The Ultimate Guide to Commercial Sinks for Restaurants

Nothing makes a restaurant owner’s heart beat faster than an unexpected visit from the health inspector. As they walk through your kitchen with their clipboard, one of the first areas they scrutinize is your warewashing station. They’re looking for a specific setup: a proper three-compartment system, correctly placed hand sinks, and proof of sanitation. The right commercial sinks for restaurants are your first line of defense against violations and fines. They are a non-negotiable part of a compliant kitchen. This guide will walk you through exactly what you need to know to choose a sink system that keeps your operation running smoothly and the health inspector happy.

How the Right Sink Can Make or Break Your Restaurant

Commercial sinks for restaurants are the backbone of every successful kitchen operation. Without the right sink setup, you can't maintain food safety standards, pass health inspections, or handle the daily demands of a busy restaurant.

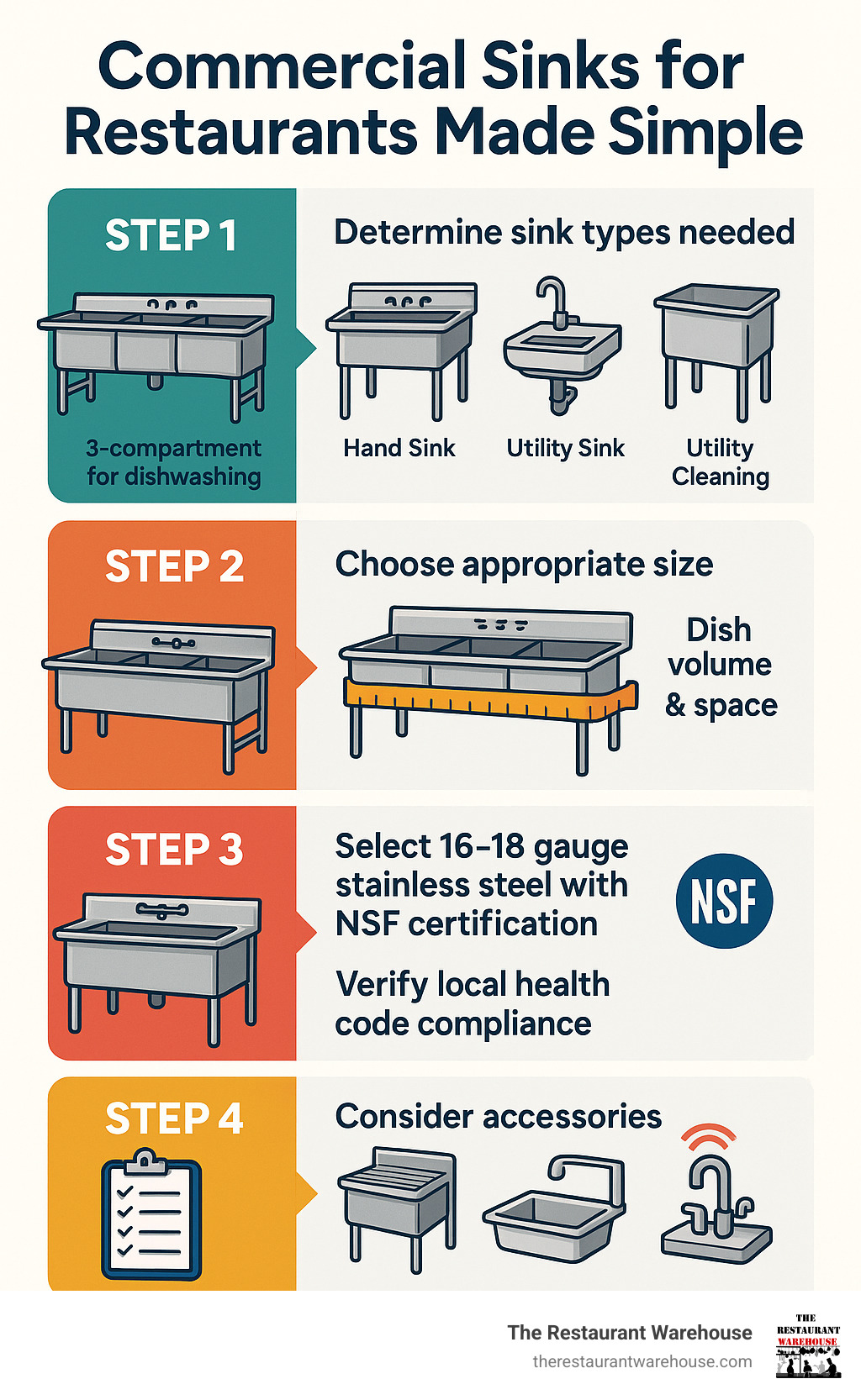

Quick Answer for Restaurant Owners: - 3-compartment sinks are required by most health codes for wash-rinse-sanitize procedures - Hand sinks must be placed in all food prep areas to prevent cross-contamination

- Stainless steel construction (16-18 gauge) offers durability and easy cleaning - Price range: $150-$1,500 depending on size and features - NSF certification ensures compliance with sanitation standards

Over 90% of commercial sinks are made from stainless steel because of its non-porous surface that prevents bacterial growth. For budget-conscious restaurant owners, choosing the right commercial sink isn't just about meeting health codes - it's about creating an efficient workflow that saves time and money.

Commercial sinks for restaurants terminology: - commercial kitchen stainless steel tables - heavy duty kitchen equipment - restaurant equipment wholesale

Getting to Know Your Commercial Sink Options

Commercial sinks for restaurants are built to handle the relentless demands of professional kitchens, where dishes pile up faster than you can say "dinner rush."

The heart of every commercial kitchen revolves around warewashing - the wash-rinse-sanitize process that keeps dishes clean and health inspectors happy. Most commercial sinks for restaurants come with 1-3 compartments, but three-compartment sinks are usually required by health codes.

Stainless steel dominates over 90% of professional kitchens because its non-porous surface prevents bacterial growth. These sinks are built for durability that can withstand decades of use. Modern designs also include water-efficient features like pre-rinse spray valves.

Why a Residential Sink Just Won’t Cut It

Cross-contamination prevention requires proper sink setup. Health codes mandate separate hand sinks in food prep areas to prevent staff from washing hands where they clean dirty equipment.

Your kitchen's workflow depends on smart sink placement. Dishes should flow smoothly from dining room through wash, rinse, and sanitize stations to clean storage. Poor positioning creates kitchen traffic jams.

Compliance keeps your doors open. Health inspectors look for proper three-compartment setups and correctly placed hand sinks. Violations can result in fines or temporary shutdowns.

Talking the Talk: A Quick Guide to Sink Lingo

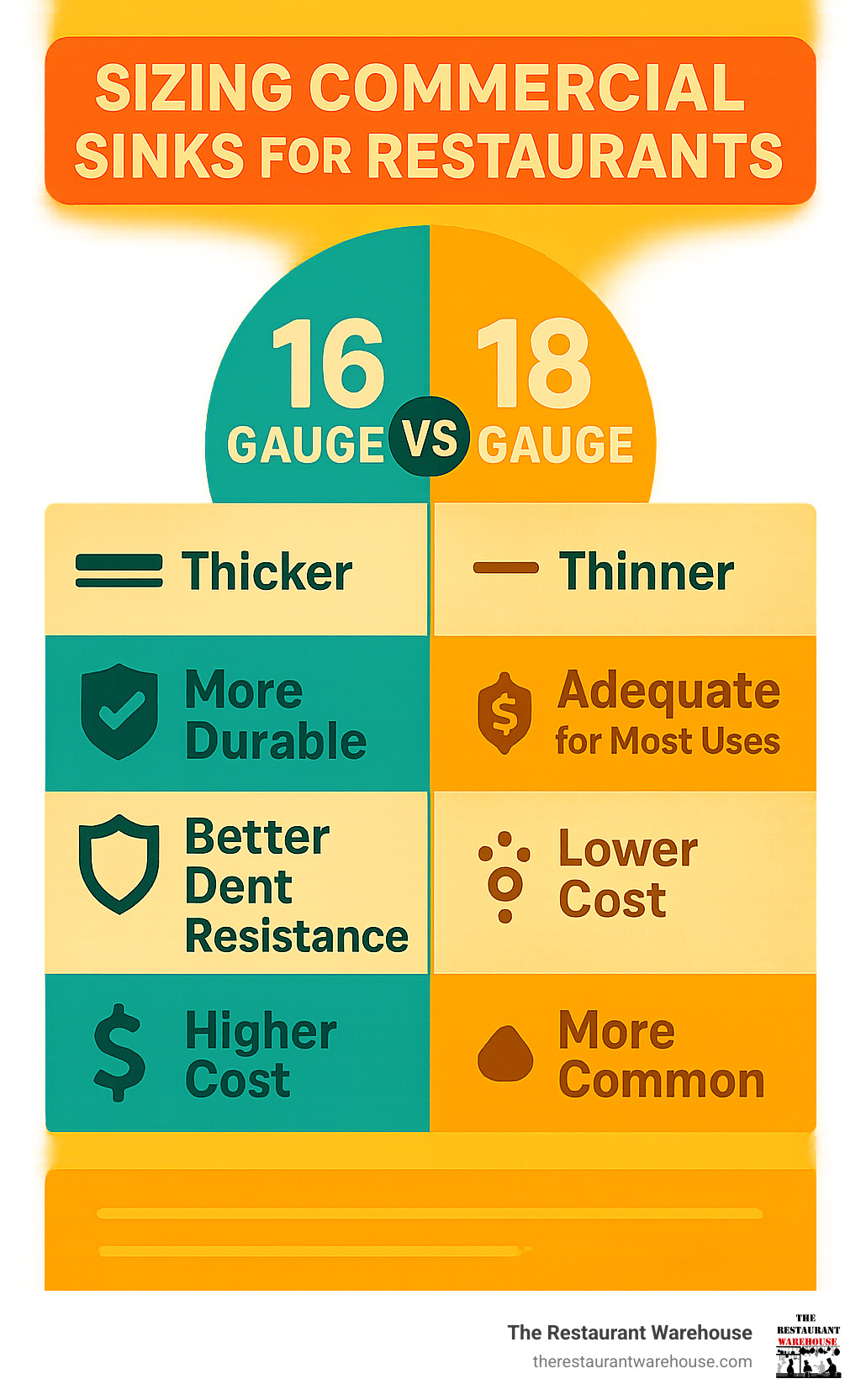

Gauge indicates steel thickness - lower numbers mean thicker, stronger steel. Most commercial sinks use 16 or 18 gauge stainless steel, with 16 gauge being more dent-resistant for high-volume kitchens.

Type 304 stainless steel is the industry standard, containing 18% chromium and 8% nickel for optimal corrosion resistance and food-safe properties.

NSF certification ensures the sink meets sanitation and health code requirements - your insurance for passing inspections.

The backsplash prevents water splashing, typically 6-8 inches high with pre-punched faucet holes. Drainboards provide 16-24 inches of drying space beside sink bowls.

Which Commercial Sink Type Does Your Restaurant Need?

Choosing the right commercial sinks for restaurants means matching each sink type to its specific job. Your kitchen has different "zones" - dishwashing areas need compartment sinks, prep areas require hand sinks, and cleaning areas need utility sinks.

The Workhorse: Compartment Sinks for Dishwashing

Compartment sinks handle your wash-rinse-sanitize routine that health codes demand. The 3-compartment setup works for most restaurants: first compartment washes with hot water (110°F minimum) and detergent, second compartment rinses with clean hot water, third compartment sanitizes with 171°F water or chemical solution.

Bowl size matters - standard dimensions range from 18" x 18" for smaller operations to 24" x 24" for high-volume restaurants. Depth usually runs 12-14 inches to accommodate large pots and pans.

For mobile operations, check our Food Truck Sinks Guide for compact solutions.

Four-Compartment Sinks for High-Volume Kitchens

In a bustling kitchen, keeping up with the mountain of dirty dishes can feel like a constant challenge. While a three-compartment sink is the standard for the essential wash-rinse-sanitize routine, high-volume restaurants often need an extra edge. This is where a four-compartment sink becomes a game-changer. That fourth basin provides much-needed flexibility, serving as a dedicated space for pre-soaking stubborn pots and pans or as an additional rinsing area. This setup prevents bottlenecks during peak service, ensuring your dishwashing station runs smoothly and your team isn't held back by a sink that can't keep up.

Like their three-compartment counterparts, these sinks are built to last. They are typically made from durable stainless steel, a material found in over 90% of commercial kitchens because its non-porous surface is easy to clean and resists bacteria. Bowl sizes are also designed for professional use, with common dimensions from 18" x 18" to 24" x 24" and depths of 12-14 inches, perfect for handling everything from stacks of plates to large stockpots. Investing in the right size and type of sink is a crucial step in outfitting your kitchen for success. You can explore a wide range of restaurant equipment to find the perfect fit for your operational needs and budget.

Hand & Prep Sinks: Your First Line of Defense for Food Safety

Hand sinks are mandatory in all food prep areas and must be separate from warewashing sinks. Health codes typically require them within 25 feet of prep areas.

Convenient placement encourages frequent handwashing. Touchless faucets eliminate contamination from dirty handles. ADA compliance ensures proper height and clearance for all employees.

Prep sinks provide handwashing spots while handling food prep tasks like washing vegetables. Our Handwash Sink Guide covers specifications and placement strategies.

The Unsung Heroes: Utility & Mop Sinks

Utility sinks and mop sinks handle heavy-duty cleaning tasks separate from food areas. Mop sinks use floor mount installation with tall sides for standard tall buckets.

Utility sinks serve as problem-solvers for oversized equipment and non-food cleaning tasks. They need easy access for cleaning staff while staying separate from food prep areas.

Look for reinforced construction that withstands harsh cleaning chemicals. Our Restaurant Mop Sink Guide covers installation and sizing considerations.

Specialty Sinks for Specific Tasks

Beyond the essential compartment and hand sinks, a range of specialty sinks can solve unique challenges in your kitchen. Think of these as specialized tools designed for one particular job, but they do that job exceptionally well. Integrating the right specialty sink can streamline a specific workflow, save precious space, and make a noticeable difference in your team's daily efficiency. When you're outfitting your kitchen with everything from refrigerators to sinks, considering these options can help you find the perfect piece of restaurant equipment to fill a specific need, ensuring every part of your operation runs as smoothly as possible.

Underbar Sinks for Tight Spaces

When every inch of counter space is prime real estate, an underbar sink is a lifesaver. Designed to fit neatly beneath a standard bar or countertop, these compact sinks are perfect for bars, coffee shops, and concession stands. They provide a convenient spot for bartenders or baristas to rinse glasses, shakers, and other small tools without having to leave their station. This keeps the workflow moving and prevents traffic jams behind the bar, making service faster and more efficient for everyone.

Workstation Sinks for Food Prep Efficiency

Imagine a sink that doubles as a complete prep area. That's the idea behind a workstation sink. These are cleverly designed for busy kitchens and often come with integrated accessories like cutting boards, colanders, and drying racks that slide right over the sink basin. This turns a single fixture into a multi-functional hub for chopping vegetables, rinsing produce, and staging ingredients, all in one contained space. It’s an excellent way to maximize productivity, especially in kitchens where counter space is limited.

Farmhouse Sinks for Large Pots and Pans

If your kitchen regularly deals with oversized stockpots, baking sheets, and bulky pans, a farmhouse sink is a game-changer. Also known as apron-front sinks, they feature a wide, deep single basin with an exposed front. This ergonomic design makes it much easier to wash large, heavy items without awkwardly maneuvering them into a standard sink compartment. They are a practical and durable choice for bakeries, catering kitchens, and any operation that relies on large-batch cooking.

Portable Sinks for Events and Catering

For businesses on the move, a portable sink provides essential flexibility. These self-contained units are ideal for caterers, food trucks, and outdoor events where permanent plumbing isn't available. They allow you to set up a fully compliant handwashing or utensil-rinsing station anywhere you need one, ensuring you can meet health and safety standards no matter the location. This freedom makes it possible to operate professionally and hygienically in a variety of settings, from farmers' markets to private parties.

Dipper Wells for Quick Rinsing

In a fast-paced environment like an ice cream parlor, smoothie bar, or coffee shop, a dipper well is an indispensable tool. This small, continuously flowing water basin is used for quickly rinsing utensils like ice cream scoops, spoons, and blenders between uses. It prevents cross-contamination and flavor transfer while keeping essential tools clean and ready for immediate action. By providing a constant stream of fresh water, a dipper well helps maintain a rapid pace of service without compromising on hygiene.

Your Sink Buying Guide: Size, Material, and Features

Picking the perfect commercial sinks for restaurants means balancing space constraints, daily operations, and budget. Measure your space carefully and ensure bowl dimensions handle your largest equipment while fitting through doorways.

16 gauge steel is thicker and more durable for high-volume operations, while 18 gauge works well for most restaurants at a lower cost. Features like drainboards create valuable drying space but require more room.

| Feature | 16 Gauge Steel | 18 Gauge Steel |

|---|---|---|

| Thickness | Thicker, more durable | Standard thickness |

| Dent Resistance | Superior | Good |

| Cost | Higher initial investment | More budget-friendly |

| Best For | High-volume operations | Most restaurant applications |

Finding the Right Fit: A Guide to Sink Sizing

Understand your peak dishwashing volume during busy periods. Bowl dimensions matter - that 18" x 18" bowl might look adequate until you try washing a full-size sheet pan. Standard depths of 12-14 inches work for most operations.

Check local health department requirements for minimum bowl dimensions based on your restaurant type. Size slightly up if you're uncertain - replacing undersized sinks later is expensive and disruptive.

Understanding Bowl Configurations

Compartment sinks are designed to handle the wash-rinse-sanitize routine that health codes demand. For most restaurants, the 3-compartment setup is the standard. The first compartment is for washing with detergent and hot water (at least 110°F), the second is for rinsing with clean hot water, and the third is for sanitizing with either 171°F water or a chemical solution. Bowl size is just as critical. Standard dimensions range from 18" x 18" for smaller operations to 24" x 24" for high-volume restaurants. A depth of 12-14 inches is typical to accommodate large pots and pans, preventing overflow and ensuring your team can work efficiently without creating a bottleneck at the wash station. When you shop restaurant equipment, consider the largest items you'll need to wash regularly.

Planning for Faucet and Accessory Holes

Beyond the bowls themselves, you need to plan for faucets and other features. Most commercial sinks include a backsplash, typically 6-8 inches high, to prevent water from splashing onto the wall. These usually come with pre-punched holes, making faucet installation straightforward. Another key feature to consider is a drainboard. Drainboards create valuable drying space right next to your sink, but they also add to the unit's overall footprint. Before you commit, measure your available space carefully. Think about how a sink with one or two drainboards will fit into your kitchen's layout alongside other essential equipment like refrigerators and prep tables to ensure a smooth and logical workflow.

Stainless Steel: The Pro's Choice for a Reason

Type 304 stainless steel earned its reputation through decades of proving itself in tough commercial environments. Its non-porous surface prevents bacterial growth, while chromium content creates protective layers against corrosion.

That 90% market share didn't happen by accident - restaurant owners choose what works reliably. Maintenance is straightforward with regular cleaning using proper commercial cleaners. The heat resistance handles boiling water and temperature swings without warping or losing sanitary properties.

Decoding Steel Gauge: 16, 18, and 20

When you see numbers like 16, 18, or 20 gauge, it’s simply referring to the thickness of the stainless steel. It’s a little counterintuitive, but the lower the number, the thicker and stronger the steel. For a busy commercial kitchen, you’ll typically be choosing between 16 and 18 gauge. A 16-gauge sink is the more robust option, offering superior resistance to dents from heavy pots and pans, making it ideal for high-volume dish pits. An 18-gauge sink is still very durable and is a cost-effective choice that works perfectly for most standard restaurant applications. The industry standard material you'll want to look for is Type 304 stainless steel, which has the right mix of chromium and nickel to fight corrosion and keep things food-safe. You can learn more about steel to make the best choice for your kitchen's needs.

Exploring Other Sink Materials

While stainless steel reigns supreme in the back of the house, it’s not the only material available. For certain applications, especially in areas visible to customers like a bar or an open-concept kitchen, other materials can provide a specific aesthetic without sacrificing durability. These alternatives can introduce different colors, textures, and styles to complement your restaurant's design. They might not be right for your main warewashing station, but they can be excellent choices for handwashing sinks, bar sinks, or low-volume prep areas where appearance is just as important as function. Exploring these options can help you find the perfect piece to complete your space. Take a look at the full shop of restaurant equipment to see how different materials can fit into your kitchen's design.

Fireclay

Fireclay sinks are crafted from a special clay that’s fired at extremely high temperatures, fusing the clay and glaze together to create a material that’s incredibly hard and durable. This process results in a smooth, non-porous surface that’s highly resistant to chips, scratches, and acids. You’ll often see fireclay in classic white farmhouse-style sinks, which can bring a warm, rustic charm to a cafe, bakery, or any restaurant with a homey vibe. Their resilience makes them tough enough for commercial use, while their clean aesthetic provides a stylish alternative to standard metal finishes, especially in open kitchens or customer-facing areas.

Granite or Quartz Composite

If you’re looking for modern durability, granite or quartz composite sinks are a fantastic option. These sinks are made by combining crushed granite or quartz with a strong resin binder, resulting in a material that is exceptionally tough. They are highly resistant to scratches, stains, and heat, making them a practical choice for busy prep areas. One of the biggest advantages of composite sinks is the wide range of available colors, from natural stone tones to bold black finishes. This allows you to match your sink to your countertops or overall design scheme, offering a level of customization that stainless steel can’t match.

Copper

Copper sinks make a bold statement and bring a unique warmth and character to any space. Beyond their stunning appearance, copper sinks are highly durable, don't rust, and are surprisingly low-maintenance. Over time, they develop a beautiful, one-of-a-kind patina, an "aged" look that adds to their charm. Perhaps their most impressive feature is that they are naturally antimicrobial, meaning the surface actively kills bacteria and viruses, which is a huge plus in any food service environment. This combination of beauty and hygienic functionality makes a copper sink an excellent choice for a front-of-house bar or a specialty prep station.

Cast Iron

Cast iron sinks are true classics, known for their incredible longevity and timeless appeal. They are constructed from a solid cast iron base coated with a thick layer of tough porcelain enamel. This creates a glossy, glass-like finish that is non-porous, stain-resistant, and exceptionally easy to clean. While the enamel is very durable, it can chip if something heavy is dropped on it. The main thing to keep in mind with cast iron is its weight; these sinks are extremely heavy and require sturdy countertop support and careful installation, often needing two people. They are a great choice for those wanting a traditional look with proven durability.

Installation and Sanitation: Getting It Right from Day One

Getting your commercial sinks for restaurants installed correctly creates a system that keeps your kitchen running smoothly and health inspectors happy.

NSF certification should be your starting point - it means equipment has been tested for sanitation and safety standards. The three-compartment rule forms the backbone of health codes, requiring separate spaces for washing, rinsing, and sanitizing.

Hand sink placement requires careful planning with easy access to food prep staff. ADA compliance matters for employee areas, and backflow preventers protect your water supply.

Choosing the Right Installation Style

How your sink connects to the countertop isn't just about looks; it impacts your daily cleaning routine and long-term maintenance. The two most common styles in commercial settings are drop-in and undermount, and each has its own set of benefits depending on your kitchen's design and countertop material. While the freestanding three-compartment sinks are a non-negotiable staple in most kitchens, you will likely also need sinks integrated into your prep counters. Understanding the difference between these installation styles is key to making a choice that supports your workflow and keeps your kitchen clean and functional for years to come.

Drop-In (Top-Mount) Sinks

Drop-in sinks, also known as top-mount, are the most popular type for a reason. As the name suggests, they simply "drop" into a pre-cut hole in your countertop, and their weight is supported by the visible rim that rests on top. This straightforward design makes them incredibly easy to install and, if ever needed, replace without having to overhaul your entire counter or plumbing setup. If you're looking for a functional, durable, and budget-friendly option, the drop-in style is a solid choice. It's a practical solution that works with almost any countertop material, making it a versatile player in any kitchen design.

Undermount Sinks

For a seamless and modern look, an undermount sink is an excellent choice. These sinks are installed from *under* the counter, creating a smooth, continuous surface from the countertop directly into the sink basin. This design isn't just about aesthetics; it's also a big win for sanitation. With no rim or lip on the counter to catch grime, you can wipe crumbs and spills directly into the sink, making cleanup faster and more effective. Undermount sinks are best suited for solid surface countertops like granite, quartz, or stainless steel that can support the sink's weight without needing the top lip for reinforcement.

Designing for an Efficient Workflow

A well-designed kitchen is all about flow. Your sink placement is central to creating an efficient system that prevents traffic jams and keeps your team moving. Think about the journey a dirty dish takes: it should move logically from the dining room to a scraping area, then through the wash, rinse, and sanitize stations of your compartment sink, and finally to a drying rack or clean storage. Poor positioning can create chaos during a busy service. When you shop restaurant equipment, always consider how each piece will fit into this larger operational puzzle to support a smooth and productive environment.

Strategic Dishwasher Placement

Your kitchen's workflow depends heavily on smart sink placement, especially in relation to your commercial dishwasher. The ideal setup allows dishes to flow smoothly from the dining room, through the wash, rinse, and sanitize stations, and then directly to the dishwasher or clean storage area. Placing your three-compartment sink right next to your dishmachine minimizes the steps your staff has to take, which reduces the risk of drops and saves valuable time during a hectic shift. This logical layout prevents kitchen traffic jams and ensures that clean and dirty dishes have separate, defined paths, which is crucial for maintaining sanitation standards.

The Importance of Professional Installation

Getting your commercial sinks installed correctly creates a system that keeps your kitchen running smoothly and health inspectors happy. While it might be tempting to handle it yourself to save money, this is one area where professional help is a wise investment. A licensed plumber will ensure all connections are secure, prevent costly leaks, and install crucial components like grease traps and backflow preventers according to local codes. Your starting point for any sink should be NSF certification, which confirms the equipment meets public health and safety standards. Proper installation brings it all together, ensuring your investment pays off for years. If you're budgeting for a kitchen overhaul, remember to factor in these costs; options like restaurant equipment financing can help manage the expense without compromising on quality.

Mastering the 3-Compartment Sink Method

The wash compartment needs water at least 110°F with proper detergent concentration. Rinsing uses clean hot water to remove detergent residue. Sanitizing requires either 171°F water or approved chemical sanitizers with proper concentration.

Air-drying is preferred after sanitizing because towel drying can recontaminate dishes. Temperature monitoring and test strips help verify proper procedures.

Are You Health Code Ready? A Sink Checklist

Signage requirements include handwashing reminders and dishwashing procedure charts. Soap dispensers must be available at every hand sink, preferably hands-free operation.

Splashguards protect surrounding areas and prevent cross-contamination. Accessible locations ensure your sink system gets used properly without creating safety hazards.

Our Commercial Kitchen Safety Checklist covers additional compliance requirements.

Beyond the Purchase: Maintenance, Accessories, and Costs

When investing in commercial sinks for restaurants, look beyond the sticker price. Real costs include daily maintenance, useful accessories, and long-term value.

Daily cleaning prevents buildup of grease, minerals, and bacteria. Descaling is essential in hard water areas to prevent clogs. The price range spans from $150 for basic hand sinks to $1,500 for large three-compartment systems.

Must-Have Accessories for a More Efficient Sink

Scrap baskets catch food particles before they reach drains, preventing expensive clogs during peak service. Drainboards provide workspace that extends beyond drying dishes to temporary staging areas.

Knee pedals and foot pedals enable hands-free operation, reducing cross-contamination while keeping hands free for handling dishes. Pre-rinse spray valves speed up dishwashing by blasting away stubborn food particles.

Considering All-in-One Sink Kits

Setting up a kitchen means outfitting different "zones" for specific tasks, from dishwashing to food prep. Instead of piecing everything together, consider an all-in-one sink kit. These packages bundle the sink with essential accessories like a compatible faucet, drainboards, and sometimes even scrap baskets. This approach saves you the headache of matching parts and ensures everything works together seamlessly from day one. For new restaurant owners or anyone undertaking a major kitchen renovation, these kits are a practical shortcut to a fully functional and compliant setup, letting you shop for equipment more efficiently.

Noise Reduction Features

A busy kitchen is loud enough without the extra clatter from your dish pit. While the durability of Type 304 stainless steel is a given, look for sinks that include sound-dampening features. Many quality commercial sinks have rubber pads or a special undercoating applied to the bottom and sides of the bowls. This simple addition absorbs vibrations from clanging pots, running water, and dropped utensils, significantly cutting down on noise. It’s a small detail that makes a huge difference in creating a less stressful and more productive work environment for your staff.

Rounded Corners for Easy Cleaning

Sharp, 90-degree corners inside a sink are a sanitation nightmare. They trap food debris and grease, making them difficult to clean and creating a perfect spot for bacteria to grow. To avoid this, always look for sinks with rounded or "coved" corners. As the source material suggests, smooth edges are key to preventing germ buildup. A rounded design allows your staff to wipe the entire basin clean with one smooth motion, ensuring no grime is left behind. This feature isn't just about convenience; it's a critical part of maintaining health standards and speeding up your closing routine.

What to Expect: Sink Costs and Shipping

Large sinks typically ship via truck freight due to size and weight. Curbside delivery is standard - plan for moving heavy sinks from street to installation location.

Assembly time varies from hours for simple sinks to days for complex systems. To make budgeting even easier, equipment financing plans are available to help spread out the cost of essential commercial sinks without delaying your opening. At The Restaurant Warehouse, we skip high commissions and retail overhead, providing wholesale pricing on quality equipment.

Our Commercial Kitchen Cleaning Tips guide helps maintain your sinks properly.

Frequently Asked Questions about Commercial Sinks

Do all restaurants need a 3-compartment sink?

Yes - most restaurants absolutely need a 3-compartment sink for proper warewashing procedures. Health departments require the wash-rinse-sanitize process that only a 3-compartment setup provides.

Few exceptions exist: coffee shops serving only pre-packaged items or juice bars using disposable cups might qualify for reduced requirements. However, even these operations need hand sinks wherever food handling occurs.

High-temperature commercial dishwashers can sometimes substitute for sanitizing, but you'll still need wash and rinse compartments for oversized items that won't fit in dishwashers.

How often should stainless steel sinks be deep-cleaned?

Daily cleaning with proper detergent and sanitizing is mandatory. Weekly deep cleaning includes descaling and drain line cleaning. Monthly maintenance should include professional drain cleaning and plumbing inspection.

Frequency depends on your situation - hard water areas need more descaling, while high-volume operations require more frequent attention.

What gauge of stainless steel is best for high-volume kitchens?

16 gauge stainless steel is best for high-volume kitchens. It's thicker and more durable, preventing denting from heavy equipment abuse.

18 gauge stainless steel works fine for moderate-volume operations and costs less upfront. The difference is significant in real-world durability - 16 gauge sinks often look great after decades, while 18 gauge may show wear sooner in busy operations.

Ready to Choose Your Commercial Sink?

Your journey to finding the perfect commercial sinks for restaurants doesn't have to be overwhelming. After years of helping restaurant owners steer these decisions, we've learned that the best choices come from understanding your specific needs rather than getting caught up in endless options.

The right sink setup is like having a reliable sous chef - it works quietly in the background, keeping your operation running smoothly while you focus on what matters most: serving great food to happy customers. When you choose quality equipment from the start, you're not just buying sinks - you're investing in peace of mind.

At The Restaurant Warehouse, we've built our reputation on a simple principle: restaurant owners deserve commercial-grade equipment without the commercial-grade markup. By cutting out the middlemen and avoiding those hefty retail overhead costs, we can offer you the same quality sinks you'd find elsewhere at prices that actually make sense for your bottom line.

Here's what successful restaurant owners consistently tell us matters most: 3-compartment sinks handle the heavy lifting of warewashing while keeping health inspectors happy, 16-18 gauge stainless steel construction stands up to whatever your kitchen throws at it, and NSF certification means you can sleep easy knowing you're compliant with health and safety standards.

The smart money is on proper sizing that gives your team room to work efficiently without wasting valuable kitchen real estate. And remember - strategic placement of hand sinks isn't just about following rules, it's about creating a kitchen culture where cleanliness becomes second nature.

Think of sink selection as setting up your kitchen's foundation. Get it right, and everything else flows smoothly. Your dishwashers work faster, your health inspections go smoother, and your maintenance headaches practically disappear. The investment in quality commercial sinks for restaurants pays for itself through improved efficiency, easier compliance, and years of reliable service.

Ready to make the smart choice for your restaurant? Our Restaurant Kitchen Equipment Checklist walks you through everything you need to create a kitchen that works as hard as you do.

Your restaurant deserves equipment that supports your success, not equipment that creates more problems. Make the upgrade today - your future self, your staff, and yes, even your health inspector will thank you for it.

Budgeting for Installation Costs

The price tag on the sink itself is just one part of the equation. Factoring in installation costs from the start will save you from budget surprises down the road. Getting your commercial sinks for restaurants installed correctly creates a system that keeps your kitchen running smoothly and health inspectors happy. Unless you have extensive plumbing experience, this is a job best left to a licensed professional. A pro will ensure your sink is properly sealed, connected to water and drainage lines, and compliant with all local codes. The cost can vary based on your location and the complexity of the job, but it’s a necessary investment for a safe and functional kitchen.

Keeping Your Sink in Top Condition

Your stainless steel sink is a workhorse, but it needs a little care to stay in prime condition. Consistent maintenance not only keeps it looking great but also prevents costly repairs and ensures you’re always ready for a health inspection. Daily cleaning prevents buildup of grease, minerals, and bacteria that can lead to stubborn stains and clogs. If your restaurant is in an area with hard water, regular descaling is essential to keep faucets and drains clear and water flowing freely. This simple routine protects your investment and extends the life of your sink significantly.

To clean your sink without causing damage, always use non-abrasive cleaners and soft cloths or sponges. Harsh chemicals and steel wool can scratch the stainless steel surface, creating tiny crevices where bacteria can hide. It’s also a good practice to regularly check faucets and plumbing connections for any drips or leaks. Catching a small leak early can prevent major water damage and expensive plumbing bills. A well-maintained sink is a cornerstone of a clean and efficient kitchen, helping your team work safely and effectively every single day.

A Simple Cleaning and Maintenance Schedule

Sticking to a consistent cleaning schedule is the easiest way to manage sink maintenance. Here’s a simple routine to follow:

- Daily: After each shift, clear all food debris from the sink and scrap baskets. Wash the sink bowls and drainboards with a suitable detergent, rinse thoroughly, and then apply a sanitizer according to health code guidelines. Always allow the sink to air dry.

- Weekly: Perform a deep clean. Use a non-abrasive cleaner to scrub away any buildup. This is also the perfect time for descaling faucets and cleaning out drain lines to prevent clogs.

- Monthly: Take a moment to inspect all plumbing connections for leaks. Check that faucets are working correctly and that water is draining properly.

Daily cleaning with proper detergent and sanitizing is mandatory for health code compliance, while weekly and monthly checks help you stay ahead of potential problems.

Financing Your Restaurant Sink

Outfitting a commercial kitchen with the right equipment is a major investment, and a high-quality sink system is no exception. Whether you're launching a new restaurant or upgrading an existing one, the upfront cost can be a significant hurdle. This is where financing can be a game-changer. Instead of draining your capital on a large one-time purchase, you can spread the cost over time with predictable monthly payments. This frees up your cash for other critical needs like payroll, inventory, and marketing, giving your business more financial flexibility.

To make budgeting even easier, equipment financing plans are available to help spread out the cost of essential commercial sinks without delaying your opening. Financing allows you to get the durable, compliant sink you truly need right now, rather than settling for a cheaper, less effective option that might cost you more in the long run. At The Restaurant Warehouse, we partner with financing companies to offer flexible plans tailored to your budget, so you can equip your kitchen with top-tier sinks and other essential restaurant equipment while keeping your cash flow healthy.

Key Takeaways

- Master Health Codes from Day One: Your sink system is non-negotiable for passing inspections. A three-compartment sink is essential for the wash-rinse-sanitize process, and dedicated hand sinks must be placed in all food prep areas to prevent costly violations.

- Choose Materials That Last: For a sink that can handle a busy kitchen, select durable 16 or 18-gauge Type 304 stainless steel. This material resists corrosion and is easy to clean. Always confirm the sink has an NSF certification to meet public health standards.

- Plan Your Layout for a Smarter Workflow: The right sink in the wrong place creates chaos. Position your sinks to create a logical flow for dishes, from scraping to washing to drying. This simple step saves time, reduces breakage, and keeps your team moving efficiently during the busiest shifts.

Related Articles

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment