Top-Rated Refrigerated Prep Tables for Your Commercial Kitchen

Why Refrigerated Prep Tables Are Essential for Commercial Kitchen Success

A refrigerator prep table is the backbone of an efficient kitchen, combining refrigerated storage with a convenient prep surface. These units keep ingredients at a food-safe 33-40°F while providing easy access for meal assembly, boosting speed and organization.

Quick Guide to Refrigerated Prep Tables:

- Purpose: Keep ingredients cold and accessible during food preparation.

- Temperature Range: 33-40°F for optimal food safety.

- Key Benefits: Faster service, better organization, improved food safety.

- Common Types: Sandwich prep (1/6 pans), pizza prep (1/3 pans), mega top (extra capacity).

- Size Range: 27" to 72+ inches wide.

- Price Range: $1,300 - $4,000+ depending on size and features.

Refrigerated prep tables deliver exceptional value by eliminating constant trips to the walk-in cooler and messy ice cleanups. Their self-contained refrigeration systems maintain consistent temperatures automatically, helping staff work faster and safer.

Beyond the headline benefits, refrigerated prep tables solve practical, everyday problems. During a rush, the difference between a well-organized, temperature-stable rail and a disorganized station is measured in minutes per ticket and consistency of portions.

Who benefits most? Virtually every segment that assembles cold ingredients: sandwich shops, salad concepts, pizza operations, hotels, commissaries, c-stores, universities, healthcare nutrition services, catering prep areas, and ghost kitchens.

Expected lifespan and ownership costs matter. With consistent maintenance, a quality refrigerated prep table can serve reliably for many years. Energy-efficient components such as R290 refrigerant and ECM evaporator motors help reduce operating costs. NSF-7 certification signals the unit is built for open food storage in a commercial environment.

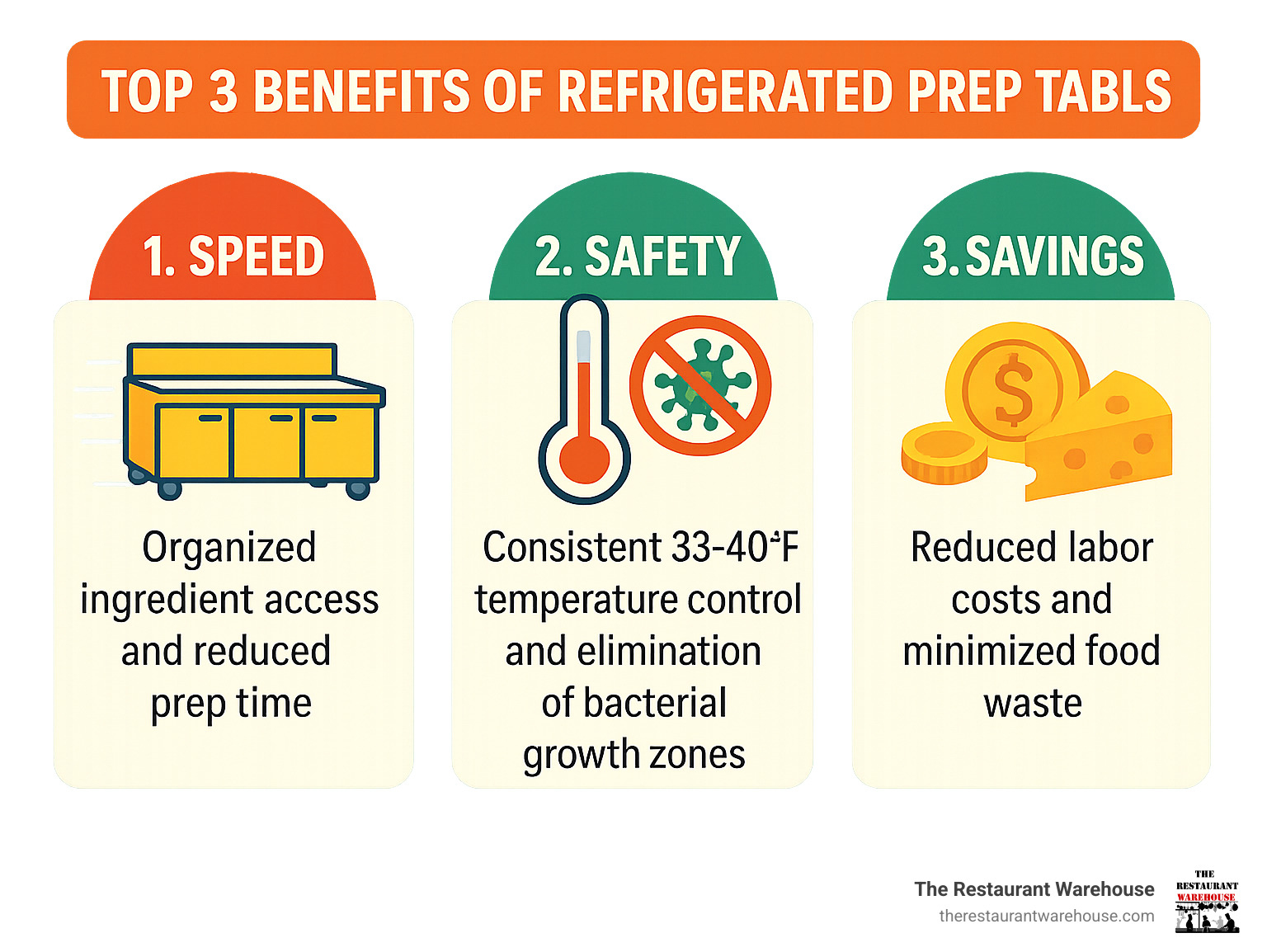

The Core Benefits: Why Your Kitchen Needs a Refrigerated Prep Table

A well-chosen refrigerator prep table delivers three game-changing benefits: improved efficiency, improved food safety, and superior organization.

The key is consistent temperature control. A quality prep table automatically maintains the crucial 33-40°F range, preventing bacterial growth and preserving ingredient quality. This precision reduces labor costs by eliminating time spent managing ice or running to the walk-in cooler. Food safety is simplified when your unit meets NSF-7 standards, helping minimize cross-contamination by keeping ingredients separated and chilled.

Ready to explore your options? Check out our comprehensive guide on Freshness on Demand: Top Commercial Prep Fridge Options to find the right model for your kitchen.

Streamlining Kitchen Workflow

A strategically placed refrigerator prep table creates a centralized command center for food prep, eliminating wasted steps. With every ingredient at their fingertips, staff can achieve faster meal assembly and dramatically reduced prep time. Modern units feature self-contained refrigeration, which means no more dealing with messy ice or mopping up melted water.

Want to optimize your kitchen layout? Our Preparation Table Kitchen Guide walks you through best practices.

Upholding Food Safety Standards

Your refrigerator prep table is a first line of defense against food safety violations and a critical control point in your HACCP (Hazard Analysis and Critical Control Points) plan. It's engineered to maintain the food-safe temperature zone of 33-40°F (0.5-4.4°C), where the growth of harmful bacteria like Salmonella and E. coli slows significantly. This is achieved through powerful forced-air cooling systems, which use fans to actively circulate cold air throughout the pan rail and storage cabinet, eliminating dangerous warm spots that can occur in static cooling systems. Insulated lids and covers are not just for show; they provide an essential thermal barrier, especially overnight or during slower periods, maintaining stable temperatures and reducing energy consumption. Furthermore, modern units with digital temperature monitoring and displays allow staff to easily verify that the unit is operating correctly at a glance, simplifying daily temperature logs and ensuring compliance with health department regulations.

For detailed maintenance procedures, check out our Sandwich Prep Table Maintenance guide.

Decoding the Options: Types of Commercial Prep Tables

Choosing the right refrigerator prep table is easier once you understand the basic categories. The right tool for the job depends on your menu—a pizza maker has different needs than a sandwich artist.

The two main types are sandwich prep units and pizza prep units. Beyond these, you'll choose between standard top and mega top configurations, and door versus drawer access.

Our detailed Pizza Prep Table Guide dives deeper into specifics for pizzerias.

Sandwich & Salad Prep Tables

For kitchens focused on sandwiches, wraps, or salads, these refrigerator prep tables are designed for speed and variety. Their key features are shallow cutting boards (around 9 inches) and space for multiple 1/6-size food pans. These compact designs are perfect for delis and cafes where floor space is at a premium but ingredient variety is essential.

For sizing guidance, our guide on the 48" Sandwich Prep Table breaks down capacity and features.

Pizza Prep Tables

Pizza prep tables are built for the unique demands of working with dough and large quantities of toppings. They feature deeper cutting boards (10-12 inches or more) to provide ample space for stretching dough. The most critical feature is the raised pan rails designed for larger 1/3-size food pans. This allows pizzerias to stock generous amounts of cheese, pepperoni, and other popular toppings.

Our Atosa Pizza Prep Table review covers a popular option in detail.

Special Configurations: Mega Tops and Drawers

A mega top unit provides more ingredient capacity in the same footprint by adding a second row of pans, increasing pan capacity by 50% or more. The choice between drawer access and door access affects daily workflow:

- Drawers offer easier access without bending and lose less cold air when opened.

- Doors have a lower upfront cost and better accommodate large containers.

Our guide on the 72" Sandwich Prep Table explores these configurations in larger units.

Buyer's Guide: Key Features to Consider for Your Refrigerator Prep Table

When shopping for a refrigerator prep table, focus on the key features that will save you headaches and money long-term.

We advise owners to focus on three key areas: construction quality for longevity, the refrigeration system for performance and utility costs, and functionality features for daily workflow.

For personalized guidance, check out our guide on how to Choose Sandwich Prep Station.

Construction and Durability

Commercial kitchens are tough on equipment, so your refrigerator prep table must be built to last. Stainless steel construction is non-negotiable, but not all stainless steel is created equal. Look for 430-grade stainless steel exteriors, which offer excellent durability and corrosion resistance at a cost-effective price point, making them ideal for the outer body. For the interior and food zones, 304-grade stainless steel is the gold standard; its higher nickel content provides superior protection against acidic ingredients like tomatoes and vinaigrettes, preventing pitting and rust over time. Pay attention to the unit's overall build quality; fully welded corners are far more durable than screwed-together frames, which can loosen with movement. Foamed-in-place polyurethane insulation is another critical feature, as it provides structural rigidity and creates a solid thermal barrier that keeps cold air in and improves energy efficiency. Finally, ensure the unit has thick, removable cutting boards (often made of high-density polyethylene) for easy cleaning and sanitizing, and heavy-duty casters (at least two with brakes) for mobility during cleaning and kitchen reconfiguration.

Our Prep Table Stainless Steel Guide breaks down material choices.

Refrigeration System and Energy Efficiency

The heart of a refrigerator prep table is its refrigeration system. Look for systems using eco-friendly R290 refrigerant, which can deliver up to 40% energy savings compared to older types. Digital thermostats and controls offer precise temperature management. Features like auto-defrost cycles save time by automatically managing ice buildup. For guaranteed savings, look for Energy Star certification.

Browse our selection of 48" Sandwich Prep Refrigerators for efficient models.

Functionality and Workflow

The biggest decision is often Standard Top versus Mega Top. A Standard Top offers a deeper cutting board with a single row of pans. A Mega Top adds a second row of pans, nearly doubling ingredient capacity—perfect for high-volume kitchens with extensive menus.

Other key features include pan layout flexibility with adjustable divider bars, proper work surface height (including ADA-compliant models at 34 inches), and self-closing doors with a stay-open feature.

Our Prep Table Kitchen Guide covers optimizing your layout.

Maintenance and Longevity: Protecting Your Refrigerator Prep Table

A refrigerator prep table is a major investment, and proper maintenance is key to protecting it. A little consistent care prevents major headaches, ensures longevity, and keeps the unit running efficiently and safely, saving you money on energy and repairs.

Routine Cleaning and Maintenance Daily cleaning is the foundation of proper care. At the end of each shift, remove and sanitize all food pans and cutting boards. Wipe down the interior of the pan rail and the stainless steel exterior to remove food debris and spills. On a weekly basis, inspect the door and drawer gaskets for tears or damage. Clean them with warm, soapy water to keep them pliable and ensure a proper seal, which is critical for temperature maintenance.

Condenser Coil Cleaning The condenser coil is critical to your unit's performance. In a busy kitchen, it can get clogged with dust and grease, forcing the system to work harder. We recommend cleaning it monthly.

- Unplug the unit for safety.

- Locate the coil, usually behind a grille at the bottom or back.

- Use a stiff brush to gently loosen debris from the fins.

- Vacuum away the loosened dust. Be careful not to bend the delicate fins.

Proper Use and Troubleshooting Avoid overfilling pans, as this blocks airflow and strains the refrigeration system. If storing food overnight, cover the pans and lower the rail cover. If you encounter issues like poor cooling, first check that the unit is plugged in, the thermostat is set correctly, and the condenser coil is clean. Excessive condensation often points to a bad gasket seal. Consistent maintenance prevents most of these common problems before they start.

For detailed instructions, our Sandwich Prep Table Maintenance guide offers step-by-step help.

Suggested Preventive Maintenance Schedule

- Daily: Sanitize the board and rail, empty and clean pans, and wipe door/drawer handles. Verify the displayed temperature before opening for service.

- Weekly: Deep clean the cabinet interior, check gaskets for tears or looseness, and inspect casters for debris.

- Monthly: Clean condenser coils, verify controller calibration, and inspect door/drawer alignment and self-closing function.

- Quarterly: Inspect evaporator area for ice buildup, clean fan guards, and confirm that condensate evaporation is functioning properly.

- Annually: Have a qualified tech perform a full performance check: superheat/subcool measurements when applicable, electrical connections, fan motor condition, and controller firmware settings.

Sanitation Best Practices Use food-safe sanitizers at the correct dilution, and give contact time per label directions. Replace cutting boards that show deep grooves. Train staff to return utensils to designated, clean locations and to keep lids closed when not actively pulling product. Label and date all pans to avoid confusion and waste.

Power Outage and Recovery Tips Keep doors and lids closed to hold temperature if you experience a brief power loss. Once power returns, confirm that the controller resumes normal operation and that the temperature falls back into range. Discard any time/temperature control for safety (TCS) foods that were out of the safe zone beyond allowable limits.

Common Issues and Quick Checks

- Rail feels warm: Confirm lids are closing fully, pans are not above the fill line, and the condenser intake is unobstructed.

- Water on the floor: Check the condensate pan and drains for clogs, ensure the unit is level, and verify that the evaporation system is functional.

- Door wont self-close: Level the unit, clean hinge areas, and inspect the gasket for warping or tears.

- Temperature swings: Review defrost schedule, check for frequent prolonged lid openings, and verify air paths are clear around product.

A disciplined maintenance routine not only extends service life; it preserves food quality, reduces energy use, and prevents inconvenient downtime.

Frequently Asked Questions about Refrigerated Prep Tables

When buying a refrigerator prep table, many customers have the same key questions. This is a critical investment for your kitchen's efficiency. Here are answers to the most common queries.

What is the typical price range for a refrigerator prep table?

Pricing for a refrigerator prep table varies widely based on size and features.

- Entry-level models (around $1,300) are typically smaller 27-inch units, perfect for food trucks or small cafes.

- Mid-range units ($1,800 to $2,500) often include 48-inch models with features like mega tops or digital controls, suiting most standard restaurants.

- High-capacity units ($4,000+) are large 72-inch+ models built for high-volume operations.

Size and features are the main price drivers. A larger unit or one with a mega top, drawers, or a premium interior will cost more. At The Restaurant Warehouse, our wholesale pricing approach avoids high retail markups, allowing us to offer significant savings and keep more money in your pocket.

What's the difference between a standard top and a mega top prep table?

The main difference is ingredient capacity versus workspace.

- A standard top has one row of food pans, leaving a deeper cutting board. It's ideal for simpler menus or when you have ample prep space.

- A mega top has two rows of pans, increasing pan capacity by 50% or more in the same footprint. This is perfect for complex menus and high-volume service, though the cutting board is slightly shallower.

Most operators find the increased ingredient access of a mega top to be a worthwhile trade-off for the reduced cutting board depth.

How do I know what size prep table I need?

Choosing the right size refrigerator prep table depends on three factors:

- Kitchen Footprint: Measure your available space carefully, accounting for door swings and traffic flow. A unit is useless if it doesn't fit or disrupts your workflow.

- Menu Complexity: A simple menu may only require a compact 27-inch unit. More complex menus benefit from 48-inch to 60-inch units that offer more pan variety.

- Customer Volume: High-volume operations need the capacity of 72-inch and larger units to avoid constant restocking during peak hours.

As a general guide:

- Small cafes/food trucks: 27" - 36"

- Standard restaurants/delis: 48" - 60"

- High-volume operations: 72"+

Consider your future needs as well. If you plan to expand, buying a slightly larger unit now can save you from upgrading later. For more on compact options, see our guide on the Best 27" Prep Tables.

Can I mix pan sizes in the rail?

Yes. Most rails use divider bars that let you mix 1/3, 1/6, and 1/9 pans to match your menu. Keep high-use items in larger pans toward your dominant hand. Maintain proper fill levels and avoid heaping product above the pan rim to preserve airflow.

How important is the ambient temperature rating?

Very. A unit rated for higher ambient temperatures will hold setpoints better in busy, warm environments. If your station sits in a warm area or experiences frequent lid openings, choose a model with robust airflow and an ambient rating suited to your conditions.

What certifications should I look for?

NSF-7 indicates the unit meets standards for open food storage and temperature performance. Electrical safety listings (such as UL/ETL) are also common. These certifications simplify health department approvals and provide confidence in sanitation and safety.

Do drawers or doors hold temperature better?

Both can perform well. Drawers often release less cold air per opening and keep backup product organized in pans. Doors can be more flexible for bulk containers. Choose based on your container types and aisle space.

How noisy are refrigerated prep tables?

Noise varies by model, compressor location, and fan design. Rear-mounted compressor units often vent at the back and can be quieter to the operator. If your concept has an open line near guests, compare decibel specs and ask about quiet fan motors.

What maintenance is essential to avoid downtime?

Keep coils clean, gaskets supple and undamaged, lids closed when not in use, and pans at the correct fill height. Verify displayed temperatures at opening, and schedule routine deep cleans. Many temperature issues trace back to airflow obstructions or dirty condensers.

Can I use these outdoors or in semi-outdoor spaces?

Most prep tables are intended for indoor, climate-controlled environments. Outdoor or semi-outdoor use exposes units to heat, humidity, and particulates that can disrupt temperature control and increase maintenance. If you must operate near exterior doors or drafts, plan shielding and ensure adequate clearances for intake and exhaust.

How long do refrigerated prep tables last?

With regular maintenance, quality units can provide many years of service. Lifespan depends on usage intensity, ambient conditions, cleaning diligence, and adherence to best practices.

Is it safe to store product in the rail overnight?

Follow your local health code. Many operators transfer product from the rail to covered containers in the cabinet or walk-in after service. If permitted and done correctly, using fitted lids and keeping the insulated cover down can help maintain temperatures, but verify with your inspector and your HACCP plan.

What about energy efficiency?

Look for R290 refrigerant, efficient fan motors, tight gaskets, and well-insulated cabinets. Energy Star-certified units can reduce utility costs. Good station practiceskeeping lids closed and avoiding overfilling pansalso lower energy use by reducing cycling.

How do I prepare for delivery and installation?

Measure all access points, ensure the site is level, plan electrical connections per spec, and clear adequate space for condenser airflow. Have casters ready if needed and confirm door swing or drawer clearance relative to nearby walls or equipment.

Should I buy a mega top if I have a small menu?

If your menu is simple and you value a deeper cutting surface, a standard top is likely the better choice. Mega tops shine when you rotate seasonal toppings or have many low-volume items that would otherwise require frequent swaps.

Conclusion

A refrigerator prep table is more than just equipment; it's a strategic investment in your kitchen's success. It directly addresses the core challenges of a commercial kitchen: improving speed, ensuring safety, and generating savings. By centralizing prep work, you eliminate wasted steps, allowing your staff to serve customers faster and more efficiently.

We've covered the options, from compact sandwich tables to robust pizza prep stations, and specialized configurations like mega tops and drawers that maximize ingredient access. Key features like eco-friendly R290 refrigerant, digital temperature controls, and durable stainless steel construction are not just add-ons; they are the foundation of a reliable, long-lasting unit that saves you money on energy bills.

This investment is about creating an optimized workspace where your team can excel. When food safety is simplified and efficiency drives profitability, your business thrives. The simple maintenance routines we've outlined will protect this investment, ensuring it performs reliably for years.

As you consider your options, assess your kitchen's space, menu complexity, and customer volume. This will guide you to the perfect unit that feels like a natural extension of your workflow.

Ready to find your perfect match? Our comprehensive Sandwich Prep Table Guide offers detailed insights to help you make a decision that will benefit your kitchen for years to come.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment