Hot Stuff: A Deep Dive into Commercial Insulated Food Containers

Why Commercial Food Warmer Containers Matter for Every Foodservice Operation

A commercial food warmer container is specialized equipment designed to hold prepared food at safe, consistent temperatures until serving. These units use gentle, controlled heat to maintain food quality, moisture, and texture, rather than cooking the food further.

Quick Overview: Commercial Food Warmer Container Essentials

- Purpose: Hold food at safe temperatures (140 degrees F or above) without cooking.

- Types: Insulated transport carriers, countertop warmers, drawer warmers, holding cabinets.

- Key Benefits: Food safety compliance, quality preservation, reduced waste, and improved workflow.

- Critical Features: Temperature precision, moisture control, energy efficiency, and durability.

- Primary Use Cases: Catering, buffet service, high-volume kitchens, and grab-and-go operations.

Cooking food to perfection is only half the battle. The real challenge is keeping that food hot, safe, and ready to serve while maintaining the texture and quality your customers expect. For any foodservice operation, choosing the right holding equipment is critical. The right commercial food warmer container is not just an expense—it is an investment that pays for itself through reduced waste, faster service, and happier customers.

High-quality insulated cabinets, for example, can use significantly less electricity than older metal holding cabinets while maintaining safe temperatures for over four hours without power. This saves money on energy bills and provides peace of mind that food stays safe during power interruptions or off-site events.

This guide offers practical, budget-friendly insights on selecting and using commercial food warmer containers. It explores the different types available, the features that matter for your operation, and how to maximize your investment while taking advantage of The Restaurant Warehouse's affordable, wholesale pricing.

What is a Commercial Food Warmer and Why is it Essential?

A commercial food warmer container is a specialized piece of holding equipment designed to maintain prepared food at a safe, consistent, and ready-to-serve temperature. It is important to note that these warmers do not cook food. Their primary purpose is to hold items at specific temperatures, ensuring they remain safe to eat, retain quality, and are ready for service. This is achieved using gentle, controlled heat to prevent further cooking, preserving the food's texture and moisture. This function is vital for any foodservice operation across the United States, from catering events to busy restaurant kitchens.

The Core Benefits for Your Foodservice Operation

Investing in the right commercial food warmer container offers significant benefits that directly impact your success:

- Food Quality Preservation: The primary goal is to keep food tasting fresh. Warmers prevent food from drying out or becoming soggy, maintaining its original texture, aroma, and taste. This means holding fried chicken crisp or keeping proteins juicy until serving.

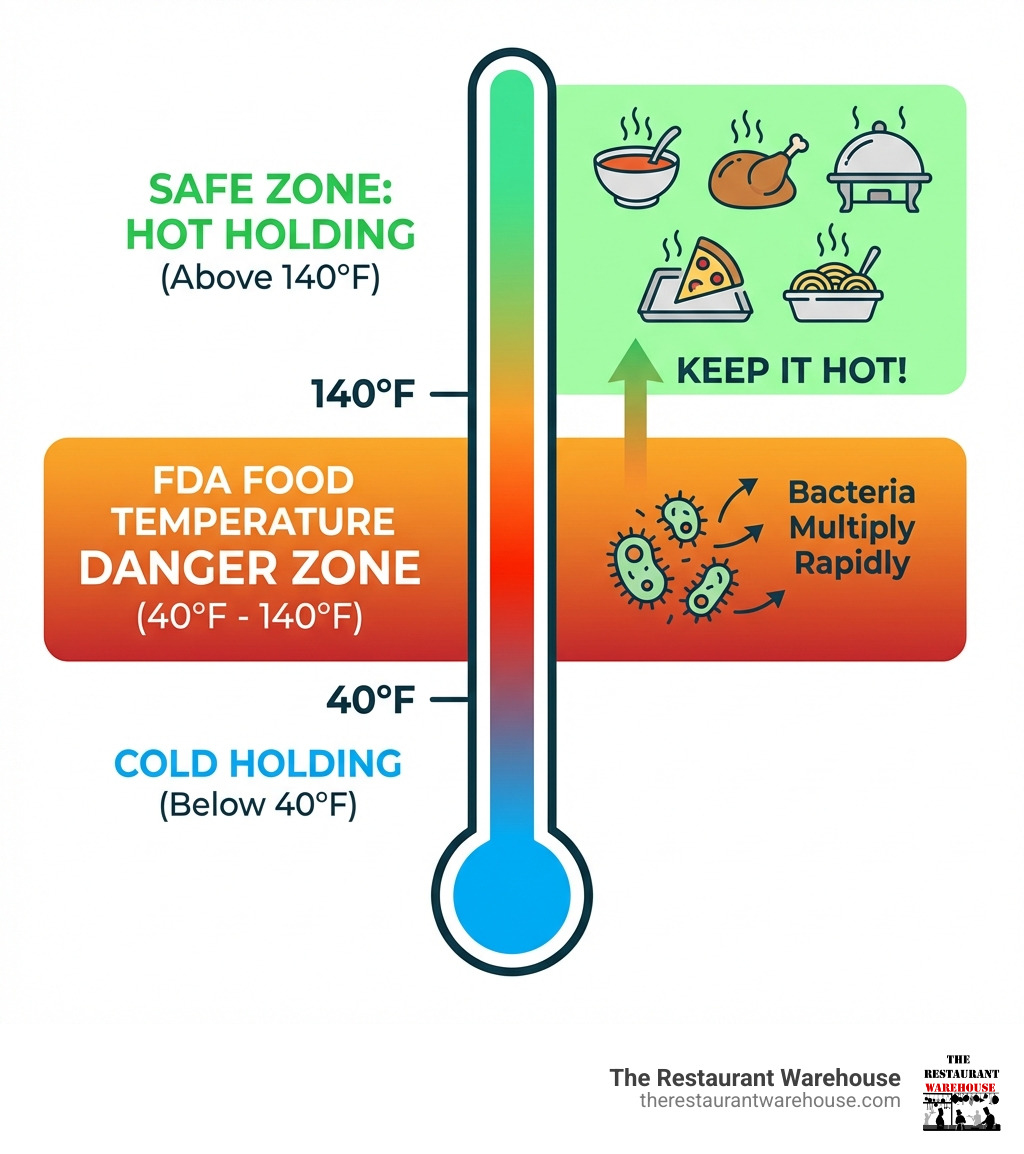

- Food Safety Compliance: This is non-negotiable. Warmers maintain food above the "danger zone" (40 to 140 degrees F), where bacteria multiply rapidly. Holding food at or above 140 degrees F ensures compliance with health codes and protects customers from foodborne illnesses.

- Operational Efficiency: A warmer acts as a buffer between cooking and serving. You can prepare dishes during slower periods and hold them at peak quality, reducing last-minute cooking stress and allowing staff to focus on other tasks. This streamlines food service, leading to faster ticket times and smoother operations.

- Reduced Food Waste: Proper holding extends food quality for longer, minimizing spoilage and the need to discard improperly held dishes. Less shrinkage and better preservation directly translate to savings.

- Increased Profitability: By reducing waste, improving efficiency, and maintaining food quality, warmers contribute directly to your bottom line. Less food thrown out, faster service, and happier customers all support higher profits and better return on equipment investments.

- Consistent Customer Experience: No one likes cold or dried-out food. Warmers ensure every customer receives their meal at the ideal temperature and quality, no matter how busy the kitchen gets, leading to better reviews and repeat business.

- Explore Commercial Food Warmer Types

If you want help matching the right model to your menu and volume, you can contact The Restaurant Warehouse team for custom guidance before you buy.

Holding vs. Cooking: A Critical Distinction

It is crucial to understand that a commercial food warmer container is a holding device, not a cooking device. While cooking uses intense heat to prepare food, a warmer uses gentle, controlled methods to maintain temperature.

- Holding, Not Cooking: Never use a warmer to cook raw food or reheat cold food to serving temperature. Its job begins after food has been cooked and brought to a safe temperature.

- Gentle Heat: Warmers employ various gentle heating mechanisms, such as moist heat, dry heat, or even passive insulation, to keep food warm without altering its state.

- Preserves Quality: By avoiding the intense heat that can continue to cook food, a well-designed warmer maintains the food's original characteristics, keeping it juicy, crisp, or tender as intended.

- Prevents Overcooking: By delivering precise, controlled heat, warmers stop the cooking process, ensuring that delicate items do not become tough or overdone while awaiting service.

Exploring the Different Types of Commercial Food Warmer Containers

The market offers a wide range of food warmers, each designed for specific applications, capacities, and kitchen workflows. Choosing the right type is the first step toward optimizing your food holding process. From portable boxes perfect for catering events to large-capacity cabinets for high-volume kitchens, understanding your options is key to making a smart investment.

| Feature | Insulated Transport Carriers (Hot Boxes) | Countertop Warmers | Drawer Warmers | Holding & Proofing Cabinets |

|---|---|---|---|---|

| Primary Use | Transporting food, off-site catering | Buffet lines, small kitchens, self-serve stations | Prep lines, holding different food types | High-volume holding, proofing dough |

| Power Source | Non-electric (passive insulation), some with thermal packs | Electric (110V/120V) | Electric (110V/120V) | Electric (110V/120V or higher) |

| Capacity Range | Varies (e.g., 2.5 Gallon soup, multiple full-size pans) | Small (e.g., 1-4 pans, 10-24 Qt soup) | Small to medium (e.g., 1-3 drawers, multiple pans) | Large (e.g., 10-20 full-size pans) |

| Best For | Catering, delivery, events | Soups, sauces, sides, small-batch holding | Proteins, breads, sides, keeping items separate | Banquets, high-volume restaurants, bakeries |

Insulated Transport Carriers (Hot Boxes)

These are the workhorses of catering and mobile foodservice. A non-electric commercial food warmer container, often called a "hot box," relies on passive insulation to maintain food temperatures.

- Non-electric operation: Their independence from power outlets makes them ideal for transporting food to remote locations or during power outages.

- Passive insulation: They feature thick polyethylene foam insulation that traps heat. This is so effective that some models can hold safe temperatures for at least 4 hours when unplugged. A high-quality carrier, for instance, is designed to maintain temperatures between 150 - 165 degrees F (65.6 - 73.9 degrees C) for hours without power.

- Portability and Durability: Built with sturdy handles and sometimes wheels, they are designed for easy transport. Many feature robust, one-piece seamless rotomolded construction for a long lifespan.

- Ideal for Catering: These carriers ensure food arrives hot and delicious for any off-site event. To extend holding times, accessories like thermal heating plates can be heated and placed inside.

If you regularly handle off-site service, explore The Restaurant Warehouse selection of insulated carriers and related accessories in their food warmers collection.

Countertop Warmers

Perfect for smaller operations or specific stations, countertop warmers offer compact and versatile food holding solutions.

- Compact Footprint: They save valuable space, making them ideal for small kitchens, food trucks, and buffet lines.

- Versatile Use: These warmers are commonly seen keeping soups, sauces, or small batches of sides ready for service in grab-and-go operations.

- Wet vs. Dry Heat: Wet heat warmers (bain-marie) use a water bath to provide moist heat, which is excellent for keeping foods like soups and stews from drying out. Dry heat warmers use direct heat without water, suitable for foods where crispness is desired, and are often more energy-efficient.

- Commercial Soup Warmers Guide

Drawer Warmers

For kitchens seeking discreet and flexible holding, drawer warmers are an excellent choice.

- Space-saving Design: They fit seamlessly under counters or into custom setups, maximizing operational space.

- Holds Different Foods Separately: Each drawer often operates independently, allowing you to hold different types of food at their optimal temperatures and humidity levels without flavor transfer. This means you can keep buns warm in one drawer and crispy items in another.

- Individual Controls: This is a key advantage, providing precise control for each drawer to maintain quality for a variety of menu items like bread, proteins, and sides.

- Types of Kitchen Warmers

Holding & Proofing Cabinets

When volume is the priority, holding and proofing cabinets are the solution. These are large-capacity, often mobile, commercial food warmer container units designed for high-throughput operations.

- High-Volume Capacity: These cabinets can hold a substantial amount of food in multiple full-size pans, making them indispensable for banquets, large-scale catering, and busy restaurant services.

- Mobility: Equipped with heavy-duty casters, these cabinets can be easily moved around the kitchen, from prep areas to serving lines.

- Advanced Controls: Many high-end models offer systems for precise temperature and humidity regulation to ensure food maintains its ideal texture and moisture. Some units offer gentle, non-radiant heat that protects prepared meals.

- Proofing Capabilities: A valuable dual-functionality, many of these cabinets can also be set to lower temperatures to proof dough, making them a versatile asset for bakeries and kitchens that prepare their own breads.

- Commercial Food Warmers: From Countertop to Catering

If you are planning a new layout or upgrading existing holding capacity, you can book a strategy call with The Restaurant Warehouse to compare models and pricing.

Key Features to Consider When Choosing Your Commercial Food Warmer Container

Once you have identified the right type of warmer, focus on the features that determine its performance, longevity, and return on investment. While a budget unit may save money upfront, a quality warmer with the right features pays for itself through efficiency, food quality, and energy savings. The Restaurant Warehouse emphasizes affordable, reliable equipment that delivers long-term value.

Temperature and Moisture Control

These are the most critical features, directly impacting food safety and quality.

- Precision: Look for warmers with consistent and accurate temperature holding. Digital controls typically offer greater accuracy and easier readability than simpler analog controls, allowing for minute adjustments to keep food safe without overcooking.

- Moisture Retention: Advanced warmers incorporate features to maintain food moisture. Some use a water bath (wet heat), while others have built-in humidity controls or designs that naturally retain moisture without an external humidifier.

- Crispness Maintenance: For items like fried foods or crispy baked goods, look for warmers that can maintain crispness, often through gentle, non-radiant heat without a direct heating coil.

- Advanced Humidity Systems: High-end models that allow you to set specific humidity levels offer strong control over the food environment, ensuring suitable holding conditions for a variety of menu items.

Capacity, Size, and Portability

Matching the warmer to your operational needs is crucial for efficiency.

- Volume: Assess your peak serving times and the volume of food you need to hold. A small cafe might need a countertop unit, while a high-volume venue would benefit from full-size cabinets.

- Pan Capacity: Most warmers are designed for standard hotel pans (full, half, or third-size). Knowing the pan sizes and quantities a unit can hold is essential for planning.

- Space: Before purchasing, accurately measure the available space in your kitchen, including width, depth, and height, especially for under-counter or pass-through models.

- Portability: For mobile units, quality casters that lock securely and comfortable, ergonomic handles are vital for safe transport, especially in busy environments.

If you are unsure which size or configuration best fits your kitchen, review the options in The Restaurant Warehouse food warmers collection and compare specifications side by side.

Energy Efficiency and Durability

These features impact the long-term cost of ownership and reliability.

- Energy Efficiency: Opting for efficient warmers can significantly reduce energy bills. Good insulation is also key. For example, thick polyethylene foam insulation helps some units use up to 48% less electricity than comparable metal cabinets over an 8-hour period.

- Durability: Stainless steel construction is the industry standard for durability and hygiene. It is easy to clean, resistant to corrosion, and built to withstand the rigors of a busy kitchen. For transport carriers, look for seamless, one-piece molding, which improves durability and makes cleaning easier by eliminating crevices.

- Save on Kitchen Costs with Used Food Warmers

Ease of Cleaning and Maintenance

Easy-to-clean equipment saves valuable staff time and promotes a safer kitchen.

- NSF Certification: Always look for NSF-certified equipment. This ensures the unit meets standards for public health protection and is designed for easy sanitation.

- Design for Cleaning: Features like removable racks and pan supports, smooth non-porous surfaces, and coved (rounded) interior corners make cleaning much simpler and more thorough.

- Benefits: Equipment that is easy to clean frees up staff for other tasks. Regular, easy maintenance also helps prevent breakdowns, avoiding costly downtime and unexpected repair costs.

For custom recommendations that balance cost, durability, and ease of cleaning, you can contact The Restaurant Warehouse and speak with an equipment specialist.

Maximizing Efficiency and Safety with Your Warmer

A commercial food warmer container is a strategic tool for improving your kitchen’s workflow and strengthening food safety protocols. Using your warmer effectively can streamline operations, reduce stress during peak hours, and ensure every dish meets health code standards, ultimately contributing to a more profitable business.

Improving Kitchen Workflow with a Commercial Food Warmer Container

The strategic use of food warmers can support kitchen efficiency:

- Batch Cooking: Prepare large quantities of popular dishes during off-peak hours and hold them in warmers, ready for the rush. This smooths out kitchen operations and reduces pressure on cooks.

- Decoupling Cooking from Serving: This allows chefs to focus on cooking new orders, knowing that previously prepared items are held safely and at quality. It effectively provides extra backup during peak times.

- Reducing Ticket Times: With food ready to serve, assembly and plating become much faster, significantly cutting down on customer wait times.

- Less Staff Stress: A less chaotic kitchen leads to more productive staff and fewer errors.

- Consistent Quality: Food warmers help ensure the quality of held items remains consistent, delivering on your brand promise even when the kitchen is busy.

- Essential Electric Food Warmers for Your Eatery

To see how these concepts translate into specific models and layouts, browse the full range of commercial food warmer containers available from The Restaurant Warehouse.

Ensuring Food Safety and Health Code Compliance

Food safety is paramount, and a commercial food warmer container plays a critical role in meeting regulatory standards.

- Stay Above 140 degrees F (60 degrees C): This is a key rule for hot holding. According to the USDA, food must be maintained at or above this temperature to help prevent the growth of harmful bacteria in the "Temperature Danger Zone."

- Prevent Bacterial Growth: Keeping food consistently hot inhibits bacterial reproduction, helping ensure dishes are safe for consumption.

- Use FIFO: Implement a First-In, First-Out (FIFO) system, often using food rotation labels, to ensure older products are used first, minimizing waste and maintaining freshness.

- HACCP Compliance: Food warmers are a key component in Hazard Analysis and Critical Control Points (HACCP) plans, serving as Critical Control Points (CCPs) for temperature maintenance. Proper monitoring and record-keeping are essential.

Understanding Non-Electric Solutions and Accessories

Non-electric options offer unique advantages, especially for catering and off-site events.

- Passive Heat Retention: These solutions rely on superior insulation to keep pre-heated food warm without generating new heat.

- How They Work: Insulated carriers feature thick foam insulation that creates a thermal barrier, effectively slowing down heat loss. High-quality carriers can maintain safe temperatures for over 4 hours without electricity.

- Extending Hold Times: To extend holding times or compensate for frequent door openings, thermal plates (like the Camwarmer) can be pre-heated and placed inside the carrier. Using two per compartment is often recommended for optimal results.

- Key Advantages: Non-electric solutions provide flexibility and peace of mind for transport, deliveries, outdoor events, or power outages.

- Propane Food Warmer Tips

The Hidden Costs of a Commercial Food Warmer Container

While the benefits are clear, be aware of potential hidden costs, especially with cheaper, less efficient models.

- Energy Usage: An inexpensive warmer that is not energy-efficient will lead to higher electricity bills over time.

- Maintenance and Repairs: Lower-quality components break down more frequently, leading to repair costs and downtime.

- Food Waste: If a warmer fails to maintain proper temperature or humidity, food quality suffers, leading to significant product loss.

- Staff Time: Units that are difficult to clean increase labor costs and reduce kitchen efficiency.

- The Value of Quality: A higher-quality commercial food warmer container may have a greater upfront cost, but it often pays for itself through lower operating costs, reduced food waste, and improved efficiency over its lifespan. It is an investment in your business's long-term success.

If you would like help comparing total cost of ownership between different warmer styles, you can book a strategy call with The Restaurant Warehouse team for expert, budget-focused advice.

Frequently Asked Questions about Commercial Food Warmers

What is the ideal temperature for holding hot food?

To support food safety and comply with health codes, hot food must be held at a temperature of 140 degrees F (60 degrees C) or higher. This helps keep food out of the “Temperature Danger Zone” (40 degrees F to 140 degrees F), where bacteria can grow rapidly. Always use a calibrated food thermometer to verify internal temperatures. Learn more about food safety from the FDA.

How long can I hold food in a non-electric insulated carrier?

A high-quality, well-insulated carrier can often hold food above 140 degrees F for 4 hours or more without electricity. For example, high-quality insulated units are designed to maintain safe temperatures for 4+ hours. Performance can be extended by pre-heating the carrier and using supplementary heat sources like thermal packs. For best results, use two thermal packs per compartment.

Can a food warmer dry out my food?

Yes, a basic warmer without proper humidity control can dry out food over time, leading to a loss of quality. This is why choosing a model with effective moisture control is critical. Look for units with manual or automatic humidity settings, or those with designs that naturally retain food moisture (like certain insulated cabinets), to keep your products juicy, tender, or crisp as desired.

If you need help selecting a warmer that protects specific menu items, from soups and sauces to crispy fried foods, reach out to The Restaurant Warehouse via their contact page for one-on-one support.

Conclusion: Investing in the Right Warmer for Your Success

Choosing the right commercial food warmer container is a strategic decision that directly impacts your food quality, operational efficiency, and bottom line. By focusing on precise temperature and moisture control, durable construction, and energy efficiency, you can select a unit that serves as a powerful asset rather than just another expense. This investment ensures the care you put into cooking is preserved until the moment it is served, resulting in safer operations and happier customers.

At The Restaurant Warehouse, the focus is on providing affordable, wholesale pricing on reliable equipment to help you make smart investments that pay off. With the right commercial food warmer container, you can lift your service, reduce waste, and build a reputation for consistent excellence while keeping upfront costs manageable.

Ready to find the perfect food warming solution for your business? Contact us today to explore our commercial food warmer guide and boost your kitchen’s workflow!

Book a strategy call with our experts or browse our full collection of commercial food warmer containers to equip your kitchen for success.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment