Deep Dive into Deep Fryers: Your Small Commercial Options

Your Guide to Small Commercial Deep Fryers

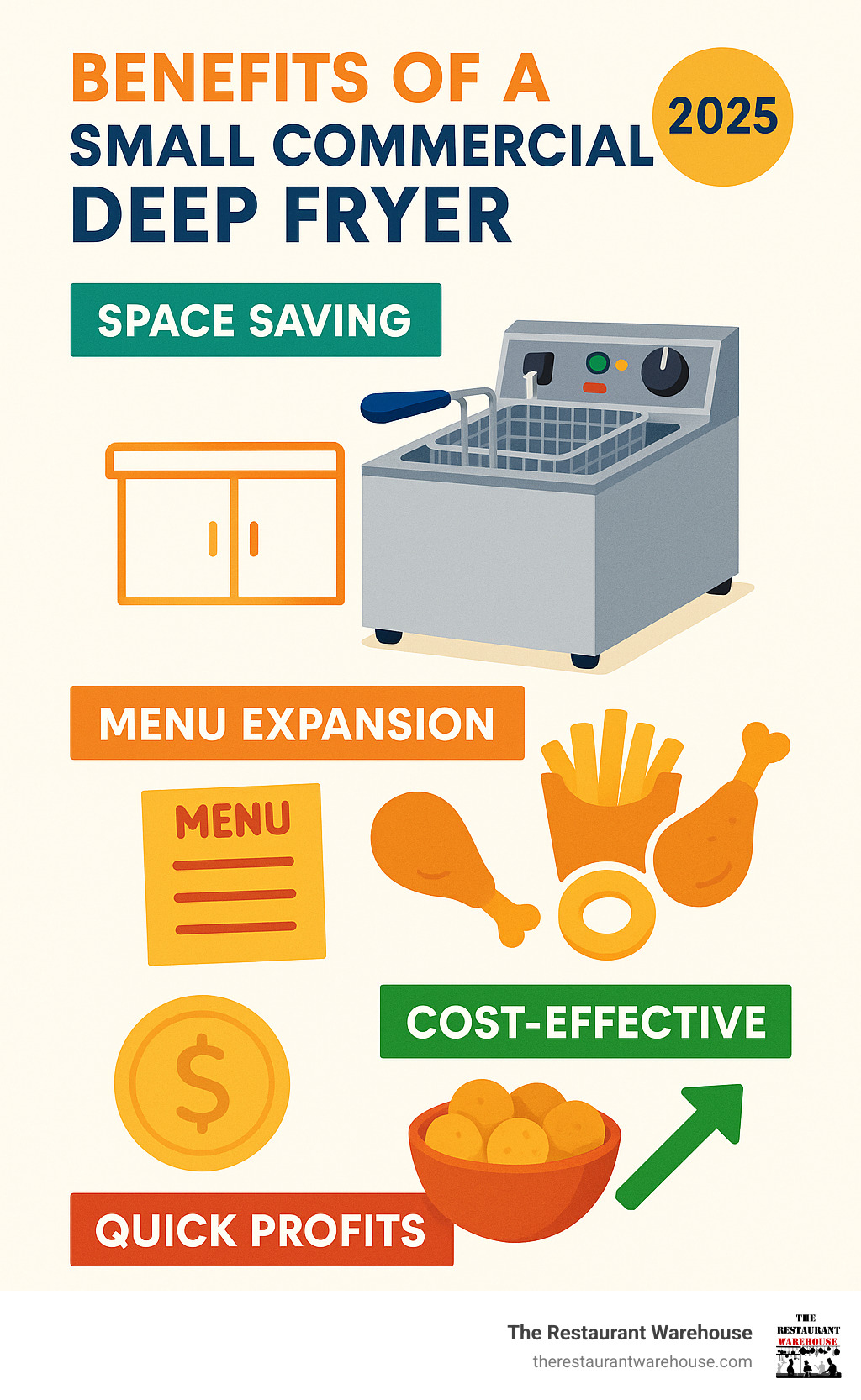

Are you looking to add delicious fried items to your menu without overspending or sacrificing precious kitchen space? A small commercial deep fryer is the perfect solution.

These compact powerhouses are ideal for:

- Small Businesses: Food trucks, cafes, delis, and pop-up kitchens.

- Menu Expansion: Easily add popular items like French fries or chicken wings.

- Budget-Friendly Options: Lower initial cost than larger fryers.

- Space Efficiency: Designed to fit on countertops in tight spots.

- Quick Profits: Fried foods are high-demand and offer excellent margins.

This guide covers everything you need to know about choosing, operating, and maintaining a small commercial deep fryer. We'll help you find the perfect model to boost your menu and your bottom line.

Easy small commercial deep fryer glossary:

- commercial cooking equipment suppliers

- heavy duty kitchen equipment

- commercial kitchen stainless steel tables

What is a Small Commercial Deep Fryer and Who Needs One?

A small commercial deep fryer is a compact yet powerful kitchen workhorse designed for businesses with limited space. Unlike large, floor-standing fryers, these units typically hold between 8.5 to 50 pounds of oil and often sit on a countertop, offering incredible flexibility.

So, who needs one? A small commercial deep fryer is ideal for businesses where every inch counts or where fried foods are a popular menu addition. This includes food trucks, small cafes, concession stands, bars, and small restaurants looking to serve tasty appetizers.

The primary benefits are their space-saving design and cost-effectiveness. A smaller unit lets you add a dedicated frying station without a major kitchen renovation or sacrificing prep space. It also has a much lower initial cost than a larger model, making it an accessible choice for new businesses. Our Small Deep Fryers Guide can help you explore options, and our guide on Small Space Big Taste: Commercial Countertop Fryers That Deliver shows how these machines deliver big flavor.

Best Foods for Small Fryers

Don't let the size fool you; a small commercial deep fryer can produce a vast array of your fried favorites. They are perfectly capable of delivering crispy French fries, juicy chicken wings, golden-brown onion rings, gooey mozzarella sticks, and even fluffy donuts. However, the versatility extends far beyond these classics. Consider adding delicate tempura vegetables, crispy fried calamari, savory samosas, or sweet churros to your menu. The key is to understand how different foods interact with the oil and to match the food type with your fryer's oil capacity and recovery rate. For instance, heavily battered or breaded items will shed more sediment, requiring more frequent oil filtration. Frozen foods will cause a more significant temperature drop than fresh items, making a fryer with a fast recovery time essential for maintaining quality. For expert tips on getting the most out of your fryer, check out our Atosa Deep Fryer Tips For Fried Food. A dual-basket countertop model can be particularly useful for preventing flavor transfer, allowing you to fry savory items like fish in one basket and neutral items like fries in the other.

The Benefits of a Compact Footprint

The compact footprint of a small commercial deep fryer is a game-changer for many kitchens. When space is at a premium, these fryers allow you to add a dedicated frying station without a full remodel. Simply place a unit on an existing counter or a refrigerated chef base to instantly expand your menu while optimizing workflow. Their manageable size also makes them portable, a huge perk for catering events, pop-up shops, or seasonal operations where kitchen setups are temporary. For mobile food businesses, these fryers are especially perfect, fitting neatly into the tight confines of a food truck or trailer. Imagine a small coffee shop adding fresh, hot donuts to their morning offerings, or a bar elevating its appetizer menu with high-profit items like loaded fries and jalapeño poppers—all made possible by a small fryer. Our Food Truck Fryers guide offers more insight into why these compact units are ideal for kitchens on wheels.

Exploring the Different Types of Commercial Fryers

When shopping for a small commercial deep fryer, you'll find several types, distinguished by power source, installation type, and ventilation requirements. Understanding these differences is key to choosing the right model for your kitchen. Our Commercial Fryers Guide and Fryer Comparison Guide offer more detailed comparisons.

Electric vs. Gas: Choosing Your Power

The choice between electric and gas depends on your kitchen setup, utility costs, and operational needs.

Electric fryers are reliable and use heating elements submerged directly in the oil. This design ensures excellent heat transfer and contributes to faster recovery times, a critical factor for producing consistently crispy food. While they may take slightly longer to heat up initially compared to gas, they rebound quickly between batches. Their portability is a major advantage; most countertop models only require a standard electrical outlet (though higher-wattage units may need a dedicated circuit), making them perfect for food trucks, catering, and temporary setups. They are also highly energy efficient, as less heat is lost to the surrounding environment compared to gas models. This can lead to a cooler kitchen and lower utility bills over time. Our Electric Deep Fryer Guide has more information.

Gas fryers are known for their raw power. They heat up very quickly and can reach and maintain higher temperatures, making them ideal for high-volume operations that need to cook large quantities of food rapidly. You have two options: natural gas models connect to your building's existing gas line, providing a consistent and cost-effective fuel source for permanent kitchens. Propane models use portable tanks, offering more placement flexibility but requiring diligent monitoring and tank refills. While gas is often cheaper per unit of energy, the installation of a dedicated gas line can be a significant upfront expense. The best choice often depends on your kitchen's existing infrastructure, local utility costs, and production needs. Our Propane Deep Fryer guide covers propane-specific details.

Countertop vs. Floor Models

Your fryer's placement depends on your available space and frying volume.

Countertop fryers are space-saving champions ideal for small businesses. These compact units sit on a counter or equipment stand, fitting into your layout without major renovations. They are perfect for low-to-medium volume operations. Their flexibility allows for easy integration into almost any kitchen. Explore our selection of Electric Countertop Deep Fryers to see their versatility.

Compact floor fryers bridge the gap between countertop models and full-size units. These freestanding fryers are still considered "small commercial" but offer higher oil capacities and production outputs. They are ideal for businesses with a dedicated fry station and consistent, higher-volume needs.

Ventless Fryers: The No-Hood Solution

Ventless fryers are revolutionary, fully enclosed systems with built-in air filtration. These sophisticated machines use a multi-stage filtration process—often involving a stainless steel baffle filter, an electrostatic precipitator, and a charcoal filter—to capture and neutralize grease-laden vapors and odors before recirculating clean air back into the kitchen. This allows you to operate a deep fryer without a traditional, expensive overhead hood system.

The cost savings are immense. You avoid the thousands of dollars associated with purchasing and installing ductwork, exhaust fans, and fire suppression systems. This also grants incredible placement flexibility, making them perfect for non-traditional locations like mall kiosks, grocery store delis, historic buildings with renovation restrictions, or airport terminals. While the initial purchase price is higher than a standard fryer, the return on investment can be rapid when you factor in the avoided ventilation costs. These units must meet rigorous safety standards; look for UL 710B certification, which confirms the unit meets strict safety requirements for recirculating systems. You can view an example of a ventless fryer compliance certificate.

Performance is also impressive. Compact ventless models can produce 20-40 pounds of fries per hour, while larger compact models can handle 50-100 pounds per hour. It's a "No Hoods? No Vents? No Problem!" solution for adding high-profit fried foods to virtually any location.

Key Features to Consider When Buying a Small Commercial Deep Fryer

Choosing the right small commercial deep fryer involves looking beyond the basic type and digging into specific features. These details determine your fryer's performance and efficiency. Our guide on How To Choose A Commercial Deep Fryer is a great place to start.

Oil Capacity and Production Output

A fryer's oil capacity, listed in pounds (lbs) or gallons, directly impacts its hourly production output. For example, a 10 lb capacity fryer might produce about 10 pounds of fries per hour, while a 2-gallon model can produce 20-40 pounds per hour. To choose the right capacity, consider your busiest periods. A dual-tank system is also a great option, allowing you to fry different foods simultaneously without flavor transfer or handle higher volumes. Explore specific models and capacities in our list of the Best Deep Fat Fryers.

Power, Temperature Control, and Recovery

A fryer's performance hinges on its power, temperature control, and recovery time.

Electric fryer power is measured in wattage (W), while gas fryers use British Thermal Units (BTUs). Higher wattage or BTUs translate to more heating power, which means faster initial heat-up and, more importantly, quicker recovery. This is crucial for getting oil back to the set temperature after dropping in a basket of frozen food, which can cause the oil temperature to plummet by 50°F or more.

Most small fryers use mechanical thermostatic controls, which are simple dials for setting a temperature between 200°F and 400°F. These are reliable and easy to use. More advanced models feature solid-state or programmable controls. These digital systems offer precise temperature management and allow you to pre-set cooking times and temperatures for different menu items, ensuring perfect consistency from one batch to the next, regardless of who is operating the fryer.

Fast recovery is the single most important factor for food quality. This is how quickly the oil returns to the ideal frying temperature after food is added. When food hits hot oil, its surface immediately seals, trapping moisture inside while preventing the food from absorbing excess oil. Slow recovery means the food sits in lukewarm oil for too long, leading to a soggy, greasy, and unappetizing final product. Electric fryers with submerged elements and powerful gas fryers excel at this. This is why high-efficiency fryers are so valuable, as detailed in Why High Efficiency Fryers Are The Secret Sauce For Food Truck Success.

Also, look for cold zone technology. This is a design feature where the area at the very bottom of the frypot remains cooler than the cooking zone above. Sediment and food particles sink into this cold zone, preventing them from burning, carbonizing, and imparting a bitter taste to the oil. This simple feature significantly extends oil life and improves food flavor.

Safety, Durability, and Certifications

Safety is paramount when working with gallons of hot oil. Choose a durable unit with robust safety features and solid construction.

Look for fryers made from heavy-gauge stainless steel (like types 304 or 430), which is durable, corrosion-resistant, and easy to sanitize. A welded, seamless frypot is preferable to a screwed or sealed one, as it eliminates potential leak points and makes cleaning easier. Essential safety features include a high-limit shutoff, a thermostat that automatically cuts power if the oil exceeds a safe temperature (around 450°F), preventing dangerous flash fires. For countertop models, sturdy, non-skid feet are critical for stability. An accessible, easy-to-use drain valve with a safety extension is a must for draining hot oil safely.

Finally, always check for proper certifications, as these are non-negotiable for commercial use and health inspections:

- NSF Approved: This mark from the National Sanitation Foundation means the fryer is designed and constructed in a way that promotes food safety, with smooth, easily cleanable surfaces and non-toxic materials.

- UL Approved: Underwriters Laboratories certifies that the product meets nationally recognized standards for safety, particularly for electrical components and fire risk.

- ETL Certified: The ETL mark from Intertek is an alternative to UL, confirming the product complies with North American safety standards.

- ENERGY STAR® Certified: For electric models, this certification indicates the fryer has met strict energy efficiency guidelines set by the U.S. Environmental Protection Agency, saving you money on operating costs.

These certifications ensure your equipment is built to operate safely, reliably, and in compliance with health and safety codes. If you encounter issues, our Atosa Fryer Troubleshooting Guide can help.

Operating and Maintaining Your Fryer for Peak Performance

A small commercial deep fryer is an investment that requires proper care to perform at its best. With the right maintenance, these machines can last 7 to 10 years or more. Proper care not only extends the fryer's lifespan but also ensures your food always tastes great. Oil management and regular cleaning are crucial. Our guide on How To Operate The Atosa Countertop Electric Fryer: A Step-by-Step Guide can help you get started.

Best Practices for Daily Operation

Simple daily habits can make a huge difference in your fryer's performance and your food's quality.

First, preheat your oil to the correct temperature for the food you're cooking, typically between 325°F and 375°F (163°C and 190°C). Next, avoid overcrowding the baskets. A good rule of thumb is to fill baskets no more than halfway. Overfilling drastically drops the oil temperature, leading to long cooking times and greasy, undercooked food. After cooking, drain food properly by holding the basket over the fryer for at least 10-15 seconds to let excess oil drip off.

Most importantly, filter your oil daily, or even more frequently if you have high volume or cook heavily breaded items. Food particles left in the oil will burn and break down, creating off-flavors and shortening the oil's life. Filtering removes these impurities and can make your cooking oil last up to twice as long, representing significant cost savings. For extra protection, consider using oil stabilizers or filter powders, which can help slow the chemical breakdown of oil and maintain its quality between deep cleanings. Finally, always cover your fryer when not in use to protect the oil from light and airborne contaminants, which also accelerate degradation.

A Step-by-Step Guide to Cleaning Your Small Commercial Deep Fryer

Regular deep cleaning, often called a "boil-out," is essential for hygiene, taste, and the longevity of your small commercial deep fryer.

Here’s a simple guide to a deep clean:

- Safety First & Cool Down: Turn off and unplug the fryer. Always let the oil cool completely to below 150°F (65°C) before draining to prevent serious burn risks.

- Drain the Oil: Once cool, carefully drain the oil. Use the drain valve and a heat-resistant container. Filter any reusable oil into a clean, airtight container for storage. Dispose of old, spent oil according to local regulations—never pour it down the drain.

- Clear Out Sediment: Use a rubber spatula or a long-handled fryer brush to scrape out any loose food bits and hardened grease from the bottom and sides of the frypot.

- The "Boil-Out": This is the deep cleaning step, performed weekly or as needed. Fill the frypot with water to just below the oil-level line. Add a commercial-grade, non-foaming, non-corrosive fryer cleaner, following the product's directions precisely. Turn the fryer on and slowly bring the mixture to a gentle boil (do not let it boil over). Simmer for 15-30 minutes to dissolve and loosen stubborn, carbonized grease.

- Scrub and Rinse: Turn off the fryer and let the cleaning solution cool before draining it. Use a long-handled brush or non-abrasive pad to scrub the inside of the frypot. Once clean, rinse thoroughly with hot water to remove all cleaning solution residue. A final rinse with a solution of one part white vinegar to ten parts water can help neutralize any remaining cleaner and passivate the stainless steel.

- Dry Completely: This step is absolutely crucial. The frypot must be completely and totally dry before adding new oil. Any remaining water will instantly turn to steam when hot oil is added, causing it to splatter violently and create a serious safety hazard. Use a clean, lint-free cloth to dry every surface.

You can Watch a demonstration of proper fryer cleaning and find more tips in our Essential Daily Cleaning Guide For Commercial Fryers. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety goggles, throughout the entire cleaning process.

Frequently Asked Questions about Small Fryers

It's natural to have questions when adding a small commercial deep fryer to your kitchen. Here are answers to some of the most common inquiries.

How much does a small commercial deep fryer cost?

The price of a small commercial deep fryer varies widely. Entry-level countertop electric models can start at a few hundred dollars, while robust gas models or advanced ventless fryers can cost several thousand. Key factors influencing the price include the type (electric is often more budget-friendly), features (programmable controls, built-in filtration), ventless technology (higher initial cost but saves on hood installation), and brand and capacity. Consider your budget, but also weigh long-term benefits.

Do I need a ventilation hood for a small electric fryer?

This critical question depends on local health codes and the fryer's certifications. Most standard commercial deep fryers, electric or gas, require a commercial ventilation hood to capture greasy vapors and prevent fire hazards. The exception is a ventless fryer. These units have a self-contained filtration system and are certified to operate without an external hood. Always check the manufacturer's specifications and, most importantly, consult your local health department and fire marshal, as they have the final say.

How often should I change the oil in my commercial fryer?

There's no single answer for how often to change the oil in your small commercial deep fryer. It depends on the food type (breaded items degrade oil faster), your frying volume, and your filtration schedule. Daily filtering is the best way to extend oil life. The quality of your oil also plays a role.

Use your senses to tell when it's time for a change:

- Look for excessive darkening, foaming, or smoking at normal temperatures.

- Taste for "off," burnt, or unpleasant flavors in your food.

As a general guideline, moderate-use kitchens might change oil weekly, while heavy-use kitchens may need to change it every few days. When in doubt, change the oil to ensure the best quality for your customers.

Conclusion

Choosing the right small commercial deep fryer is a pivotal decision for your kitchen's efficiency, menu, and bottom line. By understanding the differences in power source, size, and ventless technology, and by prioritizing key features like capacity and safety, you are well-equipped to make an informed choice. The right fryer is a culinary partner that helps you serve delicious fried foods without breaking the bank or sacrificing kitchen space.

Here at The Restaurant Warehouse, we believe equipping your kitchen with reliable gear shouldn't be an overwhelming or expensive process. We supply commercial restaurant equipment and food service supplies at lower prices by cutting out high commissions and retail overhead. Our goal is to provide affordable, wholesale pricing on the equipment you need to succeed.

Ready to find the perfect small commercial deep fryer to transform your menu? Explore our complete commercial kitchen equipment guide today and find the ideal fit for your culinary ambitions. We're here to help you fry up some success!

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment