Top Commercial Sink Suppliers: Optimize Your Kitchen Hygiene with These Picks

Why Finding the Right Commercial Sink Supplier Matters for Your Kitchen Success

Commercial sink suppliers are the foundational partners of any successful foodservice, healthcare, or institutional operation. They provide the essential plumbing fixtures that keep your facility running smoothly, safely, and in full compliance with health regulations. A truly great supplier doesn't just complete a transaction for a sink—they partner with you, offering expertise to ensure your operation meets stringent health codes, maximizes workflow efficiency, and adheres to your budget. Choosing the right partner is one of the most critical decisions you'll make for your back-of-house infrastructure.

The commercial sinks market is projected to experience robust growth, expanding at a 4.5% CAGR from 2023 to 2028. This growth is fueled by the continuous expansion of foodservice establishments worldwide and the implementation of increasingly strict hygiene and sanitation requirements by public health authorities. With literally thousands of models, configurations, and materials available, navigating this market can be daunting. Selecting an inappropriate supplier can lead to significant financial losses from inflated markups, unexpected shipping delays, and costly compatibility issues with your existing plumbing and layout.

Your sink is far more than a simple basin for washing dishes; it is the command center for food safety, operational workflow, and regulatory adherence. It's where raw ingredients are prepped, hands are washed to prevent cross-contamination, and wares are sanitized to protect public health. Whether you require a compact hand sink for a small coffee shop, a durable utility sink for a school, or a complex, multi-compartment warewashing station for a high-volume restaurant, understanding your supplier options is paramount. As specialists in commercial sink and plumbing solutions, we have guided countless business owners through the complex world of commercial sink suppliers. Our extensive experience has consistently shown that the quality of the supplier relationship can directly determine the success or failure of a kitchen's operational backbone.

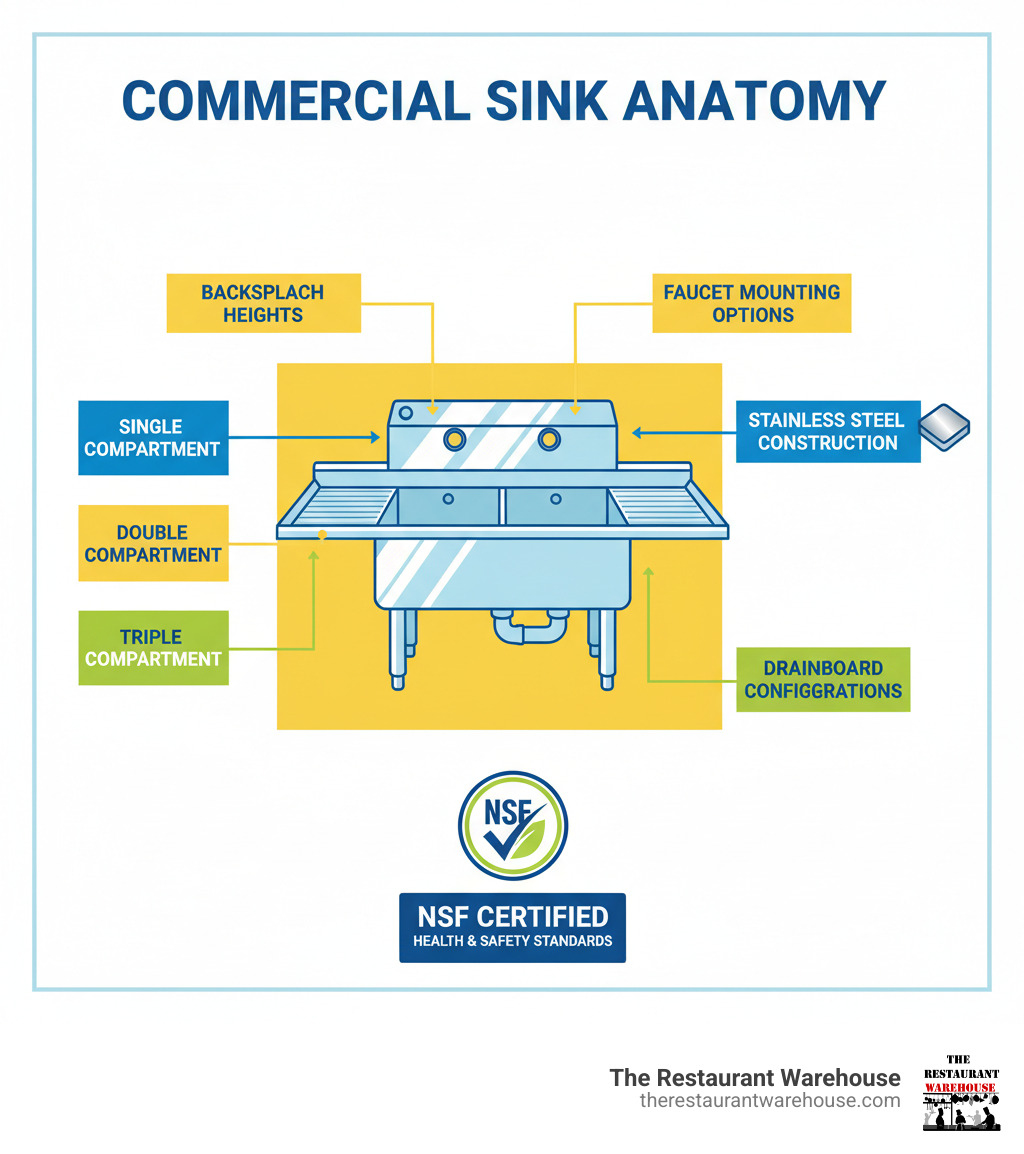

Understanding the Anatomy of a Commercial Sink

Before you begin engaging with commercial sink suppliers, it is crucial to develop a deep understanding of what makes these stainless steel workhorses function. Unlike a residential sink, a commercial-grade sink is a piece of precision-engineered hardware, meticulously designed for specific, demanding tasks while meeting rigorous health and safety standards. Every single component, from the number of compartments and the gauge of the steel to the height of the backsplash, serves a purpose. Making an uninformed choice can result in frustrating compliance failures, inefficient workflow bottlenecks, and a sink that fails prematurely.

Essential Types of Commercial Sinks

Commercial kitchens and facilities utilize a variety of sink types, each engineered for a specific function to ensure hygiene and efficiency.

- Single-Bowl Sinks: These are the versatile all-rounders, ideal for washing large stockpots, prepping bulky vegetables, or performing general tasks in kitchens with limited space.

- Double-Bowl Sinks: These significantly enhance productivity by enabling staff to multitask. For example, one bowl can be used for thawing frozen foods under running water while the other is used for washing produce, a practice that helps prevent cross-contamination.

- Three-Compartment Sinks: This is the undisputed cornerstone of manual warewashing and is mandated by health codes in the vast majority of foodservice operations. It facilitates the essential "wash, rinse, sanitize" method. Our comprehensive 3-Tier Sink Guide provides an in-depth explanation of why this specific setup is so critical for ensuring food safety.

- Four-Compartment Sinks: These sinks add a fourth basin, typically used as a pre-soak or scrap trough for heavily soiled pots and pans. This addition is invaluable in high-volume operations like banquet halls and institutional cafeterias, as it dramatically speeds up the cleaning process.

- Hand Sinks: These are compact, dedicated, and non-negotiable units for maintaining personal hygiene. Health inspectors are trained to look for these specifically, and regulations mandate that they be strategically placed within easy reach of food preparation areas, dishwashing stations, and restrooms. Our Catering Hand Wash Sink Buying Guide offers crucial tips on placement and features.

- Bar, Utility, and Mop Sinks: These sinks handle specialized, non-food-contact tasks. Bar sinks are compact, often multi-functional units designed for rinsing glassware and disposing of liquids. Utility and mop sinks are built for extreme durability, featuring heavy-gauge steel and deep basins to handle janitorial duties and harsh cleaning chemicals. For a deeper dive into these specialized applications, consult our Industrial Sink Types guide.

Decoding Sink Materials and Features

The material of your sink is the primary determinant of its longevity, cleanability, and compliance. Stainless steel is the universal material of choice for commercial settings due to its exceptional durability, resistance to extreme temperatures and corrosive chemicals, and non-porous surface that inhibits bacterial growth.

- Stainless Steel Type: The alloy composition matters. 304-series stainless steel is the premium, high-quality option, containing a higher percentage of chromium and nickel for superior corrosion resistance. It's the ideal choice for environments with constant moisture and exposure to acidic foods. 430-series stainless steel is a more economical alternative that contains less nickel, making it more susceptible to corrosion over time, but it can be a suitable choice for lighter-duty applications or drier environments.

- Steel Gauge: This indicates the thickness of the steel; a lower number signifies thicker, stronger, and more durable steel. 16-gauge steel is widely considered the industry standard for most commercial sinks, offering an excellent balance of durability and cost. 18-gauge steel is a lighter, more budget-friendly option suitable for hand sinks or low-volume prep sinks. For the most demanding environments, heavy-duty 14-gauge steel provides maximum resistance to dents and damage.

Beyond the core material, several key features define a sink's day-to-day functionality.

- Bowl Depth and Size: The dimensions of the sink bowls are critical. A depth of 14 inches is often preferred to accommodate large stockpots and prevent splashing, while shallower bowls are sufficient for hand washing. The length and width should match the size of the wares you clean most often.

- Drainboards: Integrated drainboards (available on the left, right, or both sides) provide essential space for air-drying and organizing dishes. A well-configured drainboard setup directly impacts workflow efficiency and is a key component of a functional warewashing station.

- Faucets and Plumbing: Faucets are crucial for usability. Pre-rinse faucets with high-pressure sprayers are essential for blasting food debris off plates before washing. Hands-free options, such as foot pedals or electronic sensors, are becoming standard for hand sinks to minimize cross-contamination and are a major focus for health inspectors.

For a detailed review of features designed for heavy-duty cleaning, explore our analysis of the Top Commercial Pot Wash Sinks.

Ready to find the perfect sink for your operation? Contact us today to discuss your specific requirements and get expert guidance from our specialists.

How to Choose the Right Commercial Sink for Your Industry

Selecting the perfect commercial sink is not a one-size-fits-all proposition. Every industry, from bustling restaurants to sterile healthcare facilities, operates under a unique set of regulatory requirements and operational demands that dictate the ideal sink configuration. The most reputable commercial sink suppliers possess a deep understanding of these industry-specific nuances and can guide you toward a choice that ensures your operation is both compliant and efficient.

Sinks for Food Service and Restaurants

The foodservice industry is governed by strict public health regulations designed to prevent foodborne illness. The wash-rinse-sanitize method is a non-negotiable standard in most jurisdictions, making a dedicated NSF Approved 3-Compartment Sink an absolute necessity. As detailed in the FDA Food Code section 4-301.12, this three-step process is fundamental to proper manual warewashing. Furthermore, NSF certification is your passport to health department approval. This certification guarantees that the sink's design, materials, and construction meet rigorous standards for public health and safety, ensuring it is durable and can be easily cleaned and sanitized.

To maintain an efficient and contamination-free workflow, commercial kitchens must physically separate different tasks. This means using separate prep sinks for washing produce and thawing meats, and dedicated warewashing sinks for cleaning dishes, utensils, and cookware. Hand sinks are another critical, legally mandated component. Health codes are highly specific about their placement, requiring them in all food prep areas, near dish stations, and in or adjacent to restrooms to encourage frequent handwashing. Even mobile businesses like food trucks must adhere to these strict standards, a topic we cover in our Food Truck Sinks Guide.

Sinks for Healthcare and Institutional Use

In environments like hospitals, clinics, schools, and long-term care facilities, hygiene standards are elevated to an even higher level to control the spread of infection. In these settings, hands-free operation is often not just a best practice but a mandatory requirement to prevent pathogens from spreading via contaminated faucet handles. Sinks in these facilities frequently utilize foot pedals, knee-operated valves, or electronic sensor faucets to completely eliminate the need for physical contact.

ADA compliance is another critical consideration for any sink accessible to the public or employees. The Americans with Disabilities Act (ADA) sets forth specific, enforceable standards for accessibility. These include a maximum sink rim height of 34 inches from the finished floor, adequate knee and toe clearance underneath to accommodate wheelchair users, and faucet controls that are operable with one hand without tight grasping, pinching, or twisting. For highly specialized medical applications, such as surgical scrub sinks, facilities must adhere to even more detailed specifications, like those outlined by professional organizations such as the American Society of Plumbing Engineers (ASPE).

Specialized Sinks for Bars and Utility Areas

Different commercial spaces require uniquely designed sink solutions to maximize their specific functions. Underbar sinks are engineered for maximum efficiency within the confined spaces of a bar. These compact units often feature multiple small compartments for washing, rinsing, and sanitizing glassware, and may integrate other features like glass rinsers, speed rails for bottles, and built-in insulated ice bins.

Mop basins and utility sinks are the unsung heroes that support a facility's overall cleanliness. They are built for extreme durability and function over form. These sinks are typically constructed from heavy-gauge (16-gauge or thicker) stainless steel to withstand the harsh chemicals used in cleaning and the physical abuse of filling and emptying heavy mop buckets. They feature deep basins and often include tall backsplashes to protect walls from splashes.

Contact us today to discuss your specific sink requirements! Our team understands the unique challenges each industry faces and can guide you to the perfect solution that meets your operational needs, budget, and regulatory obligations.

Vetting Your Commercial Sink Suppliers: A Buyer's Checklist

The relationship you build with your commercial sink suppliers can have a profound and lasting impact on your kitchen's operational success. A superior supplier transcends the role of a mere vendor and acts as a genuine partner, offering invaluable expertise and robust support long after the initial sale is complete. At The Restaurant Warehouse, we have structured our entire business around the principles of transparency and partnership, empowering you to invest in sink systems that will serve your business reliably for years to come.

What to Look for in a Top-Tier Supplier

When you begin the process of evaluating potential suppliers, it's essential to focus on these key indicators. They will help you distinguish the true professionals from the transactional order-takers:

- Genuine Wholesale Pricing: A trustworthy supplier is completely transparent about their pricing structure. Look for suppliers who offer genuine wholesale rates without the burdensome commissions and high retail overhead that artificially inflate costs. We founded our business on this direct-to-consumer wholesale model, passing the savings directly to you.

- Extensive Product Variety and Inventory: A comprehensive inventory is a clear sign of a supplier's commitment to the industry and their ability to meet all your potential needs. You should not have to compromise on the perfect configuration or be forced to shop at multiple vendors to assemble a complete and functional warewashing or prep station.

- Commitment to NSF-Certified Products: Top-tier suppliers have a deep understanding of health codes and prioritize offering a wide range of NSF-certified sink solutions. For our business, NSF certification is a baseline requirement for the sink units we carry, not an optional or premium upgrade. This ensures you are positioned for compliance from day one.

- Knowledgeable and Accessible Customer Service: Can the supplier's representative clearly articulate the practical differences between 16-gauge and 18-gauge steel? Do they understand the specific health code requirements in your local jurisdiction? Expert guidance is an invaluable part of the purchasing process and can save you from making costly mistakes that lead to failed inspections or inefficient workflows.

- Solid Warranties and National Shipping Capabilities: A clear, straightforward warranty and a fair return policy are your protection for this significant investment. Furthermore, reliable and affordable national shipping is crucial for businesses planning to expand to new locations or those looking to standardize sink models across a multi-unit franchise.

- After-Sales Support: What happens after the delivery truck leaves? A great supplier can provide support by helping you source replacement parts, offering maintenance advice, and being available to answer questions that arise during installation and use. This long-term support is a hallmark of a true partner.

Navigating Price and Installation Costs

The total cost of ownership for a commercial sink extends well beyond the initial sticker price. Astute buyers consider several interconnected factors to calculate the true long-term value:

- Material and Gauge: Higher-quality materials like Type 304 stainless steel and thicker gauges (such as 14 or 16-gauge) command a higher upfront cost. However, they offer vastly superior durability, corrosion resistance, and a more professional appearance, which easily justifies the initial investment in high-volume or demanding settings.

- Size and Configuration: Naturally, larger and more complex sinks with multiple compartments and dual drainboards will cost more. However, the efficiency gains realized from a properly sized and configured sink system often offset this price difference through improved workflow, reduced labor costs, and faster turnover.

- Installation: Always budget for the cost of a licensed and insured plumber. This is a non-negotiable expense that ensures your sink is installed correctly, meets all local plumbing and health codes, and avoids the risk of leaks, damage, and other expensive future repairs.

For operations on a tighter budget, high-quality used sink units can be a viable alternative. Our detailed guide on Quality Second-Hand Catering Sinks explores the pros and cons of this option.

The Future of Sink Technology

The industry is in a constant state of evolution. Keep an eye on emerging trends like integrated workstation sinks, which feature built-in ledges for accessories like cutting boards and colanders to maximize efficiency in compact spaces. Additionally, water conservation features like low-flow aerators and sensor-activated faucets are becoming increasingly important for reducing utility costs and promoting sustainability. Staying informed about these innovations helps you make a forward-thinking investment.

Ready to upgrade your operation with the right commercial sink solution? Contact us today to discuss your specific requirements.

Your Guide to Installation, Maintenance, and Compliance

The true value of a commercial sink is realized not at the moment of purchase, but over years of reliable service. Professional installation, diligent and correct maintenance, and a steadfast commitment to regulatory compliance are the three pillars that support a long-lasting and successful investment. The best commercial sink suppliers understand this and provide crucial guidance on these post-purchase aspects, ensuring your sink system serves you effectively for its entire lifespan.

Installation Essentials: Getting It Right the First Time

A commercial sink is only as good as its installation. This is a task that should never be treated as a DIY project. The risks of improper installation are simply too high.

- Hire a Licensed Plumber: This is the single most important step in the installation process. A licensed professional possesses an expert understanding of local plumbing and health codes, ensuring that all water supply and drainage connections are watertight, secure, and fully compliant. An improper installation can lead to catastrophic leaks, hidden structural damage, failed health inspections, and the voiding of your manufacturer's warranty.

- Pre-Installation Checklist: Before the plumber arrives, take these steps: meticulously measure the installation space, ensuring at least a few inches of clearance on all sides. Verify the location and condition of your hot and cold water supply lines. Check that the floor is level; if not, the sink's adjustable feet will be critical. Confirm that your wall structure can support a heavy, water-filled, wall-mounted sink if you've chosen one.

- Proper Mounting and Drainage: The sink must be installed so it is perfectly level from side to side and front to back. This ensures proper drainage and prevents water from pooling in the corners, which can become a breeding ground for bacteria. Wall-mounted units require robust anchoring directly into wall studs or reinforced backing. All drain plumbing must be installed with the correct downward slope (typically ¼ inch per foot) to prevent clogs, backups, and foul odors.

- Water Supply and Faucet Connections: Your plumbing installation must provide adequate water pressure to your chosen faucet and meet the hot water temperature requirements mandated by your local health department for washing and sanitizing (often 110°F or higher at the tap). The faucet holes on the sink's deck or backsplash (e.g., 4-inch or 8-inch centers) must precisely match the faucet you have selected.

Long-Term Care for Your Stainless Steel Investment

With a consistent and proper care regimen, a high-quality stainless steel sink can easily last for decades.

- Daily Cleaning Routine: At the end of each day, clean the sink using a mild detergent and warm water applied with a soft cloth or sponge. Crucially, always wipe in the direction of the steel's visible grain lines to avoid creating micro-scratches that can dull the finish. After cleaning, rinse the entire surface thoroughly with clean water and dry it completely with a soft towel to prevent water spots and mineral deposits.

- Avoid Harsh Chemicals and Abrasives: Never use abrasive cleaners (like Comet), steel wool, scouring pads, or chlorine bleach on your stainless steel sink. These items can scratch the surface and, more importantly, can strip away the passive chromium oxide layer that protects the steel from rust and corrosion. If you use chemical sanitizers, ensure they are specifically approved for use on stainless steel and are diluted to the correct concentration as per the manufacturer's instructions.

- Routine Inspections and Preventative Maintenance: On a weekly basis, perform a quick visual inspection for any leaks under the sink, around faucet connections, and at drain fittings. Ensure that drain strainers are always in place and are cleaned out frequently throughout the day to prevent clogs from food debris, grease, and other solids. Our Catering Hand Wash Sink Buying Guide offers more detailed tips on maintaining impeccable hygiene.

Understanding Health Codes and ADA Compliance

Adherence to public health and accessibility codes is not optional; it is a legal requirement for operation.

- Health Department Requirements: Your local health department dictates the required number, type, and placement of sinks in your facility. Their codes specify minimum hot water temperatures, require specific features like air gaps in drain lines to prevent backflow contamination, and almost universally mandate that food-contact sinks be NSF certified.

- ADA Accessibility Standards: The Americans with Disabilities Act (ADA) sets clear standards for sinks in public-facing areas and employee-accessible restrooms. This includes a maximum sink rim height of 34 inches from the floor, specified knee and toe clearance underneath for wheelchair access, and faucet controls that are operable with one hand, require less than 5 lbs of force, and do not require tight grasping.

Proactive planning and a thorough understanding of these rules are key to passing inspections without issue. Our practical guide on Using a 3-Tier Sink provides actionable compliance tips for restaurant operations.

Frequently Asked Questions about Commercial Sinks

When shopping for a major component like a sink, many questions naturally arise. Getting clear, accurate answers from potential commercial sink suppliers is essential, as these details can be the difference between a sink that serves you well for a decade and one that causes constant headaches. Here are detailed answers to the most common inquiries we receive.

What is the best gauge for a commercial stainless steel sink?

The ideal gauge for your sink depends entirely on its intended application and the intensity of use it will face. Gauge numbers work in reverse—the lower the number, the thicker, heavier, and more durable the steel.

- 16-Gauge: This is widely considered the industry standard and the "sweet spot" for most busy commercial kitchens. It is thick and robust enough to withstand the daily impact of heavy pots, pans, and general use, offering an excellent long-term value by balancing durability and cost.

- 18-Gauge: As a thinner and more economical option, 18-gauge steel is perfectly suitable for lighter-duty applications. It is a common and appropriate choice for hand wash sinks, bar sinks, or food prep sinks in lower-volume operations where the risk of heavy impact is minimal.

- 14-Gauge: This is the premium, heavy-duty choice reserved for the most demanding, high-volume environments. You'll find 14-gauge sinks in institutional kitchens, busy hotel pot-washing stations, and processing plants. While it costs more upfront, it provides the maximum possible longevity and resistance to dents, dings, and warping under extreme conditions.

When making your choice, perform an honest assessment of your kitchen's daily volume and the type of work the sink will endure. This will help you balance the upfront cost with the long-term return on investment.

Why is a three-compartment sink required in most restaurants?

The three-compartment sink is the bedrock of food safety protocols and is mandated by nearly all U.S. health departments to prevent the spread of foodborne illness. It provides the necessary separation to correctly perform the wash-rinse-sanitize process, which is the systematic, approved method for manual dishwashing.

- Wash: In the first basin, items are scrubbed in hot water (at least 110°F) mixed with a commercial detergent to remove all visible food particles and grease.

- Rinse: In the second basin, the washed items are submerged in clean, warm, and clear water to completely remove all soap residue and lingering debris.

- Sanitize: In the third basin, the rinsed items are submerged for a specific contact time (usually 30-60 seconds) in either a chemical sanitizer solution mixed to the proper concentration or, less commonly, in water heated to at least 171°F to effectively kill any remaining bacteria and pathogens.

This strict separation of steps is critical to preventing cross-contamination. Even if your establishment uses a commercial dishwasher, health codes almost always require a three-compartment sink to be present as a backup and for washing large items like stockpots and sheet pans that won't fit in the machine. Our detailed guide on Using a 3-Tier Sink breaks down this essential process step-by-step.

What is the difference between 304 and 430 series stainless steel?

This is an excellent question that gets to the heart of sink quality. The difference lies in the metal's composition, which affects its corrosion resistance and cost. 304-series stainless steel contains approximately 18% chromium and 8% nickel. The nickel content is key, as it significantly enhances the steel's resistance to rust and corrosion, especially from salts and acidic substances. This makes it the superior choice for any food-contact surface. 430-series stainless steel, by contrast, contains a similar amount of chromium but has virtually no nickel. This makes it less expensive but also more susceptible to rust and pitting over time, particularly in wet environments. While 430-series can be acceptable for external paneling or very light-duty, dry applications, 304-series is the recommended standard for sink bowls and drainboards.

Can I install a commercial sink myself?

While the temptation to save on labor costs by performing a DIY installation is understandable, it is strongly discouraged for commercial applications. We always recommend hiring a licensed and insured plumber for several critical reasons:

- Code Compliance: A professional plumber is an expert on local plumbing and health codes. They will ensure your installation, including trap placement, venting, and backflow prevention, will pass inspection the first time, saving you from costly fines and delays.

- Risk of Catastrophic Damage: An improper connection can lead to slow leaks that cause hidden mold and rot, or a catastrophic failure that floods your kitchen. These types of water damage can be incredibly expensive to repair and may not be covered by your business insurance if the work was not done by a licensed professional.

- Health and Safety Hazards: Incorrect drainage slopes can lead to clogs and backups, while missing backflow prevention devices (like an air gap) can create a scenario where contaminated water from the drain system siphons back into your clean sink, posing a severe health hazard that could lead to immediate closure by a health inspector.

- Warranty Protection: Nearly all manufacturers' warranties for commercial sinks are rendered void if the unit is not installed by a licensed professional.

The fee for a professional plumber is a small but essential investment for the safety, compliance, and peace of mind that comes with a reliable, correctly installed sink system.

Ready to find the perfect commercial sink? Contact us today, and our team can help you navigate the options and make a confident choice.

Conclusion: Your Partner for Compliant and Efficient Sink Solutions

Choosing the right commercial sink is not merely about selecting a shiny piece of stainless steel; it is a strategic investment in the safety, efficiency, and compliance of your entire operation. A well-chosen sink system, sourced from a reliable supplier, becomes a silent workhorse that underpins your success for years to come. Throughout this comprehensive guide, we have delved into the critical considerations that separate a satisfactory purchase from a truly great one—from understanding the nuanced differences between 16-gauge and 18-gauge steel to appreciating why a three-compartment sink is your staunchest ally in maintaining health code compliance.

The enduring value of a quality commercial sink is found in its robust simplicity and unwavering reliability. When you take the time to select the appropriate bowl configuration for your workflow, choose the proper steel gauge for your volume, and partner with knowledgeable commercial sink suppliers, you are laying a solid foundation for operational excellence. The right sink seamlessly integrates into your daily routine, becoming an invisible and indispensable component that simply gets the job done without fuss or failure.

What truly distinguishes an exceptional supplier relationship is the value provided beyond the product itself. The best commercial sink suppliers do not see their job as complete once they ship you a product. They act as consultants, helping you navigate complex NSF certification requirements, understand the intricacies of local health codes, and select features that deliver a tangible return on investment for your specific workflow. They are partners in your compliance and efficiency.

At The Restaurant Warehouse, we have built our entire reputation on being that kind of dedicated partner. We deliberately reject the high commissions and inflated retail markups that drive up prices at other distributors. Instead, we focus on a transparent wholesale pricing model that respects your budget and makes sense for your bottom line. Our philosophy is straightforward: provide superior commercial sink solutions at fair, honest prices, backed by the expert guidance you need to make the right choice the first time.

Your choice of a sink and supplier impacts everything from the speed of your daily cleaning tasks and the morale of your staff to the outcome of health department inspections. A well-chosen sink from a dependable supplier is one of those crucial foundational purchases you will never have to second-guess—it simply works, day in and day out.

Ready to find the perfect commercial sink for your operation? Don't let the vast number of options overwhelm you. Our expert team at The Restaurant Warehouse is here to help you cut through the confusion and find the ideal solution. Explore our complete collection of commercial sinks for restaurants made simple to discover sink packages that combine quality, compliance, and unbeatable value.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment