Steel the Show in Your Kitchen with Commercial Stainless Steel Tables

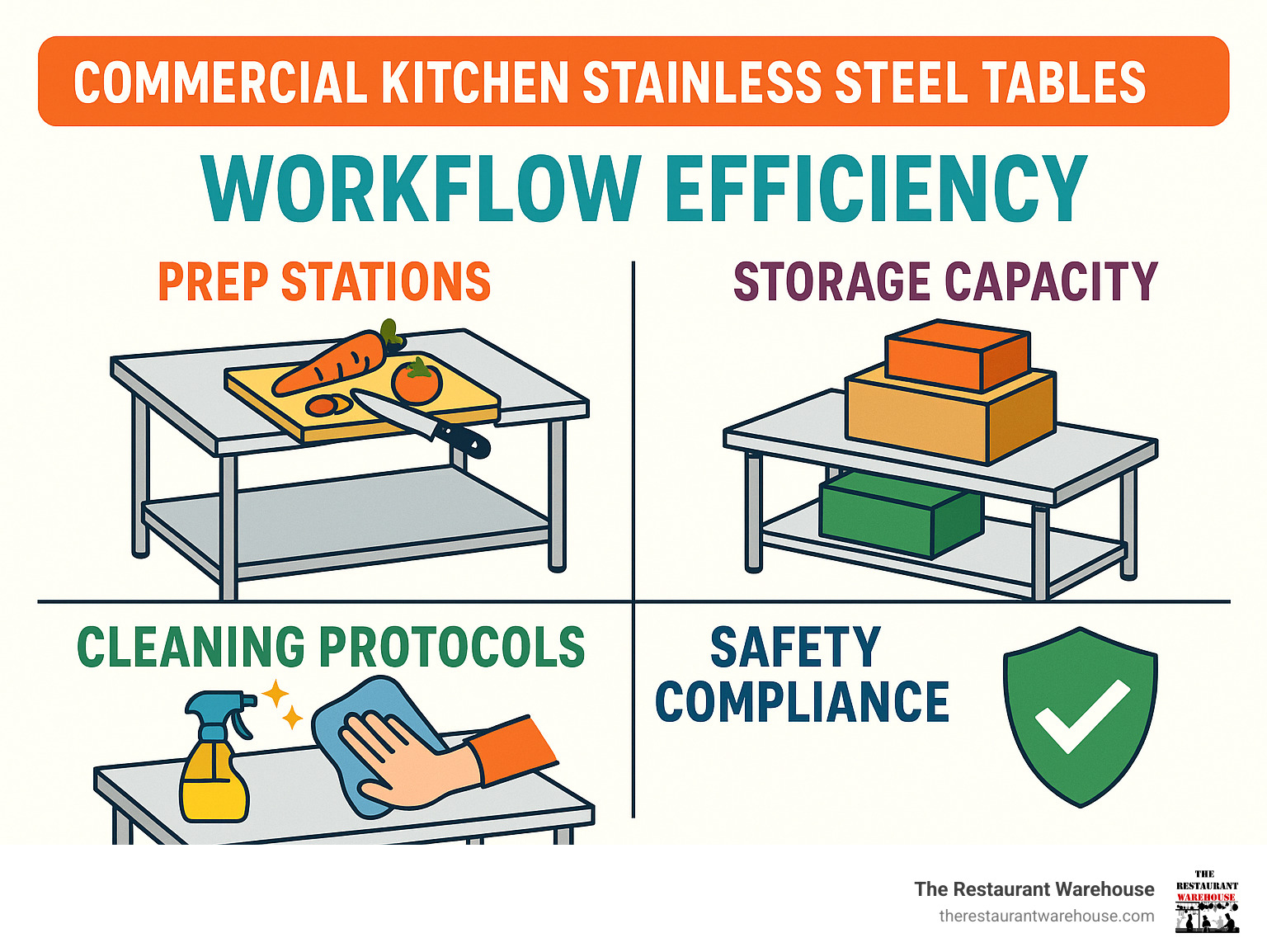

Why Commercial Kitchen Stainless Steel Tables Are Essential for Every Foodservice Operation

Commercial kitchen stainless steel tables are the backbone of professional food preparation, providing durable, hygienic work surfaces that meet strict health codes while withstanding the demands of busy restaurant kitchens.

Key benefits of commercial stainless steel tables:

- Non-porous surface resists bacteria buildup and meets NSF standards

- Load capacity up to 660 lbs on top shelf, 330 lbs on undershelf

- Corrosion resistance from 304-grade stainless steel construction

- Easy cleaning with smooth, seamless surfaces

- Variety of configurations including backsplash, sink combos, and mobile options

- Size range from 24" to 144" wide to fit any kitchen layout

The research shows that stainless steel work tables are the most common type of prep table in commercial kitchens due to their best durability and hygiene benefits. Whether you're opening a new restaurant or upgrading your existing kitchen, these tables deliver the reliability you need without breaking your budget.

From standard prep tables to specialized equipment stands, the right stainless steel table becomes your kitchen's most trusted workhorse. The non-porous surface prevents bacterial growth while the heavy-duty construction handles everything from meat tenderizing to dough prep.

Commercial kitchen stainless steel tables terms explained: - heavy duty kitchen equipment - restaurant equipment wholesale - wholesale catering equipment

Why Stainless Steel Rules: Key Features & Benefits

Commercial kitchen stainless steel tables aren't just pretty to look at - they're the unsung heroes of every successful kitchen, working harder than your newest line cook and complaining a lot less.

The magic starts with that non-porous surface. Unlike wood cutting boards that turn into bacteria hotels or plastic surfaces that develop scratches, stainless steel gives germs absolutely nowhere to hide. This isn't just convenient - it's what keeps your kitchen passing health inspections.

Corrosion resistance is where stainless steel really shows off. That protective chromium layer means your table laughs off acidic tomato sauce, harsh cleaning chemicals, and daily moisture that would turn other materials into rusty messes. You're looking at decades of reliable service.

When it comes to load capacity, these tables don't mess around. Quality models handle up to 660 pounds on the work surface and 330 pounds on that handy undershelf. That's enough weight capacity to support your stand mixer, food processor, and ingredients all at the same time.

NSF compliance means your table has been tested and approved for commercial food service, meeting strict standards for materials safety and cleanability. Health inspectors love seeing that NSF stamp.

The food safety benefits go beyond just meeting codes. Stainless steel's smooth surface makes ease of cleaning almost effortless - a quick wipe with sanitizer eliminates 99.9% of bacteria and viruses.

For technical details on keeping your investment in peak condition, check out this Scientific care guide for stainless and get More info about cleaning techniques.

How Stainless Steel Boosts Kitchen Hygiene

Stainless steel becomes your kitchen's best defense against contamination. The bacteria resistance isn't just marketing - it's built into the material. Those seamless welds and smooth joints eliminate every crevice where harmful microorganisms love to multiply.

Quick sanitizing becomes almost automatic. Spray your approved sanitizer, wipe it down, and you're done. The non-porous surface lets cleaning solutions make complete contact without being absorbed.

Most commercial codes actually require stainless steel surfaces in food prep areas. Health departments have seen the data - kitchens with stainless steel prep surfaces have significantly fewer contamination issues.

Strength & Longevity You Can Bank On

The difference between 14-gauge versus 16-gauge or 18-gauge steel is like comparing a tank to a bicycle. That 14-gauge construction offers serious dent resistance that keeps your work surface perfectly flat even after years of heavy use.

Those weight ratings up to 660 pounds represent real-world engineering that accounts for both permanent equipment and daily impact. When the dinner rush hits, your table will handle whatever you throw at it - literally.

This strength translates directly into longevity you can bank on. While cheaper alternatives might save money upfront, they'll cost you more in replacements and repairs.

Types of Commercial Kitchen Stainless Steel Tables

Not all commercial kitchen stainless steel tables look the same because different tasks require different solutions. Today's market offers exactly what your kitchen needs without settling for something that's "close enough."

Standard work tables are the workhorses in virtually every commercial kitchen. These tables feature a clean, flat stainless steel surface with either an open base or undershelf storage, handling everything from chopping vegetables to assembling sandwiches.

Backsplash tables add a 4-6 inch vertical panel along the back edge that prevents sauce splashing onto walls or liquids running down behind equipment.

Cabinet base tables feature enclosed storage underneath instead of an open base. Your supplies stay organized while you gain valuable work surface above.

Equipment stands are reinforced tables built specifically to support mixers, slicers, and other heavy appliances. Many come with mounting hardware or electrical outlets already installed.

Open base tables provide complete freedom to arrange storage bins, roll in mobile carts, or have easy access for cleaning.

Sink combination tables combine prep surface with washing facilities, eliminating the need for separate stations. Food trucks and small cafes especially love these space-saving solutions.

Poly-top tables offer polyethylene cutting surfaces that protect knives while the stainless steel base provides durability and hygiene benefits.

Mobile carts add wheels and locking casters for portable work stations that move wherever needed.

For detailed guidance on selecting the perfect table, check out our Stainless Steel Tables Guide.

Commercial Kitchen Stainless Steel Tables With Backsplash

That raised edge along the back might not look like much, but it's a game-changer. Spill control becomes automatic when liquids hit that barrier instead of cascading onto your floor.

Wall protection saves money over time. Without a backsplash, food splatter and grease gradually stain or damage walls. The stainless steel barrier takes the hit instead.

Slip hazard reduction keeps spills contained on the work surface where they can be quickly cleaned, contributing to safer working conditions.

Commercial Kitchen Stainless Steel Tables With Sinks

Sink combination tables represent smart thinking for kitchens where every square foot matters. These space-saving solutions eliminate separate prep and washing stations.

Dual-task prep and wash functionality means your team can work more efficiently. One person can prep vegetables while another washes dishes, maximizing productivity in minimal space.

Drainboard perks automatically direct water into the sink rather than onto your floor, keeping working conditions safer while reducing cleanup time.

Poly-Top & Specialty Surfaces

Poly-top tables solve stainless steel's one weakness - its tendency to dull knives quickly. The polyethylene cutting surface provides a knife-friendly work area while maintaining structural and hygiene benefits.

Scratch resistance means these surfaces maintain their professional appearance longer than traditional cutting boards. The non-porous polyethylene resists staining and won't absorb odors.

Heat buffering properties provide some forgiveness when hot pans accidentally meet the work surface.

Choosing the Right Stainless Steel Table for Your Kitchen

Finding the perfect commercial kitchen stainless steel tables isn't just about picking the biggest one that fits. It's about understanding how your kitchen works and what demands you'll place on the equipment.

Start by measuring available space, but think about how your team moves during rush periods. That perfect spot might become a traffic nightmare when servers are rushing to the pass. Consider door swings, equipment placement, and pathways that keep your kitchen flowing.

Commercial kitchen stainless steel tables range from 24" to 144" wide. Sometimes two smaller tables give you more flexibility than one massive surface. You can position them where needed most, and if one needs maintenance, you're not completely out of commission.

Weight capacity matters more than most realize. Quality tables handle up to 660 pounds on the work surface and 330 pounds on the undershelf. Add up everything you plan to store underneath - those ingredient containers add up fast.

The choice between 304 and 430 grade stainless steel significantly impacts both cost and performance. Type 304 offers superior corrosion resistance and durability for high-volume kitchens. Type 430 provides solid performance at a lower price for lighter-duty applications.

Budget planning should look beyond sticker price. Higher-grade tables cost more upfront but last longer and need less maintenance. Factor in replacement costs and downtime headaches.

Think about accessories before you buy. Undershelves, backsplashes, sinks, and features like pot racks usually cost less when built in from the start.

Check regulatory requirements. Some health departments require specific grades or NSF certification. A quick call can save you from buying wrong equipment.

| Feature | 304-Grade 14-Gauge | 430-Grade 18-Gauge |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Durability | Superior | Adequate |

| Load Capacity | Up to 660 lbs | Up to 400 lbs |

| Cost | Higher | Lower |

| Best For | High-volume operations | Light-duty use |

| Maintenance | Minimal | Regular |

Configuration & Storage Options That Matter

Undershelves aren't afterthoughts - they're game-changers for organization. That extra 330-pound capacity gives you space for ingredient bins and supplies right where you need them. Adjustable undershelves are worth the cost because your needs change over time.

Drawers are productivity boosters. Having most-used tools within arm's reach eliminates constant trips across the kitchen. Locking drawers add security for expensive items.

Crossrails add structural strength while providing mounting points for towel bars and utensil hooks. These additions transform basic tables into organized workstations.

Adjustable feet solve wobbly tables on uneven floors. Quality adjustable feet provide up to an inch of height adjustment for rock-solid surfaces.

Casters turn stationary tables into mobile workstations. Locking casters provide stability during use and easy repositioning for cleaning.

For more storage solutions, check our guide on Order Stainless Steel Shelves.

Cost Factors & Typical Price Ranges

Prices range from around $100 for basic models up to $5,000 for large, customized commercial units.

Gauge thickness has the biggest price impact. 14-gauge costs significantly more than 18-gauge, but provides better durability and higher load capacity.

Grade selection affects your bottom line. Type 304 typically costs 20-30% more than type 430, but you get superior performance that pays for itself over time.

Dimensions impact both material costs and shipping. Larger tables need more materials and often require freight delivery. Cost per square foot usually decreases with size.

Add-on features can inflate total cost. However, getting features built-in usually costs less than adding them later.

Cleaning, Maintenance & Common Issues

Taking care of your commercial kitchen stainless steel tables makes the difference between equipment that looks great for decades versus tables that show their age after just a few years.

Your daily wipe-down routine should become automatic. Warm soapy water handles most situations perfectly. Follow up with clean water rinse and dry with a clean towel. This prevents food residues from building up.

For heavy-duty cleaning, alkaline cleaners cut through grease and protein buildup better than generic degreasers. Avoid anything with chlorine - it can pit and discolor stainless steel over time.

Passivation treatment is an annual process that restores the protective layer keeping your tables corrosion-resistant. Think of it as preventive maintenance that's cheaper than replacing damaged equipment.

Scratch management means using cutting boards religiously and never dragging heavy equipment across the table. Minor scratches often buff out with polishing compound.

Stainless steel can rust if not cared for properly. Rust spots appear when the protective surface gets damaged and exposed to moisture. Catch them early with specialized rust removers.

Wobble fixes are usually simple. Most wobbly tables sit on uneven floors. Adjust the feet first before assuming you need repairs. Check for loose bolts that might need tightening.

For complete maintenance guidance, check our Stainless Steel Prep Table Guide.

Best Practices to Maximize Life Span

The secret to decades of service lies in consistency. Scheduled deep-cleaning once weekly prevents buildup that daily cleaning might miss.

Avoiding chlorine-based cleaners protects the layer that makes stainless steel "stainless." Use approved cleaners that sanitize without causing damage.

Using cutting boards protects both expensive knives and your table investment. Direct cutting dulls blades fast and creates bacteria-harboring scratches.

Don't forget tightening fasteners during regular maintenance. Commercial kitchens create vibration and temperature changes that gradually loosen connections.

Troubleshooting Drawbacks

Fingerprint visibility is stainless steel's most annoying characteristic. Regular wiping with microfiber cloths and occasional polish keeps things professional.

Noise amplification makes kitchens sound louder during prep. Strategic placement of sound-absorbing materials helps without compromising hygiene.

The cold surface becomes noticeable during long prep sessions. Anti-fatigue mats provide insulation, reduce leg fatigue, and add slip resistance for safer conditions.

Shipping, Installation & Customization Essentials

Getting your commercial kitchen stainless steel tables from order to operation involves understanding delivery, installation, and customization options to avoid surprise costs.

Most tables arrive in flat-pack delivery to keep shipping costs reasonable and prevent damage. Components come with clear assembly guides - this isn't confusing furniture assembly.

Lead times vary by order type. Standard configurations often ship within 1-2 business days. Custom orders take 1-3 weeks since they're built to specifications.

Table size and weight determines whether you need forklift or liftgate service. Smaller tables ship standard, but larger units might require commercial delivery. Without dock access, liftgate service adds $100-200.

Assembly tools are basic - standard wrenches and screwdrivers. Manufacturers include necessary hardware and step-by-step instructions. Larger tables might benefit from professional installation.

Warranty terms typically cover defects for 1-3 years. Keep assembly instructions and warranty paperwork safe for future issues.

Custom sinks and cut-outs tailor tables to specific needs. These modifications work best when ordered with the original table rather than retrofitting later.

Financing options ease cash flow when outfitting complete kitchens. Many suppliers offer payment plans that preserve working capital for other expenses.

Check the detailed Spec Sheet for exact dimensions before ordering.

Accessorize to Optimize

Pot racks maximize vertical storage while keeping cookware within easy reach. Instead of digging through crowded cabinets, your most-used items hang ready for action.

Overhead shelves double your storage capacity without eating floor space. Perfect for lighter items like containers or ingredients you don't need constantly.

Utensil hooks keep most-used tools organized and accessible. Magnetic strips work great for knife storage, keeping blades sharp and safely secured.

Electrical outlets built into designs eliminate extension cord hazards. Especially valuable on equipment stands where appliances need reliable power.

Heat lamps maintain food quality by keeping prepared items at proper serving temperatures. Particularly valuable for buffet operations or high-volume kitchens.

Frequently Asked Questions about Commercial Kitchen Stainless Steel Tables

The questions we hear most about commercial kitchen stainless steel tables reflect real concerns of restaurant owners who want to make smart equipment investments.

What grade and gauge should I choose for high-volume kitchens?

For high-volume operations, 14-gauge, type 304 stainless steel construction is the gold standard that serious operators rely on.

The 14-gauge thickness provides the backbone your kitchen needs. It handles heavy stand mixers, busy prep work impact, and fully loaded ingredient containers without breaking a sweat. No wobbling during meat tenderizing, no denting when equipment gets moved during dinner rush.

Type 304 stainless steel takes corrosion resistance to the next level. In high-volume kitchens facing constant exposure to acidic foods, cleaning chemicals, and moisture, this superior grade maintains professional appearance and structural integrity year after year.

The upfront investment pays for itself through reliability when you need it most. High-volume kitchens can't afford equipment failures during Saturday night service.

How do undershelves and backsplashes improve workflow?

Smart kitchen design keeps your team moving efficiently without wasted motion. Undershelves and backsplashes solve real workflow problems that slow down operations.

Undershelves transform wasted space into valuable storage within arm's reach. That extra 330-pound capacity accommodates ingredient bins and supplies without cluttering your main prep area. Your cooks spend less time walking to storage areas.

The organization benefits extend beyond just storage. When frequently used items have designated undershelf spots, your kitchen stays cleaner during busy periods. New staff find what they need quickly, reducing training time.

Backsplashes provide spill containment that protects walls and team safety. That 4-6 inch raised edge catches inevitable prep spills, preventing liquids from creating floor slip hazards. Your team works confidently knowing spills stay contained.

Wall protection saves maintenance money and keeps your kitchen looking professional. The stainless steel backsplash shields surfaces from food splatter and cleaning chemicals that cause staining over time.

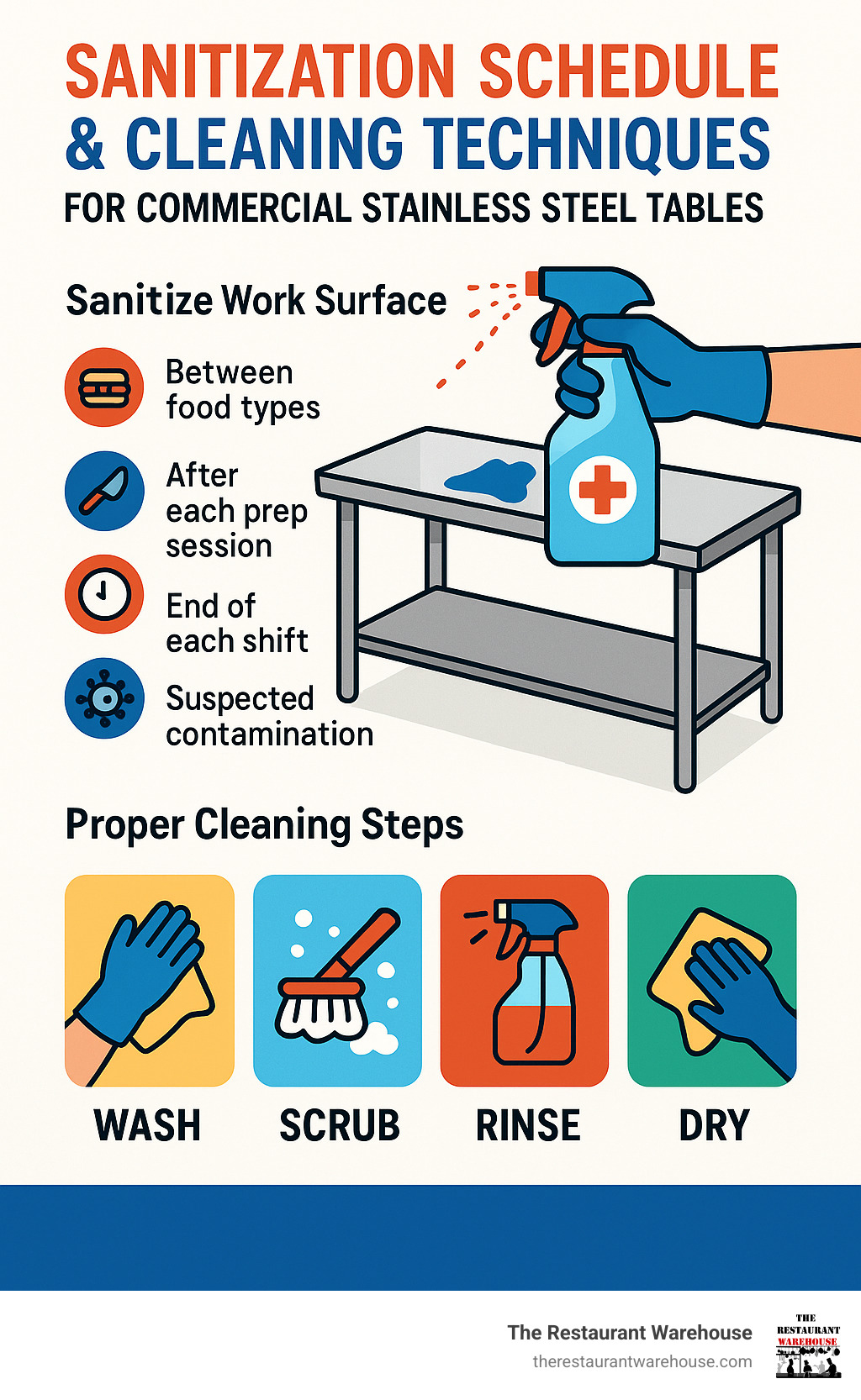

How often should I sanitize my stainless work table?

Food safety isn't negotiable, and sanitizing schedules directly impact your kitchen's safety record. Stainless steel makes effective sanitizing quick and straightforward.

Your sanitizing frequency should match food preparation activities and health department requirements. The non-porous surface means sanitizers work effectively without being absorbed.

Between different food types - especially switching from raw to cooked items - represents the most critical sanitizing moment. Cross-contamination prevention starts with proper surface sanitization.

After each major prep session ensures bacteria don't have time to multiply. Even with the same food type, extended prep periods can allow bacterial growth without proper maintenance.

End-of-shift sanitizing prepares tables for the next service while meeting health codes. This final sanitization gives peace of mind that your kitchen is ready for tomorrow.

The smooth, non-porous surface makes this routine efficient. Approved sanitizing solutions eliminate 99.9% of bacteria and viruses when used according to instructions.

Conclusion & Next Steps

When you look at everything we've covered, commercial kitchen stainless steel tables aren't just another piece of equipment - they're the foundation that makes everything else work better. The combination of rock-solid durability, bulletproof hygiene standards, and incredible versatility makes these tables investments that keep paying dividends year after year.

Your table is probably the hardest-working equipment in your kitchen. It's there for every prep session, service rush, and cleanup. When you choose the right stainless steel table, you're choosing reliability that won't let you down during the dinner rush.

The beauty lies in simplicity. The non-porous surface keeps health inspectors happy while making your life easier. The heavy-duty build quality means you can load it up with equipment and ingredients. When it's time to clean up, a quick wipe-down gets you back to spotless.

At The Restaurant Warehouse, we've built our reputation on great equipment that doesn't cost a fortune. While other suppliers pile on commissions and retail markups, we keep things straightforward with wholesale pricing that puts money back in your pocket. That extra cash can go toward other kitchen improvements or building a stronger business foundation.

Your kitchen's unique needs deserve a customized solution. Whether you're working with a compact food truck or sprawling restaurant kitchen, there's a perfect table configuration waiting. From 24" space-savers to 144" prep powerhouses, the right size and features exist to match your exact workflow requirements.

The long-term value equation makes stainless steel tables one of the smartest purchases you'll make. While cheaper alternatives might seem tempting upfront, they often cost more through replacements and repairs. Quality stainless steel tables just keep working, decade after decade.

Ready to upgrade your kitchen's efficiency and safety? Browse our selection of commercial kitchen stainless steel tables and find how wholesale pricing makes premium quality accessible. Your future self will thank you for choosing equipment built to last and priced to fit your budget.

For even more insights into optimizing your commercial kitchen setup, check out our comprehensive Commercial Kitchen Stainless Steel Guide. It's packed with expert tips that'll help you make the best decisions for your foodservice operation.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment