How to Organize a Chest Freezer for Restaurant Profit

That chaotic chest freezer tucked away in the back of your kitchen? It's costing you more than just time and sanity. A disorganized freezer quietly eats away at your profits through wasted food, lost staff hours, and a general drag on your kitchen's operations, making a systematic approach a critical part of your business strategy.

The Hidden Costs of a Disorganized Chest Freezer

For a lot of restaurant operators, the chest freezer is an out-of-sight, out-of-mind workhorse. But what’s lurking under that lid can have a direct and pretty significant impact on your bottom line. A jumbled mess of boxes, bags, and vacuum-sealed portions isn't just an inconvenience; it's a financial liability that quietly drains your resources every single day.

Think about it. Each time a line cook has to dig through layers of frozen goods to find a specific cut of beef or a container of house-made sauce, valuable seconds are lost. During a hectic dinner rush, these seconds add up to minutes of wasted labor, slower ticket times, and a seriously frustrated team.

Financial Drains Hiding in Plain Sight

The most obvious cost comes directly from food waste. Items buried at the bottom get forgotten, leading them to expire or develop severe freezer burn that makes them unusable. That's a direct loss of inventory and profit. In fact, just getting a chest freezer organized can slash food waste by up to 30%.

Poorly arranged units also struggle with uneven cooling. Temperature fluctuations can increase spoilage rates by another 25% as items nearer the top partially thaw and refreeze. Industry reports have shed a lot of light on these cold storage challenges.

Beyond spoilage, disorganization leads to over-ordering. When you can't see what you have, you inevitably buy more, tying up cash in inventory you don't actually need. This directly impacts your ability to accurately calculate your restaurant's food cost percentage and keep your margins healthy.

A disorganized freezer is like a hidden tax on your kitchen's efficiency. It creates a cycle of waste—wasted product, wasted labor, and wasted capital—that you are paying for every single service.

Ultimately, mastering how to organize a chest freezer isn't just about being tidy. It’s a core operational discipline that protects your inventory, streamlines your kitchen's workflow, and gives your profitability a real boost. The time you invest in creating a system will pay dividends, transforming a chaotic cost center into a lean, efficient, and profitable asset for your business.

Designing a Strategic Freezer Layout

A chaotic chest freezer is a money pit. Seriously. But a well-thought-out plan can turn that deep freeze into one of your kitchen's most efficient assets. Before you even think about moving a single box, you need to map out the space with intention.

This isn’t just about making things look tidy. It's about creating a logical system that actually supports your kitchen's workflow, cuts down on waste, and saves your crew precious time during a chaotic dinner rush.

Start by doing a full inventory audit. I mean it—pull everything out, group similar items together, and get a clear, honest look at what you actually have. This process alone often uncovers duplicate orders or forgotten stock that can be used right away, which immediately trims down your next supply order. Once you see it all laid out, you can start thinking strategically about where it all should live.

The Power of Freezer Zoning

The absolute core of an effective layout is zoning. This just means creating dedicated, clearly defined areas for specific food categories. Think of your chest freezer as a grid, not a bottomless pit. By assigning zones, anyone on your team can find what they need in seconds, without having to dig through a mountain of unrelated items.

A typical zoning strategy for a restaurant might look something like this:

- Raw Proteins: Group all beef, poultry, and seafood together. Ideally, you’ll keep them in separate, color-coded bins to make cross-contamination a non-issue.

- Vegetables and Fruits: Keep all your frozen produce in one area. This makes it a breeze to grab items for sides, smoothies, or sauces.

- Prepared Goods: This zone is for all your house-made sauces, soups, stocks, and any pre-portioned items that are ready for service.

- Breads and Baked Goods: Dedicate a specific space for all bread, pastries, or desserts to keep them from getting crushed.

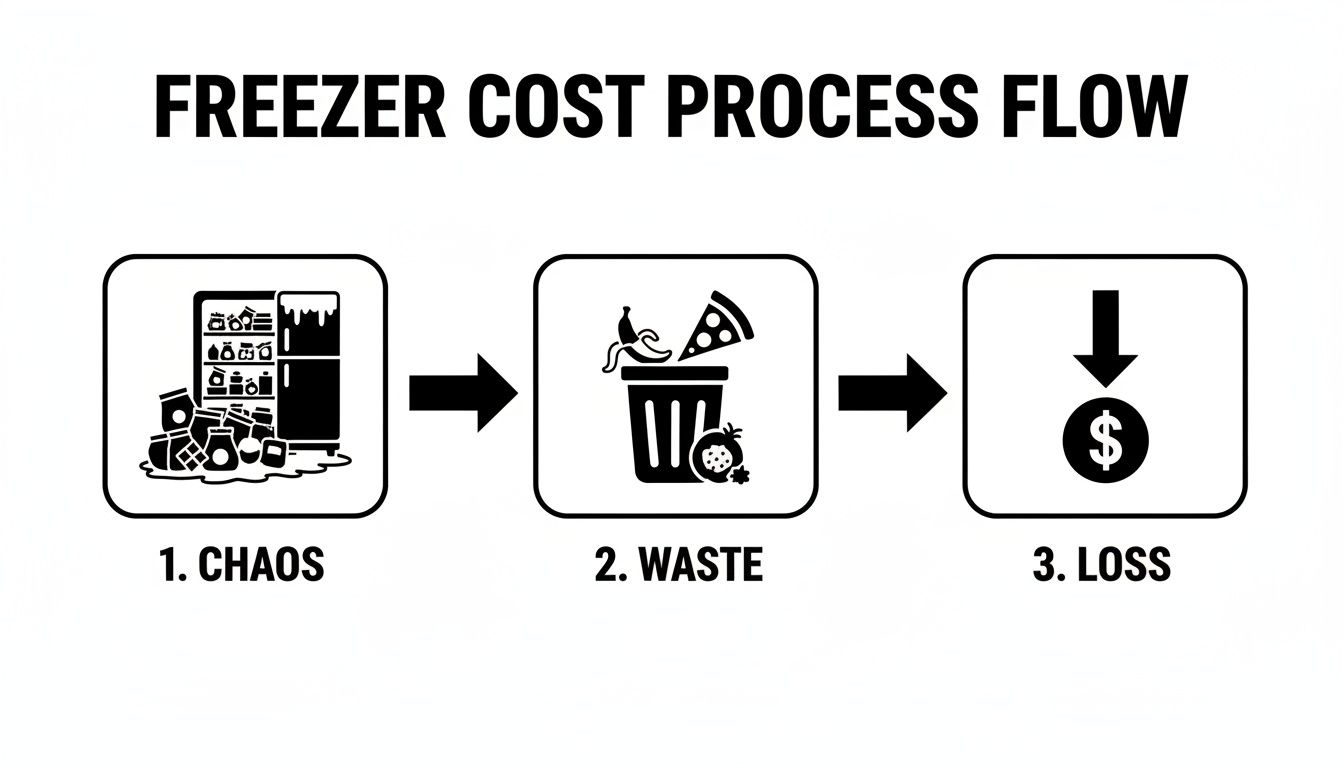

This simple chart shows how a lack of organization directly bleeds into financial loss, hammering home why a strategic layout is so critical.

This flow is a perfect illustration of the path from a messy freezer to wasted food and lost revenue. A zoned system is how you break that cycle for good.

Chest Freezer Zoning Strategy

To make this super practical, here’s a table outlining a smart zoning strategy. This approach divides your freezer based on how often you use things, which makes grabbing what you need second nature.

| Zone (Location in Freezer) | Recommended Contents | Rationale & Pro Tip |

|---|---|---|

| Top Baskets/Upper Layer | High-turnover items: pre-portioned steaks, fries, daily-use sauces, quick-grab appetizers. | These are your money-makers. Keep them in the most accessible spot to shave seconds off ticket times. Pro Tip: Use shallow, open-top bins for grab-and-go access. |

| Middle Layer (Center) | Moderately used items: frozen vegetables, fruits, prepared soups, bread, and back-up proteins. | These items are still used regularly but aren't needed every five minutes. Stacking them centrally keeps them easy to find. Pro Tip: Use clear, stackable bins with labels on the front and top. |

| Bottom Layer (Floor) | Bulk and long-term storage: large cuts of meat, cases of stock, bulk-purchased seasonal ingredients. | This is for the stuff you don't need to access daily. Storing heavy, bulky items at the bottom creates a stable base. Pro Tip: Vacuum-seal bulk items and lay them flat to maximize space. |

| Side Pockets/Corners | Small or specialized items: bags of nuts, purees, specialty doughs, ice cream bases. | These small nooks are perfect for odd-shaped packages that would otherwise get lost. Pro Tip: Use vertical dividers to create "file folders" for flat-packed items like vacuum-sealed fish fillets. |

Following a simple map like this turns a potential black hole of inventory into a well-oiled machine.

Arranging Zones for Maximum Efficiency

Once you have your categories, arrange them based on frequency of use. High-turnover ingredients, like those pre-portioned steaks for your most popular dish, should be in the most accessible spots—either near the top or in the upper baskets. Items you use less often, like bulk stock ingredients, can live at the very bottom.

Proper organization makes a massive difference in kitchen performance. In fact, a good system can boost inventory accessibility by 45%—a huge advantage for any busy kitchen. Since chest freezers hold up to 20% more than uprights, a messy one means about 25% of its contents get forgotten, leading to roughly $1,500 in annual waste for a small kitchen. You can learn more about the advantages of these units by exploring our complete chest freezer guide for restaurants.

The goal is to create an intuitive system where muscle memory takes over. Your staff should be able to reach into the freezer and grab what they need without a second thought, confident that it will be in its designated spot.

Finally, invest in the right storage containers. Stackable, clear-sided, heavy-duty plastic bins are perfect because you can see what’s inside and they can take a beating. Vertical dividers are also fantastic for creating partitions, preventing bags and vacuum-sealed packages from collapsing into a jumbled pile. These tools are what turn that deep, open space into a structured and easily navigated system.

Nail Down a Foolproof Inventory System

A killer layout with smart zones is the backbone of an organized chest freezer, but a dynamic inventory system is what keeps it from falling back into chaos. This is where we move from the physical setup to the daily habits that keep your freezer working for you. Without a reliable way to track what’s coming in and what’s going out, even the best-zoned freezer will eventually become a black hole of forgotten product.

The goal here is a system simple enough for the whole team to use, even in the middle of a chaotic dinner rush. It’s all about creating a workflow that sticks, not some complicated process everyone abandons after a week. This system becomes your single source of truth for everything you’ve got on ice.

Master FIFO with Smart Labeling

In a commercial kitchen, the First-In, First-Out (FIFO) rule is non-negotiable. It’s the simplest, most effective way to make sure you’re using older stock before it loses quality or expires. To make FIFO actually work in a deep chest freezer, clear and durable labeling is everything. Think of that label as your first line of defense against waste.

Every single item that hits your freezer needs a label with this crucial info:

- Item Name: Be specific. "Beef Short Ribs" is way better than just "Beef."

- Pack Date: The day the product was received or prepped and frozen.

- Use-By Date: The last day to use the item for optimal quality.

For a fast-moving kitchen, try color-coding your labels. For example, use a different colored marker or sticker for each month. This lets a line cook see at a glance which bin of chicken needs to be pulled first, no reading required.

A great inventory system does more than just track dates; it prevents over-ordering and ensures you're using the products you’ve already invested in. It transforms your freezer from a passive storage unit into an active, cost-saving tool.

Choose Your Inventory Tracking Method

Once your labeling is on point, you need a master list to keep track of it all. This doesn’t have to be complicated. You can go with a reliable low-tech method or a simple digital solution—it really just depends on your kitchen’s needs and your team’s comfort level with tech.

A well-run system is powerful. Strategic freezer organization can extend food shelf life by 40%. Using bins to rotate stock with FIFO has been proven to slash waste by 28% in retail settings—a critical practice as frozen food demand drives a $20.76B market.

Inventory System Comparison Low-Tech vs Digital

To help you decide which path is right for your kitchen, let’s break down the pros and cons of the two main approaches to inventory tracking.

| System Type | Pros | Cons | Best For |

|---|---|---|---|

| Low-Tech (Laminated Sheets) | Inexpensive, no tech needed, easy for all staff to learn and use. | Prone to human error, can get messy or lost, requires manual updates. | Smaller kitchens, food trucks, or operators who prefer a tangible, hands-on system. |

| Digital (Spreadsheets/QR Codes) | Accessible from anywhere, easily updated in real-time, searchable, can be linked to ordering. | Needs a device and internet access, might have a slight learning curve for some staff. | Multi-unit operations, tech-savvy teams, and kitchens wanting detailed data analysis. |

Ultimately, both methods get you to the same place: knowing exactly what’s on hand. The real key is consistency. Whichever system you pick, make updating it a non-negotiable part of the daily closing routine or weekly ordering process. This discipline turns your inventory list into a core component of your overall restaurant inventory management system.

Maintaining Food Safety and HACCP Compliance

Let's be clear: how you organize your chest freezer goes way beyond just efficiency and saving a few bucks. It's a fundamental part of your kitchen's food safety plan. A meticulously arranged freezer isn't just a "nice-to-have"—it's a critical control point in your HACCP system, directly protecting your customers and your restaurant's reputation.

The single most important job of your freezer is maintaining a consistent, rock-solid temperature. It absolutely must hold at or below 0°F (-18°C) at all times. This is the magic number that halts the growth of nasty bacteria.

A common mistake is trusting the freezer’s built-in thermostat. Those usually just measure the air temperature inside the unit, not the actual temperature of your food inventory. Instead, place a calibrated, external digital thermometer right in the freezer, nestled among the food packages. That little gadget gives you the real story and should be checked daily as part of your opening or closing routines.

Packaging and Cross-Contamination Prevention

Proper packaging is your next line of defense against disaster. Every single item needs to be sealed up tight in moisture-proof, airtight materials. Think vacuum-sealed bags or heavy-duty, commercial-grade freezer containers. This does more than just prevent freezer burn; it creates a physical barrier that stops cross-contamination between your raw and ready-to-eat products.

Think back to how you zoned your freezer. Raw proteins, especially poultry, must always live on the bottom layer or in their own dedicated, sealed bins. No exceptions. This ensures that if a package ever leaks—and it happens—the drippings can't contaminate anything stored below.

An organized freezer is a safe freezer. Every element—from temperature monitoring to proper packaging and strategic placement—works together to create a system that actively prevents foodborne illness and ensures you meet and exceed health code standards.

Safe Thawing Procedures

Finally, a well-organized freezer directly impacts how safely you can thaw food. When your staff can find the exact item they need in seconds, it eliminates the dangerous practice of pulling out multiple items "just in case" and leaving them on a counter. Never, ever thaw food at room temperature.

The only approved methods are the ones you know:

- In a refrigerator held at 41°F (5°C) or below.

- Submerged under cold, running water that's 70°F (21°C) or below.

- As an integral part of the cooking process itself.

Ultimately, keeping a well-organized freezer is all about building a system to prevent people from getting sick. It's smart to brush up on all the effective ways to prevent foodborne illness to ensure every corner of your kitchen is buttoned up. This reinforces that a systematic approach isn't just about saving money—it's about running a safe, compliant, and trustworthy kitchen.

Keep Your Freezer Humming with Routine Maintenance

An organized chest freezer is just the start. If you want that freezer to be a reliable, long-term asset for your kitchen, routine maintenance is non-negotiable. Neglecting the basics is a fast track to poor performance, sky-high energy bills, and a much shorter lifespan for your equipment.

Think of it like changing the oil in your delivery van—it’s a simple, preventive step that helps you avoid a catastrophic breakdown when you can least afford it. A little regular upkeep ensures your freezer runs at its best, protecting the thousands of dollars of inventory packed inside.

A consistent schedule is your best friend here. If you want to see how this mindset applies to all your gear, check out a general preventive maintenance schedule template. This approach is crucial for keeping your entire kitchen operational, not just your freezer.

The All-Important Defrost

For any manual-defrost model, getting rid of ice buildup is about more than just cleaning—it's about efficiency. Once ice gets thicker than a quarter-inch, it acts like an insulator. This forces the compressor to work overtime just to hold the right temperature, leading to premature wear and tear on components and a painfully high electricity bill.

Here’s the game plan for defrosting:

- Move the Food: First, get all your frozen goods into another freezer or packed tightly into insulated coolers.

- Power Down: Unplug the unit completely. No shortcuts here.

- Let It Melt: Prop the lid open and lay down towels around the base to catch the water. To speed things up, you can place a few pans of hot water inside. Just never, ever use a knife or scraper to chip away at the ice—it’s incredibly easy to puncture the freezer wall and ruin the unit for good.

- Drain and Clean: Once the ice is gone, drain the water. Give the interior a good wipe-down with a simple mix of warm water and a little baking soda to knock out any odors, then dry it completely before turning it back on.

A well-maintained freezer is a predictable freezer. By making routine checks and cleaning a non-negotiable part of your kitchen's workflow, you eliminate surprises and ensure your equipment is always ready for service.

Quick Maintenance Checklist

Beyond a full defrost, a few quick checks can save you from major headaches down the road. Try to build these into your quarterly routine.

Check the Gaskets

The rubber seal around the lid is what keeps the cold air in. Run your fingers along it, checking for any cracks, brittle spots, or gaps. A classic trick is to close the lid on a dollar bill. If you can slide the bill out without any resistance, your seal is weak and it’s time for a replacement. A bad seal makes the unit run constantly, burning up energy and stressing the compressor.

Give It Room to Breathe

Your chest freezer needs airflow to work properly. Make sure there are at least three inches of clear space on all sides and at the back. Dust and grime can clog the condenser coils, so give them a quick vacuum every few months. This simple step helps the unit dissipate heat, keeping it running coolly and efficiently.

Got Questions About Freezer Organization? We've Got Answers.

Even with the best system, running a commercial kitchen means unique questions and challenges always pop up. When you're in the middle of a busy service, you need practical, straight-to-the-point answers. This is your quick-reference guide for troubleshooting some of the most common freezer organization questions we hear from chefs and managers.

What Are The Best Containers For a Commercial Chest Freezer?

In a pro kitchen, forget flimsy consumer-grade plastic. Your containers need to be tough, safe, and let you see what's inside in a split second. Durability, safety, and visibility are the names of the game.

Go for heavy-duty, food-grade, and clear plastic bins. That transparency is a non-negotiable—it lets your team see the contents at a glance, which speeds up prep and service. Always choose rectangular or square bins over round ones. They stack perfectly and eliminate wasted space, letting you maximize every single inch of your freezer.

To nail your HACCP plan and prevent cross-contamination, a color-coded system is foolproof:

- Red Bins: Raw beef and pork only.

- Yellow Bins: For all raw poultry.

- Blue Bins: Strictly for raw seafood.

This visual system makes it incredibly simple for new hires to follow critical food safety rules from their very first day.

How Often Should I Reorganize My Restaurant's Chest Freezer?

There’s no one-size-fits-all answer here; it really depends on your kitchen's volume and how complex your menu is.

For a high-volume spot, a quick spot-check at least once a week is a must. This isn't a full clean-out. It’s a five-minute check to confirm inventory levels, make sure FIFO is being followed, and see that everything is in its proper zone. This quick check should tie directly into your weekly ordering.

A full, deep reorganization—including a complete defrost for any manual models—should be on the calendar quarterly. This is the perfect time to do a thorough audit of your frozen stock. You can pinpoint slow-moving items that might need to be featured on a special, catch any products nearing their use-by date, and make sure your zoning system still makes sense for your current menu.

Regular, scheduled maintenance isn't reactive; it's proactive. A quarterly deep clean stops disorganization from slowly creeping in and turns freezer management from a dreaded chore into a simple, routine operational task.

What Is The Most Energy-Efficient Way To Load a Chest Freezer?

How you load your chest freezer has a direct impact on your utility bill. An efficiently packed freezer doesn’t have to work as hard to stay cold, which saves energy and puts less stress on the compressor.

The golden rule is to keep it about three-quarters full. A well-stocked freezer holds cold air much better than an empty one, so the compressor kicks on less often. But don't overstuff it. A freezer packed to the brim restricts airflow, forcing the unit to run constantly just to circulate the cold air.

When you're adding new, warmer items (like a fresh delivery), place them along the interior walls. This is where the cooling elements are strongest, allowing the new products to freeze quickly without raising the temperature of everything else. Grouping items in bins also helps, as the containers themselves hold the cold during those brief moments the lid is open.

Can I Use Vacuum-Sealed Bags To Improve Freezer Organization?

Absolutely. For a commercial kitchen, vacuum sealing is probably the single best thing you can do to maximize freezer space and protect food quality. It's a total game-changer for anyone serious about how to organize a chest freezer.

Vacuum sealing pulls nearly all the air out of the package, which does two critical things:

- It stops freezer burn in its tracks. Freezer burn is caused by air exposure, so this dramatically extends the shelf life and quality of your food.

- It shrinks the volume significantly. The flat, uniform shape of sealed bags means they can be stacked vertically in bins, almost like a filing cabinet. This method can nearly double the amount of product you can store in the same space.

Just be sure to label each bag with the item name and pack date before you seal it. Once frozen solid, they become compact, easy-to-find, and perfectly preserved assets for your kitchen.

At The Restaurant Warehouse, we provide the high-quality, durable commercial freezers and storage solutions you need to build an efficient and profitable kitchen. Equip your operation for success by exploring our extensive catalog at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment