Refrigerated Sandwich Stations: Keeping Your Ingredients Cool and Your Business Hot

The Ultimate Guide to Sandwich Prep Stations: Boosting Speed and Safety

A sandwich prep station is a refrigerated counter unit that combines chilled ingredient storage and a dedicated preparation surface into one efficient, space-saving piece of equipment. For any foodservice operation looking to master its cold food assembly line, understanding these units is paramount. They are the unsung heroes of the lunch rush, transforming potential chaos into a streamlined flow of perfectly assembled orders. If you're aiming to select the perfect prep station for your establishment, this comprehensive guide will provide the key information you need to make an informed decision.

Walk into any busy sandwich shop, deli, cafe, or food truck during peak hours, and you will inevitably find a prep station at the center of the action. Staff move with practiced efficiency, ingredients are always within arm's reach, and orders are fulfilled with impressive speed. The refrigerated sandwich prep station quietly works behind the scenes, keeping everything organized, accessible, and safely chilled so your team can focus on the art of sandwich making and serving customers.

Key Features to Look For:

- Refrigerated Top Rail: This is the primary staging area for all your cold ingredients. It's specifically designed to hold multiple food pans (most commonly 1/6 or 1/3 size, but highly adaptable for other sizes) at consistently safe, cold temperatures. A forced-air refrigeration system, a critical feature in quality units, directs a curtain of cold air around each individual pan. This ensures that sliced meats, cheeses, fresh produce, and sauces stay fresh and out of the temperature danger zone, even during a continuous service.

- Integrated Prep Surface: Directly in front of the ingredient pans lies a built-in cutting board, which serves as the main workspace. This surface is typically made of high-density, non-porous polyethylene, a material chosen for its durability and hygienic properties. It won't absorb juices, odors, or bacteria, making it a safe surface for direct food contact. This integrated design supports the constant rhythm of slicing, portioning, and assembling, minimizing movement and maximizing output.

- Refrigerated Base Storage: The lower cabinet of the unit provides essential bulk cold storage. Accessible via doors or drawers, this space is used for backup ingredients, reducing the number of trips staff need to make to a walk-in cooler or other remote storage. This feature is crucial for maintaining the pace of service, as it allows for quick replenishment of the top rail without leaving the station.

- Precise Temperature Range: The ability to maintain a strict and consistent temperature range, typically between 33°F and 41°F, is the most critical function of a prep station. This specific zone is vital for food safety, as it significantly slows the growth of harmful bacteria. It also preserves the quality, texture, and flavor of perishable ingredients, reducing spoilage and waste.

- Variety of Sizes: These stations are not one-size-fits-all. They come in a wide range of widths to suit any operation, commonly from compact 27-inch units perfect for small cafes or food trucks, to expansive 72-inch models or even larger for high-volume institutional kitchens and bustling delis.

These units are engineered to solve three major challenges in a foodservice setting simultaneously: holding ingredients at safe temperatures, reducing wasted motion and labor costs, and providing a dedicated, clean surface for assembly. The result is a highly streamlined process that leads to faster ticket times, consistent product quality, and significantly fewer food safety concerns.

For budget-conscious owners and managers, a sandwich prep station is also a smart financial decision. By consolidating refrigerated storage and a prep surface into a single footprint, you reduce overall appliance needs while dramatically increasing operational efficiency and throughput.

I'm Sean Kearney from The Restaurant Warehouse, and I have spent years helping foodservice operators choose appliances that boost efficiency and profitability. From independent cafes to multi-location restaurant groups, I have seen firsthand how the right sandwich prep station can turn a chaotic service line into a smooth, high-output operation.

In this guide, you will learn how these units work, which features provide the most value, how to select the appropriate size for your volume, and what to look for in pricing and warranties. Whether you are launching your first food truck or upgrading your deli's existing line, you will finish this article better prepared to choose the right sandwich prep station for your needs and budget.

Sandwich prep station terms to remember:

If you are already thinking about upgrading, you can explore affordable options and financing directly at The Restaurant Warehouse, or contact us for a quick quote custom to your menu and layout.

The Anatomy of a Sandwich Prep Station: Key Components and Functions

At its core, a sandwich prep station is a sophisticated appliance that masterfully merges refrigeration, storage, and a dedicated workspace into a single, cohesive unit. It is meticulously designed to make foodservice operations smoother, faster, and, most importantly, safer by creating an ergonomic and temperature-controlled environment for cold food assembly.

What is a Refrigerated Sandwich Prep Station?

A refrigerated sandwich prep station serves as a self-contained workstation where all the necessary components for sandwiches, salads, wraps, and bowls are kept chilled, organized, and immediately accessible. Its primary purpose is to establish and maintain cold chain integrity, ensuring that perishable ingredients like fillings, greens, and sauces are held at safe temperatures from the moment they are prepped until they are served. This all-in-one design—combining a refrigerated ingredient rail on top, a durable prep surface, and a chilled storage base—means your staff spend less time walking to a distant walk-in cooler and more time assembling orders. This reduction in movement is a critical factor in boosting efficiency and throughput, especially in high-volume settings such as delis, sandwich shops, salad concepts, and busy cafes.

Core Components Explained

To truly understand the transformative impact of a sandwich prep station on a kitchen's workflow, it helps to know its key components and the specific role each one plays in the ecosystem of food preparation:

- Top Refrigerated Rail: This recessed, refrigerated well sits atop the unit and is the heart of the assembly line. It holds multiple food pans, and while 1/6 and 1/3 size pans are the most common, the rail can be configured with divider bars to accommodate a variety of sizes. This includes smaller 1/9 size pans for garnishes or spices, and larger 1/2 size pans for high-volume items like lettuce or primary proteins. A forced-air refrigeration system circulates cold air around each pan, creating a protective cold barrier. A hinged, insulated lid covers the pans when not in use, which not only helps maintain temperature and save energy but also protects ingredients from airborne contaminants.

- Polyethylene Cutting Board/Prep Surface: Positioned directly in front of the refrigerated rail for optimal ergonomics, the integrated cutting board is almost always made from high-density polyethylene. This material is the industry standard for several reasons: it is exceptionally durable, non-porous, and resistant to absorbing juices, bacteria, or odors. It is also relatively gentle on knife edges. The board is typically removable, allowing for thorough cleaning and sanitizing away from the unit, or for easy replacement when it becomes heavily scored over time.

- Lower Refrigerated Storage: Beneath the prep surface lies the refrigerated base cabinet, which can be configured with either hinged doors or pull-out drawers. Door models open to a spacious cabinet with adjustable shelves, making them ideal for storing bulky or irregularly shaped items like heads of produce, large sauce containers, or boxes of backup stock. Drawer models are a more ergonomic, premium option, sized to hold food pans perfectly. This makes rotating stock and replenishing the top rail incredibly fast and easy, minimizing bending and searching.

- Durable Stainless Steel Construction: Professional-grade sandwich prep stations are built to withstand the rigors of a commercial kitchen, and that starts with stainless steel. The exterior is often made from a durable and cost-effective grade like 430 stainless steel, which offers good corrosion resistance. The interior and top surfaces, which have direct contact with food and moisture, are commonly made from 304 stainless steel (also known as 18/8). This grade contains nickel, giving it superior resistance to corrosion from salts and acidic ingredients, ensuring longevity and ease of cleaning.

- Self-Contained Refrigeration System: Each prep station includes its own self-contained refrigeration system, a compact powerhouse typically located in a compartment on the rear or side of the unit. These systems are designed for plug-and-play operation. Many modern units use environmentally friendly and highly efficient hydrocarbon refrigerants like R290, which have a low environmental impact. The system circulates cold air through the base cabinet and is ducted up into the top rail to ensure consistent cooling throughout the entire unit.

When it comes to materials that contact food, it is important that the unit is certified as safe by a recognized body. Look for an NSF (National Sanitation Foundation) mark on the unit. This certification indicates that the materials used, from the stainless steel interior to the polyethylene cutting board, have been tested and meet strict public health standards for safety and cleanability.

If you are comparing models and need help understanding specifications or materials, you can reach out to The Restaurant Warehouse team for a no-pressure consultation at any time via https://therestaurantwarehouse.com/.

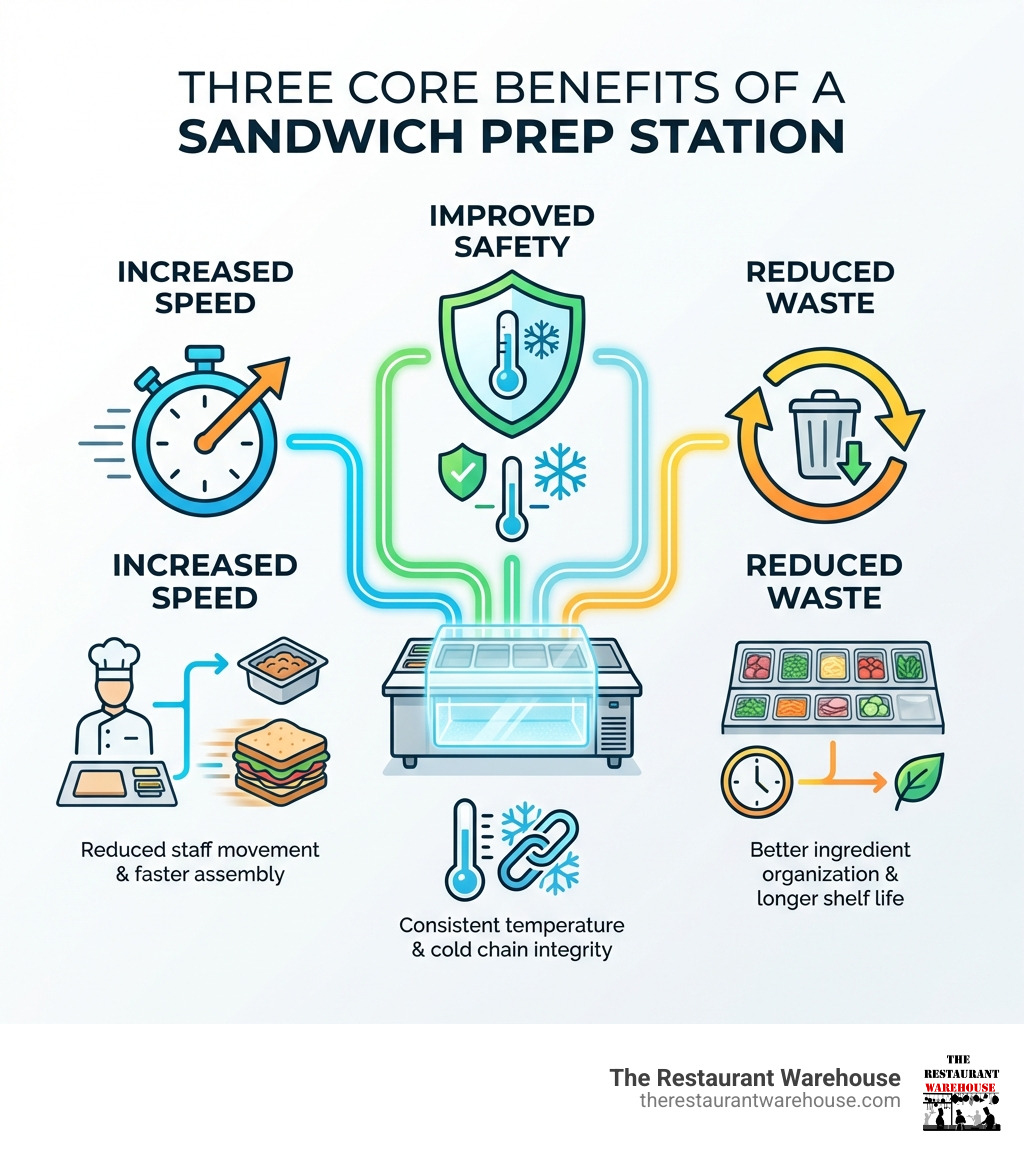

Boosting Your Bottom Line: The Benefits of a Refrigerated Prep Table

Investing in a refrigerated sandwich prep station is not just about acquiring a new piece of kitchen hardware; it is a strategic investment in your operation's core pillars: efficiency, food safety, and consistency. These units are purpose-built to address common kitchen bottlenecks and transform them into opportunities for smoother service, higher quality output, and a healthier bottom line.

Streamline Your Workflow and Save on Labor

Imagine a kitchen without a dedicated prep station. To assemble a single sandwich, an employee might walk to a reach-in refrigerator for meat, turn to a separate counter to slice it, walk back to the cooler for cheese and vegetables, and then finally assemble the order on another surface. This sequence involves dozens of wasted steps, creating a disjointed and inefficient workflow. With a sandwich prep station, this entire process is consolidated into a single, ergonomic zone. Everything needed for cold assembly—meats, cheeses, vegetables, sauces, and a cutting board—is in one place.

This consolidation of storage and workspace has a profound impact. By eliminating unnecessary movement, your team saves precious seconds on every single order. Those seconds add up to minutes, and over a full day of service, they translate into hours of saved labor. This heightened efficiency means a smaller team can handle a larger volume of orders, reducing labor pressure during peak times and creating a calmer, more organized work environment. Faster assembly leads directly to shorter ticket times, which in turn leads to happier customers and greater table turnover.

Improve Food Safety and Quality

Food safety is the bedrock of any successful foodservice operation. A refrigerated sandwich prep station is a critical tool in your food safety arsenal. Its primary function is to maintain cold chain integrity by holding perishable ingredients within the scientifically recommended temperature range of 33°F to 41°F (0.5°C to 5°C). This range is crucial because it sits below the temperature "danger zone" where harmful bacteria like Salmonella, E. coli, and Listeria can multiply rapidly.

With a prep station, cold ingredients are no longer left sitting on an unrefrigerated counter during busy periods, exposed to ambient kitchen temperatures. By keeping everything properly chilled right on the line, you are actively supporting both safety and quality. Ingredients stay fresher for longer, retaining their intended texture, color, and flavor. This not only results in a better-tasting, more appealing final product for your customers but also significantly reduces food waste from spoilage, directly impacting your food costs and profitability.

For more details on safe holding temperatures, you can review the official guidance on Safe Food Handling Temperatures from the U.S. Food & Drug Administration.

Who Benefits Most from a Sandwich Prep Station?

The remarkable versatility and efficiency of a refrigerated sandwich prep station make it an invaluable asset in a wide array of operations, particularly those where customizable cold ingredients are a cornerstone of the menu.

These units are ideal for:

- Sandwich Shops and Delis: This is the natural habitat for these stations. They are essential for the rapid assembly of subs, wraps, paninis, and classic deli sandwiches, allowing for a high degree of customization without slowing down the line.

- Cafes and Coffee Shops: Beyond just sandwiches, they are perfect for preparing grab-and-go items, bagels with various spreads, breakfast sandwiches, and holding chilled toppings for specialty coffee and tea drinks.

- Salad Bars and Bowl Concepts: These modern concepts thrive on the organization a prep station provides. They are perfect for holding a wide variety of greens, chopped vegetables, proteins, grains, and dressings needed for build-your-own salads and bowls.

- Food Trucks: In the confined space of a food truck, every square inch matters. The all-in-one design of a compact prep station saves a massive amount of footprint while providing the essential cold storage and prep space needed to execute a menu.

- School Cafeterias and Institutional Kitchens: These environments demand high-volume production in very short service windows. Prep stations are instrumental in assembling large quantities of fresh, cold items quickly, safely, and consistently.

Essentially, any operation that relies on the quick and safe assembly of cold toppings, fillings, or customizable orders can see a strong and immediate return on investment from a sandwich prep station, particularly when sourced from a value-focused supplier like The Restaurant Warehouse.

Choosing Your Perfect Match: Types of Sandwich Prep Stations

Just as sandwiches themselves come in countless variations, from a simple grilled cheese to a complex multi-layered sub, so do the sandwich prep stations designed to create them. Selecting the right model is a critical decision that hinges on a careful analysis of your menu's complexity, your daily sales volume, and the physical space you have available in your kitchen.

Standard Top vs. Mega Top Units

The most significant differentiator in the upper section of these prep tables is the ingredient pan capacity. This choice directly impacts the variety of toppings you can offer at any given time and how frequently your staff will need to pause service to restock the line.

-

Standard Top Sandwich Prep Stations: These are the classic, workhorse models. They typically feature a single row of refrigerated pans along the back of the unit. For example, a 48-inch standard top might hold around 12 1/6-size pans. The key advantage of a standard top is that it usually comes with a more generous cutting board workspace, often 10 to 12 inches deep. This deeper prep area is invaluable for assembling larger or more complex items like oversized subs, burritos, and wraps, giving staff ample room to work without feeling cramped.

- Choose a Standard Top if: Your menu is focused, you have a moderate number of ingredients, and you value a larger, more comfortable prep surface.

-

Mega Top Sandwich Prep Stations: As the name implies, mega top units are all about maximizing ingredient capacity. They feature an extended top rail, often with two or three rows of pans, that can hold approximately 30-50% more pans than a standard top of the same width. A 48-inch mega top, for instance, might hold 18 or even 20 1/6-size pans instead of 12. This configuration is essential for menus with extensive customization options (like a build-your-own sandwich or salad bar) and for high-volume operations that want to minimize pan changes during peak hours. The trade-off is a slightly shallower cutting board to accommodate the extra pans.

- Choose a Mega Top if: Your menu has a vast number of toppings, you experience very high volume, and minimizing restocking time is a top priority.

Doors vs. Drawers in the Base

The base cabinet of a sandwich prep station provides crucial refrigerated storage for backup ingredients. The choice between doors and drawers comes down to a balance of workflow preferences, organizational needs, and budget.

- Door-Style Cabinets: This is the most common and budget-friendly configuration. Hinged doors open to a spacious cabinet interior with adjustable wire shelves. This layout is highly flexible and works well for storing bulky items like heads of lettuce, large containers of sauce, and irregularly shaped packages of meat or cheese. It's a versatile, all-purpose solution.

- Drawer-Style Cabinets: Refrigerated drawers represent a more premium, ergonomic option. The drawers are specifically sized to hold food pans, allowing you to pre-portion and organize your backup ingredients perfectly. This system makes inventory rotation (first-in, first-out) incredibly simple and allows staff to grab and swap a full pan in seconds. While drawer units typically have a higher upfront cost, they can significantly improve speed and organization in very busy kitchens and reduce physical strain on staff by minimizing bending and searching.

The Difference Between a Sandwich and Pizza Prep Table

While they may look similar, it's important not to confuse a sandwich prep station with a pizza prep table, as they are engineered for different tasks.

| Feature | Sandwich/Salad Prep Table | Pizza Prep Table |

|---|---|---|

| Cutting Board Depth | Standard (8"-12") | Extra Deep (16"-20"+) |

| Primary Use | Assembling smaller, lighter items | Stretching dough, handling large pizza skins |

| Top Rail Design | Flush or slightly recessed | Often raised and angled towards the user |

| Rail Purpose | Easy access to many small-portion toppings | Holding bulk ingredients like cheese and sauce |

| Typical Pan Sizes | 1/6, 1/9, 1/3 size pans | 1/3, 1/2, and full-size pans |

Essentially, sandwich tables are optimized for variety and dexterity, while pizza tables are built for size and bulk. Choosing the right unit for your primary menu items is crucial for an efficient workflow. If you need help matching a unit to your specific menu, you can review detailed guides at The Restaurant Warehouse's prep table resource page.

The Ultimate Buyer's Guide to Your Next Sandwich Prep Station

Purchasing a sandwich prep station is a significant capital investment that will directly impact your kitchen's workflow, efficiency, and safety for years to come. To ensure you get the best return on that investment, it's crucial to move beyond the price tag and consider the specific features, specifications, and practical points that align with your operational needs. This buyer's guide will walk you through the essential considerations.

Sizing Up Your Needs: Dimensions and Capacity

Before you even look at models, you must start with your physical space and production needs. A prep station that is too large for your space or too small for your volume will create daily frustration and inefficiency.

- Measure Your Space: Use a tape measure to get the precise width, depth, and height of the area where you plan to install the unit. Crucially, you must account for ventilation clearance. Most units require at least 2–4 inches of open space at the back and sides for the refrigeration system to breathe. Also, ensure there is enough clearance for doors or drawers to open fully without obstructing walkways.

- Width and Workflow: Common widths include 27", 36", 48", 60", and 72". The width you need depends on your volume and staffing. A 27" or 36" unit might be perfect for a low-volume cafe or for a specific station (e.g., breakfast sandwiches). A 48-inch unit is a versatile choice for a medium-volume deli with one or two employees on the line. A 60" or 72" mega top can support a very busy, multi-staff operation.

- Calculating Capacity: Capacity refers to two things: the cubic footage of refrigerated storage in the base and the number of food pans the top rail can hold. Review your sales data and prep sheets to estimate the daily usage of your core ingredients. This will help you decide between a standard and mega top. Overbuying consumes valuable floor space and energy, while underbuying leads to constant restocking and slower service during your busiest hours.

Ventilation and Placement: A Critical First Step

Where and how you place your unit is just as important as which one you buy. A key factor here is the location of the air vents for the refrigeration system.

- Rear-Breathing Units: These are the most common type. They draw in and exhaust air from the back of the unit. They are generally more affordable but require significant clearance (4-6 inches) between the unit and the wall for proper airflow. Blocking this airflow will cause the compressor to overwork, leading to inefficiency and premature failure.

- Front-Breathing Units: These units have their intake and exhaust vents located on the front, usually below the doors. This design allows them to be installed flush against a wall or directly next to other appliances, making them an ideal solution for kitchens with limited space. They often come at a slightly higher price point but offer much greater placement flexibility.

Construction and Materials: Built for the Commercial Kitchen

Durability and cleanability are non-negotiable in a professional setting. The build quality of your sandwich prep station will directly influence its lifespan and the amount of maintenance it requires.

- Stainless Steel Exterior and Interior: Look for units with a high-quality stainless steel construction. A 304 stainless steel interior and top is the gold standard due to its superior resistance to rust and corrosion from food acids and cleaning chemicals. A 430-grade stainless steel is often used for the exterior sides and back, as it is durable and cost-effective.

- High-Density Polyethylene Cutting Board: The removable cutting board should be made of NSF-approved high-density polyethylene. This material is the industry standard because it is non-porous, resistant to stains, and won't dull your knives as quickly as harder surfaces. A depth of around 10–12 inches is standard for sandwich prep.

- Hardware and Finishings: Small details make a big difference in daily use. Look for heavy-duty casters (wheels) with at least two that lock, allowing for mobility for cleaning and stability during use. Recessed door or drawer handles are less likely to snag clothing in tight spaces. Easily removable magnetic door gaskets are crucial for proper sealing and deep cleaning.

Understanding Refrigeration, Power, and Temperature

The refrigeration system is the heart of any sandwich prep station. Understanding its key aspects is vital.

- Refrigeration System: Most modern units use forced-air refrigeration, where fans actively circulate cold air throughout the cabinet and across the top pans. This is superior to older 'cold wall' systems as it provides more even temperatures and faster recovery after doors are opened.

- Environmentally Friendly Refrigerants: Look for units that use modern hydrocarbon refrigerants such as R290. These are not only more environmentally friendly (with a much lower Global Warming Potential) but are also more energy-efficient than older refrigerants.

- Digital Temperature Controls: An external digital LED display is a must-have feature. It allows for precise temperature setting and at-a-glance monitoring to ensure you are staying within the safe zone of 33°F to 41°F, in line with Safe Food Handling Temperatures guidance. Most units also include an automatic defrost cycle to prevent ice buildup on the evaporator coil, which maintains efficiency.

- Power Requirements: The vast majority of sandwich prep stations run on a standard 115V electrical connection, allowing them to be plugged into a regular commercial outlet. However, larger units draw more amperage and may require a dedicated circuit to avoid tripping breakers. Always confirm your building's electrical capacity before purchasing.

Protecting Your Investment: Warranty and Support

A sandwich prep station is a long-term asset, so the warranty and after-sales support are critical components of its overall value.

- Parts and Labor Warranty: Reputable brands generally offer a 1–3 year warranty covering both parts and labor for defects in materials or workmanship.

- Compressor Warranty: The compressor is the most expensive component of the refrigeration system. Because of this, it usually carries a separate, extended warranty, often for 5 years or more.

- Return Policies and Service: Before buying, understand the vendor's return policy and any potential restocking fees. Also, inquire about their network of authorized service technicians in your area so you can get prompt and reliable support if an issue arises.

For a deeper look at specs and side-by-side comparisons, you can explore our comprehensive guide to prep tables. When you are ready to narrow down your options, contact The Restaurant Warehouse for a free consultation and price quote at https://therestaurantwarehouse.com/ to match the perfect unit to your performance needs and budget.

Frequently Asked Questions about Sandwich Prep Stations

As experts in professional kitchen supplies, we field many questions about sandwich prep stations. Answering these common queries can help you get more value from your current unit or make a smarter choice when purchasing a new one.

What temperature should a sandwich prep station be kept at?

The universally recommended temperature range for a sandwich prep station is between 33°F and 41°F (0.5°C to 5°C). This is the critical food-safe zone. Temperatures below 33°F risk freezing and damaging delicate produce, while temperatures above 41°F enter the "danger zone," where harmful bacteria can multiply at an accelerated rate. Maintaining this range is essential for complying with health department regulations and ensuring the safety and quality of your food.

How do I properly clean and maintain my unit?

Regular, diligent cleaning and preventative maintenance are the keys to extending the life of your sandwich prep station, ensuring its efficiency, and upholding food safety standards.

-

Daily Cleaning (End of Day):

- Remove all food pans from the top rail. Wash, rinse, and sanitize them according to your local food code.

- Wipe down the interior of the refrigerated rail and the base cabinet with a mild, food-safe detergent, followed by a rinse and a final wipe with a sanitizing solution.

- Remove the polyethylene cutting board and clean it thoroughly on all sides, paying special attention to any deep knife grooves where bacteria can hide.

- Wipe down all exterior stainless steel surfaces to remove spills, fingerprints, and grime.

- Clean the door or drawer gaskets (the rubber seals) with a damp cloth to remove food debris, ensuring they create a tight seal when closed.

-

Weekly Maintenance:

- Perform a deeper clean of all interior surfaces, removing shelves to clean underneath them.

- Inspect and clean the condenser coil. This is one of the most important maintenance tasks. Using a soft brush or a vacuum, gently remove the dust and grease that builds up on the coil's fins. A clean coil allows the unit to dissipate heat efficiently, reducing energy consumption and strain on the compressor.

-

Monthly/Quarterly Maintenance:

- Check that the unit is level. An unlevel unit can cause doors to not seal properly, leading to wasted energy.

- Inspect power cords and plugs for any signs of fraying or damage.

- Listen for any unusual noises from the compressor or fans, which can be an early indicator of a potential mechanical issue.

- Check the door gaskets for a proper seal using the "dollar bill test": close the door on a dollar bill. If you can pull it out with no resistance, the gasket may need to be adjusted or replaced.

What is the difference between a sandwich prep station and just putting a cutting board on an undercounter cooler?

This is a common question, and the difference is critical. An undercounter cooler is designed for bulk storage. When you open its door, the cold air spills out, and ingredients brought out of it begin to warm to room temperature immediately. A sandwich prep station, by contrast, has a refrigerated top rail with a forced-air system that constantly envelops the pans in cold air. This creates a protected, chilled environment for the ingredients, keeping them at a safe temperature even while they are being accessed during service. The integrated design is engineered for assembly line efficiency, something a separate cooler and worktop cannot replicate.

How does a prep station affect my food costs?

A prep station can have a significant positive impact on your food costs in two main ways. First, by consistently holding ingredients at the proper cold temperature, it extends their shelf life and preserves their quality, drastically reducing spoilage and waste. Second, the organized nature of pan storage allows for better portion control and inventory management. You can see exactly what you have, reducing the chance of over-prepping or ingredients getting lost and expiring in the back of a deep cooler. This leads to less waste and a healthier bottom line.

How should I organize the pans in my prep station for maximum efficiency?

Strategic pan layout can shave seconds off every order. The best practice is to arrange ingredients in the logical order of assembly, mimicking the way a car is built on an assembly line. For a typical sandwich line, this might look like:

- Start with the most-used proteins (e.g., turkey, ham) in the easiest-to-reach central pans.

- Follow with the cheeses that are most commonly paired with those proteins.

- Next, place high-volume vegetables like lettuce and tomato.

- Finally, put less-used toppings, garnishes, and condiments (like pickles, onions, or specialty sauces) in the outer or corner pans.

This creates a simple, repeatable flow from one side of the station to the other, minimizing hand movement, reducing decision time, and decreasing the chance of errors.

If you are redesigning your line or planning a new layout around a sandwich prep station, you can browse additional planning tips and example setups on The Restaurant Warehouse blog.

Conclusion

A refrigerated sandwich prep station is far more than a simple cold table; it is a dynamic hub of productivity that brings organized ingredient storage, a dedicated prep surface, and reliable temperature control into a single, powerful footprint. It is an investment that directly supports the core operational goals of any successful foodservice business: speed, safety, and consistency.

By keeping your most-used ingredients perfectly chilled and within immediate arm's reach, these stations empower your team to shorten ticket times, reduce wasteful motion, and maintain the high quality of your food from the first order of the day to the last. For any busy concept built around sandwiches, salads, bowls, wraps, or other customizable cold items, the efficiency gained from a well-chosen prep station can be the critical difference between a service that struggles and a service that flows seamlessly.

Whether you choose a compact standard top for a small cafe or a high-capacity mega top for a bustling deli, and whether you prefer the flexibility of doors or the ergonomics of drawers, the right sandwich prep station will become the backbone of your daily operations. It is a tool that protects your ingredients, supports your team, enhances your workflow, and ultimately helps you create a better, faster experience for your guests.

At The Restaurant Warehouse, our focus is on supplying professional-grade kitchen tools and supplies at affordable, wholesale-direct pricing. We believe that every business deserves access to the appliances that can help it thrive. If you are evaluating your options or planning a new build-out, visit https://therestaurantwarehouse.com/ to compare models and request a quote, or contact our expert team for a quick, no-pressure consultation about which sandwich prep station will best fit your unique menu, space, and budget.

By pairing the right appliance with smart kitchen procedures, you can keep your ingredients cool, your service efficient, and your business running hot during every rush.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment