The Strength You Need: Understanding Commercial Grade Tables

What Defines Commercial Grade Tables

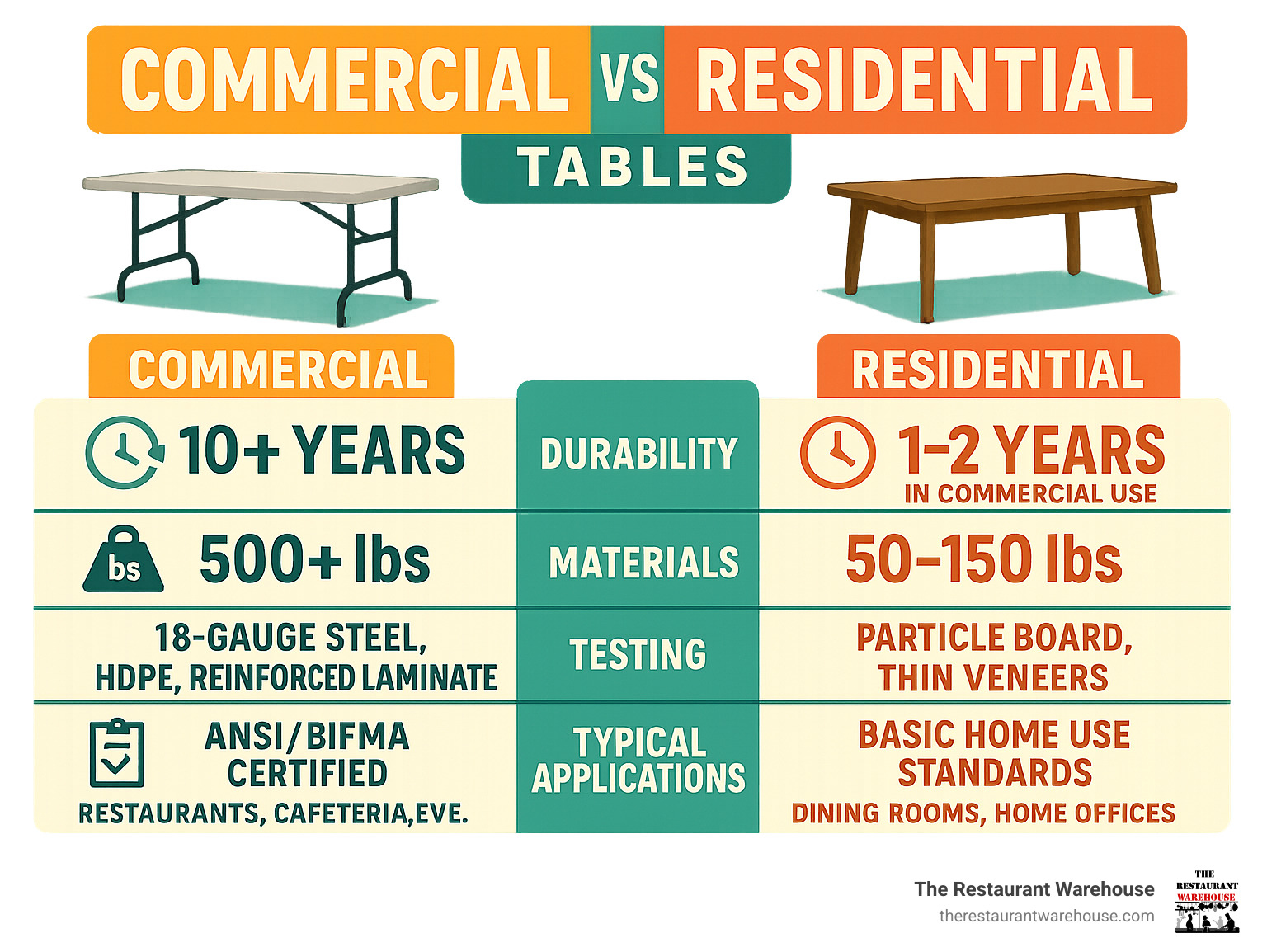

A commercial grade table is a piece of equipment engineered from the ground up to withstand the intense, relentless, and continuous use characteristic of business environments. Unlike its residential counterpart, which is designed for occasional use, a commercial table features heavily reinforced construction, superior-grade materials, and must pass a battery of rigorous testing standards that far exceed those for any furniture intended for the home. It is not merely a sturdier version of a home dining table; it is a purpose-built tool designed for performance, safety, and longevity in a professional setting.

Key Characteristics of Commercial Grade Tables:

- Weight Capacity: Commercial tables are rated to hold significant weight, often starting at 500 pounds and going much higher for heavy-duty models. This is a measure of static, evenly distributed load. This contrasts sharply with residential tables, which may only be rated for 50-150 pounds and can fail under the weight of stacked boxes, let alone professional equipment.

- Materials: The materials are chosen for durability and hygiene. Common options include 18-gauge or thicker stainless steel, which is non-porous and corrosion-resistant; high-density polyethylene (HDPE), which is impact- and weather-resistant; and high-pressure reinforced laminate, which offers a durable, cleanable surface over a robust core.

- Testing & Certification: To be considered truly commercial grade, tables must often meet or exceed standards set by organizations like the American National Standards Institute (ANSI) and the Business and Institutional Furniture Manufacturers Association (BIFMA). These tests simulate years of hard use, including stability, strength, and cycle testing.

- Construction: The difference is in the details. Look for powder-coated steel frames that resist chipping and rust, fully welded joints for maximum strength (as opposed to screwed-together joints), reinforced leg gussets to prevent wobbling, and impact-resistant corners to handle bumps and collisions in a busy workspace.

- Warranty: The warranty reflects the manufacturer's confidence in the product's durability. Commercial tables often come with substantial warranties, such as 5-year, 10-year, or even limited lifetime warranties, covering defects under commercial use. A residential table's 1-2 year warranty is typically voided the moment it's placed in a commercial environment.

- Durability: These tables are designed for a high-traffic life, built to endure 8-12 hours of daily use, constant cleaning with harsh chemicals, and the general abuse of a workplace. A residential table is built for a few hours of use per week at most.

For a restaurant, school cafeteria, or event hall, the distinction between commercial and residential tables is a matter of operational survival. A residential table is a liability; it can collapse under the weight of heavy prep equipment, become unstable from constant movement, or degrade quickly from required sanitation protocols. This creates serious safety hazards for staff and customers and leads to the costly cycle of frequent replacements. Your tables must be able to support heavy mixers and slicers, withstand constant wiping with commercial-grade sanitizers, and remain perfectly stable day after day. The initial investment in a certified commercial grade table pays for itself through unparalleled longevity, safety, and reliability, allowing a single quality table to serve your business for a decade or more, while a residential one might not last a single season in the same setting.

What Makes a Table 'Commercial Grade'?

In the demanding environment of a busy restaurant kitchen, a high-traffic cafeteria, or a dynamic event space, the term 'commercial grade' is a seal of approval. It signifies that a table has been carefully engineered to handle conditions that would quickly destroy ordinary residential furniture. These are not simply overbuilt tables; they are purpose-built workhorses, designed from the material selection to the final weld for the relentless demands of business operations.

The fundamental difference begins with rigorous, standardized testing. Commercial tables are subjected to a gauntlet of abuse designed to simulate years of real-world wear and tear. Industry benchmarks, most notably the ANSI/BIFMA standards, serve as the gold standard for this evaluation. These are not simple pass/fail tests. They include specific, measurable assessments like leg strength tests, where force is applied to simulate tipping; top-load tests that verify weight capacity; and drop tests, where a weighted bag is dropped on the surface to simulate impact. This comprehensive evaluation ensures a table can handle everything from the static weight of heavy equipment to the dynamic stress of daily cleaning, movement, and accidental impacts. Certification to these standards is your guarantee of safety, performance, and structural integrity, and is often a requirement for business insurance policies.

The heavy-duty construction is immediately apparent upon inspection. You will find reinforced joints, often with welded gussets, and thicker gauge materials throughout the frame and legs. Support channels are frequently welded to the underside of larger tabletops to prevent bowing or sagging over time. This robust build translates directly to a high weight capacity. Commercial tables are routinely engineered to handle 500 pounds or more of evenly distributed weight, a stark contrast to the 150-pound limit of many residential tables. This capacity is not just for show; it is your insurance against catastrophic failure, allowing staff to confidently place heavy stock pots, mixers, or stacks of dishes without fear of collapse.

This superior engineering ensures exceptional longevity and a lower total cost of ownership. A quality commercial grade table is designed to maintain its structural integrity and professional appearance for years, resisting the wear and tear that comes with constant use. Several key features contribute to this resilience. Reinforced frames and adjustable, non-marring feet provide superior stability, preventing the wobbling that plagues lesser tables. Surfaces are specifically engineered for scratch, stain, and heat resistance, so that dropped utensils, spilled sauces, and hot plates won't cause permanent damage. Furthermore, easy-to-clean, non-porous surfaces are critical for hygiene, allowing for rapid and effective sanitization that meets stringent health department standards. Many surfaces are also resistant to the harsh chemicals found in commercial-grade cleaners.

Thoughtful safety features, such as rounded or bullnose corners, are common to prevent injuries in crowded, environments. All these elements combine to offer exceptional long-term value. A table that lasts ten years costs far less over its lifespan than replacing cheaper, inadequate alternatives every year or two, all while maintaining a professional appearance that reflects the quality of your establishment. Some products may carry a California Proposition 65 Warning for chemical exposure, such as a nickel exposure notice for stainless steel. This is a transparency measure designed to inform consumers, not an indication that the product is unsafe when used as intended, allowing for fully informed purchasing decisions.

Built to Last: Common Materials and Construction

When you invest in a commercial grade table, you're not just buying a surface to work on; you're choosing the backbone of your daily operations. The specific materials and construction methods used are the primary determinants of a table's performance, lifespan, and suitability for a given task. Each material offers a unique profile of strengths, making it essential to match the material to your business's specific needs.

Stainless Steel: The Kitchen Workhorse

Stainless steel is the undisputed champion of commercial kitchen environments, embodying durability, hygiene, and a professional aesthetic. Its non-porous surface offers incredible hygiene properties, as it provides no place for bacteria, mold, or stains to penetrate, making it easy to sanitize and essential for meeting health codes. The gauge measurement indicates its thickness and strength; counterintuitively, lower numbers mean thicker, stronger steel.

- 18-gauge is the industry standard, offering an excellent balance of durability and cost for most applications, including general prep and assembly.

- 16-gauge is a step up in thickness and strength, ideal for heavy-duty tasks, supporting heavy equipment, or withstanding intense butchering and prep work.

- 14-gauge is the thickest and most robust option, reserved for the most demanding industrial applications.

Commercial tables typically use either Type 430 or Type 304 stainless steel. Type 430 is more affordable and offers good corrosion resistance, making it suitable for most dry applications. Type 304 contains nickel, which provides superior resistance to corrosion from salt and chemicals, making it the preferred choice for wet environments or food prep involving acidic ingredients. Features like undershelves for storage and backsplashes to protect walls are common and highly functional additions. For more details, explore our Steel The Show In Your Kitchen With Commercial Stainless Steel Tables and Prep Table Stainless Steel Guide.

High-Density Polyethylene (HDPE)

HDPE brings lightweight portability and extreme durability to the commercial world. Created through a blow-molding process, these tabletops are strong yet lightweight, making them perfect for businesses that require flexible setups, such as event venues, schools, and caterers. Its formulation includes UV protection, which prevents the material from cracking or fading under direct sunlight, making it ideal for both indoor and outdoor use. Its stain and crack resistance ensures it maintains a professional look despite spills and rough handling. HDPE tops are typically paired with powder-coated steel frames that resist rust, creating a table that is both durable and easy to move and store. This material is the top choice for folding and adjustable height tables, and many models come with ten-year warranties, a testament to their commercial-grade reliability.

Laminate and Wood

For front-of-house applications like dining rooms, cafes, and offices, laminate and wood tables offer a vast array of aesthetic options without sacrificing commercial durability. Laminate tabletops consist of a decorative top layer fused to a robust core. They can convincingly mimic the look of wood grain, stone, or solid colors while providing superior scratch and stain resistance. Their cost-effective nature makes them a smart choice for businesses needing to furnish large spaces on a budget. The choice of core material is critical: standard particleboard is economical, while medium-density fiberboard (MDF) offers a smoother surface, and plywood provides the greatest strength and moisture resistance. Edge types also vary, from protective vinyl T-molding to seamless self-edging.

Solid wood and butcher block tops offer timeless, natural beauty and can be refinished for decades of service. Maple and oak are popular choices for their hardness and attractive grain. They are ideal for bakeries, cafes, and exhibition kitchens, providing a warm, inviting surface. Regular conditioning with food-safe mineral oil is required to prevent drying and cracking.

Granite and Stone

For a premium, high-end aesthetic, granite and other stone tabletops are an excellent choice. To make them practical and affordable for commercial use, manufacturers often bond a 3/8-inch thick slab of real granite to a 3/4-inch plywood core. This innovative construction captures the luxurious beauty and feel of solid stone while significantly reducing weight and cost. Moisture-sealed construction ensures the plywood core is protected and adds stability. Granite offers exceptional heat and scratch resistance, and its naturally sanitary surface is easy to clean. It performs beautifully in both upscale indoor dining rooms and neat outdoor patios. To maintain its appearance and prevent staining, regular sealing every six months is recommended. The timeless elegance and robust performance of granite make it a worthy investment for creating a sophisticated, lasting impression.

| Material | Durability | Cost | Maintenance | Best Use Case |

|---|---|---|---|---|

| Stainless Steel | Excellent (corrosion, heat, impact resistant) | Medium to High | Easy (wipe clean, sanitize) | Commercial kitchens, food prep, industrial, labs |

| HDPE | Very Good (UV, stain, crack resistant) | Low to Medium | Easy (wipe clean) | Outdoor, events, temporary setups, schools, catering |

| Laminate | Good (scratch, stain, impact resistant) | Low | Easy (wipe clean) | Dining rooms, offices, cafes, breakrooms |

| Granite | Excellent (scratch, heat, stain resistant) | High | Medium (requires sealing) | Upscale dining, outdoor patios, high-traffic areas |

Frames and Bases

The foundation of any table is its frame or base, which dictates its stability and overall strength. In commercial tables, these are typically made from steel or cast iron. Powder-coated steel is common for its durability and resistance to chipping and corrosion. Cast iron bases, often used for dining tables, are extremely heavy and provide a low center of gravity, making them exceptionally stable and difficult to tip. Base styles vary to suit different needs: pedestal bases offer maximum legroom, T-bases and X-bases provide excellent support for rectangular tops, and four-leg frames offer classic stability for work tables and folding tables.

A Table for Every Task: Types of Commercial Grade Tables

Different jobs require different tools, and the same principle applies to tables in a commercial setting. The term commercial grade tables encompasses a wide range of specialized products, with each type engineered to excel in specific environments and applications. Matching the right table to the right task is a critical step in optimizing workflow, ensuring safety, and enhancing the customer experience.

Restaurant and Dining Tables

In a restaurant or cafe, dining tables are a central element of the guest experience, tasked with balancing comfort, style, and extreme durability. They are built with reinforced construction to endure the constant cycle of use by customers, the weight of heavy dishes, and the rigors of frequent cleaning with commercial sanitizers. When selecting tables, consider shape and size to optimize your floor plan for both seating capacity and comfortable traffic flow. Round tables can facilitate conversation, while square and rectangular tables are more space-efficient and can be pushed together for larger parties. Height options—including standard dining height (30"), counter height (36"), and bar height (42")—can be used to create distinct zones and add visual interest to a space. A key feature of commercial dining furniture is the ability to purchase separate tops and bases. This modular approach allows you to create a custom look by mixing and matching materials like laminate, wood, resin, or granite with a variety of sturdy cast iron or steel bases to perfectly suit your decor and budget.

Work and Prep Tables

Work and prep tables are the undisputed backbone of any professional kitchen, laboratory, or workshop. In food service, stainless steel surfaces are the universal standard due to their superior hygiene, non-reactivity with foods, corrosion resistance, and best durability. These tables are designed for pure function, with features that improve efficiency and cleanliness. Integrated backsplashes prevent ingredients and liquids from splashing onto walls, while undershelves (either solid or wire) provide essential storage for tools, containers, and ingredients, keeping them off the floor and within easy reach. Look for NSF International certification, which is a guarantee that the table meets strict public health and safety standards for design, construction, and materials, ensuring it is non-porous and easily cleanable. Common sizes like 48" x 24", 60" x 30", and 72" x 30" are designed to fit standard kitchen layouts, and many come with adjustable bullet feet to ensure a level, stable work surface on uneven floors. Optional accessories like casters (wheels) add mobility, while specialized edges like a 'marine edge' feature a raised perimeter to contain spills. For more guidance, see our Commercial Kitchen Stainless Steel Guide and 72x30 Stainless Steel Table Guide.

Folding and Banquet Tables

For event venues, catering companies, and institutions, flexibility is paramount. Folding and banquet tables are engineered to provide the perfect blend of durability, portability, and efficient storage. They must be lightweight enough for easy transport and setup by staff, yet sturdy enough to handle heavy loads and constant use. HDPE and laminate tops are the most popular choices, offering weather resistance and a wide variety of design options, respectively. The folding mechanism is a critical component; look for robust, user-friendly systems with secure locking systems, such as gravity rings or lever locks, to prevent any risk of accidental collapse during an event. The frame and leg construction should be of a heavy gauge steel to ensure stability. To facilitate the management of large inventories, specialized table carts and dollies are essential tools, simplifying the process of moving and storing dozens of tables for large-scale events.

Essential features for a commercial folding table include:

- Lightweight yet strong construction

- Durable, easy-to-clean tabletop materials

- Robust, heavy-gauge steel frames

- Secure, reliable locking mechanisms

- Compact folding designs for high-density storage

- UV protection for outdoor use (especially for HDPE)

- Non-marring foot caps to protect floors

- High static load weight capacity

Outdoor and Picnic Tables

Outdoor tables must be built to win a constant battle against the elements. Weather resistance is the single most important characteristic, so they are constructed from a specific palette of materials designed for exposure. These include UV-protected HDPE, powder-coated aluminum, and thermoplastic-coated steel. These materials are chosen for their ability to resist rust, corrosion, fading from sun exposure, and cracking from temperature fluctuations. Accessibility considerations, such as ADA-compliant designs with extended tabletops for wheelchair access, are crucial for public parks, campuses, and restaurant patios to ensure inclusivity. Practical features like pre-drilled umbrella holes improve customer comfort on sunny days, while features like drainage holes prevent water from pooling on the surface. For security in public areas, many outdoor tables are designed with options for surface or in-ground mounting to prevent theft. A quality commercial outdoor table is a long-lasting investment for any business looking to create a durable and inviting outdoor presence.

How to Choose the Perfect Commercial Grade Table

Choosing the right commercial grade table is a strategic decision that extends far beyond simple aesthetics. It directly impacts your operational efficiency, your customers' experience, your staff's safety, and your long-term budget. There is no single “best” table; the perfect choice is the one that aligns perfectly with the unique demands of your specific business application.

Factors for Your Specific Business Application

Before you begin browsing, conduct a thorough assessment of your requirements across several key areas.

- Intended Use: What is the table's primary job? A stainless steel surface with a marine edge is ideal for a messy food prep area, while a warm wood or stylish laminate top is better suited for a customer-facing cafe. For warehouse or workshop use, prioritize a high weight capacity (500 pounds or more) and impact resistance.

- Space and Layout: Carefully measure your space. You must account for traffic flow for both staff and customers. A good rule of thumb is to allow at least 24-30 inches between tables for comfortable passage and 36 inches for main aisles. Consider how table shape affects your layout: round tables encourage conversation and can feel less crowded, while rectangular tables maximize seating density. Adjustable height tables offer excellent versatility for multi-use spaces that host different types of events and tasks.

-

Seating Requirements: How many people do you need to seat? The answer depends not just on table size but also on your service style. A table that comfortably seats six for a quick lunch might feel cramped for a fine dining experience with more extensive place settings.

-

Quick Seating Guide:

- 30" Round/Square: Seats 2-3

- 36" Round/Square: Seats 4

- 48" Round: Seats 5-6

- 60" x 30" Rectangular: Seats 6

- 72" x 30" Rectangular: Seats 6-8

-

Quick Seating Guide:

- Indoor vs. Outdoor: This is a non-negotiable distinction. Outdoor tables absolutely require weather-resistant materials like HDPE with UV inhibitors, powder-coated aluminum, or thermoplastic-coated steel to prevent rust, cracking, and fading. Indoor tables offer more material flexibility, but must still be chosen for durability against constant use and cleaning.

- Aesthetics and Budget: Your tables are a significant part of your brand's physical identity. Choose a style that reflects the quality and character of your business. While commercial tables represent a higher upfront investment, their longevity makes them far cheaper in the long run. This concept, known as Total Cost of Ownership (TCO), accounts for the initial price plus the costs of replacement and repair over time. Laminate and HDPE are durable, budget-friendly options. For those starting out, our guide on Affordable Kitchen Essentials: Finding Quality Used Food Prep Equipment offers helpful strategies for maximizing your budget.

Understanding Lifespan and Warranty

A well-made commercial grade table, when properly cared for, can easily last 10 to 15 years, even in the most demanding environments. This impressive longevity is by design. Manufacturers back their products with substantial warranties, such as a 10-year limited warranty, because they are confident in the materials and construction. A good warranty covers defects in materials and workmanship under normal commercial use. It's crucial to read the fine print to understand what is and isn't covered. Typically, a “limited” warranty will not cover damage from abuse, improper use, non-approved cleaning agents, or normal wear and tear like minor scratches.

Maintenance, Cleaning, and Inspection

Commercial tables are designed for easy maintenance, but proper care is essential to maximize their lifespan. Different materials require different protocols.

- Stainless Steel: Always clean in the direction of the grain using a soft cloth and a specialized stainless steel cleaner or a mild soap solution. Avoid abrasive pads or steel wool, which will scratch the surface. For stubborn spots or to restore shine, a paste of baking soda and water can be effective.

- Granite: Use only pH-neutral soaps and cleaners. Acidic (like vinegar) or harsh chemical cleaners (like bleach) can damage the sealant and etch the stone itself. To maintain its stain resistance, the surface should be resealed periodically, typically every six months to a year. Consult the manufacturer's guidelines or a professional stone care resource for specific sealant recommendations.

- HDPE and Laminate: These are low-maintenance surfaces that can be easily cleaned with simple soap and water. Avoid using abrasive scrubbers on laminate, as they can dull the finish over time.

The golden rule for all tables is to clean spills immediately to prevent staining. Beyond cleaning, implement a regular inspection routine. Create a simple checklist:

- Check for Stability: Push on the table to check for any wobbling. Tighten all screws and bolts on the legs and base.

- Inspect the Surface: Look for any deep scratches, chips, or cracks that could harbor bacteria or worsen over time.

- Examine Edges: Check for peeling laminate or damaged T-molding that could snag clothing or allow moisture to penetrate the core.

- Test Mechanisms: For folding tables, regularly check that the locking mechanisms engage securely.

Frequently Asked Questions about Commercial Tables

Over the years, we've fielded countless questions from business owners navigating the process of choosing the right tables. To help you make an informed decision, here are the most common inquiries with clear, straightforward answers.

How much weight can a commercial grade table hold?

The weight capacity of a commercial grade table varies significantly based on its design, materials, and size, but it is always substantially higher than a residential table. As a general benchmark, a standard-duty commercial table can often support 500 pounds of evenly distributed weight. Heavy-duty models, particularly stainless steel work tables, can be rated for 1,000 pounds or more. It's crucial to understand the term 'distributed weight,' which means the load is spread evenly across the entire surface. 'Concentrated weight,' where a heavy load is placed in one small spot, will have a much lower limit. Always check the manufacturer's official specifications to ensure the table's capacity meets the demands of your equipment and tasks.

What is the main difference between a 16-gauge and 18-gauge stainless steel table?

The gauge system for sheet metal is counterintuitive: the lower the gauge number, the thicker, stronger, and more durable the steel.

16-gauge stainless steel is the thicker, heavy-duty option. It is approximately 1.59mm thick. This thickness provides superior resistance to denting, bowing, and warping, making it the ideal choice for high-volume kitchens, butcher shops, or for supporting very heavy countertop equipment.

18-gauge stainless steel is the industry standard for most commercial applications. It is approximately 1.27mm thick. It is still incredibly durable, corrosion-resistant, and offers excellent performance for general food prep, assembly, and storage at a more budget-friendly price point.

The choice depends entirely on the intensity of your operations. A busy bakery using heavy mixers might require 16-gauge for its main work table, while a small cafe or sandwich shop would be perfectly well-served by the durability of 18-gauge.

Can I use a residential table in my business?

While it might seem like a tempting way to save money upfront, using a residential table in any commercial setting is a critical mistake with serious consequences. Residential tables are not designed, built, or tested for the demands of commercial use. They use lighter materials, weaker joints (often screws and adhesives instead of welds), and finishes that will quickly fail under the constant activity, heavy loads, and harsh cleaning products used in a business.

Using a residential table creates significant safety and liability issues. A sudden collapse could lead to severe injuries to staff or customers, resulting in costly lawsuits and damage to your reputation. Furthermore, residential tables often have porous surfaces and designs with crevices that do not meet health department standards for sanitation, putting your business at risk of failed inspections and fines. Finally, any manufacturer's warranty is immediately voided by commercial use, leaving you to absorb the full cost of replacement when it inevitably and quickly breaks.

Investing in a proper commercial grade table is an essential, non-negotiable part of setting up a professional, safe, and compliant business. It's a foundational investment in reliability, safety, and the professional image of your establishment.

What does 'NSF Certified' mean for a table?

NSF stands for NSF International, a respected independent organization that develops public health standards and certification programs. When a table is NSF Certified, it means it has been tested and certified to meet strict standards for food safety. This certification ensures the table is designed and constructed with non-porous, non-toxic materials that are corrosion-resistant, and that it has a smooth, easily cleanable surface free of cracks, crevices, or sharp internal corners where bacteria could hide and grow. For any business involved in food preparation or service, choosing NSF Certified tables is a critical step in ensuring compliance with health codes and promoting a safe, hygienic environment.

How do I choose the right size base for my tabletop?

Pairing the correct base with your tabletop is crucial for stability and safety. An undersized base will create a wobbly, dangerous table that is prone to tipping. A simple rule of thumb is that the base's spread (the widest point of the base on the floor) should be at least as large as the tabletop's diagonal measurement, but ideally not so large that it obstructs chairs. For example, a 30" x 30" square top has a 42.4" diagonal, so you'd want a base with a spread of at least 28-30" to be stable without being too cumbersome. Most manufacturers provide compatibility charts that specify which base models and sizes are approved for specific tabletop dimensions and weights. Always follow these recommendations to ensure a safe and stable assembly.

Are there ADA-compliant commercial tables?

Yes, and they are essential for ensuring accessibility in public accommodations as required by the Americans with Disabilities Act (ADA). An ADA-compliant table must meet specific dimensional requirements to allow for wheelchair access. The key standards are a tabletop surface height between 28 inches and 34 inches from the floor, and a clear knee and toe space underneath that is at least 27 inches high, 30 inches wide, and 19 inches deep. This allows a person in a wheelchair to pull up to the table comfortably. Many manufacturers offer specific ADA-compliant dining tables, picnic tables, and workstations.

Conclusion

A commercial grade table is far more than just a piece of furniture; it is a foundational investment in your business's productivity, safety, and professional image. The right table is a workhorse that supports your success, whether it's the uncompromising durability and hygiene of an NSF-certified stainless steel prep table, the go-anywhere versatility of an HDPE folding table, or the sophisticated elegance of a granite-topped dining table that lifts the customer experience.

Throughout this guide, we've explored the critical distinctions that define commercial quality, from rigorous ANSI/BIFMA testing standards to the superior materials and construction that ensure a long service life. We've digd into the specific strengths of key materials—from the different gauges and types of stainless steel to the various cores and edges of laminate and the robust beauty of granite. Understanding these details allows you to look beyond the initial price and consider the Total Cost of Ownership, making an informed investment that saves you money over time by eliminating frequent replacements, reducing liability risks, and avoiding operational disruptions.

At The Restaurant Warehouse, we are committed to the principle that every business, regardless of size, deserves access to professional, commercial grade tables that work as hard as they do. We provide reliable, high-performance equipment at transparent wholesale pricing, stripping away the high commissions and complexities of traditional retail models. The right table can make all the difference in your team's efficiency, your compliance with health codes, and your customers' overall perception of your brand. For specialized applications, such as a dedicated pizza prep table, having the correct, purpose-built surface can lift your entire operation.

Your business is built on a foundation of quality and hard work. Your equipment should be, too. Choose furniture that is built to last, designed for safety, and priced for your success. That is the bedrock of a resilient and thriving enterprise.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment