Don't Get Washed Up—How to Choose the Best Commercial Dishwasher Service

The Unsung Hero of Your Commercial Kitchen

Commercial dishwasher service is the essential,, backbone of any food service business. A sudden dishwasher breakdown doesn't just pause your operation; it can trigger a cascade of failures that halt it entirely, leading to devastating financial and reputational consequences. The true cost of a failed dishwasher extends far beyond the repair bill. It includes lost revenue from turning away customers, paying staff who are unable to work efficiently, and the potential for long-term damage to your brand's reputation if service quality drops.

A Spectrum of Professional Service Options:

- Emergency Repairs: Immediate, same-day service for critical failures that have stopped your kitchen in its tracks.

- Preventative Maintenance: Scheduled, routine service designed to identify and fix minor issues before they escalate into costly breakdowns.

- Genuine Parts Replacement: Sourcing and installing OEM or high-quality equivalent parts for components like heating elements, pumps, gaskets, and control boards.

- Professional Installation: Expert setup and commissioning of new equipment to ensure optimal performance, efficiency, and compliance from day one.

- 24/7 Technical Support: Around-the-clock access to experts for troubleshooting and emergency dispatch, providing peace of mind for businesses that never sleep.

As one industry expert puts it: "A broken piece of appliance may not seem like a huge problem on a major scale. Nevertheless, if you own a restaurant, a bar, a hotel, or any other business that involves constant use of a dishwasher, its malfunction may cost you a lot not only in repair expenses but largely in the loss of profit."

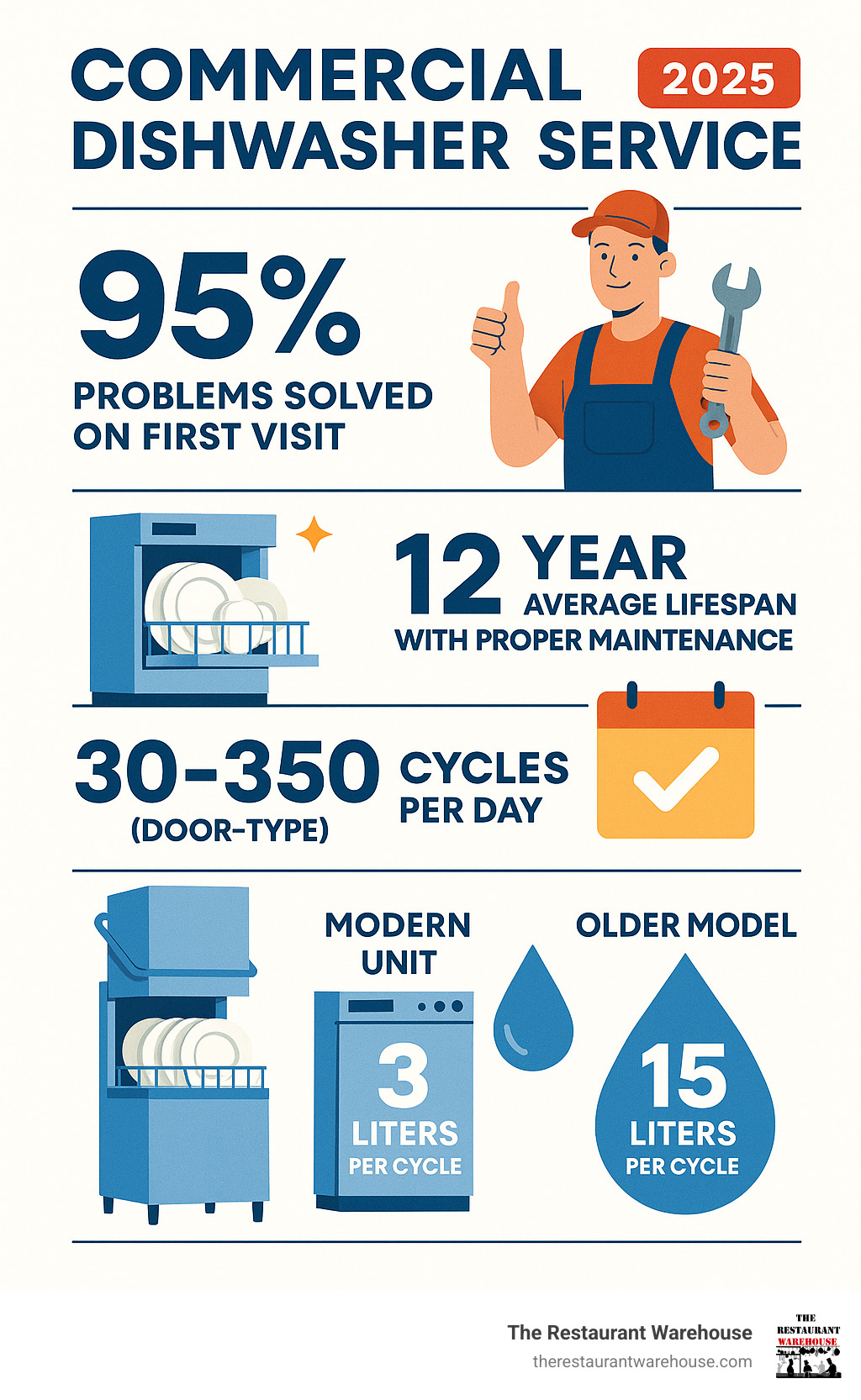

Your commercial dishwasher endures a workload that is difficult to comprehend. Door-type dishwashers can execute between 30 and 350 wash cycles every single day, while industrial conveyor models can process an astonishing 360 racks per hour. This relentless, high-stress operation means that every component, from motors to seals, wears out exponentially faster than in any residential unit.

Beyond operational continuity, commercial dishwashers are your first line of defense in food safety and sanitation. They are engineered to meet stringent health codes, using either high-temperature rinses (typically 180°F or 82°C) or chemical sanitizers to eliminate harmful bacteria. When a machine fails to reach temperature or properly dispense chemicals, you're not just left with dirty dishes—you're facing the severe risk of foodborne illness, customer safety incidents, and immediate health code violations that could shut you down. The good news is that a partnership with the right commercial dishwasher service provider can mitigate these risks and resolve most issues with speed and expertise.

This comprehensive guide will dig into what defines a superior commercial dishwasher service, explore the most common problems you'll face, and provide a strategic framework for maintaining your machine for peak performance and longevity.

Quick commercial dishwasher service definitions:

Know Your Machine: Types and Brands of Commercial Dishwashers

Not all commercial dishwashers are created equal. These hardworking machines are engineered for specific applications, volumes, and kitchen layouts. Understanding the nuances of your particular dishwasher type is the first and most critical step in securing effective commercial dishwasher service, as each design has its own unique operational characteristics, common failure points, and maintenance requirements.

For instance, the service needs of a compact undercounter glasswasher in a wine bar are vastly different from those of a massive flight-type conveyor system in a university dining hall. A technician without specialized knowledge of your machine's architecture may struggle to diagnose issues correctly, leading to longer downtime and repeat service calls. Let's break down the main categories.

Undercounter Dishwashers

Often mistaken for their residential cousins, undercounter commercial dishwashers are powerful, durable machines packed into a space-saving footprint. They are the perfect solution for small restaurants, bars, cafes, and office kitchens, sliding neatly under a standard 34-inch counter. While a home dishwasher might run one cycle per day, these units are built to handle 20-30 cycles per hour. They come in high-temperature and low-temperature chemical sanitizing models.

Common Service Issues: Beyond cloudy glassware and draining problems, these units are prone to issues with their booster heaters (in high-temp models), which are essential for reaching the 180°F sanitizing rinse temperature. Failures in the chemical pumps for detergent, rinse aid, and sanitizer are also frequent, leading to poor cleaning results. Due to their compact design, internal components are tightly packed, requiring a technician with finesse to perform repairs.

Door-Type / Pass-Through Dishwashers

These are the undisputed workhorses of most mid-sized to large restaurants. Capable of handling 30 to 350 cycles daily, their design is a model of efficiency. Staff slide a rack of dirty dishes in one side, close the hood-style door to start the cycle, and then pass the clean, sanitized rack out the other side to a clean dish table. This pass-through workflow prevents cross-contamination and keeps the kitchen's rhythm flowing smoothly. They are available in straight-through and corner configurations to fit different kitchen layouts.

Common Service Issues: The constant, forceful motion of the door makes door latch failures and issues with the door's spring or counterweight system very common. If the door switch isn't fully engaged, the machine will not start. Leakage from worn door gaskets is a constant battle. Furthermore, clogged wash and rinse nozzles, scale buildup on heating elements, and malfunctioning control panels are frequent reasons for a service call.

Conveyor Dishwashers

Welcome to the major leagues of warewashing. Conveyor dishwashers are the giants of the kitchen, designed for the highest-volume operations like hospitals, large-scale cafeterias, universities, and convention centers. When you need to wash 350 to over 1,000 racks per hour, only a conveyor system will do. These machines feature multiple tanks and zones—often including a pre-wash, power wash, power rinse, and final rinse/sanitizing zone. Dishes are loaded onto a peg or flat belt conveyor and travel automatically through each stage.

Common Service Issues: The complexity of these machines creates more potential points of failure. Conveyor belt problems—including jamming, slipping, or motor failure—are a primary concern. Each tank has its own heating element, drain, and chemical dispenser, multiplying the chances of a component failure. Clogged scrap trays can quickly lead to drain blockages, and miscalibrated chemical pumps can result in wasted supplies and poor results. Servicing these machines requires a technician with deep mechanical and electrical expertise.

Glasswashers

In bars, wineries, and fine-dining establishments, glassware is part of the presentation. A specialized glasswasher is essential for protecting this delicate and expensive inventory. These machines operate at lower temperatures and gentler water pressures than standard dishwashers to prevent etching, chipping, and thermal shock (cracking from rapid temperature changes). They use chemical sanitizers and are designed to produce crystal-clear, spot-free results in rapid 1-2 minute cycles.

Common Service Issues: The most common complaints are streaks, lipstick residue, and wet glasses. These issues often point to depleted rinse aid, incorrect water temperature, or clogged rinse arms. Water quality is paramount for glasswashers, so problems with an external water softener or filter can also be the root cause. Technicians often need to fine-tune the chemical dosage and water temperature to match the specific water hardness of the location.

Major Brands That Can Be Serviced

Top-tier commercial dishwasher service providers employ technicians with cross-brand expertise. The best companies invest in continuous factory training, ensuring their team can service over 40 different brands, from the most popular to more obscure or legacy models. This versatility is crucial, as you need a provider who can handle your entire fleet of equipment, regardless of the manufacturer.

- Hobart: The industry benchmark, known for extreme durability, reliability, and innovative technology like their Opti-Rinse™ system.

- Jackson: A leader in energy-efficient and water-saving models, popular for their conveyor and door-type machines.

- Miele Professional: Renowned for high-end, precision-engineered machines, especially in laboratory and dental settings, but also offering powerful freshwater dishwashers for restaurants.

- Electrolux Professional: Offers a wide range of innovative and ergonomic designs, including green and clean models with low environmental impact.

- Centerline by Hobart: Hobart's budget-friendly line, offering simple, reliable performance for less demanding applications.

- Champion / Moyer Diebel: A major player known for a vast range of machines, including specialized pot, pan, and utensil washers.

- CMA Dishmachines: Specializes in low-temperature, chemical sanitizing dishwashers and glasswashers, known for their energy efficiency.

- Meiko: A global leader in warewashing technology, offering highly advanced and efficient solutions for high-volume operations.

Each brand has its own engineering philosophy, diagnostic codes, and common failure points. An experienced technician's ability to quickly identify a brand-specific quirk can save hours of diagnostic time.

If you're looking for more detailed information about choosing the right dishwasher, our comprehensive guide covers everything you need to know: More info about dishwasher types.

When Things Go Wrong: Common Problems and Replaceable Parts

Even the most robust commercial dishwashers will eventually require professional attention. The relentless cycle of heat, water pressure, chemicals, and mechanical motion leads to inevitable wear and tear. When your machine breaks down, your need for commercial dishwasher service becomes urgent, as every minute of downtime disrupts your kitchen's workflow and sanitation standards. While a comprehensive maintenance plan is the best defense, having a reliable repair partner on speed dial is essential. For broader insights on keeping all your kitchen equipment in top shape, check out our guide on More on equipment repair.

Troubleshooting Common Dishwasher Failures: A Step-by-Step Guide

Before you make the call, performing some basic checks can help you provide valuable information to the technician or even solve the problem yourself. Here’s a more detailed look at common failures.

Problem: Dishes Come Out Dirty or Greasy This is one of the most frequent complaints and can have multiple causes.

- Check the Scrapping Process: Are your staff properly pre-scrapping plates? Large food debris will overwhelm the machine.

- Inspect the Filters: Remove and thoroughly clean all filters and scrap trays. A clogged filter restricts water flow.

- Examine the Spray Arms: Ensure the spray arms are not clogged with food particles or mineral deposits. Remove them and clean the nozzles with a small brush or wire.

- Verify Chemical Levels: Are the detergent and rinse aid containers full? Check that the chemical lines aren't kinked or disconnected.

- Check Water Temperature: If you have a high-temp machine, is the water hot enough? The final rinse should be at least 180°F. If not, you may have a faulty heating element or thermostat.

Problem: The Machine Won't Start This can be frustrating, but often has a simple solution.

- Check the Power Source: Is the machine plugged in? Has a circuit breaker been tripped? Check your electrical panel.

- Ensure the Door is Securely Latched: The door switch is a critical safety feature. Open and close the door firmly. If the switch is faulty, the machine will think the door is open and won't start.

- Confirm Water Supply: Is the water supply valve to the machine turned on?

- Look for Error Codes: Modern machines often display an error code on the control panel that can help diagnose the issue, such as a problem with the control board or timer.

Problem: Standing Water That Won't Drain This creates a messy and unsanitary situation.

- Clear the Drain Filter: This is the most common culprit. Food debris and foreign objects can easily create a blockage.

- Inspect the Drain Hose: Make sure the drain hose isn't kinked, crushed, or clogged.

- Check the Air Gap: If your plumbing includes an air gap, check it for blockages.

- Listen for the Drain Pump: Can you hear the drain pump trying to activate? If it's silent or just humming, the pump itself may have failed or is jammed.

Problem: The Machine is Leaking Water on the floor is a safety hazard and a sign of trouble.

- Inspect the Door Gasket: Check the rubber seal around the door for cracks, tears, or food buildup. Wipe it down.

- Check Hose Connections: Look for drips or moisture around the water inlet and drain hoses. Connections can loosen over time due to vibration.

- Examine the Machine Body: Look for cracks or corrosion on the wash tank itself. This is a more serious issue.

- Identify the Leak's Source: A leak from the center of the machine could indicate a failed pump seal, a more complex repair.

Problem: Unusual Noises (Grinding, Banging, Squealing) Your dishwasher is talking to you; these sounds are a cry for help.

- Check for Foreign Objects: A fallen spoon, glass shard, or bone can get caught in the spray arm or pump impeller, causing loud noises. Turn off the machine and carefully inspect the interior.

- Inspect Spray Arms: A loose or broken spray arm can bang against the racks and walls during the cycle.

- Listen to the Motor: A persistent grinding or squealing sound often points to worn motor bearings, which requires professional replacement.

For deeper troubleshooting wisdom, this Commercial Dishwasher Troubleshooting and Maintenance Guide is a helpful resource.

An Arsenal of Replaceable Parts

The good news is that most dishwasher failures are due to a single faulty component. A well-equipped commercial dishwasher service technician arrives with a van stocked with the most common parts, aiming for a 95% first-visit fix rate to get your kitchen back in business immediately.

- Heating Elements & Booster Heaters: These immersion heaters are responsible for getting wash and rinse water to sanitizing temperatures. They often fail due to mineral scale buildup, which causes them to overheat and burn out.

- Thermostats & Thermocouples: These are the sensors that regulate water temperature. A faulty thermostat can lead to water that's too cool for proper cleaning or so hot it damages glassware.

- Water Inlet Valves: This solenoid valve controls the flow of water into the machine. If it fails to close properly, the machine can overfill; if it fails to open, the machine won't fill at all.

- Drain Pumps & Motors: The heart of the draining system. The motor can burn out from overuse or the pump can become jammed with debris, preventing water removal.

- Wash Pumps & Motors: The powerful main pump that drives water through the spray arms. Failure of this component results in a machine that fills and drains but doesn't wash.

- Control Boards & Timers: The electronic brain of the dishwasher. A malfunction can cause a wide range of issues, from cycles not advancing to the machine being completely unresponsive.

- Door Gaskets & Seals: These rubber seals are considered a wear-and-tear item. They harden and crack over time, leading to inevitable leaks.

- Spray Arms & Nozzles: These can crack from heat and chemical exposure or become permanently clogged with limescale, reducing cleaning effectiveness.

- Chemical Pumps (Detergent, Rinse, Sanitizer): Small peristaltic pumps that inject precise amounts of chemicals. They can fail mechanically or their tubing can wear out, leading to poor wash results.

- Contactors & Relays: Heavy-duty electrical switches that control the high power flow to motors and heating elements. They can wear out and fail to make a connection.

The Ultimate Guide to Professional Commercial Dishwasher Service

When your dishwasher breaks down mid-rush, you don't just need a repairman; you need a strategic partner who understands that every minute of downtime erodes your profit margin. Choosing the right commercial dishwasher service provider is a critical business decision that can mean the difference between a minor inconvenience and a multi-day operational crisis. Finding a skilled, responsive, and reliable professional is paramount.

What to Expect from a Quality Commercial Dishwasher Service

A truly professional service provider operates as an extension of your team, offering comprehensive support for your equipment's entire lifecycle.

- Expert Diagnostic Services: Top technicians combine years of experience with modern diagnostic tools (like multimeters, pressure gauges, and temperature probes) to accurately pinpoint the root cause of a problem, not just treat the symptoms. They should be able to explain the failure in clear, understandable terms.

- On-Site Troubleshooting and Repair: Quality service is delivered at your location. Professionals come to your kitchen, minimizing disruption and saving you the immense hassle of transporting a heavy, plumbed-in appliance.

- OEM and High-Quality Parts Replacement: A reputable service uses genuine OEM (Original Equipment Manufacturer) parts or high-quality equivalents that are specifically designed for the rigors of commercial use. This ensures a lasting repair, maintains your machine's performance, and often preserves the manufacturer's warranty.

- Customized Preventative Maintenance Plans: The best providers offer scheduled maintenance programs. These proactive visits include inspection, cleaning, calibration, and tuning to catch small issues like worn belts or minor leaks before they become catastrophic failures.

- Certified Installation and Decommissioning: Proper installation is crucial for efficiency and longevity. A professional service ensures your machine is correctly leveled, plumbed, and wired according to local codes and manufacturer specifications. They can also safely decommission and remove old units.

- Best Emergency Response: Leading companies understand that equipment fails at the worst possible times. They offer 24/7 emergency support and prioritize same-day service for critical situations, with the goal of resolving the issue on the very first visit.

Key Questions to Ask a Potential Service Provider

Before committing to a service company, vet them thoroughly. Their answers to these questions will reveal their level of professionalism and reliability.

- What is your average emergency response time? For a critical piece of equipment, you need a company that can be on-site within a few hours, not a few days.

- Are your technicians certified and factory-trained? Look for technicians who are CFESA (Commercial Food Equipment Service Association) certified and have received specific training from major brands like Hobart, Jackson, or Meiko.

- Do you carry a large inventory of common parts on your service vehicles? A well-stocked van dramatically increases the chance of a first-visit fix, saving you time and money.

- What is your warranty on parts and labor? A reputable company will stand behind their work with a warranty, typically ranging from 30 to 90 days.

- Can you provide references from businesses similar to mine? Speaking to other local restaurant or facility managers is one of the best ways to gauge a company's performance.

The Overwhelming Benefits of Hiring a Professional

Attempting a DIY repair on a commercial dishwasher is a risky proposition. These are complex systems involving high-voltage electricity, scalding water, and pressurized lines. The benefits of hiring a professional go far beyond a simple fix.

- Safety and Expertise: Licensed and insured technicians are trained to work safely in a busy kitchen environment. Their experience with thousands of repairs allows them to diagnose issues quickly and accurately.

- Correct Diagnosis and Lasting Solutions: A professional can distinguish between a failing $50 relay and a $500 motor, saving you from expensive and unnecessary repairs. They fix the problem correctly the first time.

- Access to Quality Parts and Technical Bulletins: Professionals have access to supply chains for genuine OEM parts and receive technical service bulletins from manufacturers about known issues or design updates.

- Avoiding Collateral Damage: A simple mistake during a DIY repair—like cross-threading a fitting or miswiring a component—can create a much larger and more expensive problem. Professionals have the right tools and knowledge to prevent this.

- Maximizing Uptime and ROI: While professional service has an upfront cost, it is an investment in your business. Fast, effective repairs minimize downtime, protect your revenue stream, and extend the life of your expensive equipment, maximizing your return on investment.

Industries That Depend on Commercial Dishwasher Service

Any organization that serves food or beverages to the public or a vulnerable population relies on a dependable commercial dishwasher service to maintain sanitation and operational flow.

- Restaurants, Bars, and Hotels: These businesses are the most obvious clients, where a constant supply of clean plates, glasses, and flatware is the lifeblood of service.

- Hospitals and Nursing Homes: In these environments, sanitation is a matter of life and death. Dishwashers must achieve perfect, verifiable sanitization to prevent cross-contamination and protect immunocompromised patients.

- Schools and Universities: Cafeterias serving thousands of students daily require industrial-sized conveyor dishwashers that can withstand constant use and abuse.

- Catering Companies, Bakeries, and Corporate Cafeterias: From event caterers needing rapid turnover to bakeries cleaning tough, baked-on soil from pots and pans, every food business needs a reliable warewashing solution.

For more insights into the equipment needs across these industries, check out our comprehensive Restaurant Equipment Guide.

Repair or Replace? A Strategic Guide for Your Business

Every restaurant owner and facility manager will eventually face the critical question: is it better to repair the ailing dishwasher again, or is it time to invest in a new one? This decision isn't just about the immediate repair bill versus the purchase price. It's a strategic choice that impacts your long-term operating budget, kitchen efficiency, staff morale, and even your environmental footprint. A trusted commercial dishwasher service expert can be an invaluable consultant, providing an honest assessment of your machine's health to help you make a financially sound decision.

| Consideration | Repair | Replace |

|---|---|---|

| Initial Cost | Lower, typically $60-$760 (average ~$290 for minor issues) | Higher, thousands to tens of thousands of dollars |

| Downtime | Minimal, often a same-day fix (1-4 hours) | Longer (research, delivery, installation, training) |

| Lifespan | Extends existing unit's life (average 12 years total) | Resets the clock with a new 7-12 year lifespan |

| Efficiency | Retains existing energy/water usage (may be poor) | Significant improvement with modern ENERGY STAR models |

| Warranty | Typically 30-90 days on the specific part/labor | Comprehensive 1-2 year manufacturer warranty on the entire unit |

| Future Issues | Possible, especially if the unit is old or has other worn parts | Less likely in the short to medium term |

| Technology | Limited to existing features | Access to IoT, advanced diagnostics, and efficiency features |

| Regulatory Compliance | Maintains current compliance | Ensures compliance with the latest health and energy codes |

| Environmental Impact | Lower, as it keeps a large appliance out of the landfill | Higher initial impact, but offset by long-term efficiency gains |

When to Repair Your Commercial Dishwasher

In most cases, repairing your existing dishwasher is the most logical and cost-effective path. It's faster, less disruptive, and protects your cash flow.

- The 50% Rule: This is a classic industry guideline. If the quoted repair cost is less than 50% of the price of a comparable new machine, the repair is almost always the right call.

- Age of the Unit: If your dishwasher is less than 7 years old, it likely has many years of reliable service left. Commercial dishwashers are built to last 10-12 years with proper care.

- Nature of the Problem: Failures of common wear-and-tear items like door gaskets, drain pumps, heating elements, or door switches are routine repairs that do not signify the end of the machine's life.

- Reliability History: If the machine has been a dependable workhorse with few issues, it's worth investing in a repair. If this is its first major breakdown, give it the benefit of the doubt.

When It's Time to Replace

Sometimes, continuing to repair an old machine is throwing good money after bad. Recognizing the tipping point can save you significant money and chronic frustration in the long run.

- Advanced Age: Once a dishwasher surpasses the 10-12 year mark, it's living on borrowed time. The frequency and cost of repairs will likely increase dramatically.

- Chronic Breakdowns: If your service technician is on speed dial and you're facing downtime every few months, the cumulative cost of repairs, lost business, and staff frustration makes replacement a smart investment.

- Major Component Failure: If a critical, expensive component like the main wash motor, the electronic control board, or the wash tank itself fails on an older machine, the repair cost may easily exceed the 50% threshold.

- Obsolescence and Parts Unavailability: For very old or obscure models, sourcing the correct replacement parts can become difficult or impossible, leading to extended and unacceptable downtime.

- Sky-High Utility Bills: Technology has advanced significantly. Modern ENERGY STAR® certified dishwashers can use as little as 3 liters of water per cycle, while older models could use 15 liters or more. The annual savings on water, sewer, and energy can be substantial and help offset the purchase price.

If you're leaning toward replacement, The Restaurant Warehouse offers commercial dishwashers at wholesale prices. Our Guide to buying a new dishwasher can help you choose the right model.

The Power of Preventative Maintenance: Your Ultimate Strategy

The secret to avoiding the repair-or-replace dilemma for as long as possible is a robust preventative maintenance program. This is the single most effective way to extend your dishwasher's lifespan, improve its performance, and reduce operating costs. It's a shared responsibility between your daily staff and your professional service partner.

Daily Maintenance Checklist (Performed by Kitchen Staff at End of Shift):

- Power Down: Turn off the machine at the main power switch.

- Drain and Clean Interior: Open the door, drain the machine completely. Remove spray arms, scrap trays, and filters.

- Wash Components: Thoroughly wash all removed components in a separate sink with hot water and a brush to remove all food soil and debris.

- Wipe Down Interior: Use a clean cloth to wipe down the interior of the machine, paying special attention to corners where debris can hide.

- Clean Door Gasket: Wipe the door gasket and the interior door frame to remove any grime that could prevent a proper seal.

- Reassemble and Air Dry: Reinstall all components. Leave the door ajar overnight to allow the interior to air dry completely, preventing mold and mildew growth.

Weekly Maintenance Checklist (Performed by Kitchen Manager):

- Inspect Spray Arms: Check for any nozzles clogged with limescale. Use a deliming solution and a small tool to clear any blockages.

- Check Chemical Levels: Ensure all chemical containers are full and that the pickup tubes are not clogged or resting on the bottom of the container.

- Calibrate Temperatures (if possible): Use a waterproof thermometer to check the wash and final rinse temperatures to ensure they meet health code requirements.

Professional Maintenance Checklist (Performed Quarterly/Semi-Annually by a Technician):

- Inspect and test all electrical components, including heating elements, motors, and contactors.

- Check for leaks in all hoses, seals, and fittings.

- Verify the calibration of thermostats and chemical pumps.

- Descale the machine's interior and heating elements to remove mineral buildup.

- Lubricate moving parts as required by the manufacturer.

- Check the door balance and alignment.

- Provide a detailed report of the machine's condition and recommend any necessary repairs.

For more detailed cleaning procedures, check out our Restaurant Kitchen Cleaning Checklist to keep your entire operation in top shape.

Conclusion: Keep Your Operations Flowing Smoothly

Your commercial dishwasher is the powerful, tireless engine of your kitchen's sanitation system. It's the unsung hero working relentlessly behind the scenes to ensure your operation runs like clockwork. This guide has illuminated the critical importance of a comprehensive approach to commercial dishwasher service, moving beyond simple repairs to a strategic partnership in equipment management.

True mastery of your warewashing program begins with deep knowledge of your equipment. Whether you're troubleshooting cloudy results from a high-temp glasswasher or a door latch failure on a pass-through unit, understanding the specific failure points of your machine empowers you to act swiftly and communicate effectively with your service provider.

It's abundantly clear that professional service is an investment, not an expense. The best providers are strategic partners, offering a spectrum of services from 24/7 emergency repairs to carefully planned preventative maintenance programs that stop disasters before they happen. With factory-trained technicians, high first-visit resolution rates, and a commitment to using quality parts, the right service company is one of your most valuable assets.

The strategic decision between repairing and replacing a dishwasher becomes far less daunting with the right framework. For a machine under 7-10 years old, a repair costing less than 50% of a new unit's price is almost always the wisest financial move, preserving capital and minimizing operational disruption.

Perhaps the most crucial takeaway is that preventative maintenance is your ultimate secret weapon. A disciplined routine of daily and weekly tasks performed by your staff, combined with regular professional check-ups, is the proven formula to extend your dishwasher's life to 12 years or more, saving you thousands in emergency repairs and premature replacement costs.

The health of your dishwasher is directly linked to your sanitation standards, operational efficiency, brand reputation, and bottom-line success. When it runs smoothly and reliably, your staff can dedicate their energy to what truly matters: creating exceptional food and memorable experiences for your customers.

For businesses ready to invest in new equipment, The Restaurant Warehouse offers an extensive selection of commercial dishwashers at wholesale prices, helping you get the quality you need without the retail markup. To continue learning about selecting and maintaining all your essential kitchen tools, explore our comprehensive Commercial Kitchen Equipment Guide.

Finally, never underestimate the profound impact of staff training. Go beyond a simple checklist. Invest in hands-on training sessions that explain the why behind the what—why pre-scrapping matters, how a clogged nozzle impacts cleaning, what a grinding noise signifies. When you cultivate a culture of ownership and vigilance around equipment care, every employee becomes a guardian of your investment. This powerful combination of a well-trained team and an expert service partner is the key to open uping years of reliable performance, lower utility bills, and the uninterrupted flow of a successful business.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment