Buyer's Guide: Best Food Truck Equipment for 2025

Why Food Truck Equipment Selection Makes or Breaks Your Mobile Business

Food truck equipment forms the backbone of every successful mobile kitchen, and choosing the right gear can mean the difference between profit and failure on wheels. The food truck industry has been growing at an impressive 15% annual rate compared to just 5% for traditional restaurants.

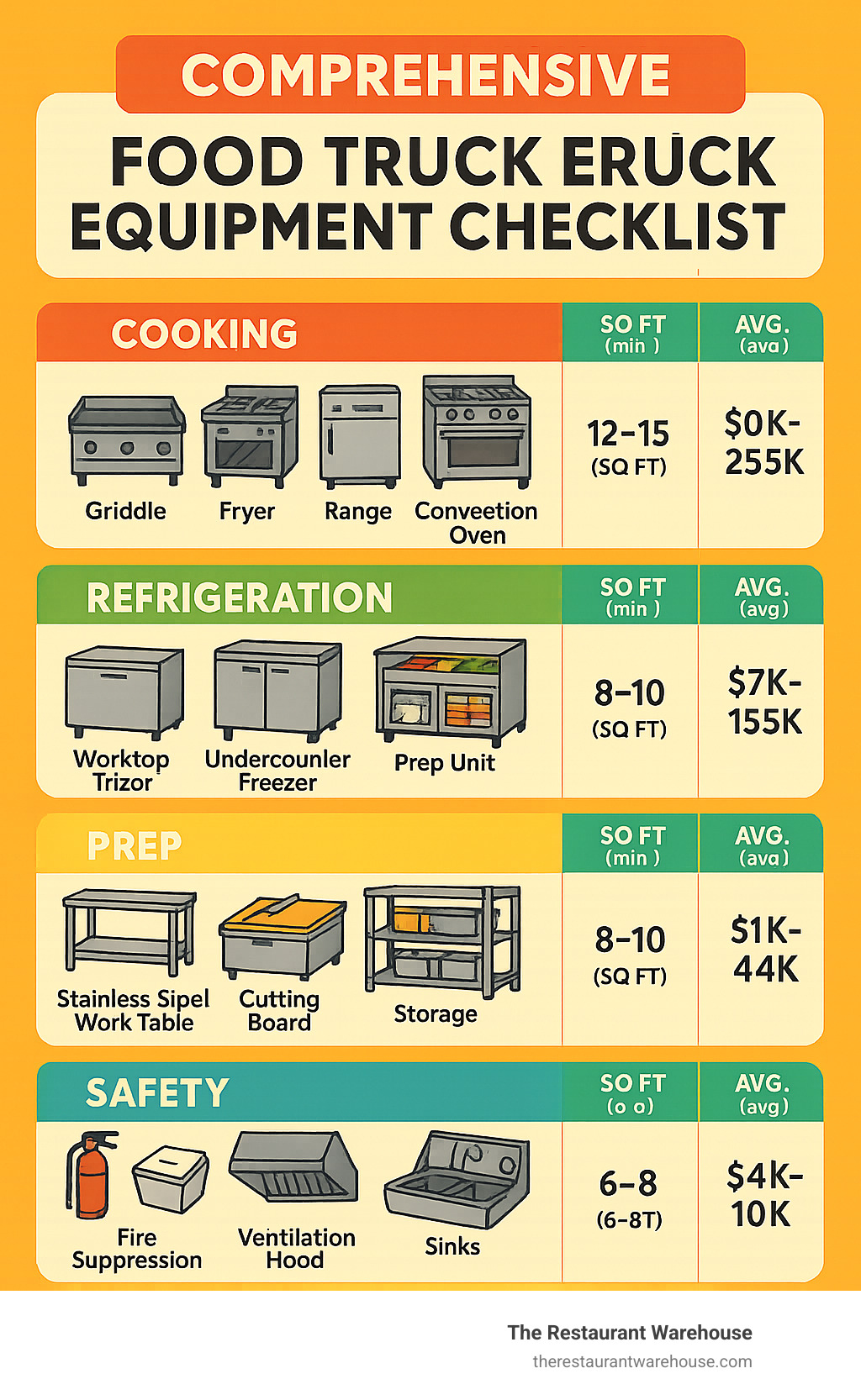

Essential food truck equipment includes: - Cooking equipment: Griddles, fryers, ranges, convection ovens - Refrigeration: Worktop fridges, undercounter freezers, prep units - Prep stations: Stainless steel work tables, cutting boards, storage - Safety systems: Fire suppression, ventilation hoods, sinks - Service supplies: Disposables, condiment dispensers, POS systems

The challenge isn't just knowing what you need - it's finding equipment that maximizes your limited space while staying within budget. Most food trucks operate in kitchens as small as 50-100 square feet, making every inch count.

With the industry projected to double over the next decade, smart equipment choices today set you up for long-term success. The key is balancing functionality, durability, and cost while meeting strict health codes and safety requirements.

2025 Food Truck Equipment Essentials

Getting your food truck equipment right from the start can make or break your mobile business. After working with thousands of food truck operators, we've learned that success comes down to choosing gear that's space-saving, energy-efficient, and pulls double duty whenever possible.

The numbers don't lie - latest research on food-truck growth shows this industry keeps expanding while traditional restaurants struggle. Smart equipment choices today set you up to ride that wave for years to come.

Think of your equipment list as three essential layers. Your cooking gear forms the heart of your operation. Your refrigeration and prep stations keep ingredients fresh and speed up service. Finally, your safety and sanitation equipment keeps you legal, insured, and open for business.

The trick is finding pieces that work overtime in your limited space. A worktop fridge gives you both cold storage and prep surface. A combi oven can bake, steam, and roast without taking up room for three separate appliances.

Cooking Food Truck Equipment Checklist

Your cooking line is where the magic happens, so let's start with the heavy hitters that'll actually make you money.

A commercial griddle or flat-top grill becomes your best friend fast. Expect to spend $1,000-$3,000 for a quality unit that can handle everything from breakfast eggs to dinner burgers. Look for precise temperature controls and surfaces that clean up easily.

Your countertop fryer ($500-$2,000) opens up a world of menu possibilities. French fries, chicken tenders, onion rings - all the crowd-pleasers that keep customers coming back. Choose units with built-in filtration and quick recovery times.

A combi oven might cost $2,000-$8,000 upfront, but it replaces multiple appliances. These combination steam and convection units can bake bread, roast vegetables, steam rice, and reheat leftovers. In a space-starved food truck, that versatility pays for itself.

Induction burners ($200-$800) give you flexibility for sauces, soups, and specialty items that need precise temperature control. They're also incredibly energy-efficient compared to gas burners. More info about Commercial Induction Burners Guide explains why smart operators are making the switch.

Don't forget your ventilation hood - it's not optional. Health codes require Type I hoods with fire suppression for any grease-producing equipment.

Cold Storage & Prep Stations

Keeping food fresh in a truck that sits in parking lots all day takes serious refrigeration planning. Modern units are designed specifically for mobile kitchens.

A worktop refrigerator gives you the biggest bang for your buck. You get cold storage below and prep surface on top - essentially two pieces of equipment in one footprint.

Your undercounter freezer handles proteins, frozen vegetables, and ice cream products. Solid doors maintain temperature better than glass, which means lower energy costs.

Sandwich prep units are game-changers for speed of service. These refrigerated tables keep your most-used ingredients in easy-reach wells while maintaining proper temperatures. Operators tell us they cut prep time by 30% with these units.

A chef base - those low-profile refrigerated drawers that slide under cooking equipment - maximizes your vertical space. Keep your most-used ingredients right at the cooking line.

Don't overlook your ice maker. A compact undercounter model producing 50-100 pounds daily handles most food truck needs. Keep several digital thermometers handy - they're your best defense against health inspection violations.

Safety & Sanitation Must-Haves

Safety equipment protects everything you've worked to build. These aren't suggestions - they're requirements that keep you legal and insured.

Your fire suppression system needs to be UL-300 compliant. These wet chemical systems detect and stop grease fires before they spread. Yes, they're expensive, but they're cheaper than losing your entire truck to a fire.

The three-compartment sink is your dish washing headquarters - wash, rinse, sanitize. More info about Food Truck Sinks Guide covers everything you need to know about sizing and installation.

A separate hand-washing sink is mandatory, not optional. It needs hot and cold water, soap, and paper towels. Health inspectors check this first.

All your food contact surfaces need NSF-certified stainless steel. This ensures durability and makes sanitization easier. Cheap equipment that can't be properly cleaned will shut you down faster than anything else.

Personal protective equipment keeps your staff safe. Cut-resistant gloves, safety glasses, and non-slip shoes prevent the most common kitchen injuries. Anti-fatigue mats with drainage holes reduce staff fatigue and prevent slips on wet floors.

How to Choose the Right Gear for Your Menu & Space

Choosing the perfect food truck equipment isn't about buying the most expensive gear - it's about finding equipment that works perfectly for your unique situation. Your menu, truck size, and power setup all play crucial roles in making smart equipment decisions.

Your menu drives everything. A taco truck needs completely different gear than a gourmet grilled cheese operation. Before you buy a single piece of equipment, sit down with your menu and really think through how each item gets made.

Power management can make or break your operation. Most food trucks run on 30-50 amp electrical systems, which sounds like plenty until you try running a convection oven, fryer, and refrigeration at the same time.

Space planning requires military precision. You're working with maybe 50-100 square feet of kitchen space, so every inch counts. Smart operators create scaled drawings of their truck layout before buying equipment.

Energy efficiency directly impacts your bottom line. Energy Star rated equipment might cost more upfront, but it'll save you money every single day through lower operating costs and longer generator runtime.

The propane versus electric debate comes down to your specific needs. Propane gives you precise heat control and lower operating costs, but requires proper ventilation and safety systems. Electric equipment is simpler to install but can strain your power system quickly.

For comprehensive planning guidance that covers all these considerations, check out our Food Truck Tips resource.

Menu Mapping to Equipment

Your menu is your equipment roadmap. Every item you plan to serve tells you exactly what gear you need - and more importantly, what you don't need.

Limited menu operations (6-8 items) can focus on quality basics: a solid griddle, single fryer, and essential refrigeration. This setup handles most burger, sandwich, and breakfast concepts beautifully.

Diverse menu concepts (10-15 items) need more flexibility. Add a combi oven for versatility, extra refrigerated prep space for ingredients, and specialty equipment like soup warmers. Each addition should serve multiple menu items to justify the space it takes up.

High-volume operations require equipment that can handle the rush without compromising quality. This means larger capacity fryers, holding units like steam tables, and maybe dual fryers for different products. Calculate your peak service needs - if you're planning to serve 200 customers during a 2-hour lunch rush, your equipment better be able to handle that volume.

Space-Saving Strategies & Innovations

Making the most of your limited space requires creativity and smart equipment choices. Every successful food truck operator becomes an expert at maximizing every square inch.

Vertical storage is your best friend. Wall-mounted shelving, overhead racks, and magnetic knife strips keep your counters clear for actual food prep and service. Think of your walls as valuable real estate - don't waste them.

Multi-functional equipment gives you the biggest bang for your buck. Refrigerated prep tables provide cold storage and work surface in one unit. Griddle and charbroiler combos offer multiple cooking methods without taking up extra floor space.

Fold-down and flip-up features provide workspace when you need it and disappear when you don't. Collapsible prep tables and flip-up counters are lifesavers during busy periods, then fold away cleanly for transport and storage.

Under-counter space should never go unused. Every inch under your work surfaces should house refrigeration, storage drawers, or equipment. Empty space under counters is literally money left on the table.

Budgeting for Food Truck Equipment: New vs Used

Let's talk money - because even the best food truck equipment won't help if it breaks your budget. Most food truck operators need between $50,000 and $150,000 for a complete equipment setup, which means every purchasing decision matters.

New equipment gives you peace of mind with full manufacturer warranties lasting 1-3 years. You'll get the latest energy efficiency standards, which can save hundreds monthly on utilities. The downside? You'll pay full retail price, and that new equipment starts depreciating immediately.

Used equipment can slash your costs by up to 75% - that's huge when you're watching every dollar. A commercial griddle that costs $3,000 new might run just $1,200 used. You'll also find immediate availability instead of waiting weeks for delivery. The catch? You're buying someone else's problems if you're not careful.

Here's what you can expect to spend on essential items:

Commercial griddles run $1,000-$3,000 new, or $400-$1,500 used. Deep fryers cost $500-$2,000 new, dropping to $200-$800 used. A worktop refrigerator might set you back $1,500-$4,000 new, but you can find good used units for $600-$2,000.

The smart play? Mix and match based on how critical each piece is to your operation. Buy new for your most important cooking equipment, then save money on prep tables and storage items.

| Equipment Type | New Price Range | Used Price Range | Best Choice |

|---|---|---|---|

| Commercial Griddle | $1,000-$3,000 | $400-$1,500 | New (heavy use) |

| Deep Fryer | $500-$2,000 | $200-$800 | Used (easier to replace) |

| Worktop Refrigerator | $1,500-$4,000 | $600-$2,000 | New (food safety critical) |

| Three-Compartment Sink | $800-$2,500 | $300-$1,200 | Used (durable item) |

Financing Smart Buys

Don't let sticker shock keep you from getting quality gear. Smart financing can spread costs while keeping your cash flow healthy.

Equipment leasing often makes the most sense for food trucks. Your lease payments are typically 100% tax-deductible as operating expenses. This preserves your precious startup capital for inventory, marketing, and those unexpected expenses that always pop up.

SBA microloans offer up to $50,000 specifically for equipment purchases. The terms are usually friendlier than traditional bank loans, especially if you're just starting out.

Keep an eye out for manufacturer financing deals. Equipment companies often run 0% interest promotions during slow seasons. That commercial oven might cost the same whether you pay cash or finance it interest-free over 12 months.

Maintaining Your Food Truck Equipment Year-Round

Here's the truth nobody wants to hear: buying equipment is just the beginning. Proper maintenance determines whether your gear lasts two years or twenty.

Daily maintenance keeps small problems from becoming expensive disasters. Clean all food contact surfaces thoroughly - grease buildup isn't just gross, it's a fire hazard. Check refrigeration temperatures twice daily and log them. Test your fire suppression system weekly, and empty grease traps before they overflow.

Weekly deep cleaning prevents the buildup that kills equipment early. Change fryer oil and filters based on usage, not calendar dates. Sanitize ice machines to prevent that funky taste customers hate. Inspect electrical connections for loose wires or corrosion.

Monthly tasks require more time but save thousands in repairs. Professional hood cleaning isn't optional - it's required by fire codes in most areas. Clean refrigeration coils monthly or your units will work twice as hard and last half as long.

Annual requirements keep you legal and safe. Fire suppression system certification is mandatory in most jurisdictions. Equipment warranty inspections can catch problems before they void your coverage.

For detailed electrical maintenance guidance, check out our More info about Wired for Success: Top Electrical Gear for Food Trailers guide.

The bottom line? Preventive maintenance costs pennies compared to emergency repairs during your busiest lunch rush.

Compliance, Safety & Future-Proofing

Running a successful food truck means staying ahead of regulations while preparing for tomorrow's challenges. Food truck equipment compliance isn't just about avoiding fines - it's about protecting your customers, your staff, and your investment.

The regulatory landscape keeps evolving, with stricter health codes, environmental requirements, and safety standards appearing regularly. What passed inspection last year might not meet this year's requirements.

Health code compliance starts with your equipment selection. Every piece that touches food must carry NSF certification - this isn't negotiable. Your refrigeration systems need to maintain consistent temperatures below 41°F, with digital monitoring becoming the standard in many jurisdictions.

Fire safety requirements have gotten more stringent too. UL-300 compliant fire suppression systems are mandatory for virtually all cooking equipment. These wet chemical systems can mean the difference between a minor incident and losing your entire truck.

Waste management has become a major focus area. Grease trap systems prevent costly sewer violations, while proper oil disposal contracts protect you from environmental penalties. Many cities now require recycling programs, and composting is becoming standard practice.

The environmental push is real and growing stronger. Energy-efficient equipment reduces your carbon footprint while cutting operating costs. Solar panels are moving from novelty to necessity in many markets.

Staying Ahead of 2025 Regulations

The permit maze gets more complex every year, but staying organized keeps you ahead of the game. Business licenses and tax registration are just the starting point. Food handler's permits now require regular renewal and continuing education in most areas.

Health department operating permits come with increasingly detailed requirements. Fire department inspections focus heavily on equipment installation and maintenance records. Parking and vending permits vary wildly by location.

Inspection readiness means more than keeping things clean. Detailed cleaning logs, accessible equipment manuals, and documented staff training create the paper trail inspectors expect. Regular self-audits using health department checklists catch problems before they become violations.

Allergen compliance has become a major focus area. Clear menu labeling for common allergens is now required in most jurisdictions. Separate prep areas for allergen-free items aren't just good practice - they're becoming mandatory.

Emerging Trends & Innovations for 2025

The food truck equipment industry is experiencing rapid innovation driven by customer expectations and regulatory changes. Smart equipment integration is moving from luxury to necessity, with IoT temperature monitoring systems providing real-time alerts about refrigeration issues.

Connected POS systems now track inventory and sales while integrating with automated cooking equipment for precise temperature and timing controls. This technology reduces human error while creating the documentation trail regulators increasingly require.

Sustainability focus is reshaping equipment choices across the industry. Battery-powered food trucks eliminate generator noise and emissions, opening up locations previously restricted by noise ordinances. Induction cooking technology offers precise, efficient heating while reducing ventilation requirements.

Compostable packaging made from plant-based materials helps meet environmental regulations while appealing to eco-conscious customers. Water recycling systems for dish washing are becoming practical options as water restrictions tighten.

Customer experience improvements often align with compliance requirements. QR code menus reduce paper waste and contact points while providing the detailed ingredient information allergen regulations require. Mobile ordering systems with pickup notifications reduce crowding around your service window.

Energy independence solutions are gaining traction fast. Solar panel systems provide supplemental power while reducing generator runtime and fuel costs. High-capacity battery storage enables off-grid operation, expanding your location options significantly.

Frequently Asked Questions about food truck equipment

Starting a food truck business brings up plenty of questions about equipment needs, and we hear the same concerns from entrepreneurs every day. Let's tackle the most common questions to help you make smart decisions about your mobile kitchen setup.

What essential food truck equipment is non-negotiable?

When health inspectors show up at your truck, they're looking for specific equipment that keeps your operation safe and legal. You simply can't operate without these basics.

Your cooking surface comes first - whether that's a commercial griddle, range, or flat-top grill. This is your money-maker, so don't skimp here. Next, you need proper refrigeration to keep ingredients at safe temperatures. Food poisoning lawsuits can destroy your business faster than any other mistake.

The three-compartment sink handles your dish washing, rinsing, and sanitizing requirements. Health departments won't budge on this one. You also need a separate hand-washing sink - using your prep sink for hand washing will earn you a violation every time.

Finally, your fire suppression system protects everyone when grease fires happen. These systems automatically detect and suppress fires before they spread throughout your truck. It's expensive but absolutely required for any truck with cooking equipment.

How can I maximize storage in a 16-foot truck?

Space planning makes the difference between a cramped, inefficient kitchen and a smooth operation. Think vertically first - your walls and ceiling offer tons of unused storage potential.

Wall-mounted shelving keeps supplies off your limited counter space. Install these shelves at different heights to accommodate various container sizes. Overhead storage racks work perfectly for lightweight items like disposable containers and paper goods.

Under your work surfaces, every inch should earn its keep. Under-counter drawers organize small tools and supplies, while undercounter refrigeration gives you cold storage without eating up floor space.

Get creative with magnetic strips for knives and metal tools. Hanging pot racks keep cookware accessible but out of the way. Consider fold-down prep surfaces that provide extra workspace during busy periods but fold flat during transport.

The secret is making every square inch serve multiple purposes. Your prep table should have storage underneath. Your refrigerator should double as a work surface on top.

Should I buy new or used food truck equipment first?

This question keeps many new operators up at night, but the answer depends on balancing your budget with reliability needs. Smart buyers mix new and used equipment strategically.

Start with used equipment for simple, durable items. Work tables, sinks, and basic storage units rarely break down and don't change much over time. You can save thousands on these basics without sacrificing quality. Look for stainless steel pieces that show normal wear but no rust or damage.

Invest in new equipment for complex appliances where warranties matter most. Cooking equipment like fryers, ovens, and griddles work hard every day. New units come with manufacturer support and energy efficiency that saves money long-term. Refrigeration equipment also deserves the new treatment - a broken freezer can cost you hundreds in spoiled inventory.

Consider the long-term return on investment too. Used equipment might save money upfront, but frequent repairs and higher energy costs can eat those savings quickly. New equipment often pays for itself through lower operating costs and fewer headaches.

The sweet spot for most operators is buying used for about 60% of their equipment and new for the critical cooking and refrigeration pieces. This approach stretches your budget while ensuring reliability where it matters most.

Conclusion

Building a successful food truck starts with making smart food truck equipment choices that balance functionality, space, and budget. The decisions you make today about griddles, refrigeration, and safety systems will impact your profitability for years to come.

The food truck industry's explosive growth means there's room for operators who do their homework and invest wisely. But success isn't guaranteed - it comes from understanding your menu needs, maximizing every square inch of space, and never compromising on safety or compliance.

Start with your menu and work backward. A simple burger concept needs different gear than a gourmet taco operation. Map out your cooking processes, then choose equipment that handles multiple tasks in minimal space.

Balance new and used purchases strategically. Buy used work tables and sinks where reliability is proven. Invest in new cooking equipment and refrigeration where warranties and energy efficiency matter most. This approach can save you thousands while ensuring reliability where it counts.

Never cut corners on safety systems. Fire suppression, proper sinks, and ventilation aren't suggestions - they're requirements that protect your investment and keep you operating legally.

At The Restaurant Warehouse, we've helped thousands of food truck operators find the right equipment at wholesale prices. We eliminate the high commissions and retail markups that make quality food truck equipment seem unaffordable.

Whether you're planning your first truck or upgrading an existing operation, we understand the unique challenges of mobile kitchens. Our team knows which equipment works best in tight spaces and harsh mobile environments.

For comprehensive guidance on outfitting your mobile kitchen, explore our More info about Commercial Kitchen Equipment Guide. You'll find detailed information on sizing, installation, and maintenance that can save you costly mistakes.

Ready to turn your food truck dreams into reality? The right equipment makes all the difference between struggling to keep up and serving customers efficiently while building profits. Contact us today to discuss your specific needs and find how wholesale pricing can stretch your startup budget further than you thought possible.

Similar topics to food truck equipment: - commercial countertop fryers - food trailer electrical

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment