Affordable Kitchen Essentials: Finding Quality Used Food Prep Equipment

Why Used Food Prep Equipment Makes Smart Business Sense

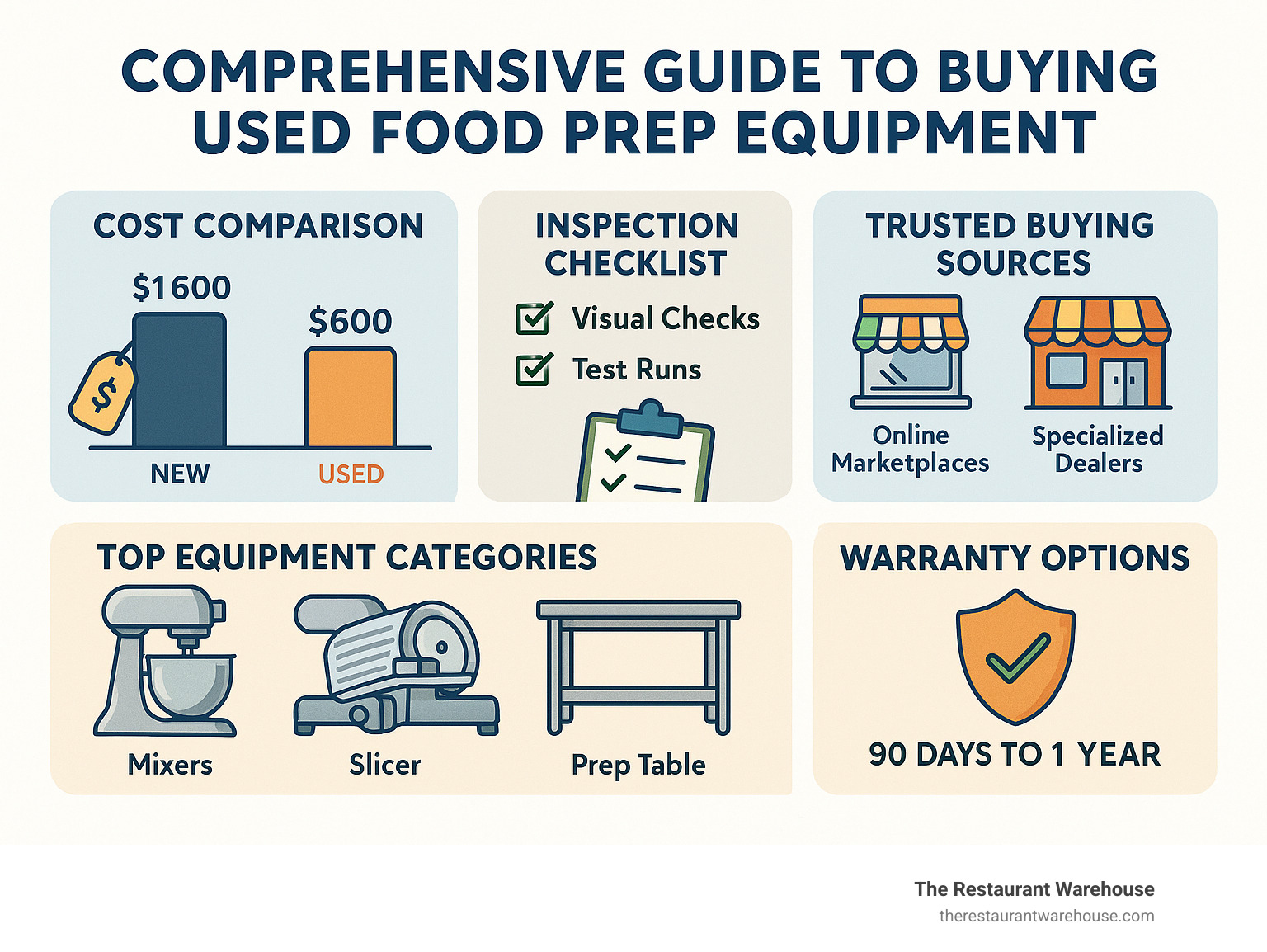

Used food prep equipment offers restaurant owners significant cost savings while delivering the same performance as new units. With equipment losing substantial value immediately after purchase, buying pre-owned allows you to access top-brand machinery at 30-60% below retail prices.

Quick Answer for Buyers: - Cost Savings: Save 30-60% compared to new equipment prices - Top Categories: Mixers, slicers, prep tables, food processors, scales - Best Sources: eBay (88,000+ listings), specialized dealers, equipment auctions - Quality Assurance: Look for refurbished units with 90-day warranties - Popular Brands: Hobart, Robot Coupe, True, Berkel, Electrolux

Starting a restaurant or expanding your kitchen doesn't have to drain your budget. The used commercial equipment market has grown substantially, with established dealers offering professionally refurbished machinery backed by warranties and quality guarantees.

As one satisfied buyer noted: "We bought a few stainless steel prep tables and love them." This reflects the growing confidence restaurateurs have in pre-owned equipment when purchased from reputable sources.

The sustainability angle also appeals to environmentally conscious operators. Buying used reduces demand for new manufacturing while giving quality equipment a second life in your kitchen.

Companies like Regal Equipment have been successfully buying and selling used food processing equipment for over 35 years, proving this market's reliability and long-term viability.

Why Choose Used Food Prep Equipment

Smart restaurant owners know that used food prep equipment offers advantages that go far beyond just saving money upfront. When you're building or expanding your kitchen, every dollar counts - and buying used lets you stretch those dollars much further.

The numbers speak for themselves. New commercial equipment loses a shocking 40-60% of its value the moment it leaves the warehouse. That expensive mixer or slicer you're eyeing? It's probably available used for half the price, working just as well as the day it was manufactured.

Think about it this way: would you rather spend $5,000 on one new mixer, or get that same mixer for $2,500 and use the savings for better ingredients or staff training? The choice becomes pretty clear when you put it like that.

Time is money in the restaurant business, and used equipment delivers fast. While new equipment can take 4-8 weeks to arrive (sometimes longer for specialty items), quality used pieces typically ship within days. We've seen restaurants get back up and running in less than a week after equipment failures - that's the difference between staying profitable and losing customers.

Your investment holds its value better with used equipment too. Since the major depreciation hit already happened to the previous owner, your purchase price stays more stable over time. It's like buying a car that's already taken the biggest depreciation hit.

Going green feels good - and it's good for business. Every piece of refurbished equipment you buy keeps perfectly good machinery out of landfills while reducing demand for new manufacturing. Your customers notice when you make environmentally conscious choices.

Flexible payment options make it even easier to upgrade your kitchen without emptying your bank account. See terms and apply now – for PayPal Credit to spread costs over time while keeping your cash flow healthy.

The bottom line? Used food prep equipment lets you build a professional kitchen without the new-equipment price tag. You get the same performance, faster delivery, and better long-term value - plus you'll sleep better knowing you made a smart financial decision.

Want to dive deeper into kitchen budgeting strategies? Check out our comprehensive guide: More info about kitchen budgeting.

Top Categories & Popular Models

Walking through any busy commercial kitchen, you'll spot the same essential pieces of used food prep equipment working hard day after day. After helping thousands of restaurant owners find the perfect gear, we've learned which categories offer the best bang for your buck in the used market.

Planetary mixers are absolute kitchen workhorses, and Hobart models like the A200 20-quart mixer practically run forever with basic care. You'll find used Hobart mixers selling for $1,500-$4,000 compared to $4,000-$8,000 new - that's money you can put toward better ingredients or staff training. Electrolux and KitchenAid commercial units also hold up beautifully in the used market.

Food processors save hours of prep time, with Robot Coupe leading the pack. Their R-series models handle everything from dicing onions to making perfect sauces. A used Robot Coupe R602 typically costs $800-$1,200 versus over $2,000 new. The CL50 continuous feed processor is a game-changer for busy kitchens that need to prep large quantities quickly.

Prep tables might seem basic, but quality stainless steel units hold their value incredibly well. We've seen over 2,000 NSF-certified 72" x 30" tables sell on major marketplaces, proving how much restaurant owners love these reliable workhorses. Used prep tables typically cost 50-70% less than new while giving you the exact same functionality.

When it comes to meat and cheese slicers, Berkel models are often called "the Rolls Royce of slicers" for good reason. The Avery Berkel 800 with its 12-inch gravity feed delivers professional results at a fraction of new equipment cost. These machines are built to slice thousands of pounds without missing a beat.

Digital scales show some of the most dramatic savings in the used market. Commercial price computing scales rated for 88 pounds often sell at 38% off retail while maintaining perfect accuracy. Your customers won't know the difference, but your wallet certainly will.

Commercial blenders from brands like Vitamix and Waring keep their powerful motors and rock-solid reliability when bought used. Whether you're making smoothies, soups, or sauces, professional-grade units typically cost 40-50% less than new.

For specialized baking operations, dough sheeters from manufacturers like Nussex, Erika, and Somerset provide the same consistent results whether they're fresh from the factory or gently used. These precision machines make specialized baking equipment accessible to smaller operations.

Refrigerated prep tables deserve special mention because they combine workspace with temperature control. True and similar brands produce units that maintain consistent temperatures for years. Every used refrigerated unit gets thorough testing before sale to ensure the cooling system works perfectly.

For detailed guidance on choosing the right prep surface, check out our Sandwich Prep Table Guide.

Budget-Friendly Used Food Prep Equipment for Startups

Starting a restaurant means making every dollar count, and used food prep equipment lets you get professional results without the premium price tag.

Entry-level mixers in the 10-20 quart range handle most startup needs perfectly. These workhorses cost $800-$2,000 used versus $2,500-$4,500 new, yet they'll mix bread dough, cake batters, and everything else you need for a restaurant serving 50-100 customers daily.

Countertop food processors like the Robot Coupe R301 Ultra fit tight spaces while delivering professional chopping, slicing, and pureeing power. Used units typically run $600-$900 compared to over $1,500 new - that's serious savings for the same great results.

Compact slicers with 10-12 inch blades meet most deli and sandwich shop needs without taking up valuable counter space. Quality used models cost $400-$800 versus $1,200-$2,000 new, making professional slicing affordable for any startup.

High-Volume Favorites

Once your restaurant hits its stride, you'll need equipment that can handle the rush without breaking down.

Floor mixers in the 40-80 quart range support serious baking and food production. Used Hobart floor mixers range from $3,000-$8,000 compared to $8,000-$15,000 new. For bakeries and large kitchens, these savings can fund other critical equipment purchases.

Continuous feed processors like the Robot Coupe CL series handle constant vegetable prep for busy kitchens. The CL50 continuous feed model processes large quantities quickly, turning what used to be hours of knife work into minutes of efficient prep.

Heavy-duty slicers such as the Omas CX Matic 35E provide consistent results with minimal operator effort. These professional units typically cost $2,000-$4,000 used versus $5,000-$8,000 new, delivering the same precision slicing that keeps customers coming back.

Evaluating, Maintaining & Pricing Your Purchase

Smart used food prep equipment purchases require thorough evaluation before buying and proper maintenance afterward. We've developed systematic approaches that help ensure you get reliable equipment that serves your operation for years.

Visual Inspection Checklist

Start with external examination for obvious damage, excessive wear, or poor maintenance signs. Check stainless steel surfaces for deep scratches, dents, or corrosion. Inspect electrical cords for fraying or damage. Look for missing parts, especially safety guards and removable components.

Examine moving parts for smooth operation. Mixer attachments should fit securely without wobbling. Slicer blades should be sharp and properly aligned. Food processor bowls should seal completely without cracks.

Test Run Procedures

Always request demonstration or testing before purchase. Run mixers through all speed settings, listening for unusual noises or vibrations. Test slicers with sample materials to verify consistent cutting thickness. Check temperature controls on refrigerated units using external thermometers.

For processors, verify all attachments function properly and safety interlocks engage correctly. Test scales with known weights to confirm accuracy across the full range.

Service Log Review

Quality sellers maintain service records showing regular maintenance and repairs. These logs indicate how well the equipment was cared for and identify any recurring issues. Equipment with documented preventive maintenance typically offers better long-term reliability.

Sanitation Standards

Commercial equipment must meet NSF (National Sanitation Foundation) standards for food contact surfaces. Verify NSF labels are present and legible. Deep cleaning should be evident, with no food residue or grease buildup in hard-to-reach areas.

Warranty and Return Policy Review

Reputable dealers offer 90-day to 1-year warranties on refurbished equipment. Understand what's covered - parts, labor, or both. Some dealers provide extended warranty options for additional peace of mind. Return policies should allow 14-30 days for evaluation, though buyer typically pays return shipping.

Cost and Lifespan Analysis

| Equipment Type | New Price Range | Used Price Range | Typical Savings | Expected Lifespan |

|---|---|---|---|---|

| 20-Qt Mixer | $3,000-$5,000 | $1,500-$3,000 | 40-50% | 15-20 years |

| Food Processor | $1,500-$3,000 | $800-$1,500 | 45-55% | 10-15 years |

| Meat Slicer | $2,000-$4,000 | $800-$2,000 | 50-60% | 12-18 years |

| Prep Table | $800-$1,500 | $400-$800 | 50-60% | 20+ years |

| Digital Scale | $300-$600 | $150-$350 | 40-50% | 8-12 years |

Preventive Maintenance Planning

Establish maintenance schedules immediately after purchase. Mixers need gear oil changes every 6-12 months depending on usage. Slicers require daily cleaning and weekly blade sharpening or replacement. Food processors need blade replacement based on usage volume.

Professional Cleaning Schedule

Deep cleaning schedules vary by equipment type and usage. High-touch items like slicers need daily sanitization, while mixers might require weekly deep cleaning. Monthly or quarterly professional service helps identify potential issues before they cause breakdowns.

For comprehensive equipment evaluation guidance, review our Used Commercial Kitchen Equipment Guide.

Maintaining Used Food Prep Equipment for Safety

Food safety remains paramount regardless of equipment age. Proper maintenance ensures your used food prep equipment meets health department standards while protecting your customers and business.

Deep Cleaning Protocols

Establish cleaning procedures that exceed basic requirements. Food processing equipment requires monthly, quarterly, or bi-annual deep cleaning depending on usage intensity. Remove all removable parts for thorough cleaning and sanitization.

Use food-safe degreasers and sanitizers approved for commercial kitchens. Pay special attention to areas where food particles might accumulate - mixer bowls, processor chambers, slicer guards, and scale platforms.

Replacement Parts Strategy

Identify critical wear parts and establish replacement schedules. Mixer beaters, processor blades, and slicer components wear predictably based on usage. Stock essential parts to minimize downtime when replacements are needed.

Work with suppliers who stock OEM (Original Equipment Manufacturer) parts when possible. Generic parts might cost less initially but could affect performance or safety.

Safety Certification Maintenance

Ensure safety features remain functional throughout equipment life. Test emergency stops, safety interlocks, and guards regularly. Replace damaged safety components immediately - never operate equipment with bypassed safety features.

Monthly Inspection Routine

Develop systematic monthly inspections covering electrical connections, moving parts, and safety systems. Document findings to track equipment condition over time. Address minor issues promptly before they become major problems.

Used Food Prep Equipment vs New: Price Breakdown

Understanding the financial implications helps justify used equipment purchases and plan realistic budgets.

Market Average Discounts

Research shows consistent discount patterns across equipment categories:

- Mixers: 40-55% savings

- Food processors: 45-60% savings

- Slicers: 50-65% savings

- Prep tables: 50-70% savings

- Scales: 35-50% savings

ROI Timeline Analysis

Most used food prep equipment purchases pay for themselves within 12-18 months through reduced capital costs. A $2,000 used mixer versus a $4,000 new unit saves $2,000 that can generate revenue through increased capacity or improved efficiency.

Energy Efficiency Considerations

Older equipment might consume more energy than current models. Factor utility costs into total cost of ownership. However, the energy difference rarely offsets the substantial purchase price savings, especially for equipment used intermittently.

Where to Buy & Support Services

Finding the right source for your used food prep equipment can make the difference between a great purchase and a costly mistake. We've spent years building relationships with trusted suppliers and learning which channels deliver the best value for restaurant owners.

Your Online Options: Bigger Isn't Always Better

The internet offers incredible selection - we're talking about 88,000+ listings for used commercial food prep equipment across major platforms. These marketplaces let you filter by brand, condition, price, and location, making it easy to find exactly what you need.

The auction format often drives competitive pricing, and you can usually find equipment that ships within days. Just remember to dig into seller ratings and return policies before clicking "buy now." A few extra minutes of research can save you weeks of headaches later.

Specialized Dealers: Your Secret Weapon

Here's where things get interesting. Professional equipment dealers focus exclusively on commercial kitchen gear, which means they actually understand what you're buying. Unlike general marketplaces, these folks know the difference between a good deal and a potential disaster.

Quality dealers offer something you can't get elsewhere: professionally refurbished equipment with real warranties. We're talking 90 days to a full year of coverage, plus the peace of mind that comes from buying from someone who stakes their reputation on every sale.

Many maintain showrooms where you can actually touch and test equipment before purchase. There's something reassuring about hearing a mixer run smoothly or seeing a slicer cut perfect, even slices before you commit your hard-earned money.

Local Auctions: The Treasure Hunt

Restaurant closures create auction opportunities that can yield incredible savings. Both live and online auctions let you bid on everything from single pieces to complete kitchen setups.

The catch? You'll need cash ready and a way to haul your purchases immediately. But if you've done your homework on equipment values, auctions can deliver prices that make even used equipment dealers jealous.

Refurbishment Centers: Like New, But Smarter

These specialized facilities take used equipment and restore it to like-new condition. Trained technicians handle everything from deep cleaning to mechanical repairs, then back their work with solid warranties.

Yes, you'll pay more than buying directly from a closing restaurant. But the quality assurance and warranty coverage often make the premium worthwhile, especially for critical equipment where downtime costs real money.

The Support Services That Matter

Professional appraisals help when you need accurate values for insurance, financing, or resale. Comprehensive reconditioning services can transform tired equipment into reliable workhorses. Asset management programs help larger operations track, maintain, and plan equipment lifecycles efficiently.

Shipping and logistics services handle the heavy lifting - literally. Professional freight companies know how to move delicate equipment safely, and many dealers offer installation and setup services that get you operational quickly.

Extended warranties provide additional protection beyond standard coverage, typically adding 1-3 years of parts and labor coverage. After-sales support continues the relationship long after purchase, providing technical help, parts sourcing, and maintenance guidance.

For comprehensive buying strategies, check out our detailed guide: Buy Used Restaurant Equipment.

Finding Us When You're Ready

When you're ready to see quality used food prep equipment in person, you can Get directions 427B E Patrick St Frederick, MD to visit our showroom. There's real value in seeing, touching, and testing equipment before you buy.

Frequently Asked Questions about Used Food Prep Equipment

Understanding the Price Landscape

Pricing varies dramatically based on what you're buying and where you're buying it. Small processors or digital scales might start around $200-$500 used, while heavy-duty mixers and specialized equipment can run $3,000-$10,000. The sweet spot for most used food prep equipment falls between 40-70% of new equipment prices.

Warranty Realities

Standard warranties typically run 90 days to a full year, covering parts and labor for mechanical failures and defects. Extended warranties up to 3 years are available for additional cost - usually 10-15% of the equipment price. Always read the fine print to understand exactly what's covered.

Meeting Health Department Standards

Quality used equipment meets identical sanitation standards as new units when properly refurbished. Look for intact NSF certification labels and verify the equipment has received professional cleaning and sanitization. Your local health department cares about cleanliness and safety, not the age of your equipment.

How much can I save by buying used?

The numbers are compelling: savings typically range from 30-60% compared to new equipment prices. We've seen customers save $1,200-$2,400 on a single mixer purchase, with average payback periods of 12 months through reduced capital requirements.

These savings multiply quickly. Outfitting a complete prep station with quality used equipment might cost $8,000-$12,000 versus $20,000-$30,000 new. That's real money you can invest in ingredients, marketing, or building your team.

What warranties are available on used gear?

Most reputable dealers provide 90-day to 1-year warranties covering parts and labor for mechanical defects. Coverage typically excludes normal wear items like blades and belts but includes the expensive stuff - motors, controls, and structural components.

Extended warranty plans often available for 1-3 additional years provide extra peace of mind for critical equipment. Some dealers offer parts-only warranties at reduced cost if you have maintenance capabilities in-house.

Is used equipment safe for food contact?

Absolutely, when properly maintained. NSF-certified equipment meets strict food safety standards regardless of age. Professional refurbishment includes thorough cleaning, sanitization, and safety system verification.

The key factors include intact NSF labels, functional safety guards and interlocks, proper cleaning protocols, and regular maintenance schedules. Quality dealers ensure equipment meets all safety standards before sale and provide documentation for health department inspections.

Your customers deserve safe food, and quality used food prep equipment delivers that safety at a fraction of the cost of new equipment.

Conclusion

Making the switch to used food prep equipment isn't just about saving money - it's about making smart business decisions that set your restaurant up for long-term success. When you can save 30-60% on professional-grade equipment while getting the same performance, those savings quickly add up to real money you can put back into your business.

At The Restaurant Warehouse, we've built our reputation on helping restaurant owners like you access wholesale pricing without the hefty commissions that drive up costs elsewhere. We know that every dollar you save on equipment is a dollar you can spend on the things that really matter - better ingredients, skilled staff, or that marketing campaign you've been planning.

The advantages speak for themselves. You get immediate cost savings that can reach thousands of dollars per purchase. You avoid the steep depreciation hit that new equipment takes the moment it leaves the warehouse. When you need equipment fast, used options are typically ready to ship in days rather than weeks. Plus, you're doing something good for the environment by giving quality equipment a second life.

Ready to get started? Begin by taking a hard look at what your kitchen really needs and which pieces will give you the biggest bang for your buck. Focus your search on dealers who stand behind their equipment with solid warranties and professional refurbishment services.

When you find equipment that looks promising, use our inspection guidelines to make sure you're getting a good deal. Don't forget to plan for ongoing maintenance from day one - a little care goes a long way toward keeping used equipment running smoothly for years.

If the upfront cost is still a concern, explore financing options that let you spread payments over time while preserving your cash flow for daily operations.

The used equipment market has been thriving for over 35 years because it works. Restaurant owners across the country have finded that buying used doesn't mean settling for less - it means being smart with your money while still getting the professional tools you need.

Whether you're just starting out, growing your existing business, or dealing with an unexpected equipment failure, used food prep equipment offers a practical path forward that won't break the bank.

Want to dive deeper into building your kitchen on a budget? Check out our comprehensive guide with More info about affordable used equipment to find even more ways to save.

Your kitchen deserves professional equipment, and your budget deserves respect. Start exploring your options today and see how the right used equipment purchases can transform your operation while keeping your finances healthy.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment