Sandwich Station Superstars: The Ultimate Mega Top Prep Table Roundup

Revolutionize Your Prep Line with the Right Equipment

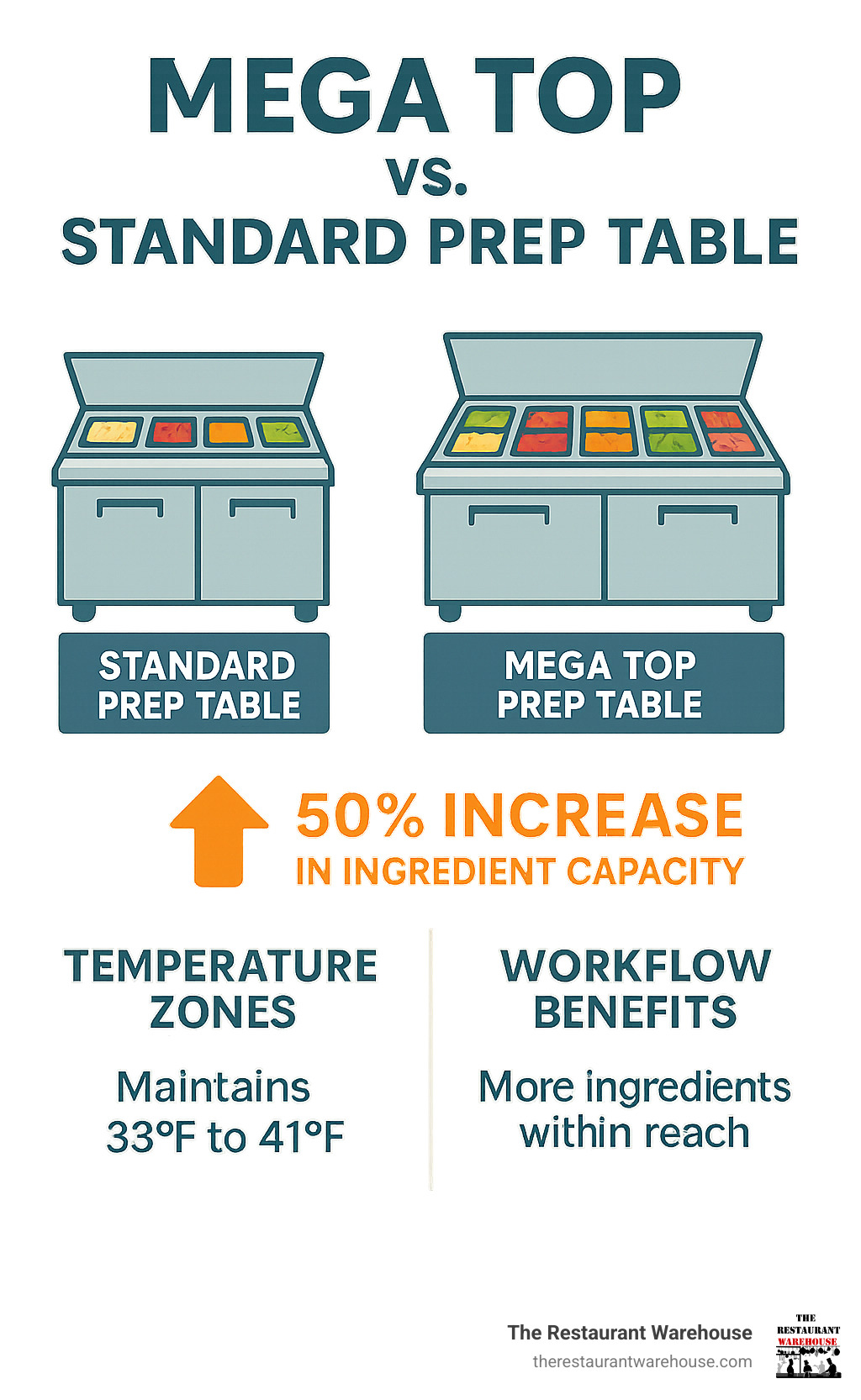

A mega top sandwich prep table is a refrigerated food preparation station that features an extended top section with three rows of ingredient pans instead of the standard two rows found on regular prep tables. This design provides significantly more ingredient storage capacity while maintaining optimal temperatures between 33°F to 41°F for food safety.

Key Features of Mega Top Sandwich Prep Tables:

- Extra Pan Capacity: Accommodates 50% more ingredient pans than standard prep tables

- Refrigerated Storage: Bottom compartment with doors or drawers for backup ingredients

- Integrated Cutting Board: Built-in prep surface with polyethylene material

- Stainless Steel Construction: Durable, easy-to-clean surfaces that resist corrosion

- Temperature Control: Maintains food-safe temperatures with forced-air cooling systems

- Multiple Sizes Available: From compact 27-inch units to large 72-inch+ models

These commercial-grade units are essential equipment for delis, cafes, quick-service restaurants, and any commercial kitchen where sandwiches, wraps, or salads are prepared regularly. The mega top design allows staff to access a wider variety of ingredients without leaving their station, dramatically improving workflow efficiency.

The increased ingredient accessibility means fewer trips to walk-in coolers, faster order fulfillment, and better organization during peak service hours. Most mega top prep tables include insulated lids to minimize condensation, heavy-duty casters for mobility, and adjustable shelving in the base compartment.

For budget-conscious restaurant owners, these units represent a smart investment that combines workspace and refrigerated storage into one efficient piece of equipment, eliminating the need for separate prep surfaces and ingredient storage solutions.

What Makes a Prep Table 'Mega'? Unpacking the Design and Benefits

The defining feature of a mega top sandwich prep table is its brilliant third row of pans. While standard prep tables offer two rows of ingredient wells, the mega top extends the refrigerated pan rail to provide extra pan capacity – essentially 50% more ingredient storage at your fingertips.

This core design difference creates a cascade of operational benefits. During peak service, that extra row becomes invaluable. Your staff can access everything they need without stepping away from their station, maintaining workflow optimization through reduced staff movement.

Improved ingredient accessibility means no more mid-rush trips to the walk-in cooler. Picture your busiest lunch hour – with a mega top, you've got backup ingredients right there in that third row, keeping service smooth and customers happy.

Maintaining food safety standards is paramount, and mega top tables excel here. Most units feature insulated lids that serve dual purposes: maintaining safe temperatures and achieving condensation reduction. Less condensation means fresher ingredients and better compliance with health regulations.

The integrated cutting boards made from durable polyethylene material are engineered for commercial abuse. This material resists knife cuts that could harbor bacteria, cleans easily, and won't absorb odors – allowing ingredients to go from cold storage to prepped in one smooth motion.

Modern usability features show manufacturers understand kitchen needs. Heavy-duty casters enable easy movement for cleaning or reorganization. Adjustable shelves in the base compartment accommodate various container sizes. Self-closing doors maintain consistent temperatures while saving energy – protecting both food quality and utility costs.

For comprehensive workspace optimization tips, check our Kitchen Prep Table Guide.

The Roundup: Finding Your Perfect Mega Top Sandwich Prep Table Size

Choosing the right mega top sandwich prep table size requires understanding your kitchen's workflow, volume, and available space. The key is matching unit capacity to your daily needs while considering future growth.

Compact Powerhouses: 27-inch and 36-inch Models

These compact models deliver professional performance in tight spaces, perfect for small cafes, food trucks, and low-volume stations.

A 27-inch model typically handles 9 to 12 pans – enough for most sandwich operations with meats, cheeses, vegetables, and spreads within reach. These units offer single and double door configurations for flexible base storage.

The 36-inch models increase capacity to 15 to 18 pans, providing extra variety without overwhelming your kitchen. Both sizes deliver mega top benefits in space-conscious environments.

For detailed comparisons: Best 27-Inch Prep Tables, 36-Inch Sandwich Prep Table, and Atosa 27-Inch Sandwich Prep Table.

The All-Rounders: 48-inch and 60-inch Models

These mid-sized units are workhorses for busy delis and high-volume sandwich shops, offering the perfect balance of capacity and practicality.

A 48-inch mega top accommodates 18 to 24 pans, enabling serious menu variety with dedicated sections for proteins, cheeses, and vegetables. The 60-inch models handle 24 to 30 pans for even greater flexibility.

Both sizes feature two-door configurations providing ample refrigerated storage for backup ingredients and bulk supplies. These versatile kitchens benefit from steady volume handling without requiring maximum space.

Explore: 48-Inch Sandwich Prep Refrigerators and Atosa 48-Inch Sandwich Prep Review.

The Heavy-Hitters: 72-inch+ Models

Built for large commercial kitchens, cafeterias, and high-capacity operations, these units serve hundreds daily without breaking stride.

With 30 or more pans offering maximum ingredient variety, these powerhouses feature three-door configurations for extensive backup storage. You can handle complex custom orders quickly while maintaining consistent quality during peak periods.

Details: 72-Inch Sandwich Prep Table.

Built to Last: Construction, Cooling, and Certifications

When you're shopping for a mega top sandwich prep table, you're not just buying a piece of equipment – you're making an investment in your kitchen's future. The difference between a table that serves you well for years and one that becomes a costly headache often comes down to three crucial factors: construction quality, cooling system reliability, and proper certifications. Think of these as the foundation of your food prep operation, supporting everything from daily efficiency to long-term profitability.

Quality construction isn't just about looking professional (though that matters too). It's about choosing equipment that can handle the daily grind of a busy commercial kitchen while maintaining the hygiene standards your customers deserve. The best prep tables combine robust materials with smart engineering, creating units that work as hard as you do, day after day.

The Importance of Stainless Steel Construction

Walk into any professional kitchen, and you'll notice one thing immediately: stainless steel everywhere. There's a good reason for this overwhelming preference, and it goes far beyond just looking sleek and professional. When it comes to your mega top sandwich prep table, stainless steel construction is absolutely essential for several compelling reasons.

Durability is perhaps the most obvious benefit. Commercial kitchens are tough environments – equipment gets bumped by busy staff, hit with heavy pots, and subjected to constant temperature changes. Stainless steel shrugs off this abuse like a champion boxer, maintaining its structural integrity and appearance even after years of hard use. Unlike other materials that might dent, crack, or show wear, quality stainless steel keeps looking and performing like new.

The corrosion resistance of stainless steel is equally impressive. In a kitchen environment filled with moisture, acidic ingredients, and harsh cleaning chemicals, many materials would quickly deteriorate. Stainless steel, however, maintains its integrity regardless of what you throw at it – literally. Spill lemon juice, splash vinegar, or use strong sanitizers, and your prep table will emerge unscathed.

But here's where stainless steel really shines: ease of cleaning. The smooth, non-porous surface doesn't give bacteria anywhere to hide, making sanitization quick and thorough. A simple wipe-down with the right cleaner eliminates germs and food particles, helping you maintain the food safety compliance that keeps your customers healthy and your business running. This isn't just convenient – it's essential for passing health inspections and maintaining your reputation.

Most commercial prep tables use specific steel grades chosen for their balance of performance and cost-effectiveness. These grades provide the perfect combination of strength, corrosion resistance, and workability that commercial kitchens demand. For a deeper dive into how stainless steel can transform your prep area, check out our comprehensive Stainless Steel Prep Table Guide.

Understanding the Refrigeration System in a mega top sandwich prep table

The refrigeration system in your mega top sandwich prep table is like the engine in your car – you might not think about it much, but everything depends on it working perfectly. Modern prep tables use sophisticated energy-efficient cooling systems that do much more than just keep things cold; they maintain precise temperatures while minimizing your utility costs.

Most quality units feature forced-air systems that circulate chilled air throughout both the ingredient wells and the base storage compartment. This constant air movement ensures even temperatures across all your ingredients, preventing hot spots that could compromise food safety. No more worrying about the ingredients at one end of your table getting warmer than the others – the forced-air system keeps everything consistently chilled.

One of the most exciting developments in commercial refrigeration is the widespread adoption of eco-friendly R290 refrigerant. This natural hydrocarbon refrigerant represents a major step forward for both performance and environmental responsibility. R290 systems are incredibly efficient, often outperforming older synthetic refrigerants while dramatically reducing environmental impact. When you choose a unit with R290, you're not just getting superior cooling – you're making a statement about your commitment to sustainability.

The efficiency gains translate directly into lower utility bills. These modern cooling systems use less energy while maintaining better temperature control, which means more money stays in your pocket every month. Over the life of your prep table, these savings can be substantial, making the initial investment even more worthwhile.

Temperature control is critical for food safety, and quality prep tables maintain the optimal temperature range of 33°F to 41°F. This range is scientifically proven to inhibit bacterial growth while preserving ingredient quality and freshness. Your prep table's refrigeration system works around the clock to maintain these temperatures, giving you peace of mind and ensuring compliance with food safety regulations.

For a detailed look at the technical specifications that define a high-performing refrigeration system, you can download an example spec sheet that shows exactly what to look for in a quality unit.

Why Certifications Matter: ETL and NSF

In commercial kitchen equipment, certifications aren't just fancy badges – they're your guarantee that the equipment meets rigorous safety and sanitation standards. For your mega top sandwich prep table, two certifications stand above the rest: ETL and NSF. These aren't just nice-to-have features; they're often required by health departments and insurance companies.

The ETL Listed mark is your assurance that the equipment meets strict electrical safety standards. This third-party testing and certification process verifies that your prep table won't pose electrical hazards to your staff or property. In a busy kitchen where water and electricity coexist, this safety certification isn't just important – it's essential for protecting everyone who works in your establishment.

Equally critical is the ETL Sanitation mark, which works hand-in-hand with NSF standards. These certifications confirm that your prep table meets stringent public health and sanitation requirements. This means the design promotes easy cleaning, prevents food accumulation in hard-to-reach areas, and uses only food-safe materials throughout construction.

When health inspectors visit your establishment, certified equipment makes their job – and yours – much easier. Equipment bearing these certifications demonstrates your commitment to food safety compliance, often helping you sail through health code inspections without issues. Many restaurant owners have found that certified equipment actually helps build trust with inspectors, who recognize the rigorous standards these certifications represent.

Quality manufacturers understand the importance of these certifications and build them into their design process from the ground up. Our guide to Atosa Sandwich Prep Tables highlights how reputable brands prioritize these certifications, understanding that they're essential for legitimate commercial operation.

When you invest in a properly certified mega top sandwich prep table, you're not just buying equipment – you're buying peace of mind, knowing that your investment meets the highest industry standards for safety, sanitation, and performance.

Your Ultimate Buying Checklist

Alright, you've learned all about what makes a mega top sandwich prep table so amazing—from its clever design to its robust construction. Now comes the exciting part: choosing the perfect one for your business. Use this comprehensive checklist to match a unit to your space, volume, and budget, ensuring you make a confident and informed decision.

| Feature | Considerations |

|---|---|

| Size (Width) | 27 in to 72 in+; confirm overall footprint, clearance, and that it fits through doors/elevators. |

| Pan Capacity | Total 1/6-pan count on the rail; plan for current needs plus ~20% growth to avoid future bottlenecks. |

| Base Storage | Doors offer flexible space for bulk items; drawers provide fast, organized access to frequently used ingredients. |

| Compressor Location | Rear-breathing needs back clearance for airflow; front-breathing allows for flush, tight installations against walls. |

| Power Requirements | Verify voltage/amps and ensure a dedicated circuit is available. Check plug type (e.g., NEMA 5-15P) and cord length. |

| Mobility | Heavy-duty locking casters are essential for cleaning and layout changes; verify overall unit height with casters installed. |

| Lids & Cutting Board | Insulated lids reduce condensation and save energy. Confirm the removable polyethylene board's length and depth. |

| Materials | Check interior/exterior stainless steel grades for durability, rust resistance, and ease of cleaning. |

| Controls & Monitoring | Look for a digital thermostat with a visible temperature display. High-temp or door-ajar alerts are valuable features. |

| Warranty & Service | Review parts/labor terms (typically 1-3 years), compressor warranty (often 5+ years), and onsite service coverage. |

Choosing the Right Configuration

Making the right choice goes beyond the spec sheet. It requires a practical assessment of your unique operational needs.

Start with a precise space assessment: measure your available footprint, but don't forget to check the width of doorways, hallways, and any elevators the unit must pass through for delivery. Account for necessary clearance, especially for rear-breathing compressors that need several inches of space behind them for proper ventilation.

Next, audit your menu honestly. If you offer complex, build-your-own sandwiches and salads with dozens of potential toppings, prioritizing a higher pan count is critical. If your menu is more focused, you might opt for a smaller rail and maximize the refrigerated base storage for backup supplies.

The doors vs. drawers debate is a classic trade-off between capacity and accessibility. Doors are king for maximizing bulk storage, easily accommodating large food pans, and odd-shaped containers. Drawers, on the other hand, excel at speed and organization. They keep frequently used items perfectly organized and at an ergonomic height, reducing bending and speeding up service. Some models offer a combination of both, giving you the best of both worlds. For a deeper planning walkthrough, see Choosing the Right Sandwich Prep Table for Your Restaurant.

Warranty and Maintenance Considerations

A good warranty is your safety net. Expect a clear breakdown of coverage for parts and labor (often 1–3 years) and a separate, longer warranty for the compressor (typically 5 years or more), as it's the heart of the unit. Before buying, confirm if the warranty includes onsite service in your area and understand any maintenance obligations required to keep the coverage valid.

Proactive maintenance is the key to longevity and efficiency. Basic upkeep protects your investment, ensures food safety, and keeps energy costs down.

- Condenser Coils: Keep them clean and free of dust and grease to ensure efficient heat exchange.

- Gaskets: Inspect door and lid gaskets regularly for cracks or tears and replace them as needed to maintain a proper seal.

- Daily Cleaning: Sanitize the cutting board, ingredient pans, and all rail surfaces daily with food-safe products.

If minimizing upkeep is a priority, consider models that offer advanced features like self-cleaning condensers. For detailed best practices on keeping your unit in peak condition, visit our Sandwich Prep Table Maintenance guide.

Conclusion: Upgrade Your Kitchen with the Perfect Sandwich Station

After diving deep into mega top sandwich prep tables, it's clear these units aren't just another piece of kitchen equipment—they're genuine game-changers for any food service operation. Think of them as the Swiss Army knife of commercial kitchens: versatile, reliable, and designed to make your life significantly easier.

The benefits we've explored throughout this guide paint a compelling picture. Increased efficiency comes naturally when your staff can access 50% more ingredients without taking a single step away from their station. No more frantic dashes to the walk-in cooler during the lunch rush, no more frustrated customers waiting while someone hunts down the last of the turkey. Everything they need is right there, chilled to perfection and ready to go.

Better organization transforms chaotic prep lines into smooth-running operations. With dedicated spots for every ingredient and ample refrigerated storage below, your kitchen becomes a model of efficiency. Your team knows exactly where everything belongs, making both prep and cleanup faster and more systematic.

Most importantly, improved food safety gives you peace of mind that's priceless in the food service industry. When ingredients stay consistently between 33°F and 41°F, and when surfaces are easy to clean and sanitize, you're not just meeting health department standards—you're exceeding them. Your customers can taste the difference that comes from properly stored, fresh ingredients.

The key selection criteria we've covered—from choosing the right size for your volume to understanding the importance of stainless steel construction and proper certifications—aren't just technical details. They're the foundation of a smart investment that will serve your business for years to come. Whether you need a compact 27-inch powerhouse for your food truck or a massive 72-inch command center for your busy deli, there's a perfect match waiting for your specific needs.

Here at The Restaurant Warehouse, we understand that every dollar counts in the food service industry. That's why we've built our business around a simple principle: cut out the middleman and pass those savings directly to you. We skip the high commissions and retail markups that drive up prices elsewhere, offering you affordable wholesale pricing on the equipment you need to succeed.

We're not just selling equipment—we're partnering with fellow food service professionals who understand that the right tools can make or break a business. When you choose a mega top sandwich prep table from our collection, you're getting more than just a refrigerated workspace. You're investing in faster service, happier customers, and a more profitable operation.

Ready to transform your sandwich station from a bottleneck into a powerhouse? Your perfect mega top sandwich prep table is waiting, and with our wholesale pricing, it's more affordable than you might think.

Explore our Sandwich Prep Table collection today and find how the right equipment can revolutionize your kitchen's efficiency and your bottom line.

The Roundup: Finding Your Perfect Mega Top Sandwich Prep Table Size

Selecting the right size comes down to space, menu variety, and volume. Use these quick pointers to match capacity to your workflow.

Compact Powerhouses: 27-inch and 36-inch Models

- Ideal for small cafes, food trucks, and low-volume stations.

- 27-inch: typically 9–12 1/6-size pans; single-door base for essentials.

- 36-inch: typically 15–18 1/6-size pans; often two-door base for better backup.

- Learn more: Best 27-Inch Prep Tables, 36-Inch Sandwich Prep Table, and Atosa 27-Inch Sandwich Prep Table.

The All-Rounders: 48-inch and 60-inch Models

- Great for busy delis and high-volume sandwich shops with varied menus.

- 48-inch: typically 18–24 1/6-size pans; reliable two-door base for ample storage.

- 60-inch: typically 24–30 1/6-size pans; supports steady peak service with fewer restocks.

- Explore: 48-Inch Sandwich Prep Refrigerators and the Atosa 48-Inch Sandwich Prep Review.

The Heavy-Hitters: 72-inch+ Models

- Best for large commercial kitchens, cafeterias, and high-capacity lines.

- Often 30+ 1/6-size pans on top and three-door bases for deep backup storage.

- Enables extensive ingredient variety and rapid custom builds during rushes.

- Details: 72-Inch Sandwich Prep Table.

Built to Last: Construction, Cooling, and Certifications

Longevity and food safety hinge on smart materials, efficient cooling, and verified compliance. Here’s the short list to keep you on track.

The Importance of Stainless Steel Construction

Stainless interiors/exteriors deliver durability, corrosion resistance, and fast sanitizing with smooth, non-porous surfaces. Common commercial grades balance cost and performance, keeping your station hygienic and inspection-ready. For a deeper dive, see our Stainless Steel Prep Table Guide.

Understanding the Refrigeration System in a mega top sandwich prep table

Look for forced-air systems that maintain 33°F to 41°F evenly across the rail and base. Eco-friendly R290 refrigerant provides strong performance with lower environmental impact and energy costs. Many units add auto defrost and high-density insulation for stability. Review a typical spec here: Download an example spec sheet.

Why Certifications Matter: ETL and NSF

ETL Listed confirms electrical safety; ETL Sanitation/NSF compliance validates cleanability and food contact safety—often required by health departments and insurers. Reputable lines, like those in our Atosa Sandwich Prep Tables guide, build certifications into the design so you can pass inspections with confidence.

Your Ultimate Buying Checklist

Choosing the perfect mega top sandwich prep table is easier when you compare the fundamentals side by side.

| Feature | Considerations |

|---|---|

| Size (Width) | From space-saving 27-inch units to expansive 72-inch+ powerhouses |

| Pan Capacity | Number of 1/6-size pans the top rail accommodates – directly impacts ingredient variety |

| Base Storage | Doors vs. drawers configuration affects accessibility and organization |

| Compressor Location | Rear-breathing vs. front-breathing impacts placement flexibility |

| Warranty | Coverage terms for parts, labor, and compressor protection |

Choosing the Right Configuration for Your mega top sandwich prep table

Start with a precise space assessment: measure footprint, doorways, aisle clearance, and any required rear or side ventilation. Then audit your menu honestly. If you offer build-your-own items with lots of toppings, prioritize higher pan counts; if your menu is focused, choose compact rails and maximize base storage.

Doors vs. drawers is about trade-offs. Doors maximize bulk storage and fit large or odd-shaped containers. Drawers excel at speed and organization, keeping frequently used items at ergonomic heights. Finally, match compressor placement to your layout: rear-breathing units need space behind them for airflow, while front-breathing models push flush against walls or adjacent equipment—ideal in tight lines. For a deeper planning walkthrough, see Choosing the Right Sandwich Prep Table for Your Restaurant.

Warranty and Maintenance Considerations

Expect a clear breakdown of parts and labor (often 1–3 years) and a longer compressor warranty (typically 3–5 years). Confirm onsite service coverage and any maintenance obligations that keep coverage valid.

Basic upkeep protects performance and energy costs: keep condenser coils clean, inspect and replace door gaskets as needed, and sanitize cutting boards, pans, and rail surfaces daily with food-safe products. If minimizing upkeep matters, consider models with self-cleaning condenser features. For detailed best practices, visit our Sandwich Prep Table Maintenance guide.

Conclusion: Upgrade Your Kitchen with the Perfect Sandwich Station

After diving deep into mega top sandwich prep tables, it's clear these units aren't just another piece of kitchen equipment—they're genuine game-changers for any food service operation. Think of them as the Swiss Army knife of commercial kitchens: versatile, reliable, and designed to make your life significantly easier.

The benefits we've explored throughout this guide paint a compelling picture. Increased efficiency comes naturally when your staff can access 50% more ingredients without taking a single step away from their station. No more frantic dashes to the walk-in cooler during the lunch rush, no more frustrated customers waiting while someone hunts down the last of the turkey. Everything they need is right there, chilled to perfection and ready to go.

Better organization transforms chaotic prep lines into smooth-running operations. With dedicated spots for every ingredient and ample refrigerated storage below, your kitchen becomes a model of efficiency. Your team knows exactly where everything belongs, making both prep and cleanup faster and more systematic.

Most importantly, improved food safety gives you peace of mind that's priceless in the food service industry. When ingredients stay consistently between 33°F and 41°F, and when surfaces are easy to clean and sanitize, you're not just meeting health department standards—you're exceeding them. Your customers can taste the difference that comes from properly stored, fresh ingredients.

The key selection criteria we've covered—from choosing the right size for your volume to understanding the importance of stainless steel construction and proper certifications—aren't just technical details. They're the foundation of a smart investment that will serve your business for years to come. Whether you need a compact 27-inch powerhouse for your food truck or a massive 72-inch command center for your busy deli, there's a perfect match waiting for your specific needs.

Here at The Restaurant Warehouse, we understand that every dollar counts in the food service industry. That's why we've built our business around a simple principle: cut out the middleman and pass those savings directly to you. We skip the high commissions and retail markups that drive up prices elsewhere, offering you affordable wholesale pricing on the equipment you need to succeed.

We're not just selling equipment—we're partnering with fellow food service professionals who understand that the right tools can make or break a business. When you choose a mega top sandwich prep table from our collection, you're getting more than just a refrigerated workspace. You're investing in faster service, happier customers, and a more profitable operation.

Ready to transform your sandwich station from a bottleneck into a powerhouse? Your perfect mega top sandwich prep table is waiting, and with our wholesale pricing, it's more affordable than you might think.

Explore our Sandwich Prep Table collection today and find how the right equipment can revolutionize your kitchen's efficiency and your bottom line.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment