Prep Like a Pro: Your Guide to Mega Top Prep Tables

The Ultimate Upgrade for Your Prep Line

A mega top prep table is a high-capacity refrigerated workstation that combines extended ingredient storage with a spacious preparation surface, making it essential for busy commercial kitchens.

Key Features of Mega Top Prep Tables:

- Improved Pan Capacity: Up to 30 ingredient pans (50% more than standard tables)

- Temperature Control: Maintains 33°F to 41°F for food safety

- Dual Function: Refrigerated storage below + prep workspace above

- Size Range: Available in 27" to 72" widths

- Perfect For: Delis, sandwich shops, cafes, and high-volume kitchens

For delis, cafes, or sandwich shops, speed and organization are critical. Standard prep tables often can't keep up, leading to ingredient shortages during rush hours, wasted time restocking, and slower service.

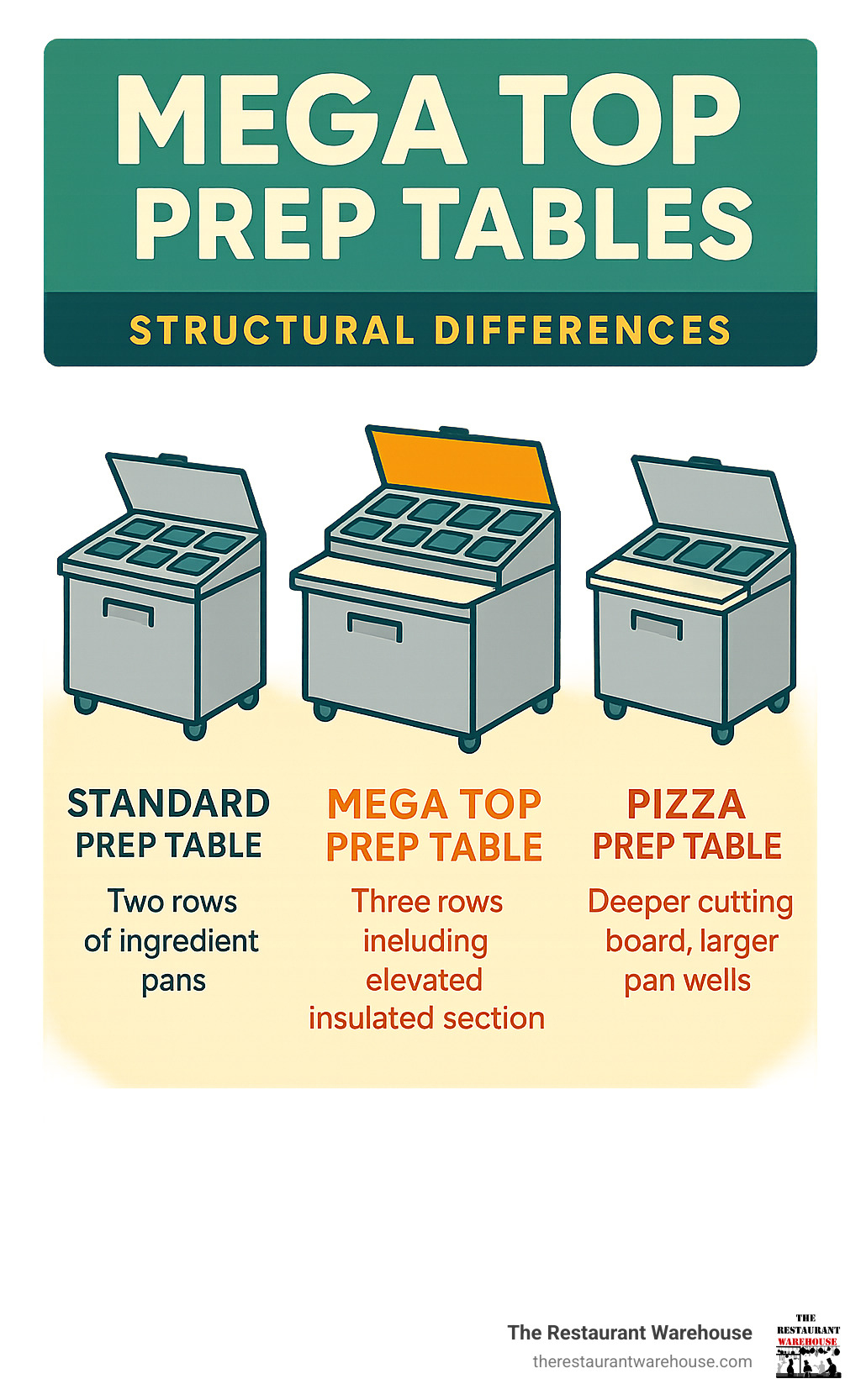

Mega top prep tables solve these problems by adding a third row of ingredient pans. This simple design change can increase your ingredient capacity by up to 50%, reduce restocking frequency, and keep your prep line moving smoothly during peak service.

The "mega top" is an insulated lid system covering a third row of food pans. This design keeps ingredients at proper temperatures while providing easy access, a significant upgrade from the two rows on standard tables.

These units maintain the critical 33°F to 41°F temperature range required for food safety while offering the workspace and storage capacity that high-volume operations demand.

Why a Mega Top? Unpacking the Advantages Over Standard Prep Tables

During a lunch rush, a mega top prep table makes a significant difference. Instead of constantly restocking, your team can focus on preparing orders, improving efficiency and customer satisfaction.

The most game-changing feature is the increased pan capacity. While a standard prep table has two rows of ingredients, a mega top prep table adds a crucial third row of pans. This provides up to 50% more ingredient storage within arm's reach of your prep station.

This means specialty cheeses, fresh vegetables, and signature sauces are organized and accessible. Reduced restocking frequency improves workflow efficiency, leading to faster service and happier customers who get their orders faster.

Beyond capacity, most mega top prep tables feature a deeper work surface, providing more prep space. This extra depth is crucial for assembling complex sandwiches or plating salads and helps prevent the mistakes and slowdowns caused by a cramped workspace.

Food safety meets efficiency with the insulated lids that cover the ingredient pans. They are a secret weapon for maintained food freshness and safety. When not in use, these lids create a protective barrier that keeps everything at the proper temperature while minimized condensation prevents sogginess that can ruin fresh ingredients.

The insulation keeps cold ingredients cold and prevents moisture buildup that leads to spoilage. This means your ingredients stay fresher longer, food waste decreases, and the quality of every dish remains consistently high.

For kitchens serious about maximizing their sandwich and salad operations, our Sandwich Prep Table Guide dives deeper into how these tables can transform your prep line from chaotic to choreographed.

When you upgrade to a mega top prep table, you're investing in smoother operations, better food safety, and a prep line that can handle any rush hour.

Anatomy of a High-Performance Mega Top Prep Table

When you invest in a mega top prep table, you're getting a carefully engineered piece of equipment where every component is designed for your kitchen's success. Let's explore what makes these units such reliable workhorses.

Construction and Materials: Built for Durability and Hygiene

Mega top prep tables are built for the rigors of a commercial kitchen, designed to withstand daily spills, heavy use, and constant cleaning.

The backbone of any quality mega top prep table is its stainless steel construction. Most units feature a combination of 430-grade stainless steel for the exterior and 304-grade stainless steel for the interior surfaces.

430-grade stainless steel offers excellent corrosion resistance and a professional, sleek appearance. It's tough enough to handle the daily bumps and scrapes of busy service.

The 304-grade stainless steel interior is the highlight, offering superior protection against food acids and chlorides. Its non-porous surface prevents bacteria growth, simplifies cleaning, and resists stains and odors.

Many manufacturers include rounded interior corners, a small detail that makes a huge difference during cleaning by eliminating hidden spots where grime can build up.

Every quality mega top prep table comes with a polyethylene cutting board that's both removable and reversible. This is a game-changer for your prep workflow. The material is gentle on knives and provides a sanitary cutting surface. When one side gets worn, simply flip it over. For deep cleaning or replacement, it lifts right out.

All of these materials come together to create units that are NSF-approved, meeting the strict standards required for commercial food service. For a deeper dive into why stainless steel makes such a difference in commercial kitchens, check out our Stainless Steel Prep Table Guide.

Refrigeration Systems: The Heart of Food Safety

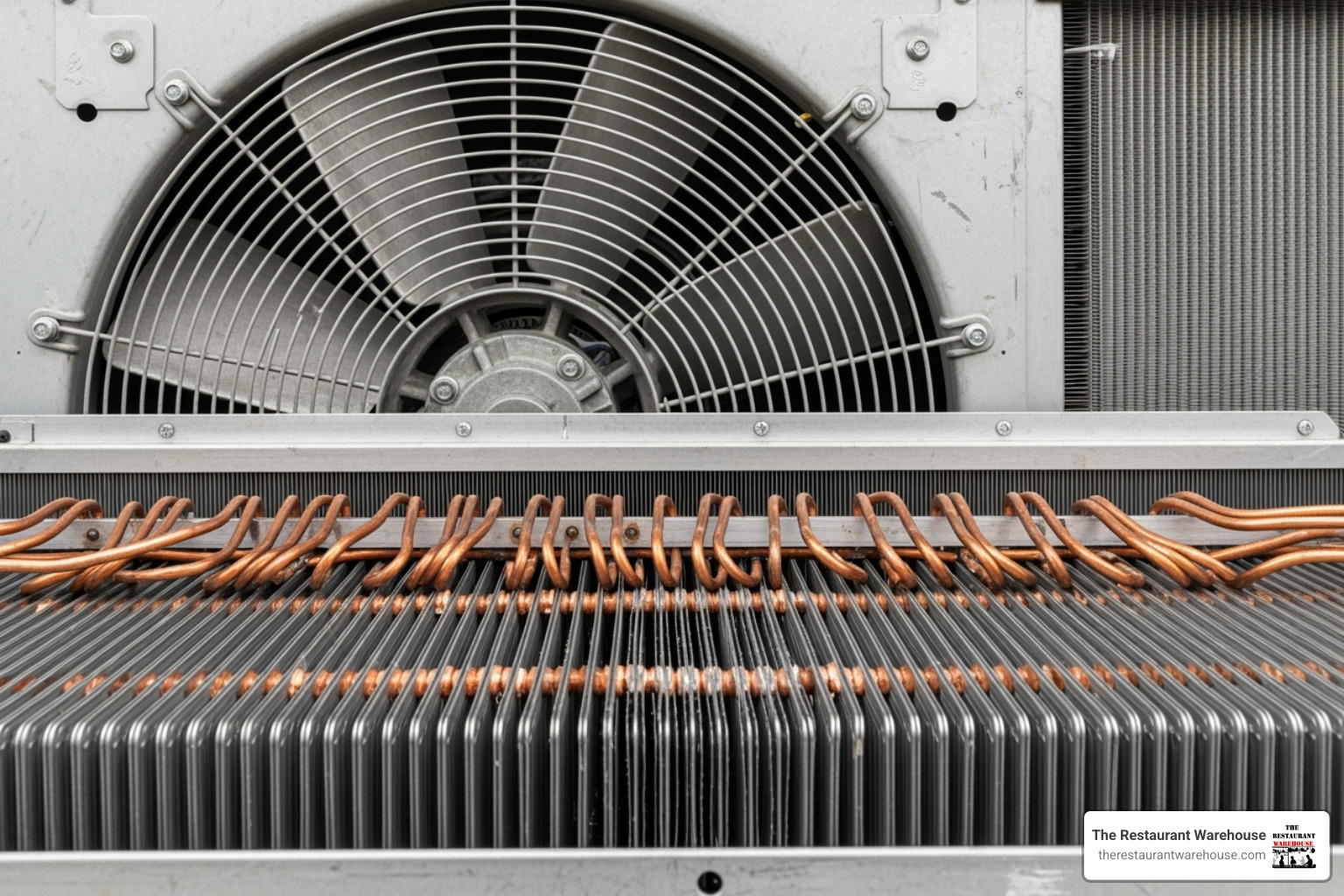

The refrigeration system is the heart of a mega top prep table, where engineering ensures food safety.

The critical temperature range of 33°F to 41°F is the food safety zone that keeps harmful bacteria at bay while preserving ingredient freshness. Staying within this range protects your customers and your reputation.

Forced-air circulation technology makes this possible. A gentle but constant breeze flows throughout the unit, ensuring cold air reaches every corner, from the cabinet below to the ingredient pans up top. This means no hot spots and consistent cooling, even during the busiest rushes.

Modern mega top prep tables widely use R290 refrigerant, an eco-friendly choice with zero Ozone Depletion Potential (ODP) and a low Global Warming Potential (GWP). Besides being better for the environment, R290 systems are more energy-efficient, lowering utility costs over the equipment's lifespan. For more information, the EPA provides excellent resources on hydrocarbon refrigerants and why these eco-friendly options matter for commercial kitchens.

Some premium units feature self-cleaning condensers, an innovation that automatically brushes away dust from the condenser coils. A clean condenser runs more efficiently, extends compressor life, and helps maintain critical temperatures.

This sophisticated refrigeration technology transforms a simple prep table into a reliable food safety partner. To explore how these advanced cooling systems can revolutionize your ingredient storage, take a look at our guide on Freshness on Demand: Top Commercial Prep Fridge Options.

Certifications: Your Assurance of Quality and Safety

Certification logos on a mega top prep table are not just decorative; they guarantee the unit has passed rigorous independent testing for food safety.

NSF certification is the gold standard in foodservice. An NSF logo means the unit has passed comprehensive testing for design, materials, and construction, ensuring it meets strict food safety standards for hygiene and cleanability.

ETL certification offers two-fold protection: ETL Listed for electrical safety, meeting North American standards, and ETL Sanitation Listed for hygienic design, complementing sanitation standards.

Some units also carry UL EPH Classified certification, providing additional confirmation of compliance with public health and safety standards.

When evaluating mega top prep tables, always look for these logos: NSF, ETL Listed, ETL Sanitation Listed, and UL EPH Classified. They represent thousands of hours of independent testing, giving you confidence that your investment will serve your kitchen safely and reliably.

Finding Your Perfect Fit: Sizing, Configuration, and Customization

Selecting the ideal mega top prep table is like finding the perfect partner for your kitchen—it needs to complement your space and match your workflow. The beauty of these units lies in their versatility, with configurations for everything from a cozy café to a busy deli line.

Choosing the Right Size Mega Top Prep Table for Your Kitchen

Choosing the right width for your mega top prep table is foundational to your prep operation. It must fit your space without being too cramped or wasting real estate.

27-inch units are a perfect starting point for smaller operations, fitting into tight spaces while delivering the mega top advantage. They are ideal for a small café or as a supplementary station in a larger kitchen.

36-inch units are a sweet spot for growing businesses. These mid-size champions typically feature two doors and provide enough workspace for expanding menus without demanding excessive floor space.

48-inch units are the workhorses of the mega top prep table world. With a generous prep surface and capacity for 18 sixth-size pans, they handle busy lunch rushes with ease. They are ideal for mid-sized delis and sandwich shops.

For high-volume establishments, 60-inch units meet the challenge. These units typically house 24 pans while offering around 15 cubic feet of refrigerated storage, perfect for busy sandwich shops.

At the top of the spectrum, 72-inch units command attention. Featuring up to 30 sixth-size pans and three doors, these giants are built for high-volume operations like large cafeterias or busy delis.

To decide on a size, assess your available space, including traffic flow. Also, evaluate your menu's complexity and your sales volume. Consider sizing up slightly to accommodate future growth and avoid outgrowing your equipment. For detailed insights on compact options, our Choosing 27 Prep Table guide offers valuable perspective.

Comparing Common Mega Top Prep Table Sizes

| Width | Typical Doors | Typical Pan Capacity (1/6 size) | Approx. Cabinet Capacity (Cu.Ft.) | Best For |

|---|---|---|---|---|

| 27" | 1 | 12 | 7-9 | Small cafes, low-volume |

| 48" | 2 | 18 | 12-15 | Mid-size delis, moderate volume |

| 60" | 2 | 24 | 15-18 | Busy sandwich shops |

| 72" | 3 | 30 | 18-22 | High-volume operations |

Functional Features That Boost Usability

Beyond size, thoughtful features make a mega top prep table truly exceptional, proving invaluable during busy service.

Adjustable shelves turn the refrigerated cabinet into a customizable storage solution. These PVC-coated wire shelves resist corrosion and adapt to your needs, whether you're storing tall containers or flat trays.

Heavy-duty casters improve kitchen maintenance and flexibility. They allow you to move the unit for cleaning or repositioning. Crucially, they must include locking wheels to keep the station secure during service.

Self-closing doors work quietly to maintain temperature and energy efficiency. When your hands are full, these doors automatically seal shut. Many units also feature a 90° stay-open feature, which is invaluable during loading and unloading.

Recessed handles are a thoughtful design feature. Beyond a sleek look, they prevent snags on aprons or clothing in a busy kitchen and reduce the risk of accidental bumps.

These features create a mega top prep table that works with your team, improving your operation. For a comprehensive understanding of how these features integrate into successful kitchen design, explore our Preparation Table Kitchen Guide.

Long-Term Value: Maintenance, Warranty, and Cost

When considering a mega top prep table, it's natural to think beyond the initial price. This is an investment in your daily operations, and you want to understand the long-term return.

A quality mega top prep table is a workhorse that delivers value for years. Getting the most out of your purchase means understanding how to protect it and what factors influence the cost.

Protecting Your Investment

A mega top prep table's warranty provides peace of mind. The industry standard is a 2-year warranty on parts and labor, paired with a 5-year warranty on the compressor. This reflects the unit's construction and potential points of failure.

The comprehensive 2-year coverage handles most issues you might encounter early on. The extended 5-year compressor warranty is valuable because the compressor is the heart of your refrigeration system and the most expensive component to replace.

However, warranties work best when paired with proper maintenance. Routine maintenance is what keeps your mega top prep table running efficiently and extends its lifespan.

Cleaning condenser coils is an essential maintenance task. Dirty coils force the compressor to work harder, increasing energy bills and wear, which can lead to premature failure. Regular cleaning prevents these expensive problems.

Checking door gaskets is also crucial. These rubber seals are your first line of defense against temperature fluctuations. Worn or dirty gaskets can't maintain an airtight seal, forcing your unit to work harder and use more energy. Most modern gaskets are removable for easy cleaning and replacement.

Don't overlook the basics, like keeping your unit level and regularly cleaning all surfaces to prevent corrosion and maintain hygiene.

For detailed guidance on keeping your unit in top condition, our Sandwich Prep Table Maintenance guide walks you through everything you need to know.

Understanding the Price Tag

Mega top prep table prices typically range from around $2,000 for compact models up to over $7,000 for large, feature-rich units. Understanding what drives this price difference helps you choose a unit that fits your needs and budget.

Size plays a major role in pricing. A 27-inch unit will cost significantly less than a 72-inch, three-door unit built for high-volume operations.

Features and functionality add value and cost. Units with self-cleaning condensers, advanced controls, or specialized drawers command higher prices but often pay for themselves through improved efficiency and usability.

Materials and construction quality are another significant price factor. The grade of stainless steel, type of insulation, and overall build quality influence both cost and durability.

Brand reputation also affects pricing, often reflecting benefits like available parts, established service networks, and proven reliability.

Choosing the right supplier impacts your bottom line. Traditional retailers have high overhead costs. At The Restaurant Warehouse, our model eliminates unnecessary markups. We offer wholesale pricing by avoiding high commissions and retail overhead, allowing you to invest in a quality mega top prep table without paying for expensive showrooms or sales commissions.

This approach lets you allocate more of your budget toward the features and capacity you need, rather than subsidizing retail overhead.

Conclusion: Streamline Your Kitchen with the Right Prep Table

After diving deep into mega top prep tables, it's clear they are problem solvers that can transform how your kitchen operates. For any busy deli, cafe, or sandwich shop, the right prep table can be the difference between chaos and smooth sailing.

A mega top prep table solves common kitchen challenges like restocking during a rush or running out of prep space. Its increased capacity, with a third row of ingredient pans boosting storage by up to 50%, is a game-changer. This leads to fewer restocking trips, less downtime, and more time serving customers.

The efficiency gains go beyond just having more ingredients. When everything is organized and accessible on one workstation, your team can work faster and more confidently. The spacious work surface means less crowding and a smoother workflow.

Most importantly, these tables excel at superior food safety. With robust refrigeration systems maintaining the critical 33°F to 41°F temperature range, your ingredients stay fresh and safe. The insulated lids and forced-air circulation work together to minimize waste and protect your customers.

Choosing the right unit comes down to your specific needs. Size matters; a compact 27-inch model might be perfect for a coffee shop, while a busy deli might need a 72-inch powerhouse. Consider your menu, volume, and space.

Don't overlook solid refrigeration technology. Look for units with eco-friendly refrigerants and consistent temperature control. Features like self-cleaning condensers can save time and headaches.

For construction, quality matters. Stainless steel, especially 304-grade for food contact areas, ensures durability and easy cleaning. Details like adjustable shelves, heavy-duty casters, and self-closing doors make daily operations smoother. Always check for NSF and ETL certifications.

At The Restaurant Warehouse, we know the right equipment transforms businesses. We provide high-quality mega top prep tables at prices that fit your budget. By eliminating middleman markups and retail overhead, we help you get professional-grade equipment without the high price tag.

Your kitchen deserves equipment that works as hard as you do. A mega top prep table is an investment in smoother operations, happier staff, and satisfied customers. Ready to see the difference? Explore our full range of sandwich prep tables and find how the right prep table can streamline your kitchen today.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment