Don't Freeze Up: Expert Commercial Freezer Repair and Maintenance

Why Commercial Freezer Reliability Can Make or Break Your Restaurant

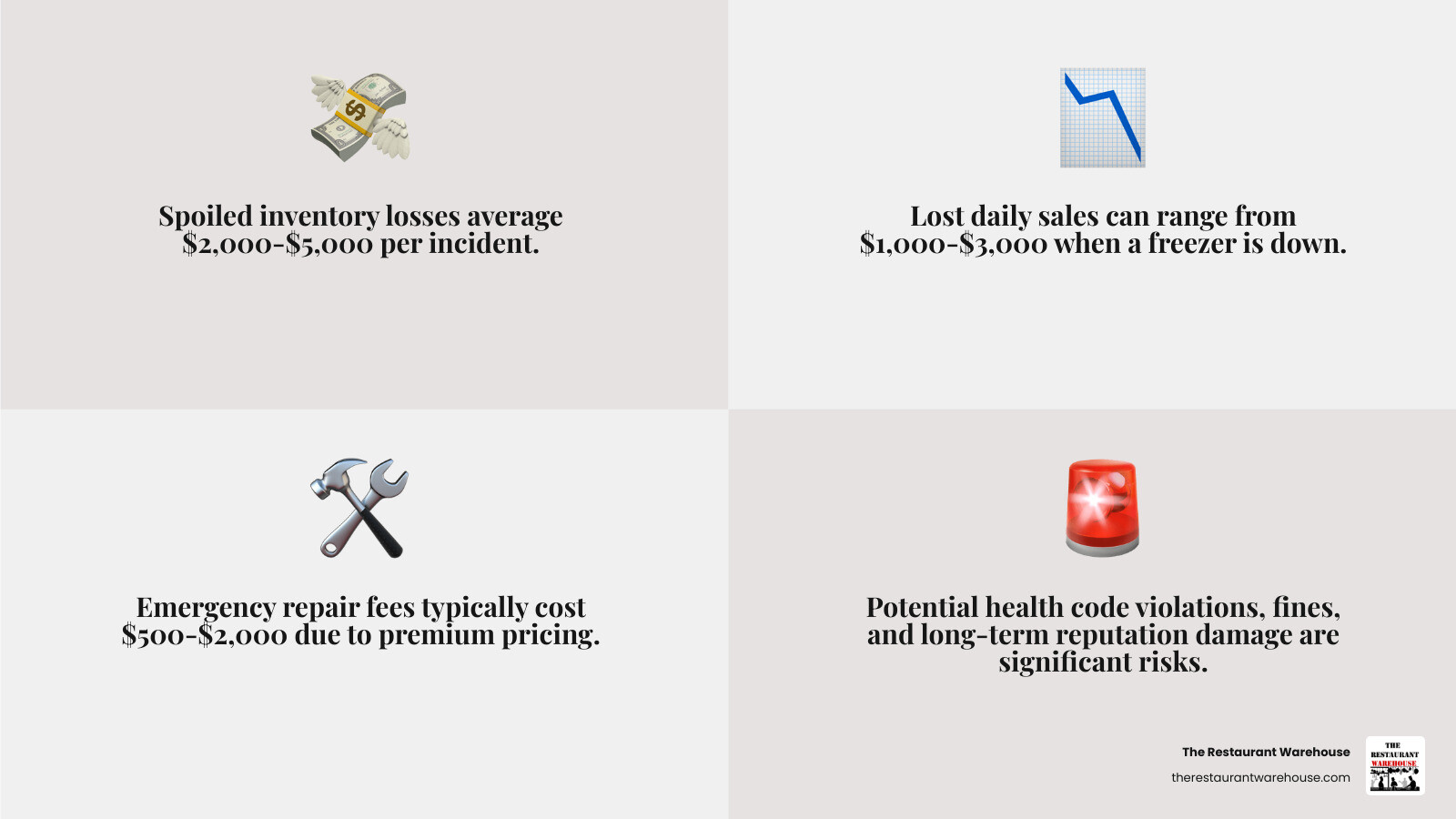

Commercial freezer repair services are not just a maintenance expense; they are a critical lifeline for your business's financial health and reputation. When a commercial freezer fails, the consequences are swift and severe, creating a domino effect of escalating costs. The most immediate and painful impact is on your inventory. A single day of downtime can result in thousands of dollars in spoiled goods, from prime cuts of meat and delicate seafood to prepared sauces and desserts. This isn't just a line item loss; it's the core of your menu, vanished.

This financial bleed extends far beyond spoiled product. Lost sales quickly accumulate when you are forced to tell customers their favorite dishes are unavailable. In a competitive market, this can drive patrons to your competitors. Furthermore, emergency repair calls, often necessary to mitigate inventory loss, come at a premium price, especially for after-hours or weekend service. These unexpected, high-cost repairs can wreak havoc on your budget and cash flow. The damage, however, isn't purely financial. A malfunctioning freezer that fails to maintain safe temperatures can lead to serious food safety violations during a health inspection, resulting in hefty fines, a lowered grade, or even a temporary shutdown. In the age of social media and online reviews, news of such a violation can spread rapidly, causing long-term reputational damage that is far more costly than any repair bill.

Key warning signs that demand immediate attention include noticeable temperature fluctuations, unusual buzzing, grinding, or clicking noises, an accumulation of excessive frost or ice on interior walls, and any signs of water leaking or pooling around the unit. If you observe these symptoms, perform a quick check of thermostat settings and ensure door seals are clean and making full contact. Clear any boxes or clutter that could be obstructing airflow around the unit's vents. For any issue beyond these simple checks, it is crucial to contact a certified technician immediately. While waiting for service, a pre-established emergency plan, including moving high-value inventory to backup storage, can significantly minimize your losses.

The vast majority of catastrophic commercial freezer failures are preventable. A proactive approach, grounded in regular maintenance and a keen awareness of early warning signs, is the most effective strategy. Understanding when to perform simple in-house checks and when to call for professional commercial freezer repair can save your business from devastating financial and reputational consequences.

Recognizing the Red Flags: When Does Your Freezer Need Repair?

A commercial freezer operates under constant demand, making it a true workhorse in any food service environment. However, even the most robust equipment provides clear clues when it's under strain. Learning to recognize these red flags early is the key to preventing a full-blown crisis, protecting your valuable inventory, and safeguarding your profits.

Temperature fluctuations are the most critical and dangerous warning sign. If you notice that items are soft, covered in ice crystals, or that the external thermostat display is erratic, your freezer's cooling capacity is compromised. This isn't just an efficiency issue; it's a major food safety hazard. Unstable temperatures allow harmful bacteria to multiply, as detailed in the official recommendations for food safety during a power outage. Fluctuations can also ruin the texture and quality of food, as repeated partial thawing and refreezing create large ice crystals that damage cell structures in meats and produce. This could be caused by a faulty thermostat, a failing compressor, or low refrigerant, all of which require immediate professional attention.

Listen for strange noises. A commercial freezer has a normal operational sound, usually a low, steady hum from the compressor and fans. Any deviation from this baseline is a cry for help. A loud buzzing can indicate a compressor that is straining to start or a failing fan motor. A persistent clicking sound may point to a faulty start relay trying to engage the compressor. A loud grinding or squealing noise is particularly alarming, as it often signals worn-out bearings in the evaporator or condenser fan motors, which could seize up at any moment. Ignoring these auditory warnings is like ignoring a smoke alarm.

Excessive frost buildup inside the freezer, especially on the interior walls or covering the evaporator coils, is a clear sign of a problem. This indicates that warm, moist air is infiltrating the sealed environment. The most common culprit is failing door seals and gaskets. When gaskets become cracked, brittle, torn, or flattened, they no longer create an airtight seal. This forces the refrigeration system to run constantly to combat the incoming warm air, leading to extreme inefficiency, higher energy bills, and eventual component failure. This constant overwork also leads to condensation and water drips around the door frames. You can learn how to install a door gasket on commercial refrigerators and freezers to address this common issue yourself.

Leaking water or puddles on the floor around the unit should never be ignored. This is often a symptom of a clogged or frozen defrost drain line. During the defrost cycle, melted ice is supposed to flow out through this line; if it's blocked, the water backs up and spills out, creating a dangerous slip hazard and the potential for costly floor damage and mold growth.

If the unit won't turn on at all, start with the simple checks: ensure it's plugged in and check for a tripped circuit breaker. If those aren't the issue, the problem is more serious, potentially involving a failed compressor, a faulty control board, or a wiring issue. For safety reasons, these electrical problems demand a professional diagnosis.

Finally, an unexplained spike in your energy bills is a subtle but important red flag. A freezer that is suddenly consuming more electricity is working harder to maintain its temperature. This inefficiency is a symptom of an underlying problem, such as dirty condenser coils, a slow refrigerant leak, or a failing compressor long before it breaks down completely.

Deeper Signs of Component Failure

Compressor: As the heart of the refrigeration system, its failure is catastrophic. Beyond loud humming or grinding, look for a unit that is hot to the touch, as overheating is a sign of extreme strain. If you hear a distinct 'click' followed by silence and the compressor doesn't start, the start relay or capacitor has likely failed. An inefficient cooling cycle, where the freezer runs for excessively long periods but struggles to reach the set temperature, also points directly to a weakening compressor that is losing its ability to pump refrigerant effectively.

Defrost System: This system is crucial for maintaining airflow. A malfunction leads to heavy ice accumulation on the evaporator coils, which acts like an insulator, preventing the coils from absorbing heat and chilling the air. This blockage of airflow is a primary cause of poor cooling performance. You may also notice water leakage if the defrost drain line is clogged with ice or debris, or if the defrost cycle isn't completing due to a faulty defrost timer, heater element, or termination thermostat.

Key Components and Common Commercial Freezer Failures

Understanding the anatomy of your commercial freezer is the first step toward effective troubleshooting and maintenance. These units are complex systems where each part has a critical role. The primary components are the compressor, condenser coils, evaporator coils, thermostat and sensors, door gaskets, fan motors (for both the condenser and evaporator), and the defrost system. These parts work in a continuous loop known as the refrigeration cycle. A failure in even the smallest component, like a door gasket, can trigger a chain reaction that leads to a system-wide breakdown.

Being able to connect a symptom to a potential component failure is invaluable. For instance, a freezer that runs but won't cool properly could be suffering from dirty condenser coils, a failing compressor, low refrigerant levels, or a malfunctioning evaporator fan motor. Strange noises almost always originate from moving parts like the fan motors or the compressor. Excessive and rapid frost buildup is typically caused by a faulty defrost system or compromised door seals. Knowing these basic relationships allows you to provide clear, actionable information to a commercial freezer repair technician, speeding up the diagnostic and repair process.

Understanding Compressor and Condenser Issues

The compressor is the engine of your freezer, pumping refrigerant vapor at high pressure to the condenser coils. The condenser's job is to release heat from the refrigerant into the ambient air. The single most common problem affecting this process is dirty condenser coils. Located where they can draw in air, these coils are magnets for dust, grease, and debris. This buildup acts as an insulator, preventing the coils from releasing heat effectively. This trapped heat forces the compressor to run longer and hotter, dramatically increasing energy consumption and leading to premature failure. Similarly, blocked airflow from placing the unit too close to a wall or storing boxes around it has the same insulating effect. A failed start relay or capacitor can prevent the compressor from turning on at all, often resulting in a 'clicking' sound. The most severe issue is a refrigerant leak, which not only stops the freezer from cooling but also requires a certified technician for repair due to environmental regulations. Proactive maintenance, such as learning how to clean the condenser on Atosa Refrigerator and Freezer units, is the best defense against these issues.

Diagnosing Thermostat and Sensor Malfunctions

The thermostat and its associated sensors are the brain of the freezer, telling the compressor when to turn on and off. A primary sign of malfunction is inaccurate temperature readings, where the external display does not reflect the true internal temperature (which should be verified with a calibrated, independent thermometer). This can cause the freezer to become too cold, leading to freezer burn, or not cold enough, creating a serious food safety risk. Another symptom is short cycling, where the compressor kicks on and off in rapid succession. This is often caused by a faulty sensor giving erratic readings, and it causes excessive wear on the compressor and wastes a tremendous amount of energy. Conversely, a faulty sensor might cause the freezer to run continuously without ever reaching its target temperature. Before assuming a component has failed, it's always wise to learn how to set the temperature on an Atosa Refrigerator and Freezer to ensure the issue isn't simply user error.

The Importance of Evaporator Coils and Fans

Inside the freezer box, the evaporator coils are where the cooling actually happens. As liquid refrigerant expands into a gas within these coils, it absorbs heat from the surrounding air. The evaporator fan is responsible for circulating this newly chilled air throughout the cabinet to maintain a consistent temperature. The biggest enemy of this process is frost buildup on the coils. This ice acts as an insulator, preventing the coils from absorbing heat and drastically reducing cooling efficiency. This leads to poor air circulation, resulting in warm spots within the freezer and inconsistent product temperatures. A worn evaporator fan motor will often make rattling, squealing, or grinding noises and may eventually seize, stopping air circulation entirely. When these components fail, the compressor is forced to run longer to compensate, wasting energy and risking overheating. If you need to source replacement parts, you can find Atosa Refrigerator Parts to get your unit back to optimal performance quickly.

The Ultimate Guide to Professional Commercial Freezer Repair

When a critical piece of equipment like a commercial freezer falters, professional commercial freezer repair is an absolute necessity, not a discretionary expense. While DIY maintenance is crucial for prevention, complex failures require the specialized knowledge, diagnostic tools, and hands-on experience of a qualified service. Attempting to fix intricate electrical or sealed-system issues yourself can lead to further damage, void warranties, and create significant safety hazards. A professional service safeguards your inventory and minimizes business disruption by providing a swift and accurate solution.

The professional repair process should be transparent and efficient. It typically begins with a thorough diagnostic check, where the technician uses tools like multimeters, pressure gauges, and leak detectors to pinpoint the exact cause of the failure. A reputable technician will then provide a clear, detailed explanation of the problem, the required parts, and a complete estimate for the repair. Once approved, the repair should be carried out efficiently using high-quality, OEM-equivalent parts to ensure longevity. Costs will vary based on the complexity of the issue, the price of replacement parts, and labor rates, but this investment is almost always a fraction of the cost of lost inventory and sales. Many services offer same-day or 24/7 emergency repairs, recognizing that in the food service industry, time is money.

What to Look for in a Quality Commercial Freezer Repair Service

Choosing the right repair partner is a critical business decision. Look for these key qualities to ensure you receive reliable and effective service:

- Certified and Insured Technicians: Ensure technicians hold relevant certifications, such as the EPA 608 certification required to handle refrigerants legally and safely. They should also be fully insured to protect your business from liability.

- 24/7 Emergency Availability: Breakdowns don't adhere to a 9-to-5 schedule. A service that offers round-the-clock availability can be the difference between a minor inconvenience and a catastrophic inventory loss over a weekend or holiday.

- Transparent, Upfront Pricing: A trustworthy provider offers a clear, itemized breakdown of costs—including diagnostic fees, parts, and labor—before any work begins. Avoid services that are vague about pricing or only offer hourly rates without an estimated timeframe.

- Warranty on Parts and Labor: A solid warranty (e.g., 90 days on labor, 1 year on parts) demonstrates the company's confidence in their work and protects your investment if the same issue recurs.

- Experience and Specialization: Look for a company with a long, proven track record and positive customer reviews. Crucially, ensure they specialize in commercial refrigeration, as it is vastly different from residential appliance repair.

Understanding Repair Costs and When to Replace

Deciding whether to repair or replace a failing freezer requires a careful cost-benefit analysis. The 50% rule is a useful guideline: if the cost of the repair exceeds 50% of the price of a new, comparable unit, replacement is often the more financially sound option. The age of the unit is another critical factor. The average lifespan of a commercial freezer is 10-18 years. If your unit is in the latter half of its expected lifespan and requires a major repair (like a new compressor), the money may be better invested in new equipment. Also, consider the frequency of repairs. If you are calling for service every few months, those costs add up and indicate the unit is nearing the end of its reliable life.

Finally, factor in the energy efficiency of new models. A modern, Energy Star-rated freezer can offer significant savings on your monthly utility bills, which can help offset the initial purchase cost over time. A trusted technician can provide an honest assessment of your current unit's condition and help you make an informed decision. When planning for a potential replacement, our resources on Determining Commercial Refrigerator and Freezer Space can be a valuable guide.

A Comprehensive Commercial Freezer Repair Overview for All Unit Types

Commercial freezers are not one-size-fits-all, and a comprehensive repair service should have expertise across all major types. Common repair needs can differ based on the unit's design and usage:

- Walk-in freezers: These large units often face issues with door seals, automatic door closers, and heated pressure relief ports that can freeze over.

- Reach-in freezers: As the workhorses of the kitchen line, they are prone to fan motor failures and damage to door gaskets from heavy use.

- Chest freezers: While generally reliable, they can suffer from broken lid hinges and damaged gaskets, leading to significant cold air loss.

- Display freezers: Glass-front units can have problems with anti-sweat heaters in the doors, interior lighting failures, and fogging due to seal leaks.

- Undercounter freezers: Their compact size means their small condensers can clog more quickly, requiring more frequent cleaning to prevent overheating.

- Glass door merchandisers: Similar to display freezers, these are susceptible to lighting and door issues, and their high-traffic location makes them vulnerable to gasket damage.

Understanding the nuances of different models is key to effective service. For more insight, you can explore the pros & cons of purchasing a commercial freezer/fridge combo.

The Power of Prevention: Maintenance to Avoid Costly Breakdowns

Most catastrophic freezer breakdowns do not happen without warning. They are the result of neglected maintenance. Regular preventative maintenance is the single most powerful strategy for changing your freezer from a potential liability into a consistently reliable asset. This proactive approach isn't about fixing things when they break; it's about creating a system of care that ensures they don't break in the first place.

The benefits of a robust maintenance program are profound and multifaceted. It leads to a significantly extended lifespan for your equipment, maximizing the return on your substantial investment. It also delivers substantial energy savings, as a clean, well-maintained unit operates with maximum efficiency. Dirty condenser coils alone can increase energy consumption by up to 30%. Most importantly, proactive care prevents costly downtime and the associated inventory and sales losses. It also ensures food safety by maintaining consistent, reliable temperatures, protecting both your customers and your reputation.

DIY Preventative Maintenance Checklist

Simple, consistent tasks performed by your in-house staff can prevent the majority of common freezer problems. Incorporate these checks into your daily, weekly, and monthly operational routines:

- Clean condenser coils monthly: Unplug the unit and use a stiff brush and a vacuum to remove the insulating layer of dust and grease. This is the single most effective DIY task for improving efficiency and preventing compressor failure.

- Inspect and clean door gaskets weekly: Wipe them down with warm, soapy water and check for any cracks, tears, or areas of brittleness. A compromised gasket is a primary source of energy waste and frost buildup.

- Check temperature settings daily: Use a calibrated, independent thermometer placed inside the unit to verify that the freezer is holding its set temperature accurately. Log these temperatures for your records.

- Ensure proper airflow: Keep the area around the exterior of the unit clear of boxes, supplies, and other clutter, allowing at least six inches of clearance for proper ventilation. Inside, avoid over-packing shelves to allow for cold air circulation.

- Clean drain lines and pans: On a monthly basis, flush drain lines with warm water to prevent clogs from ice or debris, which can lead to water damage and unsanitary conditions.

For more detailed guidance, the Atosa Refrigerator and Freezer Maintenance Instructions offer clear, step-by-step directions for common models.

The Role of Professional Servicing

While DIY care is the foundation of good maintenance, professional servicing provides a deeper level of inspection and care that requires specialized tools and expertise. A semi-annual professional maintenance schedule is the gold standard for protecting your investment. During these visits, a certified technician can perform critical tasks:

- Professional Coil Cleaning: Using specialized tools and non-corrosive chemical degreasers to remove stubborn buildup that a simple brush cannot.

- Refrigerant Level and Pressure Checks: Using gauges to detect slow leaks and ensure the system is charged to the precise specifications for optimal performance.

- Electrical System Inspection: Checking amp draws on motors and compressors, tightening electrical connections, and inspecting wiring for wear to prevent electrical faults and fire hazards.

- Lubricating Moving Parts: Applying the correct lubricants to fan motors and door hinges to ensure smooth operation and extend their service life.

- Calibrating Thermostats and Controls: Ensuring that all sensors and controls are accurate for precise temperature management, which is critical for both energy efficiency and food safety.

This modest investment pays for itself many times over by preventing emergencies, extending equipment life, and keeping energy bills low. Our General Restaurant Equipment Repair information explains why this level of expertise is so valuable across all your kitchen equipment.

Create a Simple Maintenance Calendar

A clear, documented schedule helps teams stay consistent and accountable. Use this sample calendar as a baseline and adjust it based on your kitchen's volume, environment (e.g., high grease or flour dust), and your specific unit's requirements.

-

Daily

- Verify internal temperature with an independent thermometer at the beginning and end of the day. Log the reading.

- Confirm doors close fully and latches engage properly. Remove any product or debris blocking the doors.

- Listen for any new or unusual noises. Visually check for fresh frost on vents or moisture around the base of the unit.

-

Weekly

- Wipe door gaskets with warm, soapy water and dry them thoroughly to prevent ice from bonding to the seal.

- Inspect gaskets closely for tears, flattening, or gaps. Schedule replacements promptly if any damage is found.

- Clear all debris from air intake and exhaust grilles. Ensure no boxes, trays, or other items are blocking airflow inside the cabinet.

-

Monthly

- Perform a thorough cleaning of the condenser coils with a soft brush and vacuum. In greasy environments, use a non-acidic, foaming coil cleaner designed for refrigeration systems.

- Inspect the evaporator coil area for significant ice accumulation. If present, it's a sign to investigate the defrost system and gasket integrity more closely.

- Flush the defrost drain line with warm water to prevent blockages. Sanitize the drain pan to prevent odors and bacterial growth.

-

Quarterly

- Check door hinges and automatic closers for smooth operation. Tighten any loose screws and adjust alignment to ensure gaskets make even, firm contact with the frame.

- Inspect fan guards and blades (with power off). Clean them carefully to maintain optimal airflow and prevent imbalance that can wear out motors.

- Review the defrost schedule on programmable units. Adjust the timing or frequency to account for seasonal changes in humidity and kitchen workload.

-

Semi-annually (Professional Service)

- Complete electrical system audit, including voltage and amperage checks on all components and torque checks on connections.

- Full refrigerant circuit evaluation, including superheat and subcooling measurements, leak detection, and system performance benchmarking against manufacturer specs.

- Calibration of all controls and verification of sensor accuracy against a known, calibrated reference thermometer.

How to Clean Condenser Coils the Right Way

- Power and Safety: Always begin by turning off and unplugging the unit. For hardwired equipment, follow proper lockout/tagout procedures to ensure safety.

- Access the Coils: Carefully remove the service grille or cover, which is typically at the bottom or top of the unit. Note the orientation of screws and panels for easy reassembly.

- Dry Clean First: Use a soft-bristled brush to gently loosen caked-on dust and debris. Brush in the same direction as the delicate aluminum fins to avoid bending them. Use a vacuum with a crevice tool to extract all the loosened lint and dust.

- Wet Clean When Needed: For greasy buildup that a brush can't remove, use a commercially available, non-corrosive, foaming condenser coil cleaner. Apply according to the manufacturer's instructions and allow it to work before wiping or rinsing as directed. Avoid using a high-pressure spray, which can damage fins.

- Straighten Fins: If you notice any bent fins, gently straighten them using a fin comb (a small, inexpensive tool) to restore proper airflow.

- Reassemble and Test: Replace all panels and grilles, restore power to the unit, and monitor it to ensure the compressor is cycling normally and temperatures are returning to the setpoint.

Door Gasket Care and Seal Testing

- Clean: Use only mild dish soap and warm water. Harsh chemicals like bleach or ammonia will degrade the rubber, causing it to become brittle and crack.

- Dry: Always wipe the gasket dry after cleaning so that ice doesn’t form and bond the door shut, which can tear the gasket upon opening.

- Test: The 'paper test' is a simple and effective way to check the seal. Close the door on a thin piece of paper or a dollar bill. If you can pull it out with no resistance, there is a gap. Test this all the way around the door. A proper seal will hold the paper snugly.

- Replace: If you see visible cracks, tears, hardened sections, or if it fails the paper test, replace the gasket immediately. Poor seals are a leading cause of ice buildup on coils, long run times, and high energy costs.

Airflow and Placement Best Practices

- Maintain Clearances: Adhere strictly to the manufacturer's specifications for clearance, which is typically a minimum of 6 inches around all condenser intakes and exhausts. Pushing a unit against a wall traps heat and suffocates the system.

- Avoid Heat Sources: Position freezers away from heat-generating equipment like fryers, griddles, and dish machines. Also, avoid placement in direct sunlight or near HVAC exhaust vents that raise the ambient temperature.

- Inside the Cabinet: Never overpack a freezer. Leave space between items and around the interior walls to allow cold air to circulate freely. Use vented or wire shelving to promote even air distribution from top to bottom.

- Door Discipline: Train staff to minimize door openings, especially during peak service times. Encourage them to plan ahead, retrieve multiple items at once, and close the door immediately.

Loading and Product Practices That Protect Performance

- Pre-cool Hot Items: Never place hot food directly into the freezer. This introduces a massive heat load and steam, forcing the freezer to work overtime and causing excessive frost. Pre-cool items in a cooler first.

- Staging Large Deliveries: When receiving large frozen deliveries, stage the product in a walk-in cooler temporarily if possible. Transfer items to the freezer in smaller batches to avoid overwhelming the system and causing a dangerous temperature spike.

- Labeling and FIFO: Implement a strict First-In, First-Out (FIFO) rotation system. Clearly label all items with product names and dates to minimize the time the door is open while staff search for items.

- Pan and Packaging Choices: Use containers and pans with minimal mass that allow for good air circulation. Avoid stacking items in solid, dense blocks, as this prevents the core from freezing quickly and evenly.

Temperature Monitoring, Logging, and Food Safety

- Set Targets: Most commercial freezers should be set to maintain a temperature at or below 0°F (-18°C) to ensure food safety and quality, unless a specific product requires a different temperature.

- Redundancy is Key: Use a secondary, calibrated thermometer or a wireless data logger inside the unit to verify the accuracy of the built-in control panel display. Place loggers in spots most likely to be warm, such as near the door or on the top shelf.

- HACCP Alignment: Maintain diligent daily temperature logs as part of your Hazard Analysis and Critical Control Points (HACCP) plan. If a temperature reading exceeds the safe threshold, your plan should dictate immediate corrective actions: verify with an independent thermometer, check for airflow obstructions, and call a technician if the temperature doesn't recover quickly.

- Invest in Alarms: High-temperature alarms, whether a local strobe light and buzzer or a remote notification system that sends alerts to your phone, are an invaluable investment. They can save thousands of dollars in inventory by alerting you to a problem like a power outage or a door left ajar before it's too late.

The Critical Role of Documentation

- Maintenance Log: Keep a dedicated logbook for each freezer. Record the date of every maintenance task (e.g., coil cleaning, gasket inspection) and who performed it. This creates accountability and a clear history.

- Repair Records: When a professional repair is done, file the invoice and the technician's report in the logbook. This documentation is crucial for tracking recurring issues and is often required for warranty claims.

- Insurance and Compliance: Detailed temperature and maintenance logs are your best defense in the event of a foodborne illness claim or an insurance claim for spoiled product. They demonstrate due diligence and adherence to food safety protocols.

Training and Culture

- Assign Ownership: Make preventative maintenance a formal part of someone’s job description, not an afterthought. Use clear, laminated checklists posted near the unit, with space for dates and initials.

- Daily Huddles: Use 60-second daily team meetings to reinforce best practices. Ask, "Did anyone notice any new noises or frost on the freezers today? Are all the doors closing properly?"

- Visual Aids and Reminders: Post simple visual aids showing how to properly load the freezer, the importance of closing doors, and who to contact in an emergency. A culture of shared responsibility is your best defense against equipment failure.

By integrating these daily habits, scheduled maintenance tasks, and professional servicing, you convert your freezer from a potential point of failure into a reliable, efficient cornerstone of your operation. Small, consistent actions pay massive dividends in uptime, energy savings, and food safety.

Frequently Asked Questions about Commercial Freezer Repair

When your commercial freezer starts showing signs of trouble, questions and concerns arise quickly. Getting straight, accurate answers is essential for making timely decisions that protect your business. Here are some of the most common questions regarding commercial freezer repair.

How does a malfunctioning commercial freezer impact my business?

A broken freezer triggers an immediate and cascading financial crisis. The impact is multi-faceted:

- Spoiled Inventory: This is the most direct cost, often amounting to thousands of dollars in lost meat, seafood, produce, and prepared foods.

- Lost Sales: When key menu items are unavailable, you lose revenue and risk disappointing loyal customers who may not return.

- Emergency Repair Costs: After-hours, weekend, or holiday service calls come with significant premium charges compared to standard rates.

- Health Code Violations: Most seriously, a failure to maintain safe food temperatures can lead to critical violations during a health inspection, resulting in heavy fines, a poor public rating, and even a temporary shutdown that can devastate your reputation.

How long should a commercial freezer last?

The average operational lifespan of a well-built commercial freezer is between 10 to 18 years. However, this is not a guarantee. The longevity of your unit depends heavily on its usage patterns and, most importantly, the quality of its maintenance. A unit in a high-volume kitchen that receives consistent preventative maintenance—including regular coil cleaning and semi-annual professional servicing—can often last well beyond this average. Conversely, a neglected unit in a harsh environment (high heat or grease) may fail in as little as 5-7 years. The specific type of freezer and the quality of its original construction also play a significant role.

Can I perform commercial freezer repairs myself?

There is a clear line between DIY maintenance and professional repair. Simple maintenance tasks are not only permissible but highly encouraged for in-house staff. These include cleaning condenser coils, wiping down and inspecting door gaskets, checking and logging temperatures, and clearing drain lines. These tasks are safe, require minimal tools, and are highly effective at preventing common issues.

However, complex repairs involving electrical systems, the sealed refrigerant system, or the compressor must always be handled by a certified technician. Attempting these repairs without the proper training, diagnostic tools, and safety equipment is extremely dangerous. It can lead to electrocution, refrigerant burns, causing more extensive and expensive damage to the unit, and will almost certainly void any existing warranty. For your personal safety and the integrity of your equipment, it is critical to know your limits and call an expert for any major issue.

What is the most common commercial freezer repair?

While failures can happen in any component, the most frequent repairs technicians perform are related to issues caused by a lack of basic maintenance. These include replacing failed condenser or evaporator fan motors that have burned out from overwork, replacing damaged door gaskets that are causing air leaks and frost buildup, and clearing clogged defrost drain lines. Another common repair is replacing the start relay and capacitor for the compressor, which are components that wear out over time and are stressed by conditions like dirty coils.

How much does an emergency commercial freezer repair cost?

Emergency repair costs can vary widely, but you can expect to pay a significant premium over a scheduled service call. Costs are influenced by several factors: the time of day (nights, weekends, and holidays are most expensive), your geographic location, the complexity of the problem, and the cost of the required parts. A simple emergency fix like replacing a fan motor might cost a few hundred dollars, while an emergency compressor replacement can easily run into the thousands. This is why preventative maintenance is so cost-effective—it helps you avoid these premium charges.

Conclusion

Your commercial freezer is more than just an appliance; it is a silent guardian of your profits, your reputation, and your commitment to food safety. Recognizing its importance is the first step, but protecting this critical investment requires vigilance and proactive care. Being alert to the early warning signs—subtle temperature fluctuations, unfamiliar noises, or the first signs of excess frost buildup—allows you to act before a minor issue escalates into a catastrophic and costly failure.

The importance of maintenance cannot be overstated. It is the most powerful and cost-effective strategy at your disposal. A consistent routine of simple DIY tasks, such as cleaning coils and inspecting gaskets, combined with a commitment to semi-annual professional servicing, forms a formidable defense against the vast majority of breakdowns. This proactive approach doesn't just prevent repairs; it extends your equipment's lifespan, lowers your energy bills, and ensures you are always serving safe, high-quality food.

When commercial freezer repair does become necessary, the key is to act fast and choose a certified professional. The risks of attempting complex electrical or refrigerant-related repairs yourself are far too great, both for your safety and the health of your equipment. A qualified technician brings the expertise, tools, and experience to diagnose the problem accurately and perform the repair safely and correctly, minimizing your downtime and protecting your valuable inventory.

At The Restaurant Warehouse, we understand that the reliability of your equipment is the foundation of your daily operations. We are committed to offering quality commercial restaurant equipment and food service supplies at wholesale prices, empowering you to build a resilient kitchen with reliable equipment without the high overhead of traditional retail.

The value of professional repair and diligent maintenance lies in the peace of mind and operational stability they provide. A trusted technician is a partner in your success. By staying alert to warning signs, committing to a culture of maintenance, and relying on experts for complex repairs, you take control of your equipment's destiny and ensure your business remains resilient and successful.

Don't let a failing freezer put your business on thin ice. Take a proactive stance on maintenance and, for reliable equipment and parts to support your success, explore Atosa Freezer options and parts for your business.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment