Mastering Your Commercial Freezer: From Maintenance to Temperature Perfection

Your Essential Guide to Commercial Freezer Upkeep

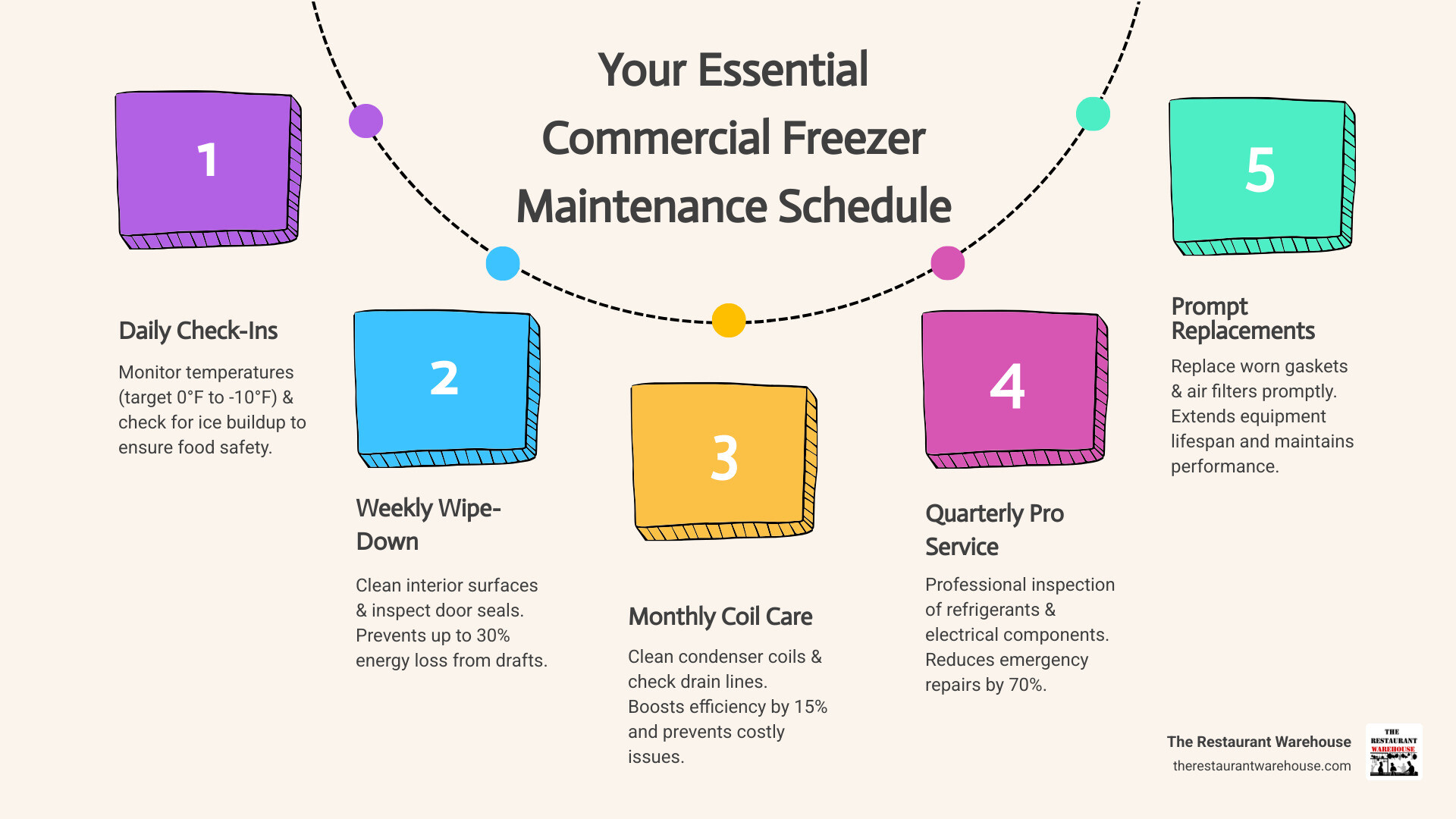

Commercial freezer maintenance is the backbone of any successful foodservice operation, directly impacting food safety, energy costs, and equipment lifespan. A consistent upkeep schedule can reduce the likelihood of emergency repairs by up to 70%, preventing costly downtime and operational chaos. Furthermore, it can improve energy efficiency by as much as 15% through simple, routine tasks like cleaning condenser coils, a task that takes minutes but pays dividends all year long.

Your commercial freezer is a significant financial investment that can account for 40-60% of your kitchen's energy costs. Without proper care, you risk equipment failure, spoiled inventory, and emergency repairs that can cost thousands. For example, a single malfunctioning door seal, which allows warm, moist air to constantly infiltrate the cold interior, can force the compressor to work overtime and increase energy consumption by a staggering 30%.

Key Maintenance Benefits:

- Food Safety and Quality: Maintaining consistent temperatures between 0°F and -10°F is non-negotiable. This range not only halts bacterial growth, protecting customers from foodborne illness, but also preserves the texture, flavor, and nutritional value of your inventory by preventing freezer burn.

- Significant Cost Control: Preventative care is a fraction of the cost of emergency repairs. A scheduled maintenance plan avoids premium charges for after-hours service, protects you from catastrophic inventory loss, and keeps your energy bills predictable and low.

- Improved Energy Efficiency: In a commercial kitchen, refrigeration is a top energy consumer. Clean components, tight seals, and a properly functioning system ensure your freezer uses the minimum amount of electricity required, directly lowering your monthly operating costs.

- Maximized Equipment Longevity: A commercial freezer is a major capital investment. Just like a car, it requires regular service to perform well for years. Diligent upkeep can easily extend a freezer's functional lifespan from a mere 8-10 years to 15-20 years, maximizing your return on investment.

Understanding when your freezer needs attention and what tasks to perform will save you money and protect your food inventory, whether you're running a small café or a large restaurant.

Recognizing the Red Flags: When Your Freezer Needs Service

Learning to spot your freezer's distress signals early can save you from costly emergency repairs and spoiled food. These warning signs are your equipment's way of asking for help before a small issue becomes a major breakdown.

Excessive Ice and Frost Buildup

While a light frost is normal, excessive ice and frost buildup is a clear red flag. Heavy ice accumulation on walls, shelves, or evaporator coils acts as an insulator, forcing your freezer's compressor to run longer and harder to maintain temperature, which drives up energy costs.

This ice buildup also causes airflow obstruction. When air can't circulate properly, you'll get inconsistent temperatures, with some products thawing while others are frozen solid. This often points to a malfunctioning defrost cycle, which could be caused by a faulty heater, timer, or sensor. The most common cause, however, is warm, humid air entering the freezer, often through a poor door seal. This not only wastes energy but also leads to freezer burn, which dehydrates food products, ruining their texture and taste and rendering expensive inventory unusable.

Inconsistent Temperatures and Fluctuations

Temperature variance is a serious threat to your inventory and customer safety. When your freezer can't hold a steady temperature, food spoilage and bacterial growth become significant risks. The primary suspect is often a thermostat malfunction, which prevents the compressor from cycling correctly.

Other causes include dirty condenser coils that can't dissipate heat, a failing evaporator fan that can't circulate cold air, or simply overloading the unit. These issues create a major food safety risk, as temperatures rising above 0°F can allow bacteria to multiply. This problem also leads to increased electricity usage, as the compressor works overtime to compensate for the inefficiency. For more on this topic, see this Commercial Freezer Guide.

Alarming Water Leaks and Puddles

Water pooling around your freezer is a sign of an underlying problem and an immediate safety hazard. Standing water can cause slip-and-fall accidents and promote mold and mildew growth.

The most common cause is clogged drain lines. During the defrost cycle, melted ice is supposed to flow out through a drain line. If this line is blocked by food debris or ice, the water will overflow onto the floor. Worn seals or improper installation that prevents the unit from being level can also lead to drainage problems. Ignoring leaks can lead to damaged flooring and more expensive repairs down the line.

Worn, Damaged, or Misaligned Doors

Freezer doors are critical for maintaining efficiency. Damaged door gaskets are a frequent problem, as these rubber seals can crack or tear over time, allowing warm air infiltration. You can test your seal by closing the door on a dollar bill; if it slides out easily, the gasket needs attention.

Broken hinges can cause the door to sag and misalign, preventing a tight seal. Faulty latches may not hold the door securely closed, leading to continuous air leaks. These door issues result in significant energy waste—a bad seal can increase energy use by 30%—and contribute to food spoilage due to temperature fluctuations. For help with this, refer to our guide on how to Install a Door Gasket on Commercial Refrigerators and Freezers.

Strange Noises or Unpleasant Odors

Your freezer should operate with a consistent, low hum. When that changes, pay attention.

- Loud or Constant Buzzing: The compressor may be struggling or failing. If it runs continuously without cycling off, it's a sign of inefficiency, likely caused by dirty coils, a bad seal, or low refrigerant.

- Rattling or Grinding Sounds: These noises often point to a problem with one of the fans—either the evaporator fan inside or the condenser fan outside. A failing fan motor or a simple obstruction could be the cause.

- Unpleasant Odors: A musty or sour smell inside the freezer, even after cleaning, can indicate hidden mold growth in the drainage system or spoiled food that has seeped into crevices. An electrical or burning smell is an urgent red flag that requires you to immediately unplug the unit and call a professional.

The Ultimate Commercial Freezer Maintenance Checklist

Proactive maintenance is the key to preventing freezer breakdowns and ensuring your equipment runs efficiently. This checklist covers the essential tasks that will extend the life of your freezer and save you money on energy and repairs.

Cleaning Condenser and Evaporator Coils

The condenser coils (outside the freezer) and evaporator coils (inside) are essential for heat exchange. When they get covered in dust and grease, your freezer's efficiency plummets. Cleaning dirty condenser coils can improve efficiency by up to 15%.

Recommended cleaning frequency is at least twice a year, or quarterly for busy or greasy kitchens. To clean them:

- Safety First: Unplug the freezer or turn off its circuit breaker.

- Locate the Coils: They are usually at the top, bottom, or back of the unit.

- Clean: Use a stiff coil cleaning brush to loosen dirt, brushing in an up-and-down motion to avoid damaging the fins. Use a shop vacuum to remove the debris. For heavy grease, a commercial, non-corrosive coil cleaner or degreaser may be needed. Always wear gloves and safety glasses when working with cleaning chemicals and ensure the area is well-ventilated.

- Evaporator Coils: Use a soft brush for the interior evaporator coils. If they are iced over, defrost the unit first.

Inspecting and Maintaining Door Components

Freezer doors and their components require regular attention to ensure a proper seal and prevent energy waste.

- Door Gaskets: Inspect weekly for cracks or tears. Clean them with warm, soapy water to remove grime that can make the seal stiff and ineffective. To perform the 'dollar bill test,' close the door on a dollar bill. If you can pull it out with no resistance, the gasket is too loose and needs to be adjusted or replaced. Test multiple spots around the entire door frame. A damaged gasket can increase energy consumption by 30%.

- Hinges: Lubricate hinges quarterly to ensure smooth operation and proper door alignment. Worn hinges can cause the door to sag, breaking the seal.

- Latches: Check latches regularly to ensure they hold the door tightly closed.

Most door component issues are easy to spot and fix. For more detailed instructions, see our guide on How to Maintain Commercial Refrigerators and Freezers.

Managing Drainage and Airflow Systems

Proper drainage and airflow are critical for your freezer's performance.

- Drain Lines: These lines carry away water from the defrost cycle. If they clog with debris, water can back up and leak onto the floor. To clean them, use a small brush or pipe cleaner to remove blockages, then flush the line with a mixture of warm water and white vinegar to inhibit mold growth.

- Air Filters: If your model has them, air filters protect the condenser coils from dust and grease. Check filters monthly and clean or replace them every 1-3 months to ensure proper airflow and maintain freezer efficiency.

Best Practices for Interior and Exterior Cleaning

A clean freezer is essential for food safety and operational efficiency.

- Interior Cleaning: Periodically, empty the freezer, turn it off, and let it defrost completely. Clean all interior surfaces (walls, shelves, floor) with a mild detergent and a non-abrasive sponge. After cleaning, use a food-safe sanitizer according to the manufacturer's instructions. Allow the interior to air dry completely before restocking to prevent ice buildup.

- Exterior Cleaning: Wipe down the exterior with a mild detergent. Use a stainless steel cleaner for stainless steel surfaces. Regularly clean and sanitize high-touch areas like door handles. Keep the floor around and under the unit clean and free of debris to ensure good airflow to the components.

Organizing for Optimal Airflow and Efficiency

How you load your freezer is just as important as how you clean it. Proper organization is a key,, aspect of maintenance.

- Avoid Overloading: Packing a freezer too tightly blocks the flow of cold air from the evaporator fan. This creates warm spots, forces the compressor to run longer, and puts your inventory at risk. Leave at least a few inches of space between items and the freezer walls.

- Follow the 'First-In, First-Out' (FIFO) Rule: Organize products so that the oldest items are used first. This reduces food waste and prevents items from getting lost at the back and expiring.

- Keep the Door Shut: Every time the door is opened, cold air escapes and warm air enters, forcing the system to work harder. Encourage staff to retrieve all needed items in one go rather than opening the door multiple times.

For more tips, check out our guide to Clean Restaurant Equipment.

Proactive Strategies for Long-Term Freezer Health

Effective commercial freezer maintenance is about being proactive, not reactive. A structured approach to upkeep will extend the life of your equipment, save money, and prevent the stress of unexpected breakdowns.

The Core Differences in Freezer Maintenance Approaches

Understanding the two main approaches to freezer care is key to managing your equipment effectively.

Preventative Maintenance: This is a proactive, scheduled approach. Tasks like cleaning coils and inspecting seals are performed regularly, regardless of whether a problem is apparent. This method is cost-saving, as it catches small issues before they become expensive failures. It keeps the unit running at peak efficiency, lowers energy bills, improves food safety, and extends the equipment's lifespan.

Corrective Maintenance: This is a reactive approach where you wait for something to break before fixing it. This type of maintenance is almost always more expensive due to emergency service fees, rushed parts, and potential inventory loss. The downtime is unpredictable and stressful, and it doesn't address the root causes of failure, often leading to recurring problems.

How to Create a Proactive Commercial Freezer Maintenance Schedule

A simple maintenance schedule ensures that essential tasks are not overlooked. Start by creating and maintaining a detailed maintenance log for each freezer, kept in a visible location nearby. This log is an invaluable record of the unit's history and should include:

- Date of Service: When the task was performed.

- Task Performed: A clear description (e.g., "Cleaned condenser coils," "Replaced door gasket").

- Technician/Staff Member: Who performed the work.

- Parts Used: Note any replacement parts and their model numbers.

- Observations: Any notes on the unit's condition (e.g., "Noticed minor frost buildup on back wall").

- Next Scheduled Service Date: A reminder for the next preventative maintenance task.

Here is a sample schedule to build from:

- Daily Checks: Monitor the temperature with an external thermometer to ensure it stays between 0°F and -10°F. Visually inspect for ice buildup or water leaks.

- Weekly Tasks: Clean interior surfaces and thoroughly inspect door gaskets for damage or gaps in the seal.

- Monthly Inspections: Clean condenser coils of any dust buildup. Check and clean drain pans and lines to prevent clogs.

- Quarterly Professional Service: Have a qualified technician inspect the freezer every 3-6 months. They can check refrigerant levels, test electrical components, and diagnose potential issues that are not visible to the untrained eye.

Assigning responsibility for these tasks is crucial for success. For a detailed breakdown, see our Commercial Freezer Maintenance: A Comprehensive Guide.

The Value of Professional Service vs. DIY

Knowing which tasks to handle in-house and when to call a professional will optimize your maintenance budget.

DIY Tasks: Your staff can handle most routine upkeep. This includes daily temperature monitoring, cleaning interior and exterior surfaces, inspecting and cleaning door gaskets, and performing basic condenser coil cleaning with a brush and vacuum.

Professional Expertise: Complex jobs should be left to certified technicians. This includes anything involving refrigerant levels, diagnosing compressor problems, and servicing electrical components. A qualified technician's inspection should be comprehensive. They will check refrigerant pressures, test the amperage draw of the compressor and fan motors, calibrate thermostats, inspect all components of the defrost system, and verify the integrity of all electrical connections.

Cost-Benefit Analysis: While professional service has an upfront cost, it can reduce emergency repairs by up to 70%. A $150 preventative service call can catch a failing fan motor that would have cost $800 to replace in an emergency, not to mention the thousands of dollars in spoiled product. Considering the high cost of emergency calls and lost inventory, preventative professional maintenance offers a significant return on investment by ensuring energy efficiency and extending your equipment's lifespan.

The Impact of Maintenance on Your Bottom Line and Food Safety

Commercial freezer maintenance is not just a chore; it's a critical business function that protects your inventory, customers, and profits. Neglecting your freezer is a gamble that can have severe consequences for your entire operation.

Consequences of Neglecting Your Freezer

Ignoring warning signs and skipping routine maintenance almost always leads to preventable problems. The consequences of neglect can be severe:

- Equipment Failure: A complete breakdown often happens at the worst possible time, leading to major disruptions.

- Lost Inventory: Thousands of dollars in food can be lost overnight, directly hitting your bottom line.

- Business Disruption: A failed freezer can halt operations, preventing you from serving customers and generating revenue.

- Costly Emergency Repairs: After-hours and weekend service calls come at a premium, turning a minor issue into a major expense.

- Health Code Violations: Improper temperatures are a primary focus for health inspectors and can lead to hefty fines, mandatory closures, and severe damage to your restaurant's reputation. A poor health score can be shared instantly online, deterring customers for years to come.

- Increased Energy Bills: A neglected freezer can use 30-50% more electricity, as components work harder to compensate for inefficiencies.

How Proper Upkeep Boosts Efficiency and Food Safety

Conversely, a well-maintained freezer is a reliable asset that supports your business. The benefits are immediate and substantial:

- Operational Efficiency: A reliable freezer maintains steady temperatures with minimal staff intervention, reducing stress and workflow disruptions.

- Energy Savings: Simple tasks yield impressive results. Cleaning condenser coils can improve efficiency by 15%, and replacing a worn gasket can cut energy use by 30%.

- Food Safety Compliance: Proper maintenance ensures your freezer consistently holds temperatures between 0°F and -10°F, which is essential for preventing bacterial growth and meeting health standards. This is a key aspect of the importance of equipment maintenance for food safety.

- Extending Equipment Lifespan: Commercial freezers are a major investment. Regular maintenance can extend their useful life from 8-10 years to 15-20 years, saving you thousands in premature replacement costs.

Repair or Replace? Making the Right Financial Decision

Eventually, you'll face the decision to repair or replace an aging freezer. A systematic approach can help you make the right financial choice.

Consider these factors:

- Age of Unit: If the freezer is under seven years old, repairs are usually cost-effective. For units over 12-15 years old, replacement is often the smarter long-term option.

- Cost of Repair: A common rule of thumb is to replace the unit if a single repair costs more than 50% of the price of a new, comparable model.

- Frequency of Breakdowns: If you're constantly calling for service, it may be more economical to invest in a new, reliable unit rather than continuing to patch up an old one.

- Energy Efficiency: A new freezer can be 20-40% more energy-efficient than a decade-old model. The long-term energy savings can help offset the initial purchase price.

- Parts Availability: For older models, parts may be difficult to find or expensive. Proactive replacement can prevent extended downtime while waiting for a rare part.

- Technological Advancements: Modern freezers offer significant advantages over older models, including superior insulation, digital temperature controls for precision, and energy-saving modes. These features can improve food quality and lower operating costs enough to justify the investment.

- Availability of Refrigerant: Older units may use refrigerants like R-22 that are being phased out and are becoming extremely expensive and difficult to source. Upgrading to a new unit that uses modern, environmentally-friendly refrigerants can be a more sustainable and cost-effective choice in the long run.

When it's time to replace, our guide to the Best Commercial Freezer Brands for 2025 can help you find a modern, efficient model.

Frequently Asked Questions about Commercial Freezer Maintenance

Here are concise answers to the most common questions about keeping your commercial freezer in top condition.

How often should a commercial freezer be professionally serviced?

The frequency of professional service depends on your freezer's usage and environment. As a general rule, schedule professional service at least twice a year. For high-volume kitchens or those with high levels of airborne grease and dust, quarterly visits are ideal. A professional service call provides a deep check of the system's health, including refrigerant levels, electrical components, and thermostat calibration, catching problems that routine cleaning might miss. Always refer to your manufacturer's recommendations first, as this will ensure optimal performance and keep your warranty valid.

What is the ideal temperature for a commercial freezer?

The recommended temperature range for a commercial freezer is 0°F (-18°C) or lower. This temperature is critical for food safety standards, as it effectively stops bacterial growth and keeps frozen food safe for consumption. It's essential to perform daily temperature monitoring with a reliable, external thermometer placed inside the unit, as the freezer's built-in display can become inaccurate over time. Log these temperatures daily to spot any upward trends before they become a problem.

Can I clean condenser coils myself?

Yes, cleaning condenser coils is a highly effective DIY maintenance task that every operator should perform. However, safety precautions are essential. Always unplug the unit or turn off the corresponding circuit breaker before you begin. Use a soft brush or a specialized coil brush to gently remove dust and debris, brushing in an up-and-down motion to avoid bending the delicate metal fins. Follow up with a vacuum to clear away the loosened particles. You should call a professional if the coils are caked in heavy grease or if you notice any damage or signs of a refrigerant leak (like an oily residue) during cleaning.

Why is my commercial freezer running constantly?

A freezer that never cycles off is a major energy drain and a sign of an underlying problem. The most common causes include:

- Dirty Condenser Coils: Clogged coils can't release heat effectively, forcing the compressor to run continuously to try and cool the refrigerant.

- Damaged Door Gasket: A poor seal allows a constant flow of warm air into the unit, making it impossible to reach and maintain the target temperature.

- Faulty Thermostat: If the thermostat is broken, it may not signal the compressor to shut off once the correct temperature is reached.

- Hot Environment: Placing a freezer next to a heat source or in a poorly ventilated room will force it to work much harder.

- Overloading: An overstocked freezer with poor airflow can also cause the system to run non-stop.

Conclusion: Protect Your Investment with Smart Maintenance

Caring for your commercial freezer is a direct investment in your business's success. It protects your inventory, ensures food safety, and keeps your energy bills under control. Your freezer works 24/7 to safeguard thousands of dollars in product, and with proper maintenance, it can serve you reliably for over a decade.

The key takeaways are simple: proactive care is always better than reactive repair. Small, consistent actions deliver significant results. Spending 15 minutes cleaning condenser coils can boost efficiency by 15%, while replacing a $50 door gasket can cut energy waste by 30%. These tasks are small investments that yield huge dividends in operational stability and profitability.

A robust maintenance plan is built on simple, repeatable steps. Daily, check the temperature. Weekly, wipe down gaskets and check the seals. Monthly, clean the condenser coils and check the drain lines. Quarterly, schedule a professional to inspect the electrical and refrigeration systems. By embedding these practices into your kitchen's routine, you transform maintenance from a chore into a strategic advantage.

Commercial freezer maintenance doesn't have to be complex. By implementing a routine of daily temperature checks, weekly cleaning, and scheduled professional service, you can prevent most major problems before they start. Staying vigilant for warning signs like ice buildup or water leaks allows you to address issues early, saving you from the stress and expense of an emergency breakdown.

Proper maintenance ensures consistent temperatures, which is the foundation of food safety. It also leads to clear financial benefits through lower energy consumption, fewer repair bills, and a longer equipment lifespan. At The Restaurant Warehouse, we understand that your freezer is a critical asset. By adopting a smart maintenance strategy, you ensure your operation runs smoothly, your food remains safe, and your profits stay healthy.

For more specific guidance, you can learn more about Atosa Freezer maintenance and find how proper care keeps your equipment running like new.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment