Wired for Success – Top Electrical Gear for Food Trailers

Power Up Your Mobile Kitchen

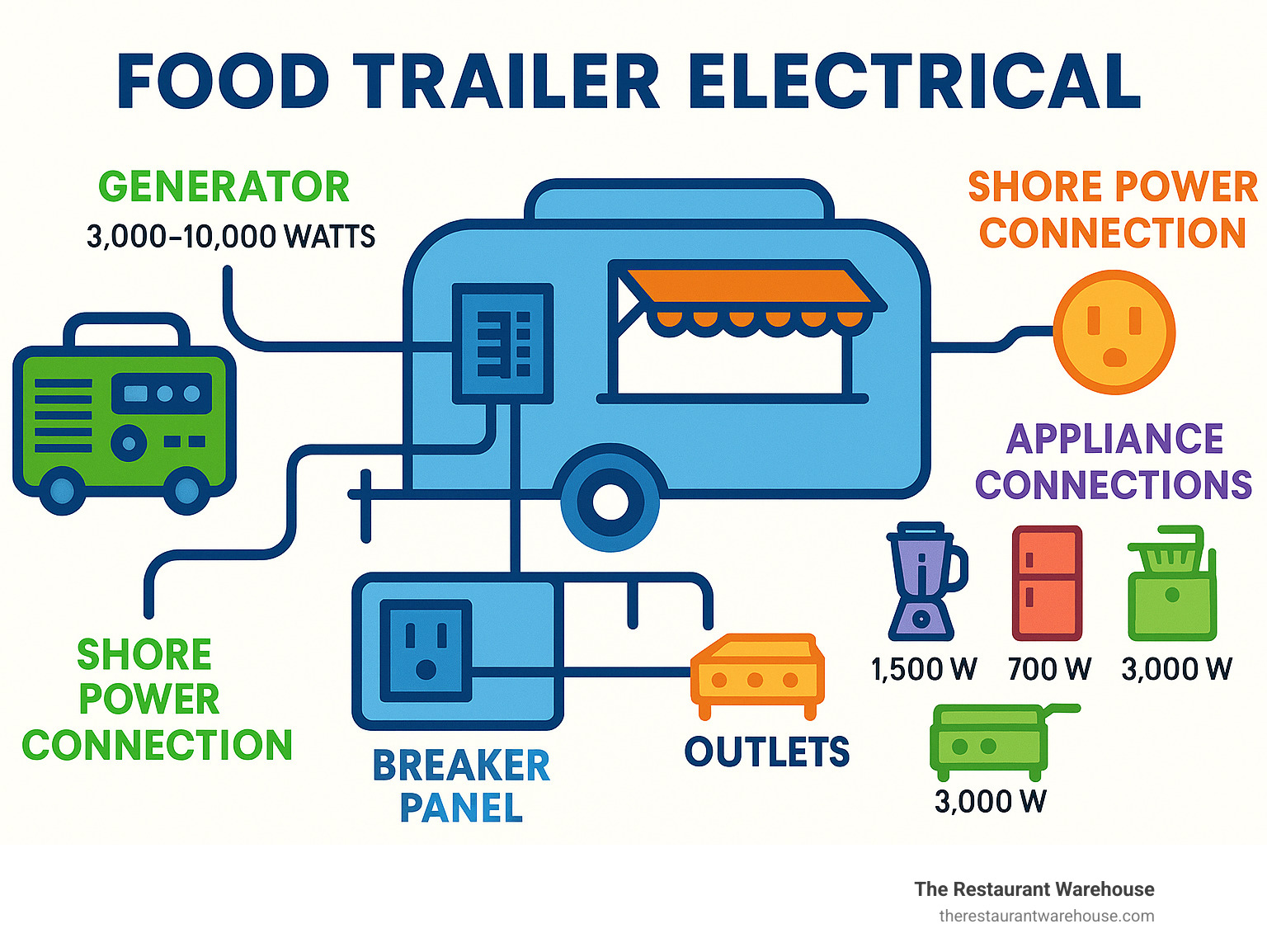

Food trailer electrical systems are the backbone of any successful mobile food business. Before diving into the details, here's what you need to know:

Quick Guide to Food Trailer Electrical Essentials:

- Power Sources: Most food trailers use one or a combination of generator power (3,000-10,000 watts), shore power connections, or solar systems

- Basic Requirements: For minimal operations (small equipment like blenders and fridges), you need at least 3,000 watts or 25 amps

- Full Operation: Primarily electrical setups typically require 5,000-7,000 watts

- Common Connectors: 4-prong 50A receptacles (NEMA 14-50R), twist-locking 30A outlets (NEMA L14-30), and standard 20A outlets

Setting up the electrical system for your food trailer isn't just about having power—it's about having reliable, safe, and sufficient power to keep your business running smoothly. Whether you're converting a vintage Airstream into an espresso bar or building a custom concession trailer from scratch, understanding your electrical needs is crucial.

The mobile food industry continues to grow, with more entrepreneurs hitting the streets with creative concepts every day. But even the most innovative menu can't overcome the frustration of blown breakers, inadequate power, or unsafe electrical setups.

According to industry data, about a third of food trucks operate on one or two 20-amp circuits, while another quarter use 50-amp connections. The remaining operations use a mix of different power setups. Knowing which category your business falls into will save you thousands in equipment costs and countless hours of frustration.

Remember: properly sizing your electrical system from the start is much more cost-effective than upgrading later. Many experienced operators recommend investing in a 10,000-watt system early, even if your immediate needs are lower, to accommodate future growth.

Powering Your Mobile Kitchen – Generators, Shore, Solar & More

Let's talk about keeping the lights on in your mobile kitchen! Whether you're slinging tacos at a festival or serving gourmet coffees downtown, your power source is the heartbeat of your operation. I've seen too many food trailer entrepreneurs learn this lesson the hard way – nothing kills your lunch rush faster than a power failure!

Portable Generator Picks

For many mobile food businesses, generators are the go-to power solution – they give you freedom to set up shop practically anywhere. Think of your generator needs in terms of watts, not fuel type:

For smaller operations (3,000-5,000 watts), a good inverter generator will be your best friend. These beauties run quieter (around 50-60 decibels – think normal conversation level) and produce "clean" power that won't fry your digital equipment. They cost more upfront but your neighbors at events will thank you for the peace and quiet!

For full-service food trailers (5,000-10,000 watts), you'll need something with more muscle. Commercial-grade generators might be louder, but they'll keep everything running smoothly – from your refrigeration to that power-hungry espresso machine.

Here's a pro tip from seasoned food truckers: Even if your current setup only needs 3,000 watts, consider investing in a 10,000-watt generator if your budget allows. It's much easier to start big than to upgrade later when you're in the middle of a busy season!

When shopping for generators, pay attention to fuel economy (how many hours per tank), weight (can you move it yourself?), and whether it offers dual-fuel options. Being able to run on both gasoline and propane can be a lifesaver when supplies are limited.

Shore Power & Event Hookups

When available, shore power (plugging into an existing electrical supply) is often the easiest option. No fuel to buy, no generator to haul, and no noise – what's not to love? But you need to be prepared for different connection types:

The NEMA 14-50R (that 50-amp, 4-prong receptacle) is the gold standard for food trailer electrical systems. It's similar to what larger RVs use and gives you plenty of power for multiple appliances. About a quarter of mobile food businesses rely on this setup.

The NEMA L14-30 twist-lock connection is another common option at events. These 30-amp connections are safer than standard plugs because they lock in place – no accidental disconnections during your busiest service!

Some smaller operations can get by with one or two standard 20-amp outlets, though this limits what equipment you can run simultaneously.

I always tell new food trailer owners to invest in a complete adapter kit. For around $200-300, you can be prepared for virtually any power situation you encounter. Your kit should include adapters to go from 50-amp down to 30-amp, 30-amp to 20-amp, and various twist-lock configurations. Don't forget heavy-duty extension cords (minimum 10-gauge) – the cheap ones from the hardware store won't cut it!

Many events prohibit generators (especially in indoor venues or food halls), so having shore power capability isn't optional – it's essential.

Solar & Alternator Hybrids

For the eco-conscious food trailer operator, solar power systems are becoming increasingly viable. Yes, they require a bigger upfront investment, but they offer some compelling advantages:

A typical solar setup includes roof-mounted panels that capture energy during daylight hours, lithium battery banks for storage, and quality inverters like the Victron Energy Quattro 5000 Watt that convert the stored DC power to AC for your appliances.

Many clever operators combine solar with alternator charging systems – these charge your battery bank while your vehicle's engine runs, giving you a backup power source for cloudy days.

The beauty of solar/hybrid systems goes beyond environmental benefits. They operate silently (great for upscale events), have minimal ongoing costs, and give you the freedom to set up in remote locations where generators are prohibited or impractical.

According to industry experts, expect to invest around $10,000 for a basic solar system for a simple operation like an ice cream truck, or about $15,000 for a comprehensive system that can power a full-service food trailer. That might sound steep, but when you factor in years of fuel savings and the marketing advantage of being a "green" business, the numbers start making sense.

Want to learn more? Check out this fascinating scientific research on solar trucks that breaks down the real-world performance of these systems.

Whatever power solution you choose, redundancy is your friend. The most successful food trailer operators have backup plans for their backup plans – because when the power goes out, so does your ability to serve customers and make money!

Food Trailer Electrical Load Calculation & Panel Sizing

Let's face it – figuring out your power needs for a food trailer can feel overwhelming, but it's actually one of the most important steps you'll take. Think of it as the foundation for your mobile kitchen's success. Getting this right means no more frustrating mid-service power outages or that sinking feeling when the breakers trip during your busiest hour!

Food Trailer Electrical Wattage Worksheet

Creating a simple power worksheet is your first step to electrical peace of mind. Here's how to do it:

Start by listing every electrical gadget and appliance you'll run at the same time. That old blender might not seem power-hungry, but when it's running alongside your refrigerator, freezer, and lighting – those watts add up quickly!

For each piece of equipment, check the label for its power rating. You'll usually find either wattage or amperage listed. If you only see amps, no problem! Just multiply the amps by the voltage (typically 120V) to get watts. So a 10-amp refrigerator needs about 1,200 watts of power.

Don't forget about those power-hungry startup surges! When motors kick on (like in refrigerators or blenders), they briefly need up to three times their running wattage. This is especially important when sizing generators.

Coffee trailer owners, pay special attention here! A commercial espresso machine can demand a whopping 4,400 watts all by itself (20 amps at 220V). That's nearly as much as some entire food trailers use!

Here's what a typical calculation might look like:

| Equipment | Volts | Amps | Watts |

|---|---|---|---|

| Refrigerator | 120 | 10 | 1,200 |

| Freezer | 120 | 8 | 960 |

| Coffee Maker | 120 | 12 | 1,440 |

| Microwave | 120 | 15 | 1,800 |

| Lighting (LED) | 120 | 2 | 240 |

| Point of Sale System | 120 | 1 | 120 |

| TOTAL | 5,760 |

Selecting the Right Breaker Panel

Now that you know your power needs, let's talk about the heart of your food trailer electrical system – the breaker panel.

Most food trailers do well with a 50-amp sub-panel. This gives you plenty of room to distribute power to different circuits without overloading any single one. When shopping for panels, you'll see two main types: main-breaker and main-lug. The difference? Main-breaker panels include a master on/off switch, while main-lug panels need a separate disconnect. For most trailers, a main-breaker panel offers simplicity and safety in one package.

For your wiring, always choose stranded (not solid) conductors. Your trailer will shake, rattle and roll down countless roads, and solid wires can fatigue and break over time. Those little wire nuts you might use at home? They're not your friends in a vibrating food trailer. Instead, consider using Wago LeverLock or spring-cage terminals that grip wires securely even when bouncing down the highway.

Here at The Restaurant Warehouse, we always recommend following the 80% rule – size your breakers at 125% of your continuous loads. So if you have equipment drawing 35 amps continuously, you'll want to protect it with a 50-amp breaker. This gives you a comfortable safety margin and helps prevent nuisance tripping.

Planning for Future Gear

Trust me on this one – your equipment list will grow! That cute little trailer that started with just a griddle and a fridge might soon house a deep fryer, panini press, or that fancy soft-serve machine you've been eyeing.

Smart food trailer owners build in room to grow from day one. Include a few spare circuits in your initial panel setup – they're much cheaper to install during the build than to add later. Run some empty conduit pathways through your walls while they're open. This gives you ready-made channels to pull new wires through later.

A good rule of thumb? Size your main service about 20% larger than what your current calculations show you need. Today's 6,000-watt operation might be tomorrow's 7,200-watt kitchen, and upgrading an undersized system typically costs 2-3 times more than building in that capacity from the start.

Document everything! Create clear labels for all your circuits and keep a wiring diagram in your trailer. Your future self (or the technician you call when something goes wrong at 2 am before a big event) will thank you profusely.

Most seasoned food truck operators we work with recommend investing in a system that can handle at least 6,500 watts, with 10,000 watts being ideal for future-proofing. It might seem like overkill now, but that extra capacity often pays for itself the first time you avoid a shutdown during a busy service.

Top Connectors, Cords & Inlets You Can't Operate Without

The connections between your power source and your trailer aren't just parts of your food trailer electrical system—they're the lifelines that keep your business running. Think of them as the handshakes between your equipment and the power grid. Getting these connections right means the difference between a smooth service and a frustrating day of tripped breakers and equipment failures.

Food Trailer Electrical Outlet Cheat-Sheet

Ever pulled up to an event only to find you can't connect to their power? You're not alone. Understanding the outlet landscape is essential for any mobile food entrepreneur:

| Outlet Type | Amperage | Voltage | Prong Configuration | Common Uses |

|---|---|---|---|---|

| NEMA 5-15/5-20 | 15/20A | 120V | 3-prong standard | Basic equipment, lighting |

| NEMA L14-20 | 20A | 120/240V | 4-prong twist-lock | Medium power equipment |

| NEMA L14-30 | 30A | 120/240V | 4-prong twist-lock | Higher power needs |

| NEMA 14-50 | 50A | 120/240V | 4-prong straight | Full service operations |

| CS6365 | 50A | 120/240V | Twist-lock | Secure event connections |

The reality is that about a third of food trucks manage with just one or two 20-amp circuits—perfect for simple setups. Another quarter rely on L14-30 connections, while the remaining quarter need the robust power of a 50-amp hookup. Having adapters for all these possibilities isn't just convenient—it might save your event day when the power options aren't what you expected.

Locking & Weatherproof Plugs

Rain or shine, your connections need to stay secure. That's where locking plugs come in—they're like insurance policies for your power supply.

The twist-lock design prevents that heart-stopping moment when someone trips over your cord and unplugs your entire operation during the lunch rush. Their weatherproof construction keeps moisture at bay, while proper strain relief prevents the cable damage that happens when cords get yanked or twisted.

For 50-amp setups, we've found the Hubbell CS6365 series connectors to be absolute workhorses. They're built like tanks and are compatible with most event power pedestals you'll encounter. The clever center pin configuration makes it nearly impossible to connect them incorrectly—a real blessing when you're setting up in pre-dawn darkness.

When it comes to weatherproofing, don't skimp. Rubber boots covering your connection points and sealed cord caps protecting unused inlets are worth their weight in gold during unexpected downpours. And remember to mount your inlets at least 24 inches from the ground—puddles and electrical connections don't mix!

Heavy-Duty Extension Cords & Adapters

Your extension cords aren't just accessories—they're critical infrastructure. The right cords make your life easier; the wrong ones can damage equipment or even create fire hazards.

For 30-amp applications, don't go smaller than 10-gauge wire (specifically #10-3 SOOW). If you're running 50 amps, you'll need to step up to 8-gauge or even 6-gauge. The "SOOW" rating isn't just alphabet soup—it means the jacket is oil and weather-resistant, essential for the harsh conditions food trailers face.

Every food trailer electrical toolkit should include a complete set of adapter pigtails. Think of these as your power translators, allowing you to speak the electrical "language" of any venue. At minimum, you'll want:

A 50A female to 30A male adapter for connecting your high-capacity trailer to more limited power sources. A 30A female to 50A male for the reverse situation. A 30A female to 20A male for those smaller venues with limited power, and various twist-lock conversions for specialty connections.

Longer cords mean more voltage drop—about 5% for every 100 feet of 10-gauge cord under full load. This silent power thief can make equipment run poorly or even damage sensitive electronics. Keep your cords as short as practical, and consider upgrading to heavier gauge for longer runs.

At The Restaurant Warehouse, we've seen too many operators scrambling to find the right connections at the last minute. We recommend storing all your cords and adapters in a dedicated weatherproof container—nothing ruins your day faster than finding your expensive cords have been sitting in a puddle all winter!

Latest research on locking plugs

Safety, Code Compliance & Installation Pro Tips

Let's talk safety—because no matter how delicious your food is, it won't matter if your trailer's electrical system causes problems! As someone who's seen the good, the bad, and the downright dangerous in food trailer electrical setups, I can tell you that doing things right the first time saves headaches (and potentially lives) down the road.

Grounding, Bonding & GFCI

I can't tell you how many times I've crawled under a food trailer to find improper grounding—it's probably the most common mistake I see in mobile kitchens.

Grounding isn't just a code requirement—it's your safety net. In your trailer, you need to keep neutral and ground separate at the load center, unlike in a house. This is a subtle but crucial difference in mobile units that even some electricians miss.

Another common mistake? Installing a bonding jumper in your trailer panel. This might work fine until you connect to shore power, then suddenly your GFCIs are tripping and you're wondering why.

Speaking of GFCIs, they're your friends in a wet environment like a kitchen. Test them monthly by pressing that little button, and keep a log of when you did it. Trust me, when an inspector asks for documentation, you'll be glad you did. Any GFCI that fails the test needs immediate replacement—no exceptions.

Consider adding surge protection at your main panel too. It's relatively inexpensive insurance for all those expensive electronics and kitchen gadgets you rely on.

Wiring Inside a Moving Vehicle

Your food trailer isn't a house—it bounces, vibrates, and experiences temperature swings that would make a house inspector cringe. That's why you need special wiring techniques.

Always use stranded conductors in your food trailer. Solid wire might be fine in a stationary building, but in your mobile kitchen, it will eventually fatigue and break from all that movement. I've seen solid wire installations fail within months in busy food trucks.

Secure your wiring properly with clamps at regular intervals. Those little plastic sticky-back wire holders? They'll fall off when it gets hot. Use proper metal clamps with rubber inserts instead.

Flexible conduit is your friend in areas subject to movement. It costs a bit more than rigid conduit, but you won't be replacing broken wires later.

Here's a pro tip from the cruise ship industry (they know a thing or two about vibration): use spring-cage terminals like Wago connectors rather than wire nuts. They maintain constant pressure even with vibration.

For lighting, LEDs are the clear winner in food trailers. They use about 80% less power than old-school incandescent bulbs, produce less heat (your AC will thank you), and handle voltage fluctuations better. Plus, you can choose warmer or cooler light temperatures to make your food look its absolute best.

Inspections & Maintenance Schedules

The most successful food trailer operators I know have one thing in common: they're religious about maintenance. Here's what they do:

Before every event, take five minutes to check your electrical system:

- Look over all cords and connections for damage

- Test your GFCIs

- Check voltage at the main panel before you turn everything on

- If you're using a generator, check oil and fuel levels

Monthly, take a deeper dive. Test all your circuit breakers by flipping them off and on (this helps prevent them from sticking). Check your panel for any signs of overheating or corrosion, which often show up as discoloration on connections.

Once a year, schedule a thorough maintenance day. Tighten every connection in your panel (electricity makes things expand and contract, which loosens connections over time). If possible, get an infrared scan of your panel while it's under load—this can identify hot spots before they become problems.

At The Restaurant Warehouse, we always recommend creating a simple maintenance log in a notebook or even on your phone. Not only does this help you stay on top of safety, but it's also valuable documentation for insurance purposes and adds to your trailer's resale value if you ever decide to upgrade.

A safe electrical system isn't just about passing inspections—it's about protecting your investment, your customers, and yourself. And if you're ever unsure about something, please consult with a licensed electrician who understands mobile food service requirements. Some things are worth doing right, and your food trailer electrical system is definitely one of them.

Frequently Asked Questions about Food-Trailer Power (3 quick answers!)

How big a generator do I really need?

This is probably the most common question we hear at The Restaurant Warehouse, and for good reason! Choosing the right generator size can make or break your mobile food business.

The answer depends on your specific equipment setup, but here's a friendly rule of thumb:

If you're running a basic operation with just refrigeration, some small equipment and lights, you'll need at least 3,000 watts (about 25 amps). Most standard operations that include cooking equipment typically require 5,000-7,000 watts. For those full-service food trailers with multiple cooking appliances, refrigeration, and other equipment running simultaneously, you're looking at 8,000-10,000 watts.

Let me give you a real-world example: If your food trailer electrical system includes an espresso machine (4,400W), refrigerator (1,200W), and basic LED lighting (240W), you'll need at least 5,840 watts. But here's a pro tip – always add about 20% capacity for future expansion. This brings your total to approximately 7,000 watts.

One thing many new food trailer owners forget is that refrigerators, freezers, and other motor-driven appliances need about three times their running wattage during startup. That morning rush when everything kicks on at once can trip your system if you haven't accounted for these power surges!

Can I plug into any event pedestal safely?

I wish I could say yes, but the truth is that event power sources can vary wildly in quality and configuration. Before you connect your precious food trailer electrical system to an unknown power source, take these simple precautions:

First, always verify the voltage and amperage available at the pedestal. What's advertised isn't always what's delivered! Next, confirm that the connector type matches your equipment (or that you have the right adapter in your toolkit). Use a circuit tester to check for proper grounding – this simple $10 tool can save you thousands in equipment damage. And if you're connecting in potentially wet conditions, make sure there's GFCI protection in place.

Most events provide either 50-amp RV-style connections (NEMA 14-50R) or 30-amp twist-lock connections (L14-30). Having adapters for both these standards will cover you in most situations.

I've seen too many food trailer operators try to force connections by modifying plugs or removing ground pins. Please don't do this! Not only does it compromise safety and violate electrical codes, but it could void your insurance if something goes wrong.

What's the difference between 30A and 50A hookups?

This question comes up all the time, especially from folks transitioning from smaller to larger operations.

A 30-amp service (typically 120V) provides up to 3,600 watts of power (30A × 120V). It usually has a single hot leg plus neutral and ground wires. The most common connector you'll see is the NEMA L14-30 twist-lock, which is great because it won't pull out accidentally. This setup is generally sufficient for basic operations with limited cooking equipment.

By contrast, a 50-amp service (typically 120/240V) delivers up to 12,000 watts of power (50A × 240V) – that's more than three times the power of a 30-amp service! It has two hot legs (each 120V) plus neutral and ground. You'll typically connect with a NEMA 14-50R straight blade plug. This robust power supply is what you need for full-service operations running multiple appliances.

The biggest mistake I see new food trailer electrical customers make is underestimating their future power needs. If you're designing a new trailer, we strongly recommend installing a 50-amp inlet even if your current equipment doesn't demand it. This simple decision provides tremendous flexibility for future expansion without requiring costly electrical upgrades down the road.

At The Restaurant Warehouse, we're always happy to help you calculate your specific power needs based on your equipment list. Just reach out with your questions!

Conclusion

Setting up the right food trailer electrical system isn't just another task on your to-do list—it's an investment in your business's future success. I've seen how proper electrical planning can make the difference between a smooth operation and a frustrating experience with constant outages.

When you're planning your food trailer's power system, remember these essential points:

First, take the time to calculate your power needs accurately. List every piece of equipment you'll use simultaneously and don't forget those startup surges—they can be three times the running wattage! This simple step will save you countless headaches down the road.

Quality matters tremendously in a mobile environment. The constant vibration, temperature changes, and movement put extra strain on electrical components. Investing in commercial-grade equipment might cost more upfront, but the reliability is worth every penny.

Always think ahead. The most common regret I hear from food trailer owners? "I wish I'd installed a bigger system from the start." Size your system at least 20% larger than your current needs—your future self will thank you when you want to add that new piece of equipment.

Be prepared for any venue by carrying a complete adapter set. Whether you're at a festival with 50-amp pedestals or a private event with standard outlets, you'll never have to turn down an opportunity because of incompatible power sources.

Maintenance might not be exciting, but it's essential. Create a simple log to track your monthly inspections and tests. This documentation not only helps prevent failures but can be valuable for insurance purposes or if you ever decide to sell your trailer.

At The Restaurant Warehouse, we understand the unique challenges of mobile food service because we've helped countless entrepreneurs power up their dreams. Our team can guide you through selecting the right components for your specific concept, from generators and panels to the smallest connectors.

There's also a practical advantage to sourcing all your electrical equipment from a single supplier—compatibility is guaranteed, and you'll often find significant cost savings compared to piecing together components from multiple vendors.

Whether you're building your first food trailer or upgrading an existing one, your electrical system is the heartbeat of your mobile kitchen. Without reliable power, even the most innovative menu and prime location can't save your business.

Ready to power up your food trailer the right way? Reach out to us today, and let's design a system that will keep your business humming along smoothly for years to come.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment