The Ins and Outs of Sandwich Prep Tables: Buyer's Guide

Why Sandwich Prep Tables Are Essential for Commercial Food Service

A Sandwich Prep Table is a refrigerated workstation that combines ingredient storage, a prep surface, and cold holding into a single, efficient unit. These commercial kitchen essentials keep toppings at food-safe temperatures (33-40°F) while providing easy access during service, streamlining the creation of subs, salads, and wraps.

Key Components:

- Refrigerated top rail: Holds 1/6 size food pans with ingredients.

- Cutting board surface: An integrated workspace for assembly.

- Cold storage base: A cabinet or drawers for backup ingredients.

- Temperature control: Maintains consistent refrigeration.

Common Sizes Available:

- 27" - holds 8 pans (small operations)

- 36" - holds 8-12 pans (cafes, delis)

- 48" - holds 12-18 pans (restaurants)

- 60" - holds 16-24 pans (high-volume kitchens)

- 72" - holds 18-30 pans (large operations)

For any food service operation, these tables offer immediate value through faster service, reduced labor costs, and improved food safety. They eliminate the inefficient movement between separate refrigerators and prep areas, which is critical for boosting ticket times during busy periods. Understanding which size, configuration, and refrigeration capacity best fits your needs is the key to open uping maximum efficiency.

Why a Dedicated Prep Table is a Game-Changer for Your Kitchen

Imagine your lunch rush. Without a dedicated Sandwich Prep Table, staff run between coolers and counters, a chaotic process that slows down service. Now, picture a streamlined command center where every ingredient is chilled and within arm's reach. The difference is transformative.

A prep table establishes a streamlined workflow, allowing staff to focus on creating food quickly and consistently. This increased speed comes from smarter, more organized movements. When every ingredient has a designated spot, consistency becomes second nature, ensuring every sandwich or salad meets customer expectations. This systematic approach also helps reduce food waste, as visible and accessible ingredients are used more efficiently.

Perhaps most importantly, improved food safety is a built-in benefit. Keeping ingredients at consistent, cool temperatures in the refrigerated rail minimizes the risk of bacterial growth. A dedicated assembly space also helps prevent cross-contamination. Finally, effortless ingredient organization means less time searching and more time serving. For more tips on optimizing your kitchen, explore our guide on restaurant prep tables and our Prep Table Kitchen Guide.

Boosting Kitchen Efficiency and Output

The culinary concept of "mise en place" (everything in its place) is the philosophy behind a Sandwich Prep Table. It creates a dedicated assembly line where every movement is purposeful. During peak hours, this efficiency is a lifeline. The reduced prep time per item adds up, leading to significantly faster ticket times and happier customers. When your team can assemble orders without breaking their rhythm, they can handle high volume and custom requests with ease.

Ensuring Food Freshness and Safety

Protecting your customers and your reputation starts with food safety. A quality Sandwich Prep Table maintains consistent temperatures between 33°F and 40°F, the ideal range for perishable ingredients. Many units are built to NSF 7 standards, which specify that food can be held in the top rail for up to four hours during service. You can learn more about what NSF Certification means for your equipment.

The design inherently supports cross-contamination prevention. The integrated cutting board provides a clean, designated workspace that is separate from other prep areas. Modern cold-holding technology uses advanced airflow to keep a protective blanket of cold air over the food pans, ensuring every ingredient stays fresh and safe. For more details on selecting the right unit, see our Sandwich Prep Table Guide.

Key Features to Consider in a Sandwich Prep Table

Choosing the right Sandwich Prep Table requires understanding how different features impact your daily operations. It's not just about size; it's about matching the unit's capabilities to your kitchen's workflow. Key factors include pan capacity, cutting board depth, the type of refrigeration system, and construction materials.

Pan capacity dictates how many ingredients you can have ready, ranging from 8 pans in smaller units to over 30 in larger ones. The cutting board depth affects workspace efficiency, while the refrigeration system's power determines how well it maintains temperature during a rush. Finally, durable construction materials like stainless steel ensure your investment lasts. For more on materials, our Stainless Steel Prep Table Guide offers valuable insights.

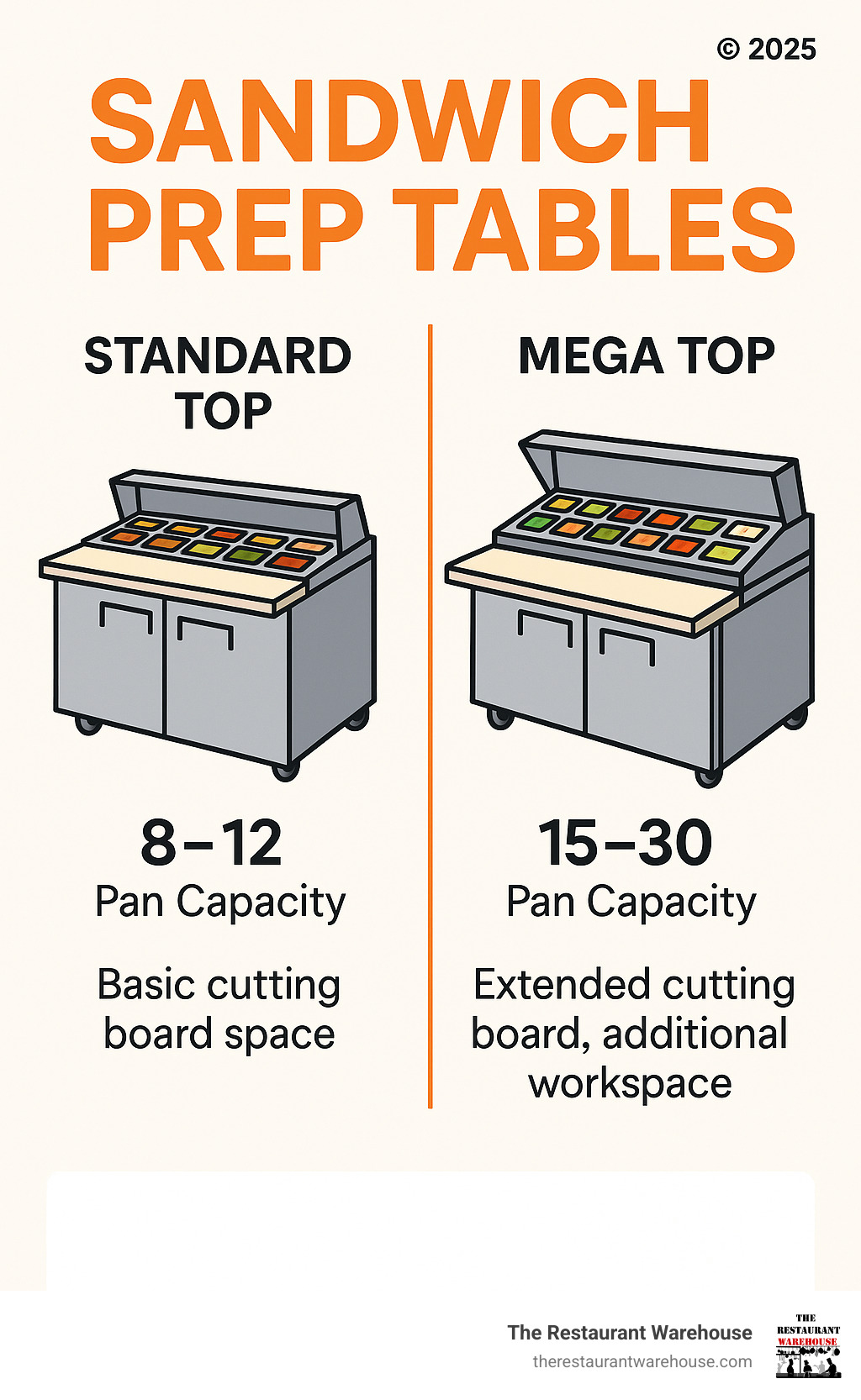

Configuration: Standard Top, Mega Top, and Cutting Surfaces

The top configuration of your Sandwich Prep Table is a critical choice.

- A Standard Top offers a single row of ingredient pans (typically 8 to 12) and a standard-depth cutting board. This is ideal for cafes and delis with focused menus.

- A Mega Top is built for high-volume operations. It features two rows of 1/6 size pans (holding 15 to 30 ingredients) and an extra deep cutting board (15 inches or more). This expanded workspace allows staff to prepare multiple orders simultaneously, which is invaluable during peak hours.

Most units use standard 1/6 size pans, but some can be adapted for other sizes. Quality cutting boards are removable for easy cleaning and made from high-density polyethylene. For a closer look at high-capacity models, see our guide on Slice Dice and Delight Top 48 Inch Mega Top Sandwich Prep Tables.

Access and Storage: Doors vs. Drawers

The storage base configuration significantly impacts workflow.

- Doors are the traditional option, opening to adjustable shelves. This provides flexible storage for bulk items, large containers, and backup pans. They are versatile and cost-effective.

- Drawers offer superior ergonomics and organization. Staff can access backup ingredients without bending or digging through shelves. Each drawer typically holds specific pan sizes, keeping everything neatly arranged and accessible. While they cost more upfront, drawers can dramatically speed up service in high-volume kitchens.

Choosing the Right Size and Capacity for Your Sandwich Prep Table

Selecting the right size depends on your kitchen layout, menu complexity, and sales volume. Measure your space carefully, and consider how many ingredients you need on the line during your busiest periods.

Common Widths:

- 27-inch: Perfect for tight spaces like food trucks. Holds ~8 pans.

- 36-inch: A popular choice for delis and small restaurants, balancing size and capacity. Holds 8-12 pans. Learn more in our 36 Inch Sandwich Prep Table guide.

- 48-inch: Ideal for medium-volume restaurants, with room for 12-18 pans and significant storage. See details in our guide to 48 Inch Sandwich Prep Refrigerators.

- 60-inch: Built for busy operations, accommodating 16-24 pans and multiple staff.

- 72-inch: The largest option for high-volume kitchens, holding up to 30 pans. Our 72 Inch Sandwich Prep Table guide covers these heavy-duty units.

Consider future growth when choosing a size; it's often wise to invest in slightly more capacity than you currently need.

Refrigeration, Airflow, and Energy Use

The refrigeration system is the heart of your prep table. Quality units use forced-air refrigeration to circulate chilled air evenly, maintaining a consistent temperature range of 33°F to 40°F. This ensures all ingredients, from the top rail to the storage base, remain safe and fresh.

Modern units increasingly use R290 refrigerant, a natural propane that is an environmentally friendly and highly energy-efficient option. With a very low Global Warming Potential (GWP), it has become the industry standard for sustainable refrigeration. Look for features that boost energy efficiency, such as high-density, foamed-in-place polyurethane insulation that improves temperature retention and structural rigidity. Self-closing doors with magnetic gaskets are also crucial, as they prevent cold air from escaping. These features reduce operating costs and extend the life of the compressor. For more on brands with reliable technology, see our article on Atosa Sandwich Prep Tables.

Essential Maintenance for Longevity and Performance

Proper maintenance is an investment in your Sandwich Prep Table's longevity and reliability. A well-cared-for unit maintains consistent temperatures, runs efficiently, and prevents costly emergency repairs. Simple daily, weekly, and monthly routines are all it takes to keep your equipment in peak condition.

Building these habits prevents the issues that lead to downtime. For a detailed breakdown of these procedures, consult our Sandwich Prep Table Maintenance guide.

Daily and Weekly Cleaning Checklist

Incorporate these tasks into your kitchen's routine for consistent performance.

Daily Cleaning Tasks:

- Wipe all surfaces: Use a food-safe sanitizer on the cutting board, exterior, and interior.

- Clean food pans and rail: Remove, wash, and sanitize all food pans. Wipe down the pan rail itself.

- Scrub the cutting board: Clean the primary work surface thoroughly.

- Rotate ingredients: Check freshness and follow the "first in, first out" (FIFO) principle.

Weekly Cleaning Tasks:

- Clean gaskets: Wipe door and drawer gaskets with mild soap and water to maintain a tight seal.

- Clear drainage systems: Ensure drain lines are clear to prevent water pooling.

- Deep clean the interior: Remove all items and wipe down interior walls and shelves.

- Check temperature settings: Verify the unit is operating within the correct range.

Key Maintenance Best Practices for Your Sandwich Prep Table

Beyond cleaning, these practices are critical for long-term performance.

- Condenser Coil Cleaning: The coils act as the system's lungs. When clogged with dust and grease, the unit works harder and consumes more energy. Clean them monthly or quarterly with a stiff brush or vacuum.

- Ensure Proper Airflow: Do not push the unit flush against a wall unless it is a front-breathing model. Keep vents clear of obstructions to allow the system to cool itself effectively.

- Gasket Seal Maintenance: Regularly inspect gaskets for tears or hardening. A poor seal wastes energy. Replace damaged gaskets promptly.

- Temperature Monitoring: Use an independent thermometer to verify the unit's internal temperature matches the display. Discrepancies can signal a developing problem.

- Schedule Professional Servicing: Have a qualified technician inspect your unit once or twice a year to catch potential issues before they cause a breakdown.

Understanding Costs and Finding the Best Value

Prices for a Sandwich Prep Table can range from around $1,500 for a basic model to over $7,000 for a large, feature-rich unit. Understanding what drives these costs helps you make a smart investment. The goal is to find a reliable unit that meets your needs without overspending.

For example, a 36-inch model might start around $1,799, while a 60-inch unit with drawers could be closer to $4,101. The key is to match your investment to your operational needs rather than simply choosing the cheapest option, which can lead to higher costs from repairs and lost revenue down the line.

What Factors Influence the Price?

Several key factors determine the final cost of a Sandwich Prep Table:

- Size and Capacity: Larger units with more pan and storage capacity cost more due to increased materials and larger refrigeration components.

- Features and Configuration: A mega top configuration or drawer storage will increase the price compared to a standard top with doors.

- Materials and Construction: Higher-grade materials like 304 stainless steel and quality components like Embraco compressors cost more but offer greater durability.

- Warranty Coverage: A longer, more comprehensive warranty (e.g., 2-year parts and labor, 5-year compressor) adds to the initial cost but provides valuable protection.

- Energy Efficiency: Units with R290 refrigerant and better insulation may have a higher sticker price but lead to significant savings on utility bills over time.

How to Get the Best Return on Your Investment

True value comes from balancing upfront cost with long-term performance.

- Prioritize Durability: A well-built unit that lasts for years is a better investment than a cheaper model that requires frequent replacement.

- Calculate Energy Savings: An energy-efficient model can save hundreds of dollars annually on electricity, quickly paying back the initial price difference.

- Match Features to Your Workflow: Don't pay for features you don't need. A busy shop will benefit from a mega top and drawers, while a small deli may not.

- Seek Wholesale Pricing: At The Restaurant Warehouse, we eliminate retail overhead and commissioned salespeople to offer professional-grade equipment at lower prices. Our Atosa 48 Sandwich Prep Review highlights the kind of value we provide.

Focusing on the total cost of ownership (TCO) is the smartest approach. This calculation goes beyond the sticker price to include the initial purchase, projected energy consumption over several years, anticipated maintenance costs, and the potential cost of lost business due to equipment failure. A slightly more expensive unit with a better warranty, superior energy efficiency, and robust construction will almost always have a lower TCO, making it the more profitable asset for your kitchen in the long run.

Frequently Asked Questions about Sandwich Prep Tables

When investing in new equipment, it's natural to have questions. Here are answers to some of the most common queries we receive from restaurant owners and kitchen managers.

What is the difference between a sandwich prep table and a pizza prep table?

While they look similar, these units are designed for different workflows. The key differences are:

- Cutting Board Depth: A Sandwich Prep Table has a narrower cutting board (10-15 inches deep) for assembling sandwiches and salads. A pizza prep table has a much deeper board (20+ inches) to accommodate large pizza doughs.

- Pan Configuration: Sandwich prep tables use smaller 1/6 size pans, ideal for holding a wide variety of toppings. Pizza prep tables use larger 1/3 size pans for bulk ingredients like cheese and sauce.

- Raised Rail Design: Pizza prep tables often have a higher raised rail to make it easier to scoop and spread toppings over a flat crust.

Choosing the right type of table is crucial for efficiency. For more on pizza-specific units, see our information on More on Pizza Prep Tables.

How long can ingredients be safely held in the top rail?

According to NSF standards, perishable ingredients can be safely held for up to four hours as long as the Sandwich Prep Table maintains a consistent temperature between 33°F and 40°F.

To ensure safety and freshness during this period, follow these best practices:

- Use the lid: Keep the lid closed as much as possible to maintain a blanket of cold air over the pans.

- Pre-chill ingredients: Never place warm or room-temperature items directly into the rail.

- Monitor kitchen temperature: Extremely hot ambient temperatures can strain the refrigeration system.

- Rotate stock: Use the "first-in, first-out" method to ensure ingredients are always fresh.

Any food held above 40°F or for longer than four hours must be discarded to prevent the risk of foodborne illness.

Can I use different size or deeper pans in my unit?

This depends on your specific model. Most quality Sandwich Prep Table units are designed to accommodate 6-inch deep pans, which allows for greater ingredient capacity and fewer refills during service.

Flexibility with different pan sizes (like 1/9 or 1/3 pans) can often be achieved using adapter bars, which fit across the rail openings. Always check your manufacturer's specifications to see what your unit supports.

However, it is critical not to use pans deeper than what the manufacturer specifies. Doing so can obstruct the engineered airflow circulation that keeps all ingredients at a safe, consistent temperature. Blocking this airflow can create warm spots, compromising food safety. Always prioritize proper airflow and temperature control by working within your unit's design specifications.

Conclusion

Choosing the right Sandwich Prep Table is a strategic investment in your kitchen's efficiency, safety, and profitability. By streamlining your workflow, you empower your staff to work faster, produce more consistent results, and improve service times, which directly impacts customer satisfaction and your bottom line.

We've covered the importance of food safety and freshness, achieved through precise temperature control (33-40°F) and proper cold-holding. We've also explored key features like mega top vs. standard top configurations and doors vs. drawers, helping you match the equipment to your specific volume and workflow. Understanding modern refrigeration technology and the importance of routine maintenance will ensure your investment provides years of reliable service.

When considering cost and value, remember to look beyond the initial price. The total cost of ownership—factoring in durability, energy savings, and reduced food waste—is a much better measure of a unit's true worth. A well-chosen Sandwich Prep Table will pay for itself many times over.

At The Restaurant Warehouse, we provide wholesale pricing on quality equipment, helping you get the best return on your investment. Your kitchen is the heart of your business, and the right equipment is essential for its success.

For a comprehensive selection of affordable and reliable prep tables that meet the highest standards of quality and efficiency, explore our Sandwich Prep Table collection. We are here to help you find the perfect solution for your needs and budget.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment