Warm Up Your Kitchen Savings with Used Food Warmers

Why Smart Restaurant Owners Choose Pre-Owned Kitchen Equipment

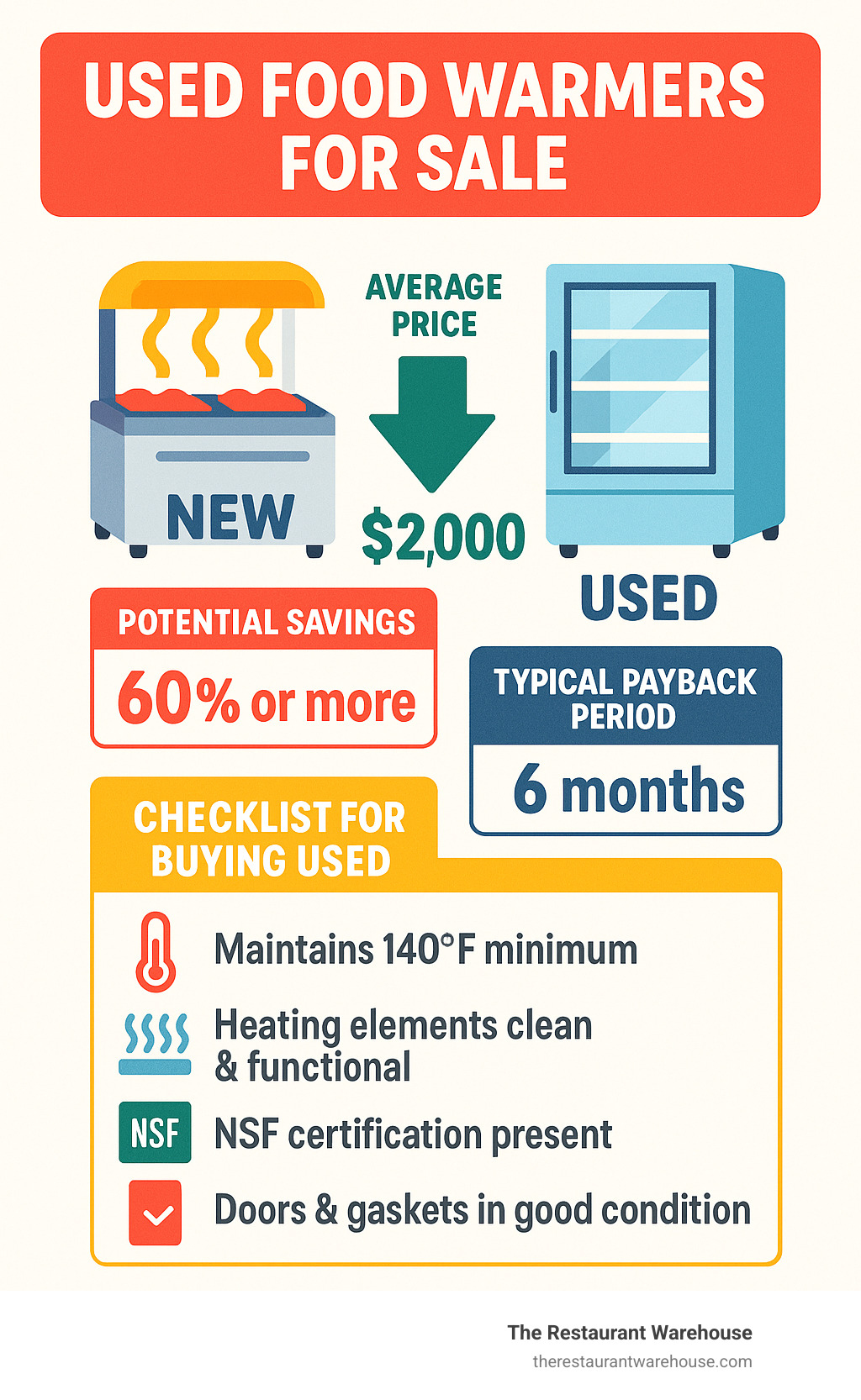

Used food warmers for sale offer restaurant owners a chance to slash equipment costs by 50% or more while maintaining the same food safety standards. Here's what you need to know:

Top Sources for Used Food Warmers: - Online marketplaces (eBay shows 8,900+ commercial warmer listings) - Specialty restaurant equipment dealers - Auction sites and liquidation sales - Direct from closing restaurants

Price Ranges You Can Expect: - Countertop steam tables: $86-$400 - Warming cabinets: $200-$1,200 - Display cases: $300-$800 - Heat lamps: $50-$200

Essential Inspection Points: - Temperature holds at 140°F minimum - Clean heating elements and working thermostats - NSF certification tags still attached - All doors, drawers, and gaskets intact

The research shows that food holding equipment and food warming equipment are among the most important purchases for a food service company. Yet new units can cost thousands while used alternatives deliver the same performance at a fraction of the price.

Whether you're launching a new restaurant or upgrading existing equipment, buying used lets you stretch your budget further while getting quality brands like Carter-Hoffman, Henny Penny, and Hatco.

The key is knowing what to look for, where to shop, and how to inspect equipment before you buy. Smart operators are saving serious cash without compromising on food safety or equipment reliability.

Must-know used food warmers for sale terms: - used food equipment - used food prep equipment

Why Used Food Warmers Matter for Food-Service Operations

When you're running a food service operation, every piece of equipment needs to earn its keep. Used food warmers for sale offer something special - they deliver the same food safety performance as new units while keeping more money in your pocket for the things that really drive revenue.

The math is straightforward. A quality steam table that costs $2,000 new might run you $800 used. That's not just savings - it's capital preservation that lets you outfit your entire kitchen instead of buying one piece at a time. Smart operators use this strategy to build complete warming stations from day one.

Used equipment often pays for itself much faster than new. While that brand-new holding cabinet might take two years to justify its cost, the used version at half price reaches profitability in under a year. This faster payback keeps your cash flow healthy and your options open.

There's also the sustainability angle. Every time you choose pre-owned equipment, you're extending the useful life of well-built commercial appliances. Your customers notice these choices, and it's a story worth telling - especially when it saves you money.

The lower depreciation on used equipment is another hidden advantage. That new warmer loses 30-40% of its value the moment you plug it in. Used equipment has already taken that hit, so your investment holds its value better over time.

Most importantly, menu-holding quality doesn't suffer when you buy used. A properly maintained food warmer keeps dishes at the same safe 140°F whether it cost you $2,000 or $800. Your customers taste the food, not the price tag.

More info about buying used equipment can help you understand the complete process and find even more benefits.

Hidden Benefits Beyond the Price Tag

The sticker price is just the beginning. Warranty transfer is one pleasant surprise - many commercial warmers from quality brands come with coverage that transfers to new owners. A unit that's only been in service for six months might still have years of protection left.

Used pricing also opens doors to brand-name access that might otherwise be out of reach. That premium display case or professional-grade soup kettle becomes affordable when you shop the secondary market.

Don't overlook the tax write-offs either. Used equipment often qualifies for immediate depreciation benefits through Section 179 deductions or bonus depreciation rules. Your accountant can show you how this might save hundreds or thousands in tax liability.

Key Risks & How to Dodge Them

Buying used equipment isn't without challenges, but most problems are easy to spot if you know what to look for. Overheating elements that cycle inconsistently are the most common issue. They'll work fine for a few hours, then start causing temperature swings that could put food safety at risk.

Worn gaskets around doors and drawers are another red flag. When seals don't close properly, your warmer has to work harder to maintain temperature, driving up energy costs and shortening equipment life.

Missing NSF tags might seem minor, but health inspectors take certification seriously. A unit without proper tags could mean expensive delays or failed inspections.

Our pre-purchase inspection checklist covers the essentials: test all heating elements under full load for at least 30 minutes, verify temperatures reach and hold 140°F minimum, check door seals for cracks or gaps, and make sure all controls respond properly.

The best test-run procedure is simple - ask the seller to plug it in and show you it works. Any reputable dealer will be happy to demonstrate their equipment. If they make excuses or seem hesitant, that's your cue to look elsewhere.

Best Types of Used Food Warmers for Sale

When you're hunting for used food warmers for sale, you'll find the same variety you'd find in new equipment showrooms - often at prices that'll make you smile. The beauty of the secondary market is that restaurants upgrade, change concepts, or close down, creating opportunities for savvy buyers like you.

Steam tables are the champions of the used market, and for good reason. These reliable workhorses handle everything from Sunday brunch buffets to school cafeteria lines. Warming drawers follow close behind, especially from hotels that renovated their breakfast areas or burger joints that switched to different holding systems.

Don't overlook heat lamps - they might look simple, but there's a world of difference between a cheap unit that creates hot spots and a professional Hatco model that delivers perfectly even coverage. Holding cabinets represent the premium end, with all the bells and whistles like humidity control and precise temperature management.

Soup kettles and display cases round out the most common categories you'll encounter. Each serves specific needs, and understanding their strengths helps you make smarter buying decisions.

Steam Tables: Top Picks of Used Food Warmers for Sale

Steam tables are the backbone of buffet operations everywhere, which explains why they're so plentiful in the used market. When you're shopping, the first decision is between wet heat and dry heat operation. Wet heat uses water to create steam and humidity, keeping foods moist and appetizing. Dry heat works without moisture, which some operators prefer for certain foods.

Pan capacity determines how much variety you can offer. A 3-pan unit works perfectly for smaller operations, while busy cafeterias need 5-6 pan capacity or more. Here's what matters most: all pan wells should be the same depth, and those drain valves need to operate smoothly. Trust me, a clogged drain will become your least favorite maintenance headache.

Thermostat accuracy isn't just about convenience - it's about food safety compliance. Your unit must reach and hold 140°F minimum without wild temperature swings. If you see fluctuations of more than 5-10 degrees during your test run, that's a red flag pointing to thermostat problems.

Look for complete units that include sneeze guards. These protective barriers are required by most health departments, and replacement guards can cost $200-$400. Finding everything together saves money and guarantees proper fit.

Display Cases & Cabinets: Eye-Catching Used Food Warmers for Sale

Display warmers earn their keep twice over - maintaining safe temperatures while showcasing your food to boost sales. Since customers buy with their eyes first, cosmetic condition matters more here than with basic steam tables tucked behind serving lines.

Glass clarity makes or breaks the merchandising appeal. Scratched, cloudy, or cracked panels turn appetizing food into something less appealing. Check that all glass components sit securely and that doors open and close without fighting you.

Interior lighting transforms ordinary food into something that makes mouths water. Many used units can be upgraded with modern LED systems that reduce energy costs while making everything look more delicious. It's often worth the investment for the improved presentation.

Humidity control separates the premium models from basic units. Adjustable humidity keeps fried chicken crispy, prevents pizza from drying out, and maintains the appeal of baked goods. This feature becomes especially valuable during slower periods when food sits longer.

Consider your service style when choosing between self-serve and staff-serve configurations. Self-serve units let customers help themselves, while staff-serve models only open from behind the counter. Your local health codes and operation style will guide this decision.

Drawer & Under-Counter Units

Warming drawers shine when you need to hold prepared items out of sight until service time. Hotels rely on them for bread service, burger joints use them for cooked burger patties, and they're perfect for keeping things warm without taking up valuable counter space.

Slide-out rails should glide smoothly even when fully loaded. Worn or damaged rails create service delays and safety hazards when drawers stick or bind. Always test each drawer with some weight to simulate real-world conditions.

Temperature consistency matters more in drawers since there's no air circulation like you'd find in cabinet models. Quality units use multiple heating elements or smart heat distribution to avoid hot spots that overcook food or cool areas that create safety risks.

Our Commercial Food Warmer Guide dives deeper into selecting the right warming equipment for your specific needs, whether you're running a quick-service restaurant or an upscale dining room.

What to Look For When Shopping the Secondary Market

Shopping for used food warmers for sale requires more detective work than buying new, but the effort pays off in serious savings. At The Restaurant Warehouse, we've seen too many buyers get excited about a low price only to find expensive problems later. A little upfront diligence saves big headaches down the road.

Your first stop should be the manufacturer's nameplate - that metal tag with all the technical details. This little plate tells you everything about voltage requirements, electrical phase, amperage draw, and the exact model number. Without this information, you're buying blind. Missing or unreadable nameplates often signal poor maintenance or equipment that's seen better days.

Voltage and phase compatibility can make or break your deal. Most small countertop warmers run on standard 120V household power, but larger units might need 208V or 240V commercial service. Getting this wrong means expensive electrical work before you can even plug the thing in. Always verify your building's electrical setup matches the equipment requirements.

Don't forget to measure twice, buy once. That perfect steam table becomes a nightmare if it doesn't fit through your kitchen door or blocks critical walkways. Account for door swings, ventilation clearances, and access for cleaning and maintenance. We've seen operators fall in love with equipment that simply won't work in their space.

Safety certifications from NSF, UL, or ETL aren't just nice-to-have features - they're absolutely essential. Health inspectors will shut you down for using uncertified equipment, and your insurance company might deny claims if accidents involve non-certified gear. Look for clear, legible certification labels that match the equipment model exactly.

The condition grading system varies by seller, but generally ranges from "like new" down to "fair" or "as-is." Don't get hung up on cosmetic scratches if the equipment functions perfectly. A few dings won't affect food safety or performance, but they might give you negotiating leverage.

Included accessories can add significant value to your purchase. Steam table pans, sneeze guards, and replacement parts often cost hundreds of dollars separately. Ask specifically what's included and factor these extras into your price comparison.

Specsheet on electric warmer examples can help you understand what technical specifications to look for when evaluating different models.

Price Benchmarks & Negotiation Hacks

The used market follows predictable patterns once you know what to look for. Expect savings of 50% or more compared to new prices, with the exact discount depending on age, condition, and demand. We typically see countertop steam tables in the $100-$2,000 range, which represents massive savings over new equipment.

Age matters more than appearance for most buyers. A five-year-old unit in excellent working condition might sell for 60-70% of new retail, while a ten-year-old workhorse drops to 30-40% of original price. The sweet spot is often equipment that's 3-7 years old - old enough for significant depreciation but young enough to avoid parts availability issues.

Bundling multiple pieces often open ups better pricing than buying individually. Sellers love moving several items to one buyer rather than dealing with multiple transactions. If you need a steam table, heat lamps, and warming drawers, ask about package pricing. The worst they can say is no.

Always ask for a load test before money changes hands. This means running the equipment at full capacity for 30-60 minutes to verify everything works properly. Confident sellers will happily demonstrate their equipment, while those who make excuses might be hiding problems.

Shipping costs can kill your savings on heavy commercial equipment. A $400 steam table becomes a $650 purchase after freight charges. Consider pickup options when possible, which also gives you a chance to inspect before paying. Local deals often offer the best value when you factor in transportation costs.

| Equipment Type | New Price Range | Used Price Range | Typical Savings | Payback Period |

|---|---|---|---|---|

| Countertop Steam Table | $300-$800 | $100-$400 | 50-70% | 6-12 months |

| Warming Cabinet | $1,500-$4,000 | $500-$1,500 | 60-75% | 8-15 months |

| Display Case | $800-$2,500 | $300-$1,000 | 55-65% | 10-18 months |

| Heat Lamp | $150-$400 | $50-$200 | 65-75% | 3-8 months |

Care, Cleaning & Compliance Tips

Your investment in used food warmers for sale pays off long-term when you maintain them properly. Think of it like buying a reliable used car - with the right care, it'll serve you faithfully for years to come.

Daily maintenance is your best friend for preventing costly breakdowns and health code violations. A simple wipe-down with approved sanitizers after each service period keeps surfaces clean and removes food residue that could harbor bacteria. For steam tables, check water levels regularly since dry heating elements can burn out quickly and cost hundreds to replace.

Temperature accuracy deserves daily attention too. Use a calibrated thermometer to verify your warmers hold 140°F minimum - this isn't just good practice, it's the law. Food safety violations can shut down your operation faster than any equipment failure.

Weekly deep cleaning tackles the buildup that daily maintenance misses. Hard water leaves mineral deposits that reduce heating efficiency and make your equipment work harder. Descaling solutions designed for commercial equipment dissolve these deposits safely without damaging internal components. Avoid harsh household cleaners that can corrode heating elements or leave chemical residues on food-contact surfaces.

Pay special attention to door gaskets and seals during weekly inspections. These rubber components wear out over time, letting heat escape and forcing your equipment to work overtime. Cracked or hardened gaskets are easy to spot and relatively inexpensive to replace.

Monthly thermostat calibration catches temperature drift before it becomes a problem. Most commercial thermostats stay accurate for years, but significant variations signal the need for professional service. Many units can be recalibrated rather than replaced, saving you money while maintaining food safety compliance.

Understanding NSF/ANSI Standard 4 helps you maintain your equipment properly and spot potential issues early. This standard covers everything from materials and cleanability to temperature control and safety features. Your local health department relies on these standards during inspections, so following them protects your operation.

Don't forget that local health codes sometimes go beyond federal requirements. Some areas require specific temperature logging, cleaning schedules, or additional certifications. A quick call to your health department clarifies any special requirements before they become citation issues.

More info about used kitchen gear maintenance helps you develop comprehensive care procedures that keep your equipment running smoothly.

Refurbish or Upgrade?

Sometimes a few strategic improvements transform good used equipment into great equipment. The key is knowing which upgrades deliver real value versus those that just look nice.

After-market parts availability varies dramatically between brands. Popular manufacturers like Hatco, Carter-Hoffman, and Henny Penny maintain extensive parts inventories even for older models. This parts support makes these brands excellent choices in the used market since repairs stay affordable and straightforward.

Energy-saving thermostat upgrades often pay for themselves within 12-18 months through reduced electricity bills. Modern digital controls offer precision that older mechanical thermostats simply can't match. The improved temperature stability also means better food quality and fewer safety concerns.

Door gasket replacement ranks as one of the most cost-effective improvements you can make. New gaskets typically cost $30-$80 but can extend equipment life by several years while reducing energy consumption. The improved heat retention means your equipment cycles less frequently, reducing wear on heating elements and controls.

LED lighting conversions make sense for display cases where food presentation drives sales. LED systems produce less heat, use less electricity, and last much longer than traditional bulbs. The improved light quality makes food look more appetizing, potentially increasing sales enough to justify the upgrade cost quickly.

The smart approach is upgrading components as they wear out rather than trying to modernize everything at once. This spreads costs over time while ensuring you get maximum value from each improvement.

Frequently Asked Questions About Used Food Warmers

The most common questions we hear from restaurant owners center around three main concerns: food safety compliance, parts availability, and financing options. Let's tackle these head-on so you can buy with confidence.

Do used food warmers still meet the 140°F food-safety rule?

Absolutely! A used food warmer for sale that's properly maintained will hit that critical 140°F minimum just like it did when it rolled off the factory floor. The secret is thorough testing before you hand over your money.

Here's the thing - age doesn't automatically mean poor performance. We've seen 15-year-old steam tables that maintain perfect temperatures while 3-year-old units struggle because of poor maintenance. It's all about how the equipment was cared for, not how many birthdays it's celebrated.

During your inspection, bring a calibrated thermometer and test multiple spots throughout the warming area. Let the unit run for at least 30 minutes to see how it performs under normal operating conditions. If it can't maintain 140°F consistently, walk away - or negotiate a lower price to cover repair costs.

The good news? Most temperature issues are fixable. A faulty thermostat replacement typically runs $100-$200, while heating element repairs might cost $150-$300. Even with these potential repairs, you're still way ahead compared to buying new.

Where can I find replacement parts for an older model?

This is where buying quality brands pays off big time. Companies like Hatco, Carter-Hoffman, Wells, and Henny Penny keep parts in stock for equipment that's 15-20 years old or more. They know that parts support keeps customers loyal and coming back.

Start with the manufacturer's parts department - they'll have the exact components and often the best prices. Most major brands now offer online parts catalogs with detailed diagrams that make ordering straightforward. You can usually find what you need in just a few clicks.

When manufacturer parts aren't available, third-party suppliers step in to fill the gap. These companies specialize in foodservice equipment parts and often stock common items like heating elements, thermostats, and door gaskets that work across multiple brands.

Don't overlook your local restaurant equipment service companies either. These folks often maintain parts inventories for equipment they service regularly. They might have exactly what you need sitting on their shelf, and you'll save on shipping costs too.

The bottom line? Parts availability is rarely a deal-breaker for quality equipment from reputable manufacturers. Do your homework on the brand before buying, and you'll be covered for years to come.

Can I finance a used warmer purchase?

Yes, and it's probably easier than you think! Many dealers offer financing programs specifically for used equipment purchases, often with terms that rival new equipment financing. The lenders understand that quality used equipment delivers excellent value and reliable performance.

Traditional equipment financing companies like Balboa Capital and Crest Capital provide used equipment loans with competitive rates. They focus more on your business's cash flow and credit history than the equipment's age, as long as it meets their minimum value requirements.

Credit requirements for used equipment financing mirror those for new equipment loans. Lenders want to see stable cash flow, reasonable credit scores, and a solid business plan. The equipment's age matters less than your ability to make payments.

Lease-to-own programs offer another path, especially if your credit history is limited. These programs typically require higher monthly payments but provide easier qualification and eventual ownership. You get the equipment you need now while building business credit for future purchases.

At The Restaurant Warehouse, we work with multiple financing partners to help you find the right solution for your budget and credit situation. Don't let financing concerns keep you from exploring the savings that used food warmers for sale can provide.

Conclusion

Shopping for used food warmers for sale might just be the smartest move you'll make for your restaurant this year. We've covered everything from steam tables to display cases, and the message is clear - quality used equipment delivers the same performance as new units while keeping thousands in your pocket.

The numbers don't lie. When you can save 50-70% off retail prices and still get equipment that maintains perfect 140°F temperatures, the choice becomes obvious. That extra cash flow gives you breathing room to focus on what really matters - creating great food and building your customer base.

We've seen too many operators struggle because they spent their entire equipment budget on just a few new pieces. Meanwhile, smart buyers who choose used equipment can outfit their entire warming station for the cost of one new holding cabinet. The difference in cash flow can make or break a new restaurant.

The key is doing your homework. Test everything thoroughly, verify those NSF certifications, and don't skip the load test demonstration. A reputable seller will be happy to show you their equipment in action. If they won't, keep shopping.

At The Restaurant Warehouse, we understand that every dollar matters in this business. Our wholesale approach means you're not paying retail markups or high commissions - just honest pricing on quality equipment that works. We've built our reputation by helping operators like you find reliable solutions that fit real-world budgets.

There's also something satisfying about giving quality equipment a second life instead of sending it to a landfill. Your customers notice when businesses make environmentally conscious choices, and choosing used equipment shows you care about more than just profits.

Whether you're opening your first location or expanding an existing operation, the used equipment market offers incredible opportunities. Quality brands like Carter-Hoffman, Hatco, and Henny Penny hold their value because they're built to last. You're not buying someone else's problems - you're getting proven performers at prices that make sense.

Ready to start saving? Our Kitchen Gear on a Budget guide walks you through finding quality equipment without breaking the bank.

The restaurant business is tough enough without overspending on equipment. Choose used, choose smart, and watch your bottom line improve while your food stays perfectly warm and safe for every customer.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment