time.

- Throughput & Profit: Faster recovery times mean you can cook more food in less time, increasing your profit margins during rushes.

- Electrical Load: For trucks with generators, every watt saved is critical. Our Food Truck Fryers guide can help you choose the right model for your mobile setup.

In short, high-efficiency fryers are a competitive advantage that pays for itself through lower costs and better food.

The Sizzling Benefits: Slashing Costs and Boosting Food Quality

Switching to high efficiency fryers is a smart business move that pays dividends. These advanced fryers deliver impressive energy savings, extend oil life, and help you serve better food to your customers. The benefits mean real money in your pocket, less time on maintenance, and happier customers who return for that perfect crispy texture.

Unpacking the Financial Savings

The ENERGY STAR statistics tell a compelling story. Certified high efficiency fryers achieve a 30-35% energy efficiency increase over standard models.

- An ENERGY STAR certified gas fryer saves approximately 50 MMBTU annually, putting about $410 back in your pocket each year (or $4,500 over its lifetime).

- An ENERGY STAR certified electric fryer saves about 2,390 kWh annually, equaling $260 in yearly savings (or $2,600 over its lifetime).

These fuel savings are especially critical for food trucks using Propane Deep Fryer systems. The savings on oil are even more dramatic. High-efficiency fryers can cut oil consumption by up to 37% and extend oil life, with some operators reporting 80% fewer oil discards. Also, explore local rebates and incentives from utility companies for purchasing ENERGY STAR equipment to improve your payback period.

How They Improve Cooking and Extend Oil Life

The magic of high efficiency fryers is evident in your food quality and oil management.

Consistent temperature control is the key. These fryers maintain oil temperature within a degree or two of your target, ensuring faster recovery times and steady output. This precision creates a crispier product by sealing the food's exterior, which prevents the excessive oil absorption that leads to greasy results.

The cold zone effectiveness is another game-changer. This cooler area at the bottom of the frypot traps crumbs before they burn and contaminate the oil, which reduces taste transfer between different foods and leads to slower oil degradation. Your oil stays cleaner and lasts longer. For practical tips, see our guide on Atosa Deep Fryer Tips For Fried Food. This efficiency also leads to labor savings and improved sustainability by reducing energy and oil waste.

Under the Hood: The Technology Driving Superior Performance

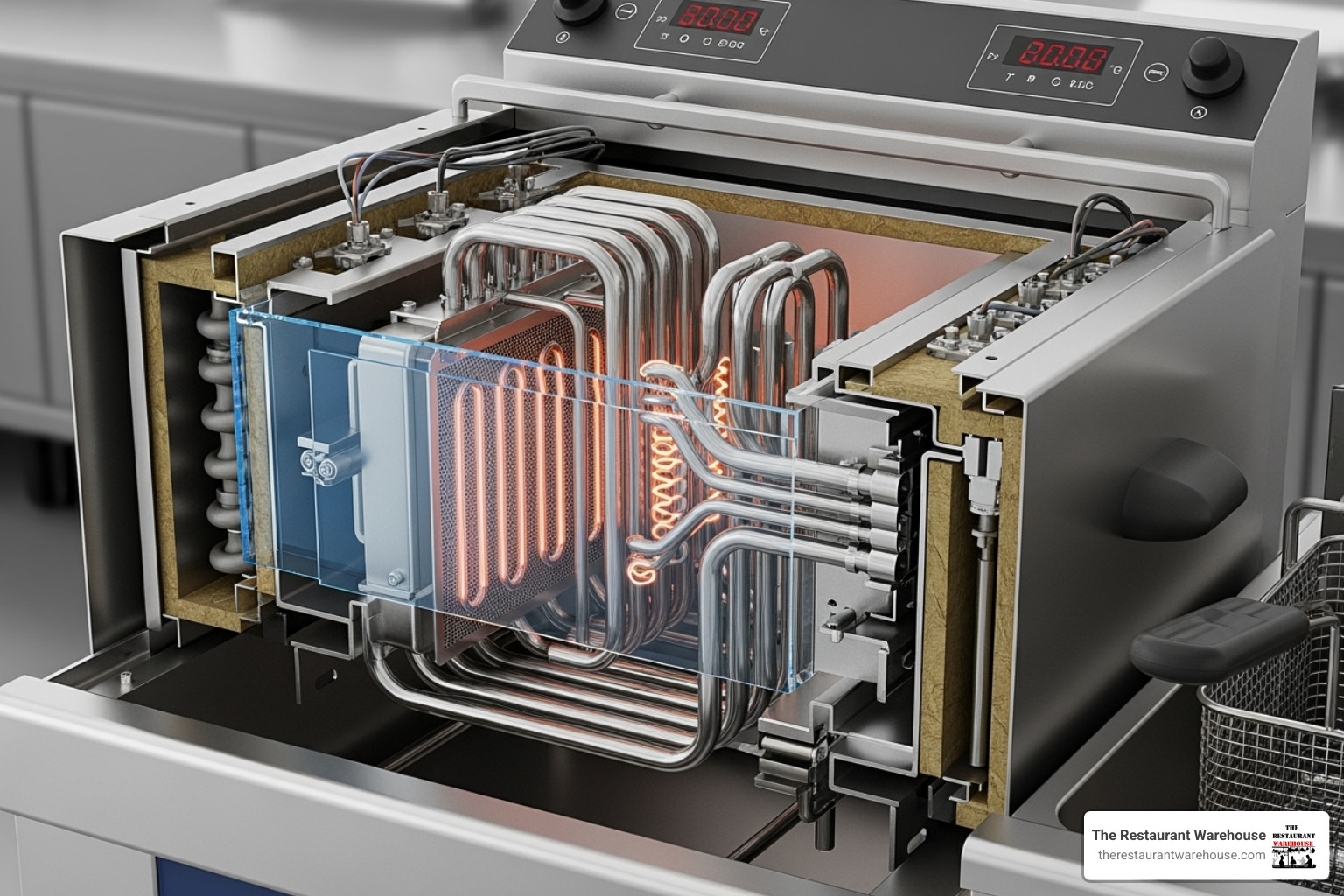

The superior performance of high efficiency fryers comes from smart engineering in several key areas: heat exchangers, burner design, filtration systems, digital controls, and insulation. Each component works to ensure energy goes toward making food delicious, not just heating up your food truck.

Advanced Heat Transfer Systems

The heart of a fryer is how it transfers heat to the oil. High efficiency fryers use sophisticated infrared burners and blower systems to create a hotter, more complete flame. In tube-fired designs, larger tubes with internal baffles force hot gases to transfer more heat to the oil before escaping. This incredible heat capture means less wasted fuel. For electric models, Deep Fryer Electric Options use highly efficient immersed elements to maximize surface area. The goal for both is to convert more energy into usable cooking heat while reducing flue gas temperature and waste.

Built-in Filtration and Oil Management

For busy food trucks, built-in automatic filtration is a game-changer. It saves space by eliminating the need for separate equipment and simplifies a messy, time-consuming job. Many systems feature easy-to-use filter pans and may include oil quality sensors that alert you when it's time to filter or replace oil. This proactive approach maintains food quality and can extend oil life significantly, saving you time, mess, and money. The How To Set Up The Atosa Fryer Oil Filtration System guide can walk you through the process.

Smart Controls and Insulation

The "brain" of a modern fryer is its smart control system. Thermostatic controls maintain oil temperature with pinpoint accuracy, while programmable cook cycles ensure consistency for different menu items. An idle mode feature automatically reduces energy use during slow periods, minimizing standby losses. This is paired with superior frypot insulation that keeps heat inside the oil instead of radiating into your kitchen, saving energy and making the workspace more comfortable. For help with controls, see our How To Operate The Atosa Countertop Electric Fryer A Step By Step Guide.

How to Choose the Right High Efficiency Fryers for Your Mobile Kitchen

Selecting the perfect high efficiency fryer for your food truck requires balancing several factors unique to a mobile kitchen. You must consider size constraints, your power source (propane or generator), your menu items and expected volume of service, and your budget. While high-efficiency models may cost more upfront, their energy and oil savings often make them cheaper to own over time. For comprehensive guidance, our How To Choose A Commercial Deep Fryer guide breaks down everything you need to consider.

Gas vs. Electric: What's Best for a Food Truck?

The gas versus electric debate is critical for a mobile operation. Both offer high-efficiency options, but with key trade-offs.

| Feature | Gas High-Efficiency Fryers | Electric High-Efficiency Fryers |

|---|---|---|

| Cost (Fuel) | Can be more volatile, but often cheaper per BTU than electricity | Generally stable, but can be more expensive per kWh |

| Power Source | Propane (most common for trucks) or Natural Gas | Generator (for truck) or shore power |

| Efficiency Rating | ENERGY STAR: Minimum 50% cooking efficiency | ENERGY STAR: Minimum 80% cooking efficiency |

| Heat-up Time | Generally very fast, powerful BTU output | Can be fast, depends on KW rating |

| Installation | Requires gas line connection, ventilation | Requires appropriate electrical hookup, generator capacity |

Propane availability makes gas fryers a common choice for food trucks, offering powerful BTU output for fast heat-up and recovery times. However, they require proper ventilation. Electric models boast a higher efficiency rating (80% vs. 50% for gas) but demand significant generator capacity. Electric Countertop Deep Fryers are a great option for smaller trucks with limited space. The choice often comes down to your existing setup and power capabilities. If you're propane-equipped, our Propane Fryer selection has excellent options.

Understanding Certifications and Standards for high efficiency fryers

Certification labels are your guarantee of performance and safety.

- The ENERGY STAR label ensures the fryer meets strict EPA criteria: a minimum cooking efficiency of 50% for gas models and 80% for electric models. This translates to real energy savings and may make you eligible for rebates and incentives. Consider signing up for the ENERGY STAR newsletter to stay informed.

- NSF certification and ETL-Sanitation labels ensure the fryer meets public health standards for design and construction, which is essential for food safety.

Installation and Maintenance Considerations for high efficiency fryers

Proper installation and maintenance are key to protecting your investment. Gas line connections and electrical hookups require professional installation to ensure safety and performance, especially in a mobile unit. Proper ventilation requirements must also be met. Once installed, daily cleaning is crucial for efficiency. Built-up grease reduces heat transfer, forcing the fryer to work harder. The deep-cleaning boil-out procedure is also essential for removing carbonized grease from heat transfer surfaces. Our guide on How To Properly Boil Out Your Gas Fryer For Optimal Performance simplifies this process. Regular filter paper replacement for units with built-in filtration will keep your oil clean and your fryer running efficiently.

Frequently Asked Questions about High Efficiency Fryers

We know that investing in new equipment for your food truck brings up plenty of questions. Here are straightforward answers to common queries about high efficiency fryers for your mobile kitchen.

How much can a food truck really save with a high-efficiency fryer?

The savings are substantial. Based on annual savings estimates, ENERGY STAR certified gas fryers save about $410 per year in fuel, while electric models save around $260 annually. Over the fryer's lifetime, that's about $4,500 in savings for gas and $2,600 for electric. The biggest savings, however, often come from reduced oil use. These fryers can extend oil life dramatically, potentially saving thousands of dollars on oil each year. The payback period is often just a few years, making it a smart investment.

Are high-efficiency fryers harder to clean or maintain?

No, they are often easier to maintain. The biggest advantage is the automatic filtration benefits on many models, which automates a messy and time-consuming task. While the boil-out process is still necessary, manufacturers have focused on simplified designs with smoother surfaces and better access to components, making daily and deep cleaning more straightforward. Proper daily cleaning is important for any fryer, but these models often streamline the process. If you encounter issues, our Atosa Fryer Troubleshooting Guide can help.

Can I get a high-efficiency model for a small food truck?

Absolutely. Manufacturers offer many options for compact mobile kitchens. Countertop models deliver efficient performance without using floor space. You can also find oil-conserving designs, including split-pot fryers for cooking different items simultaneously, and compact floor models with small footprints. The key is matching the fryer to your menu and volume. High efficiency is for any operator who wants to fry smarter. Our guide on Small Space Big Taste Commercial Countertop Fryers That Deliver offers more ideas.

Conclusion: Fry Smarter, Not Harder for Food Truck Profitability

Running a successful food truck means making smart choices, and high efficiency fryers are a game-changing decision for any mobile kitchen. They deliver significant cost reduction through energy savings of 30-35% and dramatically extended oil life, with gas models saving $410+ annually and electric models saving $260+.

These savings flow directly to your bottom line. Beyond the financials, these fryers lift your food quality with consistent temperatures and faster recovery times, giving customers that perfect crispy texture. The advanced technology—from smart controls to built-in filtration—creates a more efficient and comfortable kitchen, giving you a real competitive advantage.

While the upfront cost may be higher, the rapid payback period and long-term savings make high efficiency fryers a smart long-term investment. At The Restaurant Warehouse, we know every piece of equipment must earn its place. High-efficiency fryers are the foundation for increased profitability and customer satisfaction.

Ready to fry smarter? Download our complete restaurant kitchen equipment checklist to ensure you have everything you need. Making the switch is a smart business decision that pays dividends for years.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment