From Bus Carts to Utility Carts: Finding Your Perfect Commercial Kitchen Trolley

Why Every Professional Kitchen Needs the Right Commercial Kitchen Trolley

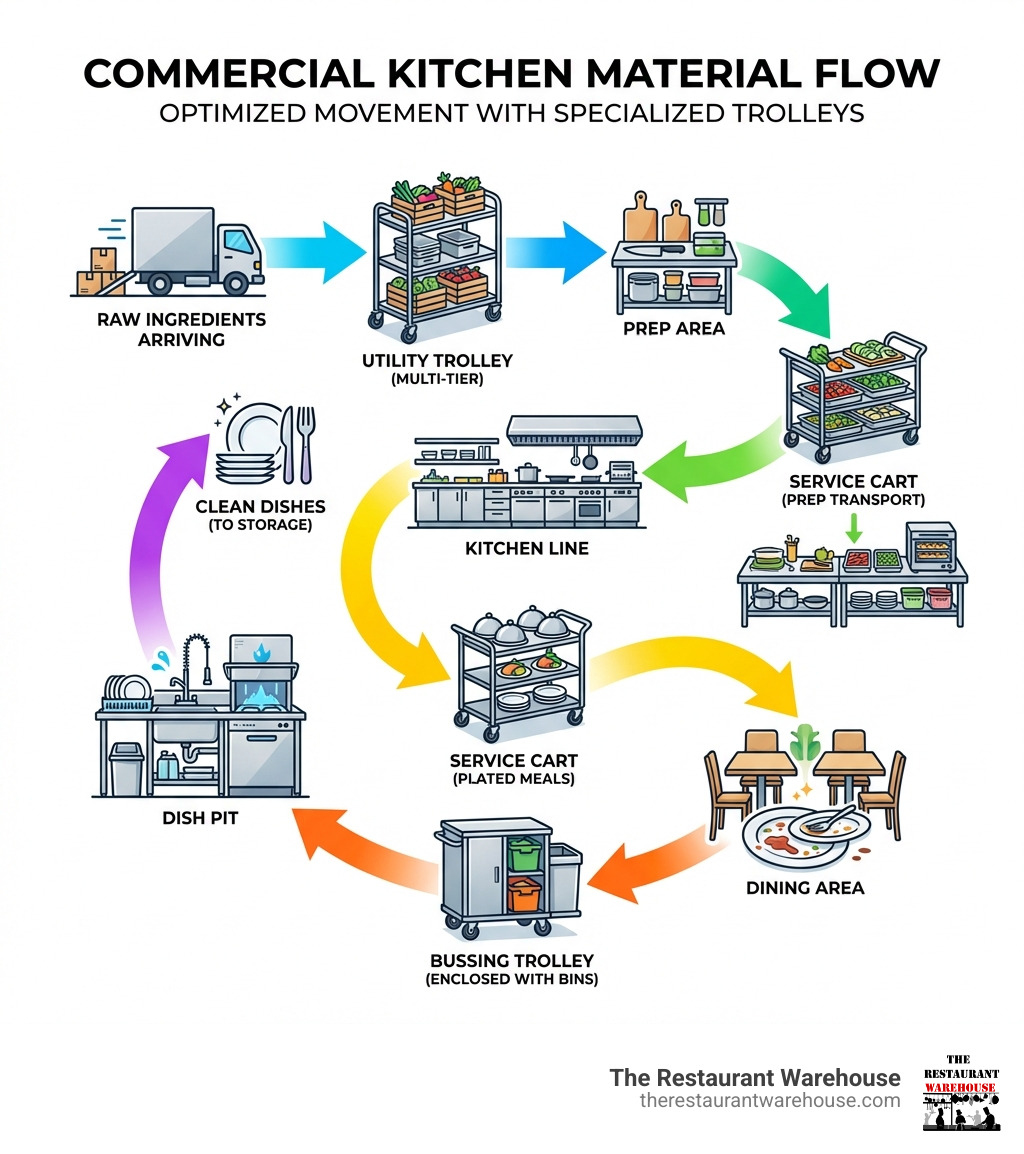

A commercial kitchen trolley is a wheeled cart, an unsung hero specifically designed to transport food, dishes, items, and supplies with maximum efficiency throughout the demanding environment of foodservice operations. While they may not be the centerpiece of your kitchen, their impact on workflow, safety, and profitability is immense. Here's what you need to know to make an informed choice.

Types of Commercial Kitchen Trolleys:

- Utility/Service Trolleys - Versatile, multi-tier carts for transporting everything from raw ingredients and small items to plated meals.

- Bussing/Clearing Trolleys - Purpose-built carts, often enclosed, with bins for the rapid and discreet collection of dirty dishes.

- Racking/Pan Trolleys - High-capacity vertical units designed for storing and moving gastronorm pans or standard baking trays.

Key Features to Consider:

- Materials - Stainless steel is prized for its durability and hygiene, plastic/composite offers a lightweight and affordable alternative, while wood is chosen for its aesthetic appeal in front-of-house settings.

- Load Capacity - This can range significantly, from lighter models handling around 200 lbs to heavy-duty versions capable of supporting 700+ lbs.

- Mobility - Look for heavy-duty casters, reliable locking brakes, and non-marking wheels to protect your floors.

- Hygiene - Essential features include smooth, easy-to-clean surfaces, rounded corners to prevent debris buildup, and NSF certification for compliance with food safety standards.

Typical Price Ranges:

- Budget models: £70-£150

- Mid-range: £150-£350

- Premium/specialized: £350-£600+

Walk into any bustling restaurant kitchen during peak service, and you'll witness a carefully choreographed dance of activity. Amidst the sizzle of the grill and the calls of the expediter, you'll see them everywhere—gleaming stainless steel carts gliding between the prep station and the line, sturdy plastic bins rolling silently towards the dish pit, and tall racking trolleys loaded with sheet pans waiting to enter or exit the ovens. These workhorses might not be glamorous, but they are the logistical backbone of any successful culinary operation. Industry data reveals a vast market with over 111 different commercial kitchen trolley products available from 27 manufacturers, with options ranging from simple 3-tier utility carts to specialized 30-tier gastronorm pan racks.

The right trolley does far more than just move items from point A to point B. It is a strategic tool that accelerates service, reduces unnecessary labor costs, and critically, helps prevent workplace injuries from manual lifting and carrying. It brings order to the chaos of a dinner rush, ensuring your team has what they need, when they need it. Whether you're clearing tables in a packed dining room, transporting precisely prepped ingredients for a complex dish, or organizing trays for a large baking run, choosing the right cart for the job directly impacts your kitchen's efficiency and, ultimately, your bottom line. This is a crucial consideration for any new venture, as detailed in our guide on planning your restaurant's finances.

I'm Sean Kearney from The Restaurant Warehouse, and I've dedicated my career to helping restaurant owners and chefs find the right tools to build a smooth, safe, and profitable operation. From my early days in sales to my current work in the foodservice industry, I've learned that the best commercial kitchen trolley isn't necessarily the most expensive one—it's the one that perfectly matches your specific workflow, space constraints, and budget, acting as a seamless extension of your team.

The Many Faces of the Commercial Kitchen Trolley

A busy commercial kitchen is a symphony of coordinated effort, and at the heart of that coordination often lies a fleet of specialized trolleys. These aren't just generic carts; they are purpose-built tools designed to streamline specific tasks, optimize workflow, and ensure the smooth operation of your front-of-house or back-of-house activities. Understanding the different types available is the first step in making an informed decision for your establishment, transforming potential logistical bottlenecks into a fluid and efficient process.

From moving heavy sacks of raw ingredients from the receiving dock to elegantly serving a delicate dessert at the table, there's a commercial kitchen trolley specifically engineered for the job. We'll explore some of the most common and essential types that keep modern kitchens running at peak performance.

Utility and Service Trolleys

These are the versatile, indispensable workhorses of any foodservice operation. Utility and service trolleys are designed for adaptable transport, capable of moving everything from heavy boxes of produce and cases of beverages to stacks of clean plates, small items, or even fully plated meals ready for service. Their sheer adaptability makes them a fundamental tool in nearly every corner of the kitchen, from storage areas to the main service line. Imagine effortlessly moving 50-pound sacks of flour from storage to the prep station or transporting all the necessary items to set up a remote beverage station in one trip. That's the power of a good utility trolley.

Most utility trolleys feature multiple tiers of shelves, typically two or three, providing ample, organized space for various items. Some advanced models even offer adjustable shelves, allowing you to customize the vertical space to accommodate taller items or specific containers. While stainless steel construction is a popular choice for its unmatched durability and hygienic properties, high-quality plastic models also offer a lightweight, rust-proof, and cost-effective alternative. They are perfect for daily tasks like restocking pantry items, moving prepared dishes to the serving line, or transporting catering supplies for off-site events. Their sturdy design and easy maneuverability help reduce the need for manual carrying, which not only boosts overall productivity but also significantly minimizes the risk of spills, product damage, and staff injuries.

To maximize the impact of your utility trolleys, consider how they integrate into your kitchen's overall layout and storage strategy. A well-placed utility trolley can act as a mobile landing zone, freeing up valuable counter space and keeping essential items within easy reach. For personalized advice on optimizing your space with the right tools, we invite you to book a strategy call with our experts.

Bussing and Clearing Trolleys

When the dinner rush is in full swing and tables need to be turned quickly and efficiently, bussing and clearing trolleys become your front-of-house team's most valuable asset. These specialized trolleys are designed specifically for the efficient collection of soiled dishes, cutlery, and glassware from dining areas, transporting them swiftly and hygienically to the dishwashing area. Their role is critical in maintaining a clean, inviting atmosphere for guests and maximizing seating availability.

A key feature of many bussing trolleys is their enclosed sides or deep tub-like shelves. This design choice is intentional, as it helps contain spills and conceal messy, used items from the view of diners, thereby maintaining a professional and pleasant front-of-house appearance. They often come equipped with integrated, removable waste bins for food scraps and separate compartments or bins for cutlery, which dramatically streamlines the sorting process before washing. Many of these carts are constructed from durable, high-density polyethylene, a material that is exceptionally resistant to impacts and chemicals and is very easy to clean, making it ideal for the demanding environment of dish collection.

The primary advantage of a dedicated bussing trolley is its ability to significantly reduce labor costs and the time spent clearing tables. Instead of staff making multiple, strenuous trips with armloads of dishes, a single trolley can handle the load of several tables at once. This improves table turnaround times—a direct contributor to revenue—and allows staff to focus more on attending to guest needs. For any high-traffic restaurant, investing in robust bussing trolleys with strong capacity is a game-changer for operational efficiency.

Here are some essential features for a high-traffic bussing trolley:

- Heavy-duty construction: To withstand the constant, rigorous use and heavy loads of dishes, glassware, and cutlery.

- Multiple bins/compartments: For the efficient pre-sorting of waste, cutlery, and different types of dishes, saving valuable time at the dish pit.

- Non-marking, swivel casters with brakes: For smooth, quiet movement through dining areas and the stability to park securely when needed.

- Rounded corners and smooth surfaces: For easy and thorough cleaning, preventing the accumulation of food particles and bacteria.

- Ergonomic handles: For comfortable pushing and pulling, reducing physical strain on staff, even when the trolley is fully loaded.

- Sufficient Capacity: The trolley must be large enough to handle peak dining periods without requiring constant trips to be emptied, which would defeat its purpose.

Racking and Pan Trolleys

For kitchens that deal with high volumes of baked goods, prepped ingredients in gastronorm (GN) pans, or any form of large-scale food production, racking and pan trolleys are absolutely indispensable. These trolleys are essentially mobile shelving units, engineered to hold multiple pans or trays in a vertical configuration, thereby maximizing storage density and facilitating organized, safe transport between different kitchen zones.

Racking trolleys are commonly used for a wide array of critical tasks:

- Transporting GN pans: Moving prepped vegetables, marinated meats, or sauces in standard GN sizes (e.g., 1/1 GN) between prep areas, walk-in coolers, and service lines. Some high-capacity trolleys can hold up to 30 x 1/1 GN pans, representing a massive improvement in efficiency.

- Baking and Cooling Racks: Designed to accommodate standard baking trays (e.g., 40cm x 60cm), these are crucial for bakeries and kitchens that produce a lot of baked goods. They allow for the efficient cooling of items post-baking, proofing of dough, or simply staging products before finishing. We've seen models with 15, 16, 18, or even 30 tiers, offering significant capacity in a small footprint.

- Holding and Staging: Keeping plated meals warm under heat lamps or chilled in a walk-in cooler before service, which is especially vital in large banquet or catering settings to ensure food quality and timely service.

You'll find these trolleys in various configurations, such as end-loading (where pans slide in from the short side) or side-loading (from the long side). The choice depends on the size of your pans, the width of your aisles, and your preferred workflow. Their ability to stack numerous pans or trays vertically makes them incredibly space-saving, a premium feature in busy kitchens where floor space is precious. They help maintain order, prevent cross-contamination by keeping items separate, and dramatically speed up the transfer of ingredients or finished products. Integrating the right racking and pan trolleys into your operation can drastically improve your storage and transport logistics, a key component of a successful restaurant that requires a solid financial plan.

Built to Last: Materials and Construction

The material composition of your commercial kitchen trolley is not just about aesthetics; it's a critical factor that directly influences its durability, hygiene, weight, and suitability for specific tasks within your unique kitchen environment. When we guide clients through their selection, we always advise them to consider the intense demands of their operation, their long-term budget, and the practicalities of daily maintenance. Choosing the right material ensures your investment will stand the test of time, adhere to stringent food safety standards, and serve your team reliably for years to come.

Here's a quick comparison of the most common materials used in commercial kitchen trolleys:

| Material | Durability | Hygiene | Cost | Best Use Case |

|---|---|---|---|---|

| Stainless Steel | Excellent; resistant to corrosion, rust, impact | Superior; non-porous, easy to sanitize | Moderate to High | Back-of-house, heavy-duty transport, direct food contact, wet areas |

| Plastic/Composite | Good; resistant to dents, scratches, chemicals | Very good; non-porous, easy to clean | Low to Moderate | Bussing, light utility tasks, color-coding systems, noise-sensitive areas |

| Wood | Moderate; prone to moisture damage, scratches | Moderate; requires sealing, more porous | Moderate to High | Front-of-house presentation, beverage/dessert service, dry use only |

Stainless Steel: The Industry Standard

Without a doubt, stainless steel is the reigning champion of materials for commercial kitchen trolleys, and for good reason. Our research shows that metal is the most common material, with stainless steel specifically mentioned in 100 products. This market dominance isn't surprising given its exceptional properties that are perfectly suited for a professional food environment.

Key benefits of stainless steel trolleys:

- Superior Corrosion Resistance: High-quality stainless steel, particularly Grade 304 (also known as 18/8), contains chromium and nickel, which create a passive layer that is highly resistant to rust and corrosion. This is vital in the humid, acidic, and chemically-rich conditions of commercial kitchens.

- Unmatched Hygiene: Its smooth, non-porous surface is a food safety dream. It prevents bacteria, grime, and food particles from embedding, making it incredibly easy to clean and sanitize to the highest standards, thus preventing cross-contamination.

- Exceptional Durability and Strength: Stainless steel can withstand heavy-duty use, impacts from pots and pans, and extreme temperatures without warping, denting easily, or breaking down. The thickness of the steel, or its gauge (a lower number means thicker steel), also plays a role, with 16- or 18-gauge steel offering excellent structural integrity.

- Professional Aesthetic: It offers a clean, bright, and professional look that fits seamlessly into any commercial kitchen design, signaling a commitment to quality and cleanliness.

While stainless steel trolleys might have a higher upfront cost compared to their plastic counterparts, their incredible longevity, superior hygiene benefits, and robust performance make them a more cost-effective choice in the long run. This is a crucial factor to consider when planning your restaurant's finances.

Plastic and Composite: The Lightweight Alternative

For specific applications where weight, noise reduction, or budget are primary concerns, plastic and composite trolleys offer an excellent and practical alternative. Our data indicates that plastic is used in 43 commercial kitchen trolley products, showcasing its significant and valuable presence in the market.

These trolleys are typically made from materials like high-density polyethylene (HDPE) or polypropylene, often using a structural foam molding process that creates a durable, rigid product. These materials offer several distinct advantages:

- Lighter Weight: Plastic trolleys are significantly lighter than stainless steel ones, making them easier for staff to maneuver, especially when navigating tight corners or pushing up slight inclines.

- Impact and Scratch Resistance: Unlike some metals that can dent or scratch, plastic is often more resilient to impacts and can hide scuffs, maintaining its appearance longer in rough-and-tumble environments like a busy dish pit.

- Noise Reduction: The inherent properties of plastic and rubber casters significantly reduce the clatter and noise associated with moving dishes and supplies, contributing to a quieter and more pleasant work environment, especially important for bussing in or near dining areas.

- Color-Coding for Safety: Many plastic trolleys and bins are available in different colors. This is extremely useful for implementing HACCP-compliant color-coding systems to prevent cross-contamination (e.g., green for produce, red for raw meat, blue for fish).

- Cost-Effective: Generally, plastic trolleys are more affordable than stainless steel, making them a great option for businesses with tighter budgets or for tasks that don't require the extreme heat resistance or strength of steel.

These trolleys are particularly well-suited for bussing stations, light-duty utility tasks, or any environment where hygiene is paramount but heavy-duty transport isn't the main requirement.

Wood: For Front-of-House Appeal

While rarely seen in the back-of-house due to hygiene and durability concerns in wet environments, wooden trolleys carve out an important niche in front-of-house operations where aesthetics and ambiance are paramount. Our research notes that 5 wooden trolley products are available, indicating a specialized but significant market for presentation-focused service.

Wood, often solid hardwoods like beech, oak, or walnut, is chosen for its neat, warm, and upscale appearance, making it perfect for:

- Beverage Service: A classic wine cart or a mobile cocktail station can add a touch of theater and sophistication to the dining experience.

- Dessert Carts: Presenting an array of tempting desserts directly to guests at their table is a powerful upselling tool that feels luxurious.

- Ambiance and Decor: A beautifully crafted wooden trolley can enhance the decor of a fine-dining restaurant, hotel lobby, or country club, reinforcing the brand's image. For expert advice on all aspects of your operation, from layout to supplies, feel free to contact our team.

However, wooden trolleys require more care. They need higher maintenance, including regular cleaning with gentle products and periodic sealing or oiling to protect against moisture and stains. They are not ideal for areas with frequent spills or heavy cleaning with harsh chemicals. When selecting a wooden trolley, prioritize high-quality craftsmanship and a durable, food-safe finish, and ensure it's used in an appropriate, drier environment where its aesthetic value can truly shine.

Key Features When Choosing Your Commercial Kitchen Trolley

Selecting the right commercial kitchen trolley is more than just picking one that looks good or fits a certain budget. It's about making a smart, strategic investment that will seamlessly integrate into your daily operations, improve your team's workflow, and provide long-term, reliable value. When we advise our clients, we emphasize looking beyond the basic function to the specific features that will profoundly impact daily use, safety, and efficiency.

From size and load capacity to the nuances of caster design and hygiene certifications, each detail plays a crucial role in the overall performance and suitability of your trolley. Let's break down the essential features to consider to ensure you make the best choice.

Size, Load Capacity, and Configuration

Before you even think about materials or special features, the practical dimensions and capabilities of a trolley must align with your physical space and operational needs. A trolley is only useful if it can move freely where it's needed most.

- Kitchen Layout and Aisle Width: The first step is always to measure. Get out a tape measure and check your doorways, hallways, and the width of your narrowest kitchen aisles, especially during peak service when they might be partially obstructed. A trolley that's too wide will become a constant bottleneck, hindering movement and causing frustration.

- Storage Space: Where will the trolley be stored when not in use? It can't live in the middle of a walkway. If space is at a premium, a more compact model or even a foldable design could be a huge space-saver for smaller kitchens or mobile catering operations.

- Weight Capacity: Trolleys are engineered with specific load capacities, ranging from around 200 lbs for lighter utility tasks to over 700 lbs for heavy-duty ingredient transport. A 300 lb capacity is suitable for general utility and bussing, while a 700 lb capacity is necessary for moving multiple sacks of flour or full beverage containers. Consistently overloading a trolley is a recipe for disaster, leading to structural failure, instability, and serious safety hazards.

- Number of Shelves and Shelf Spacing: Consider what you'll be transporting. Multi-tier trolleys are great for organizing, but ensure the spacing between shelves is adequate for the height of your standard containers, stock pots, or plated dishes. Adjustable shelves offer the greatest flexibility, allowing you to adapt the trolley for different tasks.

Choosing the right size and configuration ensures that your trolley works for your kitchen, not against it. It's about creating a harmonious flow that supports your culinary team, a principle we strongly believe in. You can learn more about us and our philosophy.

A Deeper Look at the Commercial Kitchen Trolley and Mobility

The ability of a commercial kitchen trolley to move smoothly, quietly, and safely is paramount. This performance characteristic largely depends on the quality and type of its casters (wheels) and other mobility-enhancing features.

- Caster Quality and Material: This is not the place to cut corners. Invest in high-quality, heavy-duty casters with smooth bearings. Flimsy wheels will wear out quickly, become noisy, and make the trolley difficult to maneuver. Polyurethane wheels are an excellent all-around choice, offering great durability, a smooth roll, and floor protection. Rubber provides superior grip and shock absorption.

- Swivel vs. Fixed Casters: Most trolleys use a combination for optimal control. The most common and effective configuration is two swivel casters at the front (where the handle is) for steering and maneuverability, and two fixed casters at the back for straight-line stability and tracking.

- Locking Brakes: This is a non-negotiable safety feature. At least two of the casters, typically the swivel ones, must have reliable locking brakes. This is crucial for preventing the trolley from rolling away when being loaded or unloaded, especially on any kind of incline.

- Non-Marking Wheels: To protect your expensive flooring from unsightly scuffs and black streaks, especially in front-of-house areas, always opt for non-marking wheels.

- Corner Bumpers: Protective bumpers, usually made of rubber or soft plastic, are a small feature with a big impact. They protect both the trolley and your walls, doorways, and other items from damage during accidental collisions, extending the lifespan of your assets.

- Ergonomic Handles: Well-designed handles placed at a comfortable height provide a secure grip, reducing strain on staff and giving them better control, especially when pushing heavy loads.

Hygiene, Cleaning, and Regulatory Standards for a Commercial Kitchen Trolley

In any foodservice environment, hygiene is the foundation of your reputation and your legal compliance. Your commercial kitchen trolley must be designed for easy and effective cleaning to prevent the buildup of bacteria and meet health regulations.

- Design for Cleanability: Look for trolleys with smooth, seamless surfaces and fully welded joints. Bolted joints and sharp corners create crevices where food particles, grease, and bacteria can hide and are difficult to clean.

- NSF Certification: This is the gold standard. Look for trolleys that are NSF certified, specifically to NSF/ANSI 2 standards for foodservice items. NSF International is a globally recognized public health and safety organization. An NSF certification provides assurance that the trolley's materials are safe for food contact, and that its design and construction meet strict standards for cleanability and durability. It means the trolley has been tested and verified to be non-toxic, non-absorbent, and resistant to corrosion, and that it can be thoroughly cleaned and sanitized, leaving no place for bacteria to hide. This certification is a critical assurance of quality and compliance for health inspectors and for your own peace of mind. For a comprehensive overview and personalized recommendations for choosing the right carts for your needs, we encourage you to book a strategy call with our experts.

Frequently Asked Questions about Commercial Kitchen Trolleys

We often get questions from business owners looking to make the best choice for their operations. Choosing the right trolley can feel overwhelming given the options, but breaking it down into practical considerations makes the process much clearer. Here are some of the most common inquiries we address, with detailed answers to guide you.

How do I determine the right size trolley for my kitchen?

Determining the right size for your commercial kitchen trolley involves a practical, on-site assessment of your physical space and operational flow. A trolley that doesn't fit is worse than no trolley at all. We recommend following this step-by-step process:

- Measure Key Passageways: Start by measuring the width of all essential doorways and hallways. This includes the kitchen entrance, walk-in cooler and freezer doors, and any service area doorways. This measurement gives you your absolute maximum width constraint.

- Assess Aisle Width During Peak Hours: Don't just measure an empty kitchen. Observe your busiest aisles during a service rush. Account for staff moving back and forth. The trolley should allow for comfortable passage without obstructing other staff or creating a safety hazard. A good rule of thumb is to ensure at least 36 inches of clear aisle space when the trolley is present.

- Identify a 'Parking' Spot: Where will the trolley be stored when not in use? It needs a dedicated home that is out of the main traffic flow. Measure this storage footprint. If space is extremely tight, a foldable model or one with a more compact, vertical design might be the ideal solution.

- Evaluate Turning Radius: Consider the tightest corners in your kitchen. A longer trolley will have a wider turning radius and may be difficult to navigate around 90-degree turns. A shorter, more compact trolley will be more nimble in confined spaces.

- Match Capacity to Peak Demand: Think about the maximum volume of items you need to move at one time. If your bussers clear 10 tables before returning to the dish pit, you need a bussing cart that can handle that load. If you transport ingredients for an entire day's prep in the morning, your utility cart must be up to the task. Choosing a higher capacity trolley reduces trips and boosts efficiency.

What is the difference between a bussing cart and a utility cart?

While both are wheeled carts used for transport in a restaurant, their primary functions, designs, and typical locations are quite different. Confusing the two can lead to inefficiency and even hygiene issues.

Bussing Carts are specialists. They are specifically designed for the "dirty" work of collecting soiled dishes, cutlery, and glassware from dining areas. Their design prioritizes containment and discretion. You'll often see them with deep, tub-like shelves or enclosed sides to contain spills and hide the unappealing sight of dirty dishes from guests. They frequently include built-in bins for waste and cutlery sorting, streamlining the cleanup process. They are typically made from durable, impact-resistant plastics that are easy to sanitize and reduce noise in the dining room. Their home is in the front-of-house and the path to the dishwashing area.

Utility Carts are generalists. They are the multi-purpose workhorses for transporting a wide range of "clean" items throughout the back-of-house. They typically feature flat, open shelves, making them versatile for countless tasks: moving sacks of flour and sugar, transporting cases of vegetables, carrying stacks of clean plates to service stations, or moving prepped ingredients from one station to another. Because they are often used for heavy loads and in hot kitchen environments, they are frequently constructed from robust, hygienic stainless steel.

In short, bussing carts are for post-service cleanup, while utility carts are for pre-service and mid-service logistics and organization.

How often should I clean my commercial kitchen trolley?

Maintaining the cleanliness of your commercial kitchen trolley is absolutely crucial for food safety, regulatory compliance, and the longevity of the item itself. A dirty trolley can be a prime vehicle for cross-contamination. We advise a multi-tiered approach to cleaning, integrated into your daily routine.

Daily Cleaning Routine (At the end of each shift/day):

- Empty and Pre-Scrape: Remove all items, bins, and debris from the trolley. Scrape off any large food particles into a waste receptacle.

- Wash Thoroughly: Wash all surfaces—shelves, handles, legs, and bumpers—with hot, soapy water using a clean cloth or brush. For bussing carts, pay special attention to the tubs and waste bins, which should be washed and sanitized separately.

- Rinse Completely: Rinse all surfaces with clean, hot water to remove any soap residue.

- Sanitize: Apply a food-safe sanitizing solution according to the manufacturer's instructions (paying attention to contact time). Allow to air dry.

Weekly Deep Cleaning:

- Inspect and Clean Casters: This is often overlooked. Tip the trolley on its side and inspect the wheels. Remove any tangled hair, string, plastic wrap, or caked-on debris. This not only improves hygiene but ensures the casters roll smoothly.

- Check for Wear and Tear: During the weekly clean, inspect all joints, welds, and fasteners. Look for any signs of damage or rust that could compromise structural integrity or create a new place for bacteria to hide.

Always adhere to your local health department's guidelines and your establishment's HACCP plan for cleaning and sanitation frequencies. For stainless steel, avoid abrasive scrubbers like steel wool that can scratch the surface and allow bacteria to harbor.

Conclusion: Rolling Towards a More Efficient Kitchen

The commercial kitchen trolley, in its many forms, is an often-underestimated cornerstone of a well-functioning foodservice operation. It is far more than a simple cart; it is a dynamic tool that, when chosen correctly, actively enhances the rhythm and flow of your entire establishment. We've seen how these versatile tools contribute significantly to efficiency, organization, safety, and hygiene across both front-of-house and back-of-house environments. From the robust stainless steel utility cart that streamlines ingredient delivery to the specialized racking trolley that optimizes production, and the indispensable bussing cart that keeps your dining area pristine, each trolley plays a vital and distinct role.

As we've explored, the journey to selecting the perfect commercial kitchen trolley involves a thoughtful analysis of your specific needs. It begins with understanding the distinct roles of utility, bussing, and racking trolleys and matching them to your daily tasks. It continues with a careful evaluation of materials—from the hygienic durability of stainless steel to the lightweight versatility of plastic. Finally, it culminates in scrutinizing the critical details: load capacity, high-quality casters, ergonomic design, and the non-negotiable assurance of NSF certification.

Investing in the right trolleys is not just an expense; it's a strategic decision that directly impacts your labor costs, service speed, staff morale, and overall operational fluidity. A well-chosen commercial kitchen trolley is a smart investment that pays dividends in productivity and peace of mind every single day.

At The Restaurant Warehouse, we pride ourselves on supplying food service supplies at lower prices by avoiding high commissions and retail overhead. Our unique selling proposition is to offer affordable, wholesale pricing directly to the foodservice industry. We believe that every kitchen, regardless of size or budget, deserves access to reliable and efficient tools that help them thrive.

We invite you to explore our extensive selection of carts and storage solutions to find the perfect fit for your operation. With our commitment to quality and affordability, we're here to help you roll towards a more efficient and profitable kitchen.

Contact us today for a quote! Book a Strategy Call with Our Experts

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment