NSF Approved 3 Compartment Sink Buyers Guide

An NSF approved 3 compartment sink is pretty much the foundation of sanitation in any commercial kitchen. It's specifically built for the mandatory wash, rinse, and sanitize process that every health department requires.

When you see that NSF (National Sanitation Foundation) certification, it’s a guarantee. It tells you the sink's materials, design, and the way it's built have been put through the wringer to stop bacteria growth and keep food safe.

What an NSF Approved 3 Compartment Sink Really Means

Think of the NSF seal as a promise—both to your customers and to the health inspector. It confirms the equipment you're using isn't just functional, but purpose-built to meet the highest public health standards. This isn't about having a fancy piece of gear; it's about building a safe, compliant, and efficient kitchen from the ground up.

An NSF approved 3 compartment sink is engineered with specific features that you just won't find in a typical basin. These details are there to eliminate the common sanitation headaches you run into in a busy restaurant.

Here's what that certification really looks at:

- Hygienic Design: Sinks have to have smooth, seamless welds and coved (rounded) corners. This is huge because it prevents food bits and bacteria from getting trapped in those hard-to-clean crevices—a major issue with lower-quality sinks.

- Safe Materials: The sink must be made from non-toxic, corrosion-resistant materials, which is why you almost always see high-grade stainless steel. This ensures no nasty stuff can leach into your water and that the sink can handle tough cleaning chemicals without breaking down.

- Ease of Cleaning: The whole construction has to make cleaning and sanitizing straightforward. This includes thoughtful features like properly sloped drainboards that keep water from pooling, which would otherwise become a breeding ground for germs.

The NSF certification process is exhaustive. They look at everything from the choice of materials and the manufacturing process to the final product testing. This ensures every single sink that gets the NSF mark meets a consistent, verifiable standard for safety and sanitation.

Ultimately, choosing an NSF approved sink is one of the first, most fundamental steps in setting up a professional kitchen. For a deeper dive into picking the right gear, our guide on how commercial sinks for restaurants made simple is packed with valuable insights.

Why NSF Certification Is a Must-Have for Your Kitchen

Think of NSF certification not as some optional add-on, but as the foundational defense system for your entire kitchen. Its main job is to protect against foodborne illness, a nightmare scenario that can absolutely wreck a restaurant's reputation overnight. Choosing an NSF approved 3 compartment sink is more than just a purchase; it's a strategic business decision that protects your customers, your team, and your bottom line from day one.

The real difference is in the details you can't always see. NSF standards demand specific design features that are engineered to fight bacterial growth. For instance, a sink that isn't certified might have sharp, 90-degree corners and visible weld seams. To you, they might look fine, but to bacteria, those tiny crevices are the perfect hiding spots for food particles, making them almost impossible to clean out completely.

An NSF-certified sink, on the other hand, is built differently from the ground up.

- Seamless Welds: Every joint is ground down to be perfectly smooth, leaving zero gaps for grime to build up.

- Coved Corners: The bottom corners of the sink basins are curved, not sharp, allowing sponges and brushes to glide effortlessly across every single surface.

These features aren't just for looks. They are engineered for sanitation and are a huge part of why certified equipment is your ticket to passing health inspections without a hitch.

The Real Cost of Non-Compliance

Going with a cheaper, non-certified sink might feel like a smart way to trim the budget, but it’s a gamble that can backfire spectacularly. A single failed health inspection because of improper equipment can lead to painful fines, mandatory closures, and public reports that shatter customer trust in an instant. The peace of mind that comes from knowing your equipment is fully compliant? That’s priceless.

This is exactly why the demand for these sinks keeps climbing. The global market for commercial sinks, pushed by strict sanitation rules, was valued at around USD 915.7 million in 2025 and is expected to hit USD 1,686.9 million by 2035. You can dig deeper into what's driving this growth by checking out the full research about commercial sink trends.

Investing in an NSF approved 3 compartment sink is an upfront commitment to quality and safety. It sends a clear message to health inspectors and customers that you take public health seriously, building a foundation of trust that is absolutely essential for long-term success.

Deconstructing an NSF Approved Commercial Sink

So, what exactly turns a regular sink into a certified sanitation machine? An NSF approved 3 compartment sink is way more than just three tubs welded together; it's engineered from the ground up with public health as the top priority. Every single curve, material choice, and component is there for a reason—to win the daily battle against contamination.

It all starts with the foundation: the material. The vast majority of compliant sinks are built from high-grade stainless steel, usually 16 or 18 gauge. A lower gauge number actually means the steel is thicker and tougher, ready to stand up to the daily abuse of heavy pots and harsh chemicals without denting or corroding. That non-porous surface is critical because it gives bacteria absolutely nowhere to hide.

But it’s the construction details that really set an NSF sink apart. You’ll hear terms like “coved corners,” which is just a technical way of saying the bottom edges of each basin are rounded. This small design tweak makes a massive difference, eliminating those sharp 90-degree angles where food particles and gunk love to get trapped. The result? Cleaning is faster and far more effective.

Key Anatomical Features for Compliance

A few other components are non-negotiable for earning that NSF seal, and each one plays a role in creating a safer kitchen. Getting to know these parts helps you size up a sink’s quality like a seasoned pro.

- Integrated Drainboards: These aren't just for stacking dishes. Properly sloped drainboards are a must-have for air-drying, which is often a health code requirement to stop recontamination from dirty towels.

- High Backsplash: A tall backsplash is your first line of defense against splashes, keeping dirty water from soaking the wall behind the sink—a common breeding ground for mold and bacteria.

- Rolled Edges: You'll notice the front and side edges are smooth and rolled. This provides extra structural strength and gets rid of any sharp points that could injure staff or snag cleaning cloths.

When buying an NSF sink, the gauge of the stainless steel is one of the most important factors to consider as it directly relates to the sink's durability and longevity. Thicker steel (lower gauge) is better suited for high-volume, demanding environments. This table breaks down the common gauges to help you decide.

Stainless Steel Gauge Comparison for Commercial Sinks

| Gauge | Thickness (inches) | Durability & Dent Resistance | Best For |

|---|---|---|---|

| 14 | 0.0781 | Highest. Extremely durable and highly resistant to dents, scratches, and bowing. The premium choice. | High-volume restaurant kitchens, institutional use, butcher shops, and any setting with constant, heavy-duty use. |

| 16 | 0.0625 | Excellent. A great balance of durability and value. Resists denting and wear from daily commercial use. | Most restaurants, bars, cafes, and commercial kitchens. A very popular and reliable all-around choice. |

| 18 | 0.0500 | Good. Suitable for lighter-duty applications. More prone to denting from heavy impacts. | Light-duty commercial use, prep areas, coffee shops, or kitchens with less frequent and lighter use. |

Ultimately, choosing a lower gauge like 14 or 16 is a smart investment for most busy kitchens, ensuring your sink can handle the pressure for years to come without showing signs of wear and tear.

The NSF certification standards for these sinks are incredibly strict. A typical NSF approved 3 compartment sink can run anywhere from 59 to 108 inches long, with basins deep enough to fully submerge large pots for proper washing and sanitizing. They must have seamless welded joints and integrated drainboards that prevent water from pooling—a critical detail checked during NSF testing. You can explore more about sink specifications at Elite Restaurant Equipment.

Think of an NSF sink as a complete system. Each element—from the gauge of the steel to the slope of the drainboard—works together to create an environment that actively resists contamination and simplifies sanitation.

Mastering the 3-Step Wash Rinse Sanitize Process

Having an NSF approved 3 compartment sink is the first critical piece of the puzzle, but true food safety comes down to using it correctly. Every. Single. Time.

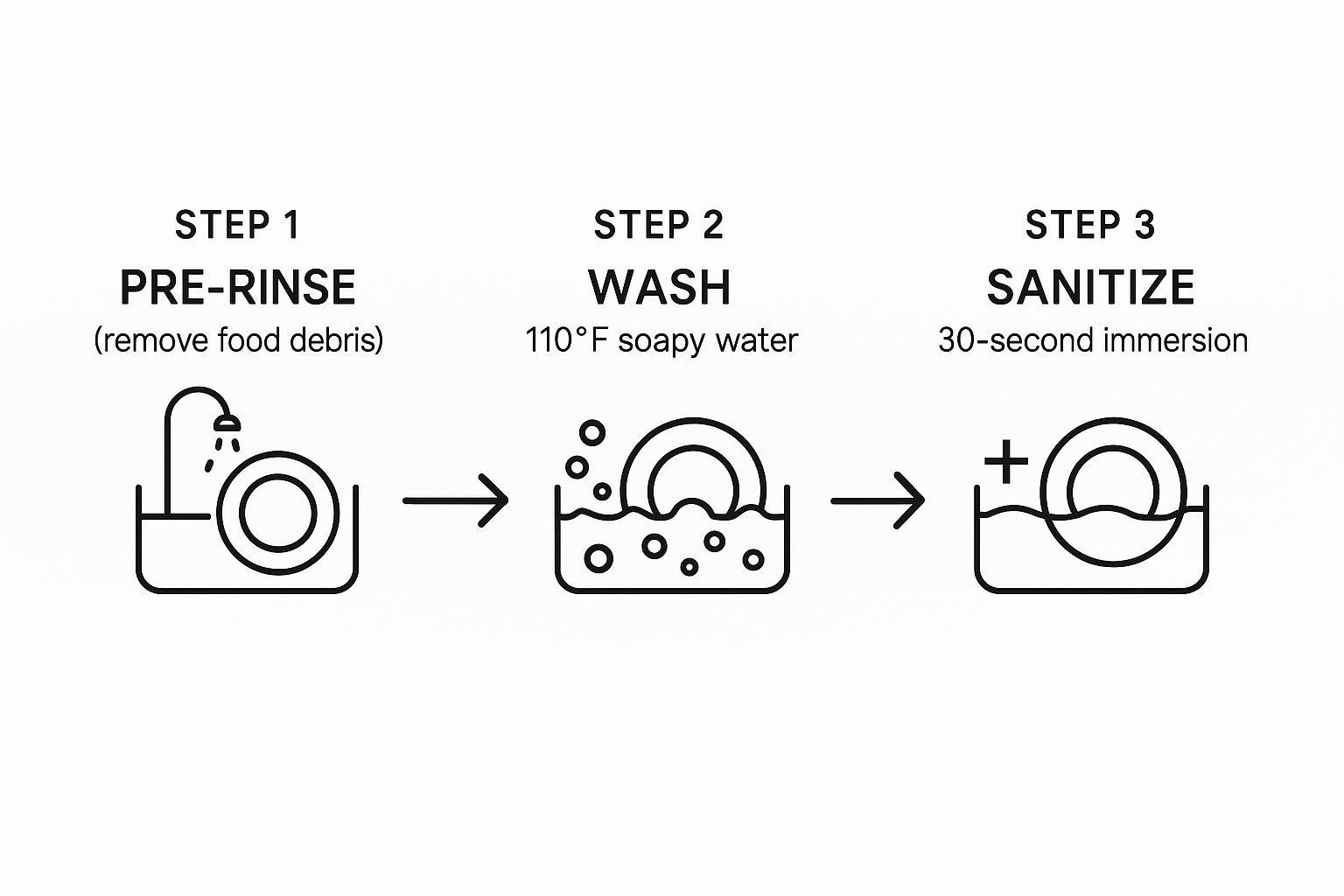

The wash, rinse, and sanitize process isn't just a friendly suggestion; it's a non-negotiable health code requirement. This method is the backbone of any solid sanitation program, designed to systematically knock out harmful germs and bacteria from your kitchenware.

Each compartment in your sink has a specific and vital job. The process actually starts before the first dish even hits the water, with a thorough scrape and pre-rinse to get rid of any loose food. Skipping this quick step means your wash water gets gross and ineffective way too fast.

The Three Stages of Sanitation

The first basin is all about washing. You'll fill this compartment with hot water—at least 110°F—and a commercial-grade detergent. This combo works together to cut through grease and lift away stuck-on food.

Next up is the second basin, which is dedicated to rinsing. It should be filled with clean, warm water to wash away every last bit of soap. If you rush this step, you can leave behind a chemical residue that not only messes with the taste of your food but can also prevent the sanitizer from doing its job.

This infographic breaks down the essential flow for perfect warewashing.

As you can see, each stage builds on the last, creating a clear path from a dirty dish to a properly sanitized one.

The Final and Most Critical Step

The third and final basin is for sanitizing. This is the step that actually kills off any lingering bacteria. You've got two main ways to get this done:

- Chemical Sanitizer: Submerge your items in a solution of water and an approved sanitizer, like chlorine or quaternary ammonium. Keep them in for at least 30-60 seconds, depending on the chemical. It's absolutely crucial to use test strips to make sure your sanitizer concentration is in the right zone.

- Hot Water Sanitizer: If you go this route, you'll immerse the items in water heated to a scorching 171°F for a minimum of 30 seconds.

After sanitizing, every single item needs to be placed on a drainboard to air-dry completely. Grabbing a towel to dry things off can reintroduce bacteria and undo all your hard work. For some more hands-on advice, check out these extra tips on using a 3 tier sink effectively in a busy kitchen.

How to Choose the Right NSF Sink for Your Kitchen

Picking the perfect NSF approved 3 compartment sink is a big deal. It’s not just a purchase; it's an investment in your kitchen’s daily rhythm and long-term success. Before you even think about brands or models, grab a tape measure. The very first step is getting the exact dimensions of your available space to make sure the sink will actually fit, leaving enough room for plumbing and for your staff to move around without bumping into each other.

Once you know your measurements, it’s time to think about volume. On your busiest night, how many dishes, pots, and pans are you washing? Your answer will point you toward the right bowl size and depth. Deeper bowls are a lifesaver for those giant stockpots, but shallower basins can help your team fly through smaller items much faster.

Balancing Size with Workflow

The layout of your sink is just as critical as its size. One of the biggest decisions you'll make is whether to go with one or two drainboards. A sink with two drainboards gives you a clean, simple workflow: dirty dishes pile up on one side, and clean ones air-dry on the other. This setup is a dream for high-volume kitchens where organization is everything.

On the other hand, a single drainboard model can be a smart, space-saving choice for smaller kitchens. If you're trying to make every inch count, check out our tips for effective restaurant kitchen design.

Your sink should be a helper, not a hurdle. Picture your team during a crazy dinner rush—does the sink layout support their movements, or does it create a traffic jam?

And don't forget the faucet! It's the heart of your warewashing station, so it needs to be a tough, commercial-grade model built to handle constant use. Getting it installed correctly is also crucial for everything to work right and stay up to code. For any tricky plumbing, it's always a good idea to know the top reasons to hire a commercial plumber who can make sure the job is done right.

It’s no surprise that the market for these sinks is growing. With a bigger focus on sanitation and durability, the compartment sinks market was valued at USD 1,145 million in 2025 and is expected to nearly double by 2035. This growth is all about the demand for compliant, high-quality sinks that can handle the heat of a professional kitchen.

Common Questions About NSF 3 Compartment Sinks

Even after you get the hang of the rules, a few specific questions always pop up when it's time to actually pick, install, or take care of an NSF approved 3 compartment sink. Getting straight answers to these common questions is the best way to make sure you're making smart choices for your kitchen's efficiency and compliance right from the start.

These are the questions we hear all the time, covering everything from whether a tiny food truck really needs one to the nitty-gritty of daily cleaning. Let's clear up some of the most frequent points of confusion.

Is an NSF Approved Sink Required for a Small Cafe or Food Truck?

Almost always, the answer is a firm yes. Health codes in most areas don't care how big or small your operation is; if you're a commercial food establishment, you need to use NSF-certified equipment for washing dishes.

These rules are all about protecting public health. Trying to get by with a residential sink is one of the quickest ways to fail a health inspection, which could lead to fines or even a temporary shutdown. Your safest bet is to always check with your local health department, but investing in a proper NSF sink is the professional move for any food business.

What Is the Difference Between NSF Certified and NSF Listed?

You’ll hear these terms thrown around, and for your purposes as a buyer, they mean the exact same thing: the product meets NSF standards. "NSF Certified" is the process where a product gets tested and verified. "NSF Listed" just means the product passed certification and now appears in NSF's official online database.

What really matters to a health inspector is the physical NSF mark on the sink itself. That little circular blue seal is the definitive proof of compliance they’ll be looking for when they walk through your kitchen.

How Should I Clean and Maintain My Stainless Steel Sink?

Keeping your sink in top shape is simple, but you have to be consistent. Clean it every day with a mild detergent and a soft sponge. Here’s a pro tip: always wipe in the direction of the steel's grain to avoid tiny scratches. Then, rinse it thoroughly so no soap residue is left behind.

Whatever you do, stay away from abrasive pads like steel wool or harsh chemicals like bleach. These can destroy the protective layer on the stainless steel and lead to rust, which completely undermines its sanitary surface. A little gentle, regular cleaning will keep your sink hygienic and make sure it lasts for years.

Can I Install a Garbage Disposal in an NSF 3 Compartment Sink?

Yes, you can absolutely install a commercial-grade garbage disposal in one of the sink bays—usually the washing or pre-rinse compartment. The key here is to check your local health and plumbing codes first.

Some jurisdictions have very specific rules about where and how disposals can be installed in a commercial kitchen to prevent plumbing and sanitation nightmares. And, of course, make sure the disposal unit itself is also designed for commercial use.

Ready to equip your kitchen with a sink that guarantees compliance and durability? The Restaurant Warehouse offers a wide selection of NSF approved 3 compartment sinks designed for any commercial operation. Explore our collection and find the perfect fit for your needs at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment