Drain Pump Solutions: Essential Parts for Your Ice Machine

Why Your Ice Machine Needs a Drain Pump

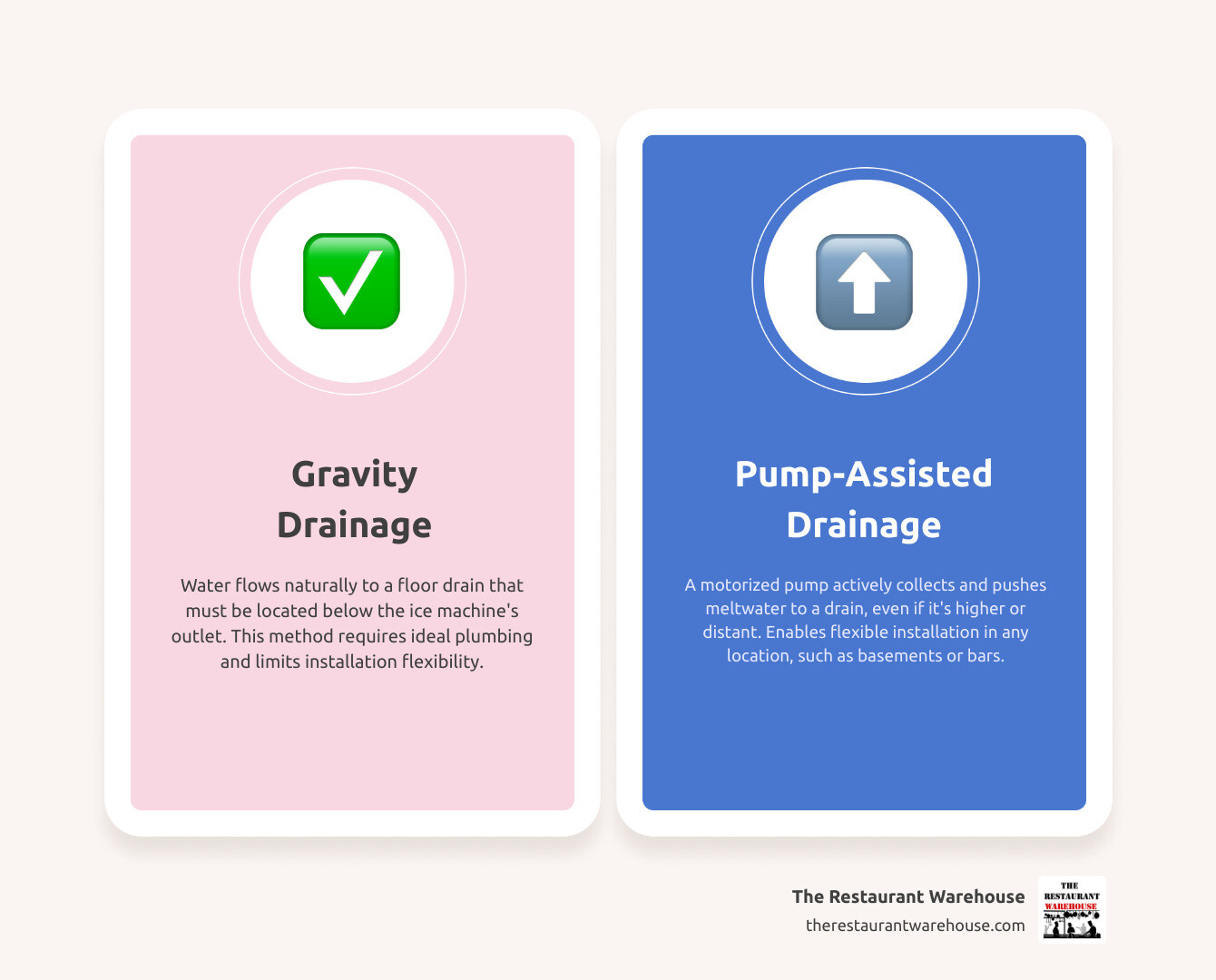

What is an Ice Machine Drain Pump? An ice machine drain pump is a small, motorized device designed to remove meltwater and condensation from an ice maker. It is essential when a direct gravity drain is unavailable or located above the ice machine's drain outlet.

Why is it essential for your ice machine?

- Enables Flexible Installation: Allows ice machines to be placed in basements, upper floors, bars, and offices where a floor drain isn't conveniently located.

- Prevents Water Damage: Efficiently purges excess water, preventing overflows and potential damage to your property.

- Ensures Proper Operation: Critical for ice machines that cannot rely on gravity for water drainage.

The ice machine drain pump is a critical component for many commercial and residential ice makers, ensuring efficient water removal and flexible installation options. When your ice machine produces ice, it also generates meltwater and condensation. Without a proper drainage system, this excess water can lead to overflows, potential property damage, and even operational failure.

This compact yet powerful device solves that problem by actively collecting excess water in a reservoir and then pumping it to a higher or more distant drain. This means you can install ice machines in a wider variety of locations, such as basements, upper floors, bars, office breakrooms, or professional settings where a traditional floor drain isn't feasible or conveniently situated.

Sean Kearney, from The Restaurant Warehouse, is an expert in ice machine systems. His background includes connecting with customers and understanding their needs to ensure they have the right components, including essential parts like the ice machine drain pump, for a successful setup.

Ice machine drain pump terms you need:

We often encounter situations where a floor drain isn't conveniently located for an ice machine. This is where an ice machine drain pump truly shines, providing a problem-solving solution for condensate and meltwater removal. Imagine setting up a new bar in a historic building without the option to cut into the concrete for new plumbing, or placing an ice maker on an upper floor where gravity alone can't do the trick. A drain pump makes these installations not just possible, but practical and efficient. It ensures that the excess water, which can reach up to 105.67 quarts per hour in some systems, is effectively purged, preventing any messy or damaging overflows. Our goal at The Restaurant Warehouse is to equip you with affordable, wholesale solutions that make your operations smoother, and a reliable drain pump is definitely one of them.

How an Ice Machine Drain Pump Works

An ice machine drain pump operates on a simple yet ingenious principle of automatic water collection and discharge. It's essentially a small, self-contained pumping station for your ice maker's meltwater.

The Pumping Cycle Explained

The process begins when meltwater and condensation from the ice machine flow into the drain pump's internal reservoir, often a water tank with a capacity around 0.6 liters. As the water level rises within this reservoir, it lifts a float switch or activates a water level sensor (using probes). Once the water reaches a predetermined level, this float switch triggers the pump's motor, typically a low-wattage motor around 5 watts.

The motor then activates an impeller, which rapidly spins and creates pressure, forcing the collected water out of the reservoir through a discharge tube. This discharge tube is routed to a suitable drain, which could be a sink, a standpipe, or a distant floor drain. Crucially, as the water is pumped out, a check valve within the system prevents any backflow of water once the pump stops. The float then lowers with the decreasing water level, and once it hits a minimum threshold, the switch deactivates the motor, completing one cycle. The pump remains dormant until enough water accumulates again to trigger the next cycle. This automatic operation ensures efficient and quiet water removal, with some units operating at a mere 22 dB, quieter than a whisper.

Core Components and Their Roles

Understanding the core components helps us appreciate the simplicity and effectiveness of an ice machine drain pump:

- Reservoir/Water Tank: This is the primary collection point for the ice machine's meltwater. Its capacity, such as 0.6 liters, dictates how much water can accumulate before the pump activates.

- Float Switch Mechanism/Probes: This is the "brain" that detects the water level. A physical float rises and falls, mechanically activating a switch, or electronic probes sense the water's presence to signal the motor.

- Centrifugal Pump Motor: The heart of the system, this motor drives the impeller. Often a low-power unit (e.g., 5-watt motor), it's designed for intermittent operation and energy efficiency.

- Impeller: A rotating component inside the pump housing that creates the centrifugal force to move water.

- Inlet Port: Where the drain line from the ice machine connects to the pump's reservoir, allowing meltwater to enter.

- Outlet Port/Discharge Tube: Where the pumped water exits the unit, connecting to the main drain line.

- Vent Tube: An essential component that allows air to enter and exit the reservoir, preventing airlocks and ensuring smooth, efficient pumping. It must be attached and secured, and never kinked or blocked, to ensure correct drain operation.

- Power Cord: Connects the pump to an electrical outlet, providing the necessary power for the motor.

- Check Valve: A one-way valve typically located at the pump's outlet. Its crucial role is to prevent discharged water from flowing back into the reservoir or the ice machine once the pump stops, protecting against potential overflows.

These components work in harmony to provide an automated and reliable solution for ice machine drainage. For more information on maintaining your ice maker, including drain pump care, you can explore our resources on ice maker maintenance.

Choosing the Right Ice Machine Drain Pump for Your Needs

Selecting the correct ice machine drain pump is crucial for ensuring efficient drainage and the longevity of your ice maker. It's not a one-size-fits-all situation; several factors come into play, from the pump's capacity to its compatibility with your specific ice machine. When considering options, we look at both external pump kits and ice machines that offer built-in pump options.

Key Factors to Consider

Lift Height (Head Pressure): This is perhaps the most critical specification. It refers to the maximum vertical distance an ice machine drain pump can push water. For instance, many pumps are designed to purge excess water up to 10 feet vertically. If your drain is higher than the pump's specified lift height, the pump won't be able to effectively move the water, leading to overflows. Always measure the vertical distance from the pump's intended location to the drain inlet. Some pumps offer a 6.6 ft. lift for different heights, which is sufficient for many undercounter installations.

Flow Rate: Measured in gallons per hour (GPH) or liters per hour (L/H), the flow rate indicates how much water the pump can move within a given time. Our research shows some pumps can handle a water flow of 105.67 quarts (100 liters) per hour. This needs to match or exceed the meltwater production rate of your ice machine to prevent the reservoir from overflowing. A higher flow rate is generally better, especially for larger commercial ice makers.

Power Consumption (Wattage): This relates to the energy efficiency of the pump. A 5-watt motor, for example, is very energy-efficient. While pumps run intermittently, lower wattage means lower operating costs over time. We at The Restaurant Warehouse believe in providing solutions that are not only effective but also economical. To learn more about energy-efficient appliances, you can visit ENERGY STAR certified products.

Noise Level: For installations in customer-facing areas like bars or office breakrooms, a quiet pump is highly desirable. Noise levels are measured in decibels (dB). A pump operating at around 22 dB is exceptionally quiet, significantly below the volume of normal conversation (40-60 dB). We aim for solutions that minimize disruption.

Reservoir Capacity (Water Tank): This is the volume of water the pump's internal tank can hold before activating. A typical capacity might be 0.6 liters. A larger reservoir can handle larger influxes of meltwater without constantly cycling, potentially extending the pump's lifespan.

Navigating these specifications can sometimes be challenging, especially when trying to match a pump to a specific ice machine model. If you're unsure which pump is right for your setup, our team of experts is here to help. Contact us today for personalized guidance to ensure you get the perfect fit for your needs.

Understanding Compatibility for your ice machine drain pump

Compatibility is paramount to avoid frustration and ensure proper function.

Ice Maker Size and Production Capacity: Many drain pumps are designed for specific ice maker categories, such as "50-lb ice makers." This refers to the daily ice production capacity. Ensure the pump you choose is rated for the size of your ice machine.

Manufacturer Date and Model Number Check: Some drain pump kits are compatible with ice makers manufactured within a certain timeframe, for example, "all 50-lb ice makers manufactured in the year 2000 or later." Always verify your ice maker's model number and manufacturing date against the pump's compatibility list. Checking your specific model number is an actionable step you should always take.

OEM vs. Universal Kits: Original Equipment Manufacturer (OEM) parts are designed specifically for certain brands and models, ensuring a perfect fit and tested performance. Universal kits offer broader compatibility but might require more adaptation during installation. While OEM parts often highlight quality assurance, we recommend focusing on the specifications that meet your machine's needs.

Electrical Connections and Safety Switches: Ensure the pump's electrical requirements (voltage, amperage) match your ice machine's specifications and local electrical codes. Some ice makers use "jumper connectors" for pump integration; if the pump is removed, this connector must be reattached for the ice maker to operate. Drain pumps often include a safety switch that can turn off the ice machine if the pump fails or the water level gets too high, preventing major spills.

By carefully considering these factors, you can select an ice machine drain pump that provides reliable, long-lasting service for your commercial or residential needs. For more resources on ice makers, we invite you to explore our ice maker resources.

A How-To Guide for Installation and Safety

Installing an ice machine drain pump might seem daunting, but with the right preparation and attention to safety, it can often be a straightforward process, even for those with novice repair experience and basic hand tools. However, if you ever feel uncertain, or if the installation involves complex electrical or plumbing work beyond your comfort level, we always recommend consulting a qualified professional.

Essential Safety Precautions

Before you even think about touching your ice machine or the drain pump, safety must be your absolute priority.

- Disconnect Power: This is non-negotiable. Always unplug the ice machine from its electrical outlet or, if it's hardwired, shut off the house circuit breaker for the appliance. Electricity and water are a dangerous combination, and this step protects you from electric shock.

- Turn Off Water Supply: For any water-connected appliance, you must turn off the main water supply valve to the ice machine before starting work. This prevents leaks and flooding during the installation process.

- Read Manufacturer Manual: Every drain pump and ice machine will have specific installation instructions. Reading both manuals thoroughly is crucial. They often contain critical details, warnings, and step-by-step guides unique to your model.

- Wear Protective Eyewear: Splashing water, small parts, or unexpected movements can cause eye injury. Protective eyewear is a simple but effective safeguard.

Taking these precautions will make your installation experience safer and smoother.

General Installation Steps for an external ice machine drain pump

While specific steps may vary depending on your ice machine and drain pump model, here's a general guide for installing an external ice machine drain pump:

- Positioning the Pump: Choose a location for the drain pump that is close to the ice machine's drain outlet and below it, allowing gravity to feed meltwater into the pump's reservoir. Ensure there's enough space for proper ventilation and access for future maintenance.

- Connecting Inlet Hose: Connect the drain hose from your ice machine's drain outlet to the inlet port of the drain pump. Use appropriate hose clamps to secure the connection tightly, ensuring it is water-tight to prevent leaks.

-

Routing the Discharge Tube: Connect the pump's outlet port to the discharge tube (often provided in the kit). This tube will run from the pump to your chosen drain point (e.g., a standpipe, utility sink, or floor drain).

- Avoid Kinks and Bends: Route the discharge tube as straight as possible, avoiding sharp bends or kinks that can restrict water flow and strain the pump.

- Consider Lift Height: Remember the pump's maximum lift height (e.g., 10 feet). Ensure the highest point of the discharge tube is within this limit.

- Air Gap: It's good practice to create an air gap at the drain connection point to prevent wastewater from siphoning back into the ice machine or pump.

- Attaching the Vent Tube: If your pump has a vent tube, attach it as per the manufacturer's instructions. This tube helps prevent airlocks and ensures efficient operation. It must be open and not restricted or jammed.

- Electrical Connections: Connect the drain pump's power cord to a grounded electrical outlet. If your ice machine requires a "jumper connector" for pump integration, ensure it's correctly installed. Always ensure all electrical connections are secure.

-

Testing the Pump: Once all connections are made and secure, and before fully integrating the ice machine back into service, perform a test:

- Pouring Water into Bin: Slowly pour about a quart of water (or as specified by the manual) into the ice machine's reservoir or drain pan where meltwater collects. This should activate the drain pump.

- Checking for Leaks: Observe all connections for any signs of leakage while the pump is running and after it stops.

- Test Safety Switch: If your pump has a safety switch that turns off the ice machine in case of pump failure, you might test this feature according to the manufacturer's instructions (e.g., by temporarily blocking the discharge tube to simulate a blockage and see if the ice machine shuts off).

- Final Placement: Once you've confirmed everything is working correctly, position your ice machine and drain pump in their final locations, ensuring no hoses or cables are pinched or blocked.

Proper installation ensures your ice machine drain pump operates efficiently and reliably, preventing water damage and contributing to the smooth operation of your ice maker. For insights into ensuring your equipment meets safety standards, you can refer to What is NSF Certification?.

Maintenance and Troubleshooting Common Issues

To ensure optimal performance and a long operational life, your ice machine drain pump requires regular, proactive maintenance. Neglecting this essential care can lead to unexpected breakdowns, inconvenient water spills, and costly repairs. We at The Restaurant Warehouse understand the importance of keeping your operations running smoothly, which is why we emphasize this proactive approach.

Routine Maintenance for Longevity

A consistent maintenance schedule, ideally every 6 months, can significantly extend the life of your drain pump and prevent most common issues.

- Cleaning Schedule: Implement a routine for cleaning the pump's reservoir. Mineral deposits, slime, and debris can accumulate over time, potentially clogging the pump or fouling the float switch. Disconnect power and water, then access the reservoir to clean it with a mild detergent and brush.

- Inspecting Hoses and Connections: Regularly check the inlet and discharge hoses for kinks, cracks, or signs of wear. Ensure all hose clamps are tight and that connections are water-tight. Loose connections are a common cause of leaks.

- Clearing Blockages: Inspect the inlet and outlet ports for any blockages from foreign substances. This includes the air vent tube, which must remain open for proper airflow.

- Descaling and Mineral Deposit Prevention: If your water supply has high mineral content, scale buildup can affect pump efficiency. Some ice machines recommend using a manufacturer-recommended descaling solution to reduce mineral deposits. While primarily for the ice machine, using softened water or appropriate filtration can also benefit the drain pump.

- Verifying Check Valve Function: Periodically ensure the check valve is working correctly, preventing backflow. You can often observe water flow direction when the pump activates to confirm its function. If water flows back into the reservoir after the pump stops, the check valve might be faulty.

Common Problems and Solutions

Even with diligent maintenance, issues can arise. Here's a troubleshooting guide for common ice machine drain pump problems:

-

Pump Won't Turn On:

- Check Power Supply: Ensure the pump is plugged in and the circuit breaker hasn't tripped.

- Faulty Float Switch: The float might be stuck or the sensor probes might be dirty. Disconnect power, clean the reservoir, and manually test the float's movement. If it's electronic, check for debris on the probes.

- Motor Failure: If power is present and the float switch is activating, the motor itself might have failed. This usually requires pump replacement.

-

Pump Runs Constantly (or too frequently):

- Stuck Float: The float switch might be stuck in the "on" position, continuously signaling the pump to run even when the water level is low. Disconnect power, inspect, and free the float.

- Failed Check Valve: If the check valve isn't preventing backflow, water might continually drain back into the reservoir, causing the pump to cycle repeatedly. This requires check valve repair or pump replacement.

- Partial Blockage in Discharge Line: A partial blockage can restrict water flow, making the pump work harder and longer to clear the reservoir. Check and clear the discharge tube.

- Oversized Pump for Small Meltwater Flow: If the pump is too powerful for the ice machine, it might short-cycle. This is less common but can happen.

-

Leaks from Connections:

- Loose Clamps: The most common culprit. Tighten all hose clamps at the inlet and outlet ports.

- Damaged Hoses: Inspect hoses for cracks or punctures. Replace any damaged hoses.

- Cracked Reservoir/Housing: If the pump itself is cracked, it will need to be replaced.

- Over-pressurization: Ensure the discharge line isn't excessively long or routed against too much head pressure, which could strain connections.

-

Pump is Noisy (more than usual):

- Debris in Pump/Impeller: Foreign objects like ice chips, mineral deposits, or slime can get into the impeller, causing grinding or rattling noises. Disconnect power, disassemble the pump (if accessible), and clear any debris.

- Motor Issues: A failing motor might emit unusual noises (e.g., humming, grinding). This often indicates the need for replacement.

- Vibration: Ensure the pump is sitting on a stable, level surface. Dampening feet can help reduce vibration noise.

By following these maintenance tips and troubleshooting steps, you can keep your ice machine drain pump in top working condition, ensuring your ice machine continues to operate efficiently.

Frequently Asked Questions about Ice Machine Drain Pumps

When do I actually need an ice machine drain pump?

A drain pump is necessary when a gravity-fed floor drain is not available, is located too far away, or is positioned higher than the ice maker's drain outlet. It provides the flexibility to install an ice machine in locations like basements, bars, or any area without ideal plumbing. For example, if your ice machine is in a basement and the only drain is at ground level, a pump is essential to push the water upwards. Similarly, if you're installing an undercounter ice maker in a bar where the main drain is several feet away or lifted, a drain pump becomes a critical component. Some ice machine manufacturers, for certain models, explicitly state that condensate pumps are not recommended, implying that gravity drainage is the preferred method. However, for situations where gravity drainage is not an option, a pump becomes the only viable solution.

How high can a typical drain pump push water?

This varies by model, but many common drain pumps are designed to push water vertically up to 10 feet (10'H). Our research shows that some kits are specifically designed for this capacity. Other pumps might offer a 6.6 ft. lift. It is crucial to check the "lift height" or "head" specification of a pump to ensure it meets the requirements of your specific installation. Always measure the vertical distance from the pump's outlet to the highest point of the drain connection. For instance, an installation manual might specify that a drain hose should be no longer than 20 feet horizontally and 8 feet vertically, indicating the typical limits for these systems.

Can I install an ice machine drain pump myself?

Installation can often be done by someone with basic hand tools and novice repair experience. However, safety is paramount. Always disconnect all power and water sources before starting. If you are unsure about any step, especially electrical connections, it is best to consult a qualified technician. Manufacturer manuals will often provide detailed, step-by-step instructions, emphasizing safety precautions like unplugging the appliance or shutting off the circuit breaker and turning off the water supply. Incorrect installation can lead to property damage, which manufacturers typically state they will not be liable for.

Conclusion

The ice machine drain pump is a small but mighty hero in ice production. It offers unparalleled installation flexibility, allowing ice machines to be placed in virtually any location, from busy bar areas to quiet office breakrooms, regardless of floor drain availability. By efficiently purging meltwater, it prevents costly water damage and ensures your ice maker operates smoothly and continuously.

When choosing a drain pump, we've seen how critical it is to consider factors like lift height, flow rate, power consumption, noise level, and reservoir capacity. Compatibility with your specific ice maker model and manufacturing date is also key to a successful setup. While installation can be a DIY project for those with basic experience, prioritizing safety by disconnecting power and water, and consulting the manufacturer's manual, is always paramount.

Regular maintenance, including cleaning the reservoir, inspecting hoses, and clearing blockages, will ensure your drain pump delivers optimal performance and a long, efficient lifespan. By understanding these aspects, you're not just buying a part; you're investing in the longevity and efficiency of your ice-making operation. At The Restaurant Warehouse, we're committed to providing affordable, wholesale solutions that help your business thrive. We're here to help you find the right ice machine drain pump solutions to keep your ice flowing and your business chilling.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment