Prep Like a Pro: How to Get Your Cutting Board Ready for Action

Why Cutting Board Prep Is Your Kitchen's First Line of Defense

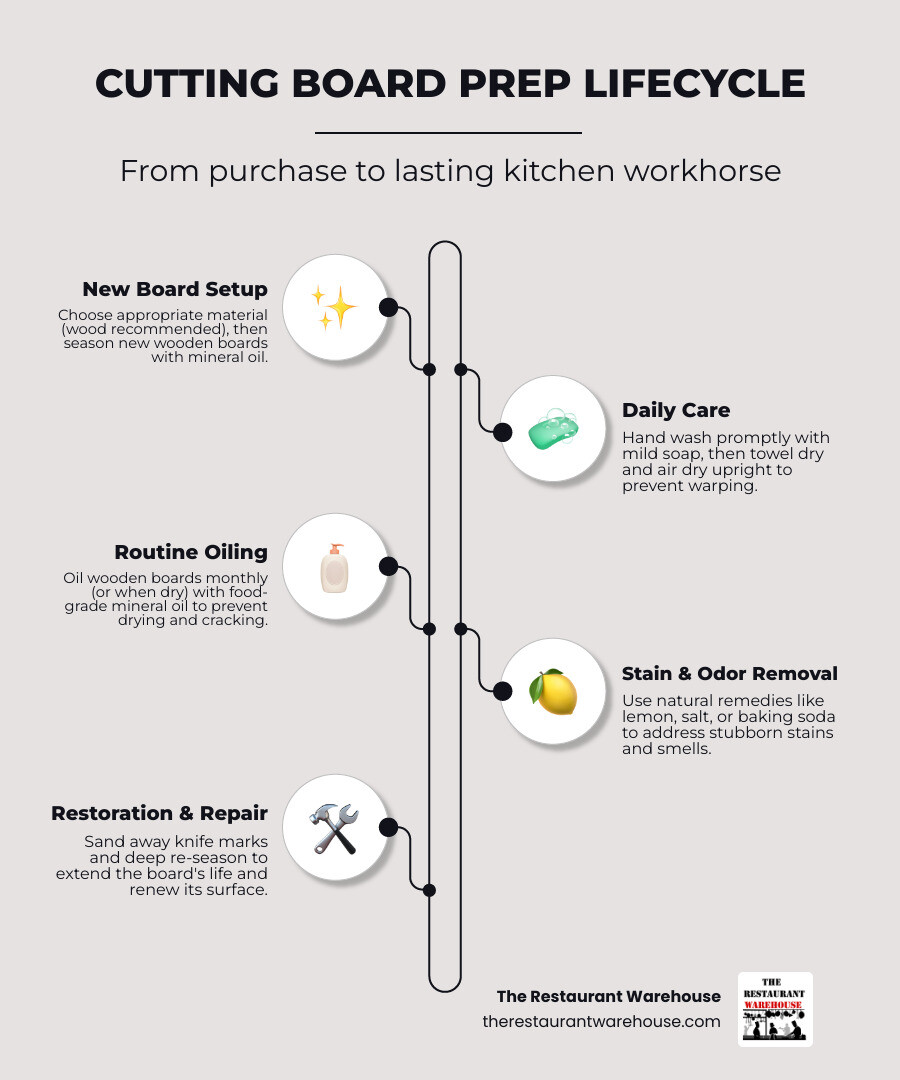

Cutting board prep is the foundation of safe, efficient food service. Proper preparation turns a raw piece of wood into a hygienic, long-lasting kitchen workhorse, protecting your investment and keeping your kitchen running smoothly.

Quick Answer: Essential Cutting Board Prep Steps

- Choose the right material - Wood for durability, plastic for raw meat separation

- Season new wooden boards - Apply food-grade mineral oil, let soak overnight, repeat 2-3 times

- Clean properly - Hand wash with mild soap, never use dishwashers

- Dry completely - Towel dry, then air dry standing upright

- Oil monthly - Use the water drop test to check if board needs conditioning

- Store upright - Allow air circulation to prevent warping

A well-prepared cutting board isn't just about food safety; it's about efficiency. When prep surfaces are maintained, knives stay sharper, cleanup is faster, and your kitchen workflow improves. As one woodworking expert notes: "A high quality wooden cutting board requires a bit of maintenance from time to time to stay in tip-top cutting shape." This maintenance takes just minutes each month but adds years to your board's life.

The key insight that changes everything: wood is actually safer than plastic. Research shows bacteria have a much lower survival rate on wood surfaces compared to plastic, where knife cuts create hiding spots that are nearly impossible to sanitize completely.

Choosing Your Culinary Workhorse: A Guide to Cutting Board Materials

In any professional kitchen, chefs are particular about their cutting boards. The right material keeps knives sharp, food safe, and the cutting board prep routine effective. Your choice affects everything from food safety to knife maintenance. Some materials last for months, while others can last for decades with proper care.

| Material | Pros | Cons | Best Use |

|---|---|---|---|

| Wood | Knife-friendly, hygienic (low bacteria survival), aesthetic, durable, self-healing (end-grain) | Requires seasoning/oiling, not dishwasher safe, can warp/crack if not maintained | General prep, gentle on knives, aesthetically pleasing |

| Plastic (HDPE) | Dishwasher safe, affordable, color-coded for cross-contamination | Dulls knives faster, knife scores harbor bacteria, needs frequent replacement | Raw meat/poultry, high-volume prep, allergen separation |

| Bamboo | Sustainable, hard surface, lightweight | Can dull knives faster than wood, can splinter over time, requires oiling | Light prep, serving, budget-friendly |

Why Hard Surfaces Are Your Knife's Enemy

Before diving into good options, let's discuss what to avoid. Glass, marble, and metal cutting surfaces are brutal on your knives. These ultra-hard surfaces will dull blades with every cut, similar to running them against a grinding stone. A dull knife is inefficient and dangerous, leading to more pressure, slips, and costly blade maintenance.

Wood's Amazing Natural Properties

For years, plastic was assumed to be more hygienic than wood because it's non-porous. However, research shows that bacteria have a much lower survival rate on wood compared to plastic. Wood's porosity is its secret weapon; it draws moisture away from bacteria, pulling them into its fibers where they die. Meanwhile, knife scores on plastic boards become permanent hideouts for bacteria that are nearly impossible to clean out completely.

Not all wood porosity is equal. Closed-grain hardwoods are best, as they are porous enough to trap bacteria but tight-grained enough to resist excess moisture. This is why proper seasoning and cutting board prep are so critical for a wooden board's performance.

Wood: The Professional's Choice

Professional kitchens often prefer wood for its combination of durability, knife-friendliness, and natural antimicrobial properties. A beautiful wooden cutting board also improves the cooking experience.

The Hardwood Hall of Fame

When shopping for a wooden board, stick with proven performers. Maple is the gold standard—dense, fine-grained, and tough. Walnut is slightly softer, making it incredibly gentle on knife edges, and its dark grain hides marks. Cherry is a medium-density hardwood that develops a rich patina over time and is also kind to blades.

Softwoods and Open-Grained Woods to Avoid

Avoid pine, cedar, and other softwoods, which are terrible for cutting boards. They show knife marks easily, splinter, and can have oils that affect food flavors. Red oak and white oak, despite being hardwoods, are also poor choices. Their open-grain structure creates too many hiding spots for food particles and bacteria, making them sanitation risks.

Plastic and Composite Boards

Plastic boards have a place in a well-organized kitchen, especially for food safety protocols.

High-Density Polyethylene (HDPE) is the standard for commercial plastic boards. It's non-porous, durable, and can handle high-temperature dishwashers.

When to Use Plastic Boards

The primary advantage of plastic is for raw meat separation. Kitchens often use color-coded boards (e.g., red for beef, yellow for poultry) to prevent cross-contamination. Their non-porous surface doesn't absorb juices and is easy to sanitize. For high-volume operations, plastic boards are invaluable.

Lifespan and When to Discard

Plastic boards have an expiration date. Once knife scores become deep grooves that you can feel with a fingertip, the board is impossible to sanitize properly and must be replaced. Those grooves are bacteria hotels that no amount of scrubbing can clean.

Composite Board Features

Composite boards, made from paper fibers and resin, split the difference between wood and plastic. They are typically dishwasher-safe and gentler on knives than plastic. They resist warping better than wood and last longer than plastic, but they lack wood's natural antimicrobial properties.

The Essential First Step: How to Season a New Wooden Cutting Board

Before you use a new wooden cutting board, there's one crucial step that determines whether it becomes a lifelong kitchen companion or a warped, cracked disappointment: cutting board prep through proper seasoning.

Think of seasoning as giving your board a protective suit of armor. Without it, the wood is vulnerable to water and moisture, which leads to warping and cracking. Wood is hygroscopic, meaning it absorbs and releases moisture. Too dry, it cracks; too wet, it swells and warps. Seasoning prevents drying, cracking, and warping by keeping the wood fibers hydrated and flexible.

Seasoning also creates a protective barrier that repels moisture and food juices. The oil penetrates the wood's pores, creating a shield that keeps liquids on the surface for easy cleanup. This prevents stains, odors, and bacterial growth from juices that would otherwise soak into the wood.

Selecting the Right Oil

Using the wrong oil is a costly mistake. Not all oils are created equal, and the wrong choice can ruin your board.

Food-grade mineral oil is the gold standard for board care. Unlike cooking oils, mineral oil is inert, meaning it won't break down or oxidize. It penetrates deeply into the wood fibers, provides excellent protection, and remains stable over time. It doesn't go rancid and is completely safe for food contact.

Never use cooking oils like olive, vegetable, or coconut oil. These organic fats will oxidize, creating a sticky, smelly, rancid mess on your board's surface. This process, known as rancidity, is irreversible and will ruin your board.

Beeswax and carnauba wax conditioners are an upgrade for ultimate protection. Combined with mineral oil, these natural waxes create a cream that forms a top-layer seal. The wax provides a durable barrier that repels water and gives your board a beautiful, smooth finish.

The Seasoning Method

This process is straightforward, but patience is key. Rushing will lead to poor results.

First, ensure your new board is completely clean and dry. Wipe it with a damp cloth and let it air dry completely. Any trapped moisture will prevent the oil from penetrating.

Next, apply the oil with a clean cloth. Be generous—pour the mineral oil directly onto the surface and spread it evenly across the entire board, including the edges and ends, which are most vulnerable to cracking.

The most important step is waiting. Let the oil soak in for several hours or overnight. The wood needs time to absorb the oil deep into its fibers. You may notice some areas look dry after a few hours; this is a good sign the wood is absorbing the oil.

After soaking, wipe off any excess oil. The board should feel conditioned, not greasy. For a new board, plan on applying two to three coats over a week. Follow the same process for each coat: apply, soak overnight, and wipe off the excess. This ensures the board is thoroughly saturated and protected from day one.

During seasoning, store the board flat on a surface that won't be damaged by oil, or prop it upright for air circulation. Keep it away from direct sunlight or heat sources to prevent uneven drying or warping.

Mastering Your Daily Cutting Board Prep and Maintenance Routine

A wooden cutting board is a trusted kitchen partner that requires daily attention. The real art of cutting board prep is the consistent care that follows the initial seasoning, changing a piece of wood into a lifelong culinary companion.

A well-maintained board is safer, more efficient, and ready for any task. Establishing a solid maintenance routine prevents a beloved board from warping or developing deep, bacteria-harboring grooves. These daily habits take minutes but can add decades to your board's life, ensuring every cut happens on a hygienic surface.

Proper Cleaning and Sanitizing: The Foundation of Cutting Board Prep

Every great cutting board prep routine begins with a simple truth: clean boards are safe boards. Proper cleaning requires consistent, gentle care after every use.

The gentle hand-washing approach is best. After each use, especially with raw proteins or pungent ingredients, use mild dish soap and warm water. The mechanical action of scrubbing with a soft sponge or brush, combined with flowing water, flushes away bacteria and food particles. Rinse both sides thoroughly with hot water.

Never put your wooden cutting board in the dishwasher. The intense heat, prolonged water exposure, and harsh detergents will cause it to warp, crack, split, and strip away its protective oils.

Proper drying is crucial. After rinsing, immediately towel-dry the board thoroughly. Then, stand the board upright to finish air drying. This allows air to circulate around all surfaces, ensuring even drying and preventing the warping that occurs when a board is laid flat. Trapped moisture underneath can also lead to mold.

For extra sanitization, especially after preparing raw meat, use a white vinegar solution. Mix equal parts white vinegar and water in a spray bottle. After cleaning, spray the solution over the surface, let it sit for five to ten minutes, then rinse and dry as usual. The acetic acid in vinegar is effective against bacteria like E. coli and Salmonella and is gentler on wood than bleach.

The Art of Regular Oiling and Conditioning

Even a well-seasoned board needs ongoing nourishment. Monthly oiling replenishes the protective barrier and keeps the wood supple.

The timing of oiling depends on usage and climate. As a rule, monthly oiling is sufficient for most kitchens. If you use your board heavily, you may need to oil it every few weeks.

The water drop test is the best way to know when to oil. Sprinkle a few drops of water on your clean, dry board. If the water beads up, the board is protected. If the droplets spread out and soak in, the board is thirsty.

Other signs include a dull, faded appearance or a dry, rough feel. White or light patches, especially on the ends, are a clear signal that the board needs oil.

Applying maintenance coats is simple. On a clean, dry board, use a cloth to apply a thin, even layer of food-grade mineral oil to all surfaces. Let it soak for several hours or overnight, then wipe away any excess. The surface should feel smooth, not greasy.

Board cream or wax provides an extra layer of protection. These blends of mineral oil and wax (like beeswax) are great at repelling liquids and preventing stains. Apply a small amount and buff it into the wood with a soft cloth for a beautiful, satiny sheen.

Smart Storage and Common Mistakes to Avoid

Proper storage can be the difference between a board that lasts decades and one that warps in a year. Storing your board upright is the golden rule, as it maximizes air circulation and prevents trapped moisture.

Keep your board away from direct sunlight and heat sources like the stove, as extreme temperature changes can cause cracking and splitting.

Avoid these common mistakes:

- Soaking the board in water: This causes the wood to swell and crack as it dries unevenly.

- Using cooking oils: These oils go rancid, creating a sticky, smelly mess.

- Laying flat to dry: This traps moisture and leads to warping.

- Using harsh chemicals like bleach: This can make the wood brittle and prone to cracking.

Advanced Care: Restoring and Repairing Your Wooden Cutting Board

Even with a dedicated cutting board prep routine, signs of wear are inevitable. After years of service, a wooden board might develop stains, odors, or deep knife marks. The good news is that unlike plastic, wooden boards are remarkably forgiving and can often be restored.

Restoration gives your board a second chance. Whether it's a neglected hand-me-down or a well-loved workhorse, these techniques can bring back a smooth, fresh, and hygienic surface. The beauty of wood is its ability to be renewed. A scarred plastic board must be replaced, but a wooden board can be sanded smooth and re-seasoned, making it an investment that can last for decades.

Tackling Stains and Odors with Your Cutting Board Prep

Lingering smells from garlic or stains from berries are common issues. Wood's natural properties make it responsive to simple, natural cleaning methods.

For persistent onion and garlic smells, the classic lemon and coarse salt treatment is highly effective. Sprinkle coarse salt generously over the board. Cut a lemon in half and use it as a scrub brush, squeezing the juice while working the salt into the wood grain. The salt acts as a gentle abrasive, while the citric acid neutralizes odor-causing compounds. Let it sit for ten minutes, then rinse thoroughly with hot water.

When dealing with stubborn stains from berries or meat, use a baking soda paste. Mix two tablespoons of baking soda with one tablespoon of salt and three tablespoons of hot water. Work this paste into the stained area with a soft brush, let it sit for fifteen minutes, then wipe clean with a damp cloth and dry immediately. The baking soda deodorizes while the salt provides gentle scrubbing action.

Acidic solutions like lemon juice and vinegar work by breaking down the organic compounds responsible for odors and stains, making them water-soluble and easy to rinse away.

Understanding Wood Grain: End-Grain vs. Edge-Grain

Why do some boards hide knife marks better than others? The answer is in the wood grain's orientation.

Edge-grain boards are the most common type, constructed with long strips of wood glued side by side, with the grain running parallel to the cutting surface. They offer excellent durability and are often less expensive, making them a reliable, cost-effective solution for busy kitchens.

End-grain boards are the premium option. Here, the wood fibers run vertically, creating a checkerboard pattern. When your knife cuts, it slides between the fibers rather than slicing across them. This makes end-grain boards incredibly gentle on knife edges, keeping blades sharper for longer. This is a key reason many professional chefs prefer them.

End-grain boards also have a self-healing property, where the wood fibers spring back together after a cut, minimizing visible scars and leaving fewer places for bacteria to hide. The trade-off is that they require more frequent oiling because the exposed vertical fibers absorb oil more readily. Your cutting board prep routine will need to include oiling every few weeks instead of monthly.

Repairing Minor Scratches and Damage

Unlike plastic, a wooden board's battle scars can be completely erased.

Sanding is the primary tool for removing knife marks. The key is to work through progressively finer grits of sandpaper. Start with 120-grit for deeper scratches, move to 180-grit to smooth out those marks, and finish with 220-grit for a satin-smooth surface. Always sand with the grain direction, not against it, to avoid visible scratches.

A professional trick is the grain-raising technique. After final sanding, lightly mist the board with water. As it dries, microscopic wood fibers will stand up. Once completely dry, give the board one final light sanding with your finest grit. This clips off the raised fibers, ensuring the surface stays smooth even after washing.

After any sanding, your board needs deep re-seasoning. Sanding removes the protective oil layer, leaving the wood thirsty and unprotected. Apply multiple generous coats of food-grade mineral oil over several days, just as you would with a new board, letting each coat soak in thoroughly. This restores the protective barrier and ensures your board will serve you well for years to come.

Frequently Asked Questions about Cutting Board Care

Here are answers to the most common questions about cutting board prep and care.

What is the safest material for a cutting board?

Wood is often the safest choice for most cutting board applications. This surprises many people who assume plastic is more hygienic. Research shows that bacteria have a significantly lower survival rate on wood surfaces. Wood's natural porosity draws moisture away from bacteria, trapping them in its fibers where they die.

Plastic boards, while non-porous, develop knife scores over time. These grooves become hiding spots for harmful bacteria like Salmonella and E. coli and are nearly impossible to clean completely. That said, the key to safety with any material is proper and thorough cleaning after each use.

Can I use cooking oils like olive or coconut oil on my wooden board?

Absolutely do not use any cooking oils on your wooden cutting board. While it seems logical, food-based oils like olive, vegetable, or coconut oil are organic fats that will oxidize and go rancid. This creates a sticky, foul-smelling surface that can ruin the board and is nearly impossible to remove.

Food-grade mineral oil is your only safe bet. It is an inert substance, meaning it will not break down or go rancid. It penetrates deeply into the wood to provide excellent protection without imparting any flavor or odor to your food.

How do I know when my wooden cutting board needs to be replaced?

The good news is that wooden boards are remarkably durable and can often be restored rather than replaced.

Replace your board when safety becomes a concern. The main red flags are deep grooves and cracks that you can't clean thoroughly. If food particles remain trapped in crevices even after scrubbing, the board can harbor bacteria.

Warping is another deal-breaker. If a board rocks on the counter, it becomes unstable and dangerous for cutting. A wobbly board is a safety hazard when using a sharp knife.

However, don't give up on a board with surface scratches or light stains. These issues can usually be fixed with sanding and re-seasoning. With proper cutting board prep and maintenance, a quality wooden board can last for decades.

Conclusion

We've covered the full lifecycle of cutting board prep, from selecting the right material and seasoning it properly to daily cleaning and advanced restoration. We hope you now feel equipped to give your cutting boards the care they deserve.

The journey highlights a few core truths. First, choosing the right material is paramount, with wood often leading for its knife-friendly nature and hygiene. Second, initial proper seasoning is the foundation of a board's long life. Finally, consistent daily and monthly maintenance is an act of care that pays dividends. These pillars are the bedrock of exceptional cutting board care.

A well-maintained board is a safe, reliable, and long-lasting investment that protects your knives, ensures food is prepared hygienically, and lifts your entire culinary experience. A little attention can transform a simple block of wood into a kitchen workhorse that serves you faithfully for years.

At The Restaurant Warehouse, we believe quality kitchen equipment, paired with the right knowledge, empowers any culinary operation. We are passionate about supplying commercial restaurant equipment and food service supplies, cutting out the middlemen to bring you affordable, wholesale pricing. For all your professional kitchen needs, from essential prep tools like cutting boards to major equipment, The Restaurant Warehouse is here to provide quality supplies. And if you’re looking to truly optimize your workspace, don't miss our comprehensive guide on choosing the right sandwich prep table. Invest in your tools, nurture them with proper cutting board prep, and they will serve you well.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment