Trailer-Made Meals – Concession Trailer Cooking Equipment Essentials

Why Concession Trailer Cooking Equipment is the Heart of Your Mobile Food Business

Concession trailer cooking equipment forms the backbone of every successful mobile food operation. These specialized appliances must deliver restaurant-quality meals in a fraction of the space while meeting strict health codes and handling outdoor service demands.

Essential concession trailer cooking equipment includes:

- Hot-side equipment: Griddles, fryers, ranges, and charbroilers

- Cold-side equipment: Prep refrigerators, freezers, and holding units

- Plumbing systems: 3-compartment sinks, hand-wash stations, and water tanks

- Ventilation: Exhaust hoods with fire suppression systems

- Power systems: Generators, electrical panels, and propane connections

The mobile food industry has grown 15% annually compared to just 5% for traditional restaurants. With over 4,000 licensed food trucks operating across the U.S., competition for prime locations and customer loyalty is fierce.

Your equipment choices directly impact success. The right setup handles 200+ orders during lunch rush while maintaining food safety standards. Poor equipment selection leads to bottlenecks, health violations, and lost revenue.

Unlike traditional restaurants with unlimited space and utility access, concession trailers demand equipment that's compact, efficient, and completely self-contained. Every square foot matters in a 12x8 foot kitchen on wheels.

Concession trailer cooking equipment terms explained:

What Is Concession Trailer Cooking Equipment & Why It Matters

Concession trailer cooking equipment isn't regular restaurant gear squeezed into smaller space. These are specially designed appliances built to handle mobile food service challenges - from bumpy roads to limited power supply to working in spaces tighter than most home kitchens.

The mobile food industry shows 15% annual growth compared to traditional restaurants' 5%. With over 4,000 licensed food trucks nationwide, this isn't just a trend - it's a legitimate business model that's here to stay.

Equipment selection matters: your menu should drive every decision. A breakfast burrito truck needs different gear than a gourmet grilled cheese operation. The secret is matching your cooking style to equipment that handles your busiest day while fitting through your trailer door.

Quality concession trailer cooking equipment pays for itself through faster service, consistent food quality, and fewer breakdowns. Poor equipment choices cost you customers, create safety headaches, and drain profits through constant repairs.

Definition & Core Functions

Your cook-line serves as your operation's heart. Griddles, fryers, ranges, and specialty equipment like charbroilers must pump out consistent results from opening to closing, regardless of order volume.

Prep and holding equipment keeps everything running smoothly. Refrigeration units maintain ingredient freshness, while steam tables and warming cabinets keep finished food at safe serving temperatures. Without proper holding equipment, you'll run out of popular items or waste food that sits too long.

Plumbing and power integration is critical. Water tanks, electrical systems, and propane connections must work flawlessly because there's no calling repair services when you're parked at a festival. Everything needs to be self-contained and road-ready.

Why It's Critical for Mobile Success

Today's food truck customers expect restaurant-quality meals. Your equipment directly impacts whether you can deliver that quality consistently. A temperamental fryer or undersized griddle shows up in every order during rush periods.

Speed of service can make or break your mobile business. Equipment that heats quickly, cooks efficiently, and recovers fast between orders means serving 150 customers during lunch rush versus 50. Those extra customers add up to serious revenue.

Health-code approval isn't optional. Every piece of equipment must meet NSF standards and satisfy local health department requirements. Using non-approved equipment can shut down your operation before it starts.

Concession Trailer Cooking Equipment Essentials

Building a successful mobile kitchen means choosing equipment that handles your menu, fits your space, and keeps customers happy. Industry data shows clear patterns in what works best for concession trailer cooking equipment setups.

The VIVOHOME 20.7 Qt Commercial Electric Deep Fryer sees 100+ monthly purchases - delivering serious frying capacity without hogging counter space. The SYBO Commercial Grade Stainless Steel Bain Marie Buffet Food Warmer shows similar volume, proving smart food holding solutions are crucial.

The Kidde Multi Purpose Fire Extinguisher gets purchased over 10,000 times monthly, showing how seriously successful operators take fire prevention in mobile kitchens.

More info about food truck fryers

Hot-Side Must-Haves

Your flat-top griddle becomes the star performer in most concession trailers. It's your kitchen's Swiss Army knife - perfect for burgers, sandwiches, breakfast items, and stir-fries. Find one with solid heat distribution and surfaces that clean easily after busy rushes.

Deep fryers earn their keep fast when serving anything crispy. That popular VIVOHOME 20.7 Qt unit fits under low-profile exhaust hoods while cranking out serious volume. Twin-basket designs let you fry different items simultaneously without flavor mixing.

A solid stock-pot burner gives you high-heat muscle for soups, sauces, and pasta dishes. Propane units typically win over electric alternatives with better heat control and lower operating costs.

Countertop equipment fills gaps in your cooking arsenal. Compact steamers, salamanders, and specialty appliances expand your menu dramatically without eating valuable floor space.

Cold-Side & Holding Gear

Prep refrigerators with worktop surfaces are genius in tight spaces. You get cold storage below and prep space above - doubling functionality in the same footprint. Look for units with easy-access drawers and reliable temperature controls.

Under-counter freezers handle frozen ingredients and ice cream operations. Commercial-grade units maintain steady temperatures even in blazing heat - something residential freezers can't handle.

Bain-marie warmers and steam tables keep prepared foods at safe serving temperatures without overcooking. The SYBO Commercial Grade unit's popularity makes sense - reliable food holding separates pros from amateurs.

Plumbing & Utility Staples

Your 3-compartment sink isn't just equipment - it's your health department lifeline. Most jurisdictions require separate wash, rinse, and sanitize compartments.

Hand-wash stations must be completely separate from food prep sinks and easily accessible to staff. NSF-approved units ensure you'll pass health inspections.

Fresh and grey water tanks give you complete independence from utility hookups. Most successful operations run 40-60 gallons for fresh water and 60-100 gallons for waste water.

On-demand water heaters provide hot water for cleaning without gobbling space like traditional tank heaters.

Sizing & Selecting Gear for Tight Spaces

Working in a concession trailer means every square inch counts. You're building a full commercial kitchen in a space smaller than most home kitchens - and it needs to be mobile, efficient, and profitable.

Space optimization starts with understanding your trailer's physical limits. Most concession trailers measure 8.5 feet wide by 16-20 feet long, but walls, insulation, and required clearances shrink your actual working space dramatically.

Weight becomes a concern faster than expected. Standard dual 3,500-pound axles handle the load, but heavy-duty concession trailer cooking equipment adds up quickly. A commercial fryer weighs 200 pounds empty, refrigeration another 300 pounds, plus propane tanks, water, and inventory.

Generator sizing often catches people off guard. Most 8.5x20 mobile kitchens need at least a 9,500-watt generator to avoid constant breaker trips when multiple appliances run simultaneously.

The propane versus electric debate usually comes down to your operating environment. Propane gives better heat control and lower operating costs, but some venues require all-electric equipment.

Right-Sizing Your Line

Getting your cook capacity right feels like solving a puzzle. Size too small, and you'll have frustrated customers during lunch rush. Size too big, and you've wasted money and space on idle equipment.

Start with projected volume during peak periods. If you expect 150 customers during two-hour lunch rush, your equipment needs to handle that pace consistently.

Equipment footprints matter more in trailers than traditional restaurants. That beautiful 48-inch range might cook perfectly, but if it doesn't fit through your trailer door or leaves no prep space, it's wrong.

Smart operators use menu matrix analysis to prioritize equipment purchases. If your flat-top griddle handles 60% of your menu items, it deserves prime real estate and bigger budget than that specialty steamer used twice weekly.

New vs. Used: Pros & Cons

The used equipment market offers serious savings - sometimes up to 75% off new prices. For cash-strapped startups, this can mean the difference between opening with professional-grade equipment or settling for inadequate alternatives.

Quality used equipment often comes with warranties after proper reconditioning. Reputable suppliers put used gear through thorough restoration addressing both functionality and appearance.

New equipment provides peace of mind through full warranties and latest features. Energy efficiency improvements alone might justify higher costs over time.

The sweet spot often involves mixing new and used pieces. Buy used for major cooking equipment where you can inspect functionality easily, but consider new for complex items like POS systems.

Energy- & Space-Saving Innovations

Multifunction units are game-changers in tight spaces. Combination steamer and convection units give you two cooking methods in one footprint. Griddle and charbroiler combinations let you offer both smash burgers and grilled items without doubling equipment needs.

Low-profile refrigeration maximizes vertical space usage. Under-counter units provide comparable storage to full-height models while creating valuable prep space above.

Ventless equipment opens new possibilities by eliminating exhaust hood requirements for certain applications. However, check local regulations carefully - not all areas accept ventless equipment for commercial use.

Reliable and Efficient Exhaust Fans

Designing Workflow, Safety & Compliance

Creating a concession trailer cooking equipment layout that works smoothly while meeting safety standards is like solving a puzzle - every piece must fit perfectly. Your trailer's design directly impacts how efficiently you serve customers while keeping your team safe and inspectors happy.

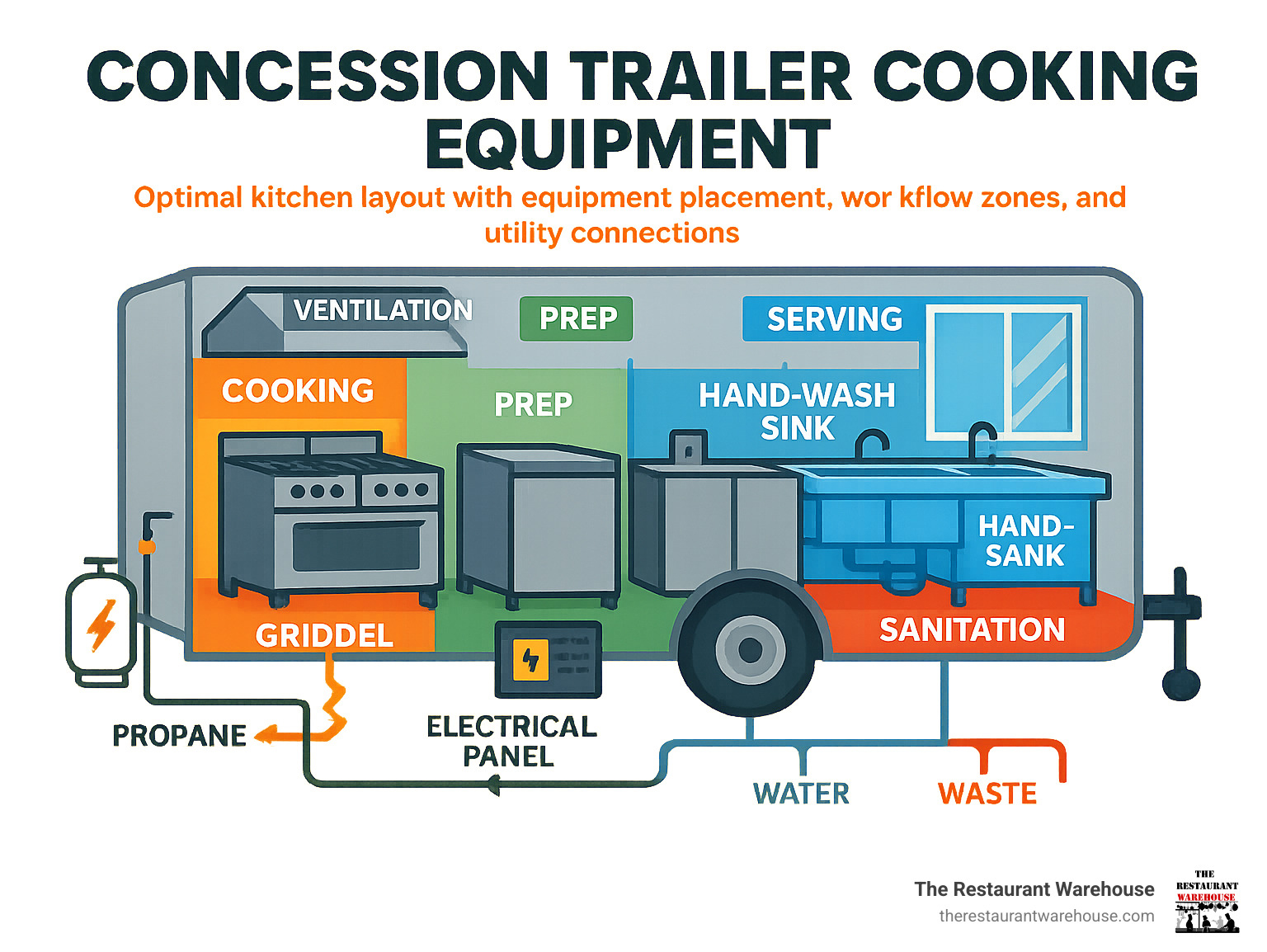

Station zoning forms the foundation of good workflow design. Think of your trailer as having three distinct areas: prep area, cooking zone, and service window. Each needs its own space and equipment, but they must work together seamlessly.

Employee flow patterns should feel natural, not like an obstacle course. The classic kitchen triangle - moving from prep to cook to service - works even in compact trailers. Smart operators design space so one person handles multiple stations without taking more than a few steps.

Cross-contamination control protects customers and your business. Raw and cooked foods need dedicated spaces, cutting boards, and utensils. This separation prevents harmful bacteria from spreading.

Local codes vary dramatically from city to city. What passes inspection in Austin might fail in Denver. Before buying equipment, research specific requirements in your target markets.

More info about food truck regulations

Health-Department Checklist

NSF sinks are non-negotiable in most jurisdictions. Both your 3-compartment wash sink and separate hand-wash station must carry NSF certification to pass inspection.

Thermometer logs and temperature monitoring systems document that you're keeping food safe. Digital systems can automate this task, providing audit trails that satisfy inspectors.

Washable surfaces throughout your kitchen make cleaning easier and inspections smoother. Stainless steel remains the gold standard, but approved plastic surfaces work for certain applications.

Fire & Ventilation Requirements

Class K fire extinguishers are specifically designed for kitchen fires involving cooking oils and fats. These must be easily accessible and regularly inspected by certified professionals.

Hood length requirements ensure your exhaust system captures cooking vapors effectively. Most codes require hoods to extend at least 6 inches beyond cooking surfaces on all sides.

Suppression system tags and inspection records must stay current and visible. These automated systems require professional installation and regular maintenance.

Sanitation & Waste Management

Greywater capacity planning prevents operational headaches. Under-sizing your waste water tank leads to frequent pump-outs and potential shutdowns during busy periods. Most successful operations size greywater tanks at least 50% larger than fresh water capacity.

Grease traps keep cooking oils from clogging your waste system. These devices require regular cleaning and proper disposal of collected grease.

Daily cleaning schedules ensure equipment lasts longer and inspections go smoothly. The most successful operators treat cleaning as part of their cooking process, not an afterthought.

Budgeting, Buying & Maintaining Your Mobile Kitchen

Understanding the financial side of concession trailer cooking equipment can make or break your mobile food dreams. Equipment costs represent a hefty chunk of your startup investment, but smart planning helps you get the most value.

Startup costs for your mobile kitchen typically run between $15,000 and $40,000, depending on your menu complexity. Your total investment for a complete operation usually falls between $50,000 and $175,000, including trailer, equipment, permits, and initial inventory.

Financing options give you flexibility. Equipment financing often beats traditional business loans because your equipment serves as collateral, usually meaning better interest rates.

Budget about 10-15% of your equipment's value each year for maintenance and repairs. It's cheaper than dealing with broken equipment during lunch rush.

Supplier Showdown: Food Truck Equipment Suppliers Ranked

Typical Cost Ranges & Financing Options

Equipment bundle pricing can save serious cash compared to buying piece by piece. Many suppliers offer complete kitchen packages including installation and training.

Used equipment savings can reach up to 75% off new prices. That's the difference between scraping by and having a comfortable operating budget. Factor in potential repair costs and shorter lifespan than new gear.

Financing terms vary based on your credit score and equipment type. Most equipment loans offer 3-7 year terms with competitive rates.

Maintenance & Cleaning Routines

Daily wipe-downs are non-negotiable. Grease buildup is a fire hazard and equipment killer. Spend 15 minutes daily cleaning, and save hundreds in repairs.

Quarterly deep-cleaning goes beyond daily routine. This means taking apart equipment to clean unreachable areas.

Descaling removes mineral deposits from water-using equipment. In hard water areas, do this monthly.

Gasket checks might seem minor, but worn seals affect temperature control and energy efficiency. A $5 gasket replacement beats a $500 compressor repair.

Where to Shop & What to Ask Suppliers

Warranty terms aren't all equal. Know what's covered, how long coverage lasts, and what actions void your warranty.

Lead times can mess with opening plans. Stock items ship immediately, but custom equipment might take 6-12 weeks.

Compliance certificates ensure your equipment meets local health department requirements. Request this documentation before buying.

The Restaurant Warehouse offers wholesale pricing without retail markup - because your success is our success.

Concession Trailer Equipment for Sale: Your Mobile Kitchen Awaits

Frequently Asked Questions about Concession Trailer Cooking Equipment

Running a mobile kitchen brings unique challenges that don't exist in traditional restaurants. These are the questions we hear most often from operators getting started with concession trailer cooking equipment.

What's the minimum equipment required by most health departments?

The bare minimum for most jurisdictions includes a 3-compartment sink for washing dishes and utensils, plus a separate hand-wash sink that's easily accessible to staff. You'll also need approved refrigeration for storing ingredients safely and adequate cooking equipment that matches your menu.

If you're using any equipment that involves grease or oil - think fryers, griddles, or charbroilers - you'll typically need a fire suppression system installed over your cooking area. This isn't optional; it's a safety requirement that protects both your business and your customers.

Here's the catch: requirements vary significantly between cities and counties. What passes inspection in one location might get you shut down in another. Always check with your local health department before making equipment purchases. It's much easier to buy the right equipment upfront than to retrofit later.

How do I power multiple appliances without tripping breakers?

This is probably the most common headache for new operators. Your trailer's electrical system is like a highway - it can only handle so much traffic before everything grinds to a halt.

Start with a properly sized electrical panel, typically 100-125 amps for most operations. Your electrician should distribute equipment across multiple circuits so you're not overloading any single breaker. Think of it like not putting all your eggs in one basket.

The real trick is load management. Don't fire up your fryer, griddle, and microwave all at the same time. Stagger your equipment use during busy periods, and consider propane alternatives for some appliances to reduce electrical demand.

Many successful operators use propane for their primary cooking equipment and reserve electricity for refrigeration, lighting, and smaller appliances. This approach gives you more cooking power while staying within your electrical limits.

Are countertop appliances acceptable replacements for full-size units?

Absolutely - if they meet your volume needs and carry proper certifications. Many successful food trucks rely heavily on countertop equipment to maximize their limited space.

The key is matching equipment capacity to your expected volume. A countertop fryer might handle 50 orders per hour perfectly, but it'll become a bottleneck if you're trying to serve 100 customers during lunch rush.

Make sure any countertop equipment carries NSF certification for commercial use. Residential equipment might look similar and cost less, but it won't pass health department inspection. Also verify that your ventilation system can handle the heat and steam from countertop units.

Countertop appliances work particularly well for specialty items or backup cooking capacity. A countertop steamer can expand your menu options without taking up valuable floor space, while a backup fryer ensures you can keep serving customers even if your main unit needs maintenance.

Conclusion

Your mobile food success begins with smart concession trailer cooking equipment choices. Think of your equipment as your business foundation - get it right, and everything else becomes easier.

Operators who invest in quality equipment from the start see faster payback periods and higher profit margins. Your fryer that handles 200 orders without breaking down pays for itself quickly compared to cheaper units that fail during lunch rush.

Your roadmap to mobile kitchen success:

Start with your menu - let your food concept drive every equipment decision. Calculate your space and power needs early. Research local regulations before buying anything. Set a realistic budget balancing new versus used equipment.

Choose suppliers who understand mobile food operations. You need partners who know the difference between restaurant equipment and concession trailer cooking equipment. Plan for maintenance from day one - daily cleaning and quarterly deep maintenance keep equipment running for years.

The lifetime ROI of quality equipment makes the initial investment look small. We've seen operators using the same griddle after serving 50,000+ customers. That's what happens when you buy right and maintain properly.

At The Restaurant Warehouse, we've equipped hundreds of mobile kitchens. Our wholesale pricing helps stretch your equipment budget further because we skip middleman markups. We know mobile operators work on tight margins, so we work on tight margins too.

Your mobile food dreams are profitable when you start with the right foundation. Take time to plan, invest in equipment that fits your operation, and establish good habits early.

Ready to build your mobile empire? Our Buyers Guide: Best Food Truck Equipment for 2025 walks you through specific equipment recommendations and insider buying tips.

The mobile food industry is waiting for what you bring to the table. Make sure your concession trailer cooking equipment is ready to deliver it perfectly, order after order.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment