Kitchen Gear on a Budget: Finding Quality Used Food Equipment

Smart Savings: Investing in Used Food Equipment

Used food equipment offers a cost-effective solution for restaurateurs looking to outfit their kitchens without breaking the bank. Here's what you need to know:

- Cost savings of 30-50% compared to buying new

- Immediate availability versus weeks or months of lead time

- NSF-certified options with 90-day warranties from reputable dealers

- Environmentally responsible choice that keeps thousands of pounds of waste out of landfills

- Tax-deductible purchases with slower depreciation than new equipment

For restaurant owners and food service entrepreneurs operating on tight budgets, the commercial kitchen equipment market presents a significant challenge. New equipment costs can quickly consume your startup capital or renovation budget, potentially delaying your opening or expansion plans.

That's where the secondary market for food service equipment comes into play. From mixers and refrigeration units to ranges and dishwashers, previously-owned commercial kitchen gear offers a practical alternative that can slash your equipment costs by up to half.

"Purchasing used restaurant equipment is one of the best ways to save money while still getting quality items," notes industry experts. This approach not only preserves your capital but also gives you access to high-end brands that might otherwise be out of reach.

The best part? Many reputable dealers thoroughly inspect, repair, and detail used equipment before resale, ensuring it meets National Sanitation Foundation (NSF) requirements. Many even offer warranties similar to those you'd get with new purchases, providing peace of mind along with the savings.

Whether you're launching a new restaurant, upgrading your existing kitchen, or replacing a single piece of equipment that unexpectedly failed, exploring the used market could be the financial lifeline your business needs.

Why Choose Used Food Equipment?

When it comes to outfitting a commercial kitchen, those shiny new appliances might catch your eye—but your budget might have other ideas. That's where used food equipment comes into the picture, offering a practical path that thousands of successful restaurant owners have already traveled.

Let's talk about why pre-owned kitchen gear might be the smartest move for your food service dreams.

Used Food Equipment ROI Facts

The financial advantages of choosing used food equipment are too compelling to ignore.

You'll typically save up to 50% on your upfront costs compared to buying new—money that can go toward other critical startup expenses or simply stay in your bank account. A commercial convection oven priced at $12,000 new might be yours for just $6,000 used. Imagine what you could do with that extra $6,000!

Beyond the immediate savings, pre-owned equipment has already weathered its steepest depreciation period. While that shiny new range might lose 20-30% of its value the moment you install it, used food equipment tends to hold its value much better, creating a more stable asset for your business.

And here's something many new restaurateurs don't realize: you'll face significantly reduced lead times. While manufacturers might keep you waiting months for new equipment (especially in today's supply chain), quality used gear is typically available immediately, helping you open your doors faster.

| Equipment Type | Average New Cost | Average Used Cost | Typical Savings |

|---|---|---|---|

| Commercial Range | $3,500-$10,000 | $1,750-$5,000 | 40-50% |

| Walk-in Cooler | $6,000-$15,000 | $3,000-$7,500 | 45-55% |

| Dough Mixer | $5,000-$12,000 | $2,500-$6,000 | 40-50% |

| Ice Machine | $2,500-$6,000 | $1,250-$3,000 | 45-50% |

| Dishwasher | $3,000-$8,000 | $1,500-$4,000 | 40-50% |

From a tax perspective, used food equipment enjoys the same advantages as new purchases. It remains fully deductible as a business expense, allowing you to reduce your tax burden while building your kitchen at half the cost.

Environmental Wins of Used Food Equipment

Your wallet isn't the only thing that benefits when you choose pre-owned equipment—Mother Earth thanks you too.

Commercial kitchen equipment contains substantial amounts of stainless steel, copper, aluminum, and other valuable materials that require significant energy to produce. By purchasing used food equipment, you're extending the lifecycle of these resources and keeping thousands of pounds of perfectly functional machinery out of landfills.

You're also reducing your carbon footprint by eliminating the need for new manufacturing, packaging, and shipping. It's a form of recycling that makes both environmental and business sense.

As one of our customers recently told us, "My restaurant is built on sustainability principles, and our kitchen reflects that. Our used food equipment not only saved us nearly $40,000 on startup costs, but it also aligns perfectly with the values we promote to our customers."

When you choose pre-owned equipment, you're participating in the circular economy—a system that maximizes the use of resources we've already extracted and processed. It's a small but meaningful step toward more sustainable business practices in an industry not always known for its environmental consciousness.

Ready to explore how used food equipment can transform your kitchen plans? Check out our comprehensive Buy Used Restaurant Equipment guide to get started.

Where to Source Quality Gear

Finding reliable used food equipment doesn't have to feel like searching for a needle in a haystack. At The Restaurant Warehouse, we've guided countless food service professionals to quality pre-owned equipment, but we also know there's more than one path to finding your kitchen's perfect match.

Trusted Channels for Used Food Equipment

The hunt for used food equipment can actually be quite enjoyable when you know where to look. Specialized dealers like us offer perhaps the most hassle-free experience, with showrooms where you can see, touch, and even test equipment that's been professionally inspected and serviced. What's more, we typically back these items with 90-day warranties and can handle the logistics of getting that heavy mixer or refrigeration unit to your doorstep.

Equipment auctions present another avenue for the bargain hunter in you. When restaurants close or upgrade, their equipment often heads to auction where exceptional deals await. Just remember that auction items usually come "as-is" – so bring your inspection checklist and maybe that mechanically-inclined friend of yours.

Online marketplaces have revolutionized how we shop for used food equipment, connecting you with sellers across the country. This expanded geographic reach can be particularly valuable when you're seeking that specific model that's rare in your local market.

Liquidation sales happen when restaurants unfortunately close their doors. The silver lining? Their equipment often needs to move quickly and at steep discounts. Keeping an ear to the ground in the local restaurant community can alert you to these opportunities before they're widely advertised.

Trade shows bring together equipment of all kinds – both shiny new models and quality pre-owned pieces. The advantage here is hands-on inspection and the ability to negotiate on the spot with knowledgeable representatives.

"Every piece of used equipment on the showroom floor at reputable dealers meets NSF requirements and comes with a warranty," notes one industry expert. This peace of mind is harder to come by through some other channels, but worth its weight in gold when you're making such an important investment. For more detailed guidance, our Buy Used Restaurant Equipment resource walks you through the entire process.

Financing & Payment Options

Contrary to what many believe, financing isn't just for new equipment purchases. When investing in used food equipment, your wallet has options:

Equipment-specific loans from banks familiar with the restaurant industry can provide favorable terms, while leasing programs allow you to preserve your capital while still accessing quality gear. Some dealers even offer installment plans that spread payments over time.

Traditional payment methods remain popular, with cashier's checks, wire transfers, business checks, and cash all accepted widely. Credit cards work too, though be prepared for processing fees that might take a bite out of your savings.

At The Restaurant Warehouse, we understand that financing can make or break your equipment strategy. We work with customers to find payment solutions that align with their budget realities and cash flow needs. For those just starting out, our guide to Restaurant Equipment Leasing for Startups offers valuable insights for preserving your precious startup capital.

While used food equipment requires a smaller upfront investment (that's the beauty of it!), we always recommend keeping a financial buffer for potential maintenance. The good news? With the substantial savings from buying used, you'll likely have room in your budget for any necessary tweaks or repairs down the road.

Inspect Before You Invest: Safety & Quality Checklist

Let's face it – buying used food equipment is a bit like dating. You need to look beyond the shiny exterior and make sure what you're getting is reliable, safe, and won't leave you stranded when you need it most! This inspection stage isn't just a good idea – it's absolutely essential for ensuring you get equipment that will serve your kitchen faithfully.

Used Food Equipment Quality Checklist

I've seen too many restaurant owners rush through inspections only to regret it later. Take your time with this process – what you find might save you thousands in headaches down the road.

Start with a thorough visual inspection. Look closely at the equipment for any rust spots, dents, or structural damage that might compromise performance. Pay special attention to welds, seams, and corners – these areas often reveal the true condition of the piece. Don't forget to check gaskets and seals, as these wear items can be expensive to replace but are crucial for proper operation.

Whenever possible, power up the equipment for a test run. This is your chance to verify all functions work as expected and to listen for any unusual noises – the mechanical equivalent of a bad cough! For refrigeration or heating equipment, check temperature accuracy with a reliable thermometer. Those digital readouts aren't always telling the truth!

"Each piece of equipment tells a story," as one of our technicians likes to say. That's why asking for maintenance records is so important. A well-documented service history can reveal if you're looking at a workhorse with routine maintenance or a problem child with recurring issues. Don't be shy about asking when major components were last replaced or what environment the equipment was used in previously.

Before finalizing any purchase, confirm the equipment's compatibility with your kitchen. There's nothing worse than finding your new-to-you oven requires different electrical specifications than what your building offers! Verify voltage requirements, gas types for applicable equipment, and make sure the physical dimensions will fit your space. Double-check that water connections, drainage, and ventilation requirements align with your infrastructure.

Warranty & Regulation Essentials

When it comes to warranties on used food equipment, expectations need to be realistic. Most reputable dealers (including us at The Restaurant Warehouse) offer 30-90 day warranties – significantly shorter than what you'd get with new equipment, but enough time to find any hidden issues.

Be crystal clear about what's covered under warranty. Does it include both parts and labor? What's the process for making a claim? How quickly can you expect service? These questions might seem tedious now, but they're lifesavers when you're facing equipment problems during a busy service.

Regulatory compliance isn't optional in the food service industry – it's mandatory. Verify that any equipment you're considering has NSF certification, especially for surfaces that contact food. This certification ensures the equipment meets strict standards for cleanability and food safety. For electrical equipment, look for the UL listing that confirms it meets safety standards.

Don't forget to check that the equipment complies with local health department regulations, current fire codes, and ADA requirements where applicable. Health inspectors aren't particularly sympathetic to the "but I didn't know" excuse!

Understanding the return policy before purchase can save tremendous headaches. Most dealers offer a 30-day window for returns, but be aware of potential restocking fees and who bears responsibility for return shipping. Always get the policy in writing – memories tend to get fuzzy when problems arise.

While equipment from auction sales typically comes with no warranties (the dreaded "as-is" purchase), established dealers like us at The Restaurant Warehouse pride ourselves on transparency about equipment condition. We've created our Used Commercial Kitchen Equipment Guide specifically to help buyers steer these waters with confidence.

A thorough inspection isn't being picky – it's being smart. When done right, buying used food equipment can give you commercial-grade performance at budget-friendly prices, with minimal compromise on reliability or safety.

Top Categories & Popular Picks

When shopping for used food equipment, certain categories stand out as particularly smart investments. These kitchen workhorses tend to maintain their reliability and performance for years, making them excellent candidates for pre-owned purchases.

Best Value Used Food Equipment Picks

The savvy restaurant owner knows that some equipment simply lasts longer than others. Commercial mixers, especially the legendary Hobart A200 20 Qt models, are built like tanks and often run perfectly for 15-20+ years with basic maintenance. When you find these mixers on the secondary market (typically at 40-50% below new pricing), you're getting a machine that's likely to serve your kitchen faithfully for another decade or more.

Refrigeration units from trusted brands like True, Beverage-Air, and Traulsen hold both their value and their cooling performance remarkably well. When examining used refrigeration, focus on energy-efficient models with digital temperature controls, and always check the compressor age and maintenance history. Glass-door merchandisers often represent particularly good deals in the used market.

Commercial ranges from manufacturers like Garland, Vulcan, and Wolf are literally built to last decades. Gas models typically offer better longevity than electric versions, so look for units with cast iron grates and solid stainless steel construction. Just be sure to verify burner function and gas valve integrity before purchasing.

Steam equipment represents another category where buying used makes tremendous sense. Tilting steam kettles, particularly from Cleveland and Groen, provide exceptional versatility and durability. These kitchen powerhouses can transform your production capabilities while saving you thousands compared to new models. Check out this tilting steam kettle example to see what I mean.

Food processors and slicers round out our top picks for used equipment value. Hobart and Berkel slicers maintain their precision for decades, while Robot Coupe food processors are commercial workhorses that keep running through countless prep shifts. These items often appear on the used market at 50-60% below new pricing, making them budget-friendly additions to any kitchen.

As one of our customers recently shared, "The used Hobart slicer I bought from The Restaurant Warehouse five years ago still performs like new, and I paid less than half of retail. Best equipment decision I ever made."

Energy-Smart Choices

Energy efficiency matters just as much with used equipment as it does with new. Your utility bills, after all, don't care how old your equipment is—they just reflect how much energy you're using.

When looking at used refrigeration, seek out units with high-efficiency compressors (generally post-2010 models). Digital temperature controls not only offer more precise cooling but typically deliver better efficiency than analog systems. Always check door seals and gasket condition, as these are inexpensive to replace but crucial for energy performance.

For cooking equipment, consider that convection ovens use 20-30% less energy than standard ovens, even when purchased used. Induction cooktops are remarkably efficient at 85-90% energy transfer (compared to just 40% for gas), making them worth seeking out on the secondary market. Combi-ovens that combine multiple cooking methods can reduce your overall energy footprint while expanding your culinary capabilities.

The ENERGY STAR label remains relevant even on older equipment. A 5-year-old ENERGY STAR refrigerator purchased used will typically consume significantly less energy than a 15-year-old conventional unit, translating to substantial operational savings over time. When possible, verify the certification date to understand exactly which efficiency standard the equipment met.

At The Restaurant Warehouse, we carefully select our used food equipment inventory with these efficiency considerations in mind, helping you build a kitchen that's friendly to both your budget and your utility bills.

Integrating Pre-Owned Equipment Into Your Kitchen

Getting your used food equipment up and running smoothly isn't just about making the purchase – it's about creating a seamless transition into your existing kitchen operations. With a bit of planning and proper setup, your pre-owned equipment can perform just as reliably as new gear.

Used Food Equipment Setup Tips

The day your used food equipment arrives is exciting, but don't rush the installation process. Professional installation is worth every penny, especially for complex items like ventilation systems or gas ranges. A qualified technician will ensure all utility connections are properly secured, preventing potential hazards down the road.

Before finalizing your kitchen layout, double-check those equipment dimensions! There's nothing more frustrating than finding your beautiful "new" used refrigerator won't fit through the doorway or leaves your prep staff with no elbow room. Leave enough clearance around equipment not just for daily operations but also for those inevitable maintenance days.

"I once had a client who bought a gorgeous used six-burner range at an incredible price," shares our equipment specialist. "But they hadn't measured their gas line capacity. The modification costs ate up all their savings. Check for full compatibility with your facility's infrastructure before making the purchase."

Your utility requirements deserve special attention when installing used food equipment. Verify that your electrical system can handle the load – that vintage mixer might need different voltage than you currently have available. For gas equipment, confirm both the type (natural vs. propane) and required pressure. Water-using equipment like dishwashers and ice machines may need specific water pressure and filtration to perform optimally.

Before putting that equipment into service, give it a thorough cleaning, calibrate all temperature controls, and run complete operational cycles. This initial testing period can reveal any issues that weren't apparent during inspection and gives you time to address them before you're in the middle of a busy service.

Long-Term Care & Asset Management

The secret to making used food equipment last for years? Treat preventive maintenance like it's non-negotiable. Create equipment-specific maintenance calendars and stick to them religiously. Your staff should understand their daily cleaning responsibilities, while professional service technicians handle the more complex maintenance at manufacturer-recommended intervals.

Smart operators keep detailed maintenance logs for each piece of equipment. These records not only help with warranty claims but also provide valuable information if you ever decide to sell the equipment down the road. They also help you spot recurring issues before they become major problems.

Parts availability can make or break your experience with used equipment. Before purchasing, research whether replacement parts are still readily available. For crucial equipment that would shut down operations if it failed, consider keeping critical replacement parts on hand. Building relationships with knowledgeable service technicians who understand your specific equipment models can be invaluable when problems arise.

"Implement routine maintenance to maximize equipment lifespan," is advice we give all our customers at The Restaurant Warehouse. This is especially true for pre-owned equipment, where a little preventive care goes a remarkably long way.

Keep an eye on performance metrics over time. Is your refrigerator running longer cycles than it used to? Is your oven taking longer to reach temperature? These subtle changes often signal developing issues that can be addressed before they lead to equipment failure – often during slower business periods rather than in the middle of your busiest service.

Looking ahead, develop a realistic timeline for eventual replacement of each equipment piece. Even the best-maintained used equipment will eventually need upgrading. By planning these expenses in advance and monitoring our resource on how to Compare Restaurant Equipment Prices, you'll be prepared to make smart decisions about when to repair versus when to replace.

With proper setup, ongoing maintenance, and thoughtful planning, your used food equipment investment can provide exceptional value and reliable service for years to come – keeping more money in your pocket while your kitchen runs smoothly day after day.

Frequently Asked Questions about Used Food Equipment

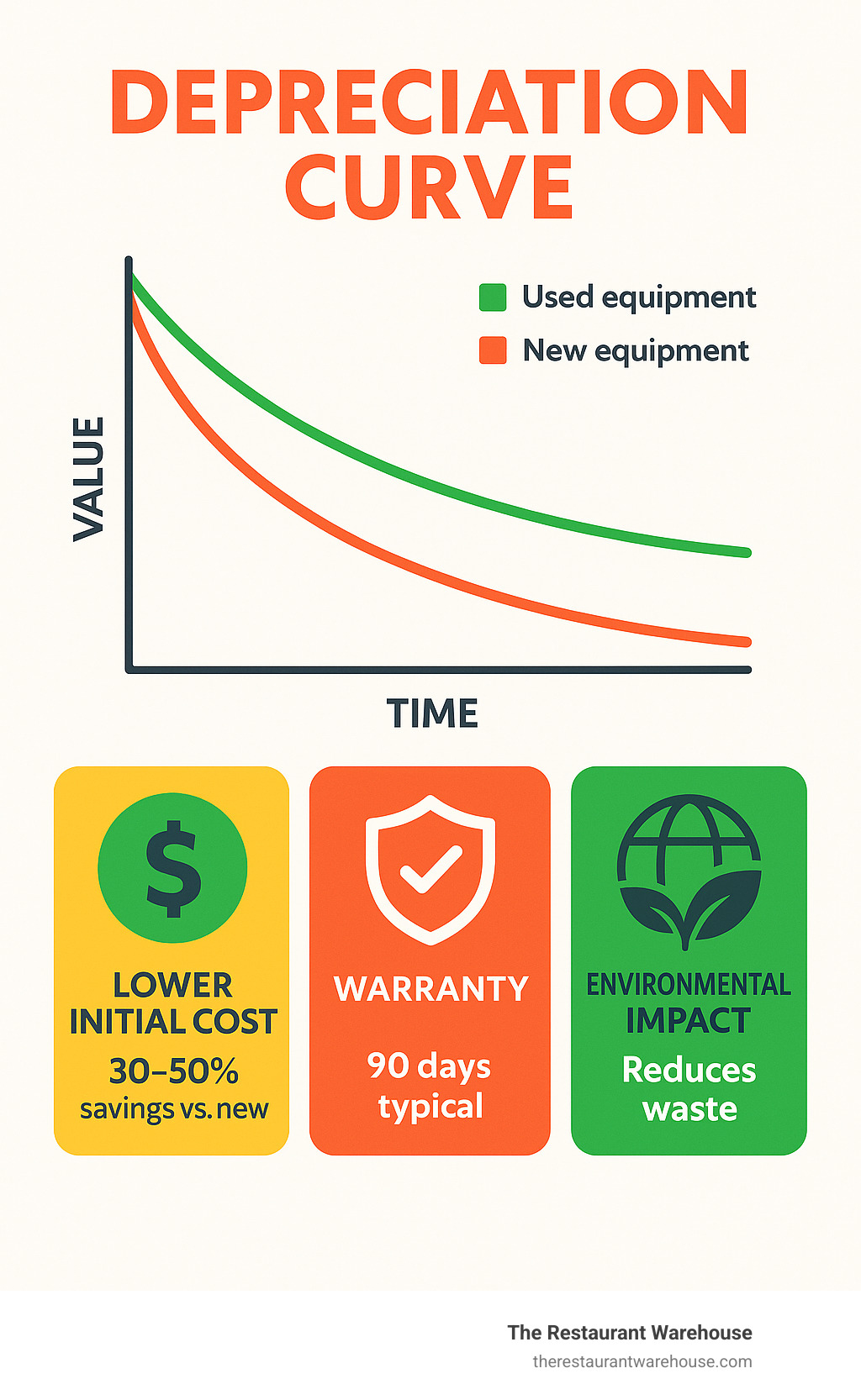

How does depreciation differ between new and used gear?

Picture this: You buy a shiny new commercial refrigerator for $10,000. The moment you wheel it into your kitchen, its resale value drops by 20-30%. That's the harsh reality of new equipment depreciation – a steep decline right out of the gate.

Used food equipment, on the other hand, has already taken that initial depreciation hit. When you purchase a three-year-old refrigerator at half its original price, you're getting equipment that will hold much of its value moving forward. This creates a much gentler depreciation curve for your business assets.

I've seen many restaurant owners surprised by how stable their used equipment investments remain on their balance sheets. As one chef told me, "My used mixer cost 40% less than new, and five years later, I could still sell it for almost what I paid."

This financial advantage is one of the hidden benefits of buying pre-owned. The previous owner absorbed that initial value drop, leaving you with equipment that depreciates at a much slower rate while delivering the same operational value.

Are refurbished items safe for food contact?

Absolutely! When properly refurbished, used food equipment is completely safe for food preparation and service. The key is purchasing from reputable dealers who follow rigorous restoration protocols.

Good dealers ensure all food-contact surfaces meet NSF (National Sanitation Foundation) standards – the exact same standards that new equipment must satisfy. This typically involves a comprehensive process:

- Deep cleaning and commercial-grade sanitization

- Replacing worn gaskets, seals, and food-contact components

- Repairing or replacing any damaged surfaces

- Testing temperature control and all functions

- Verifying compliance with current health codes

At The Restaurant Warehouse, we stand behind the safety of properly refurbished equipment. That's why most items come with a warranty – giving you peace of mind that your equipment isn't just affordable, but also food-safe and reliable.

Before purchasing, simply ask about the refurbishment process and certification status. A reputable dealer will happily share these details.

Can I return equipment that doesn't fit my space?

We've all been there – that moment when delivery arrives and something just doesn't fit right. Most reputable dealers (including us) offer a 30-day return window for used food equipment, but it's important to understand the fine print.

Return policies typically come with some reasonable conditions. You might be responsible for return shipping costs, and restocking fees (usually 15-25%) often apply. The equipment must be returned in the same condition you received it, and any custom modifications generally make items non-returnable. Installation damage almost always voids return eligibility.

To avoid return headaches, I always recommend these simple steps:

First, measure your space carefully – twice! Next, verify all utility requirements and connections before purchasing. Always get the return policy in writing, and finally, inspect equipment thoroughly upon delivery, before installation begins.

At The Restaurant Warehouse, we believe in being transparent about equipment dimensions and requirements. We'd rather help you get it right the first time than deal with returns. That's why we provide detailed specifications for all our equipment and encourage questions before purchase.

A little preparation upfront can save significant hassle down the road when investing in used food equipment for your business.

Conclusion

The journey through used food equipment brings us to a simple truth: smart restaurateurs know that pre-owned doesn't mean second-best. Throughout this guide, we've seen how choosing quality used equipment creates a win-win situation for your budget and business growth.

Think about it - when you save 30-50% on commercial kitchen equipment, you're not just cutting costs. You're creating breathing room in your budget for other critical areas of your business. Maybe that means upgrading your ingredients, sending your chef to a specialty training course, or finally launching that marketing campaign you've been putting off.

Used food equipment also gives you the gift of time. While your competitors might be waiting months for new equipment to arrive from manufacturers, you could be up and running within days. In the restaurant world, where timing is everything, this advantage can't be overstated.

The environmental benefits deserve special mention too. By extending the lifecycle of perfectly good equipment, you're keeping thousands of pounds of metal and components out of landfills. It's a small but meaningful way your business can contribute to sustainability efforts - something more and more customers care about these days.

From a practical business perspective, the slower depreciation curve of pre-owned equipment makes perfect sense. Why absorb that initial 20-30% value drop when someone else already has? Your accountant will appreciate this approach as much as your bank account does.

At The Restaurant Warehouse, we've helped countless restaurant owners, food truck entrepreneurs, and institutional kitchens find the sweet spot between quality and affordability. We understand that every kitchen has unique needs, and every business has budget constraints. That's why we're passionate about connecting food service professionals with equipment that helps them succeed without unnecessary financial strain.

Whether you're just starting out or looking to expand, the path to a well-equipped kitchen doesn't have to drain your resources. With careful selection, proper inspection, and regular maintenance, used food equipment can serve your business reliably for years to come.

Ready to explore your options? We invite you to browse our carefully curated selection at Used Restaurant Equipment or reach out with questions. Our team is here to help you build a kitchen that works as hard as you do - without breaking the bank.

In the restaurant business, it's not about having the shiniest new toys in the kitchen. It's about creating amazing food, memorable experiences, and a sustainable business. Sometimes, the smartest way to get there starts with smart equipment choices.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment