Smarter Commercial Kitchen Storage Solutions Guide

Smart commercial kitchen storage is the unsung hero of a successful restaurant. It’s the invisible system that dictates your kitchen’s speed, safety, and profitability. This is about more than just having shelves; it's about creating a highly organized environment that slashes waste and fine-tunes your workflow for peak performance.

The Hidden Engine of a Profitable Kitchen

Picture two kitchens slammed with a dinner rush. In one, there's controlled chaos. Staff are bumping into each other, hunting for misplaced ingredients, and losing precious time. The other kitchen is a picture of seamless efficiency, where every tool and ingredient is exactly where it needs to be, allowing service to flow effortlessly.

That difference isn't just about being tidy—it's about strategic design.

An intelligent storage setup is the hidden operational engine that pushes your business forward. It’s a system that fundamentally reshapes your kitchen’s entire workflow, and that directly boosts your bottom line in a few critical ways:

- Enhanced Speed: A logical layout means your staff take fewer steps to grab what they need, shaving valuable seconds off every single prep and plating time.

- Improved Safety: Proper organization is your first line of defense against cross-contamination and also drastically cuts down the risk of slips, trips, and other accidents.

- Reduced Waste: Smart systems like First-In, First-Out (FIFO) ensure you use older products first, which means less spoilage and a healthier inventory.

Don't think of your storage as a static collection of shelves. See it for what it truly is: a dynamic tool for productivity. It's a strategic investment in the very core of your culinary business, turning potential chaos into profitable, predictable order. This guide will show you exactly how to build it.

Choosing Your Core Storage Equipment

Getting the right hardware in place is the first real step to building a storage system that actually works. Think of it like pouring the foundation for a house; these core pieces are what your entire operation will rest on. The three pillars of commercial kitchen storage are versatile shelving units, heavy-duty dunnage racks, and space-saving wall-mounted shelves.

Each one has a very specific job, and putting the right piece in the right zone is a game-changer for your kitchen’s workflow and safety. This isn't just about buying racks—it's a strategic move that affects everything from how fast your team can grab ingredients to staying on the right side of the health inspector.

Selecting the Right Material for the Job

The material your storage is made from is just as crucial as its design. The environment where you plan to use it should be the deciding factor.

- Stainless Steel: This is the undisputed champ for hot prep lines and your general dry storage areas. It’s incredibly tough, non-porous, and a breeze to sanitize, making it a reliable workhorse you can count on.

- Polymer or Epoxy-Coated: This is your go-to solution for any damp or humid spot, like walk-in coolers, freezers, and dishwashing stations. The magic here is that they are 100% rust-proof, which stops the corrosion that can mess with food safety and force you into expensive replacements.

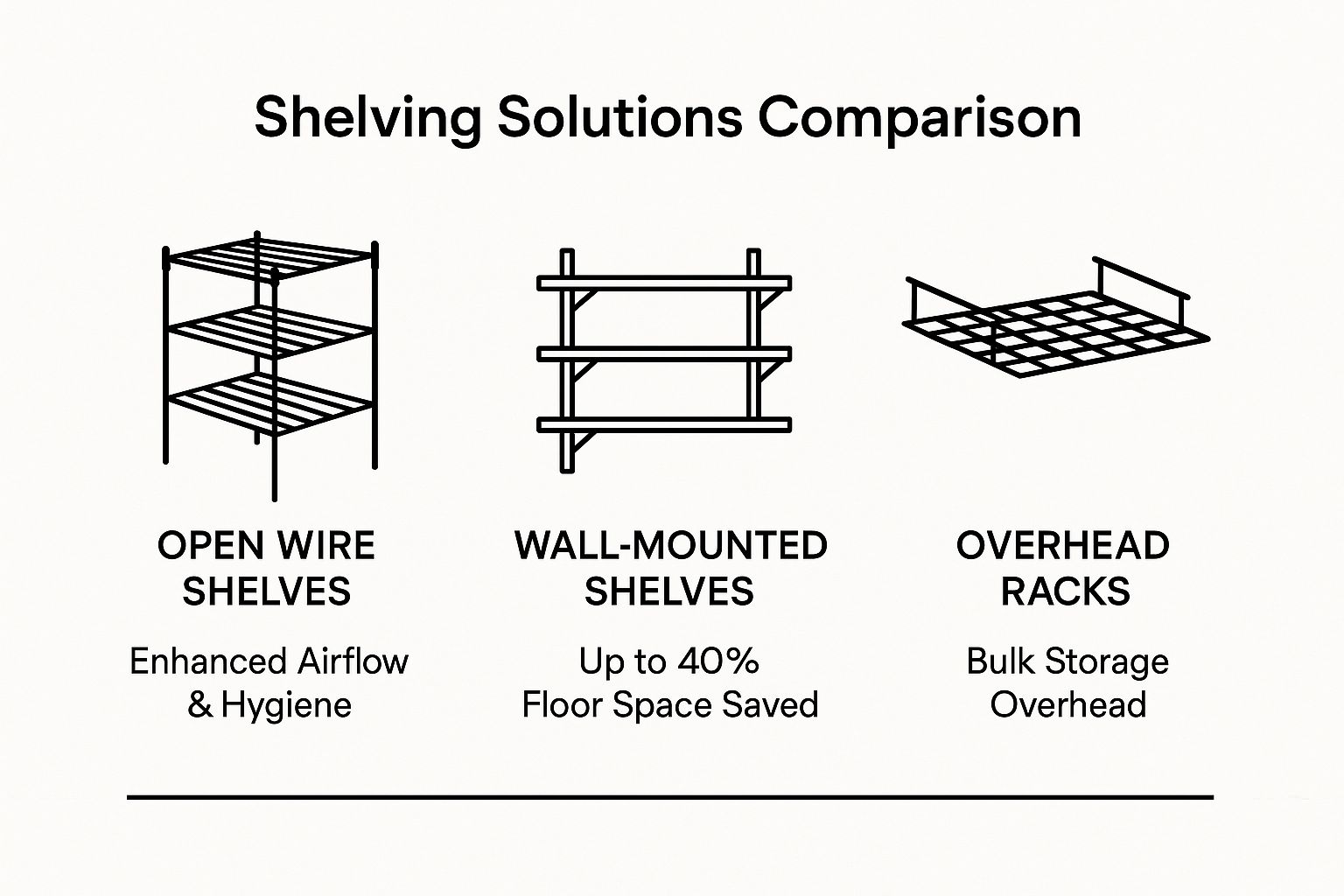

To give you a better idea of how these different vertical storage solutions can transform your kitchen, check out this infographic.

As you can see, wire shelving is a big win for hygiene, wall units help you reclaim precious floor space, and those overhead racks are perfect for stashing bulk items.

When you start looking at different materials for your shelving and racks, it helps to have a quick way to compare them. Each one has its place in a commercial kitchen.

Comparing Common Storage Materials

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Stainless Steel | Dry storage, prep areas, high-heat zones | Extremely durable, easy to sanitize, heat resistant | More expensive, can rust in very humid or corrosive environments |

| Epoxy-Coated Steel | Walk-in coolers, freezers, dishwashing areas | Rust-resistant, durable, more affordable than stainless steel | The coating can chip or peel over time, exposing the steel underneath |

| Polymer/Plastic | Humid environments, walk-ins, chemical storage | 100% rust-proof, lightweight, resistant to chemicals and moisture | May not have the same weight capacity as steel, can stain |

| Chrome-Plated Steel | Dry storage only, retail display | Aesthetically pleasing, very affordable | Prone to rusting and corrosion if exposed to moisture |

Ultimately, matching the material to the environment is the key to getting equipment that lasts.

Matching Equipment to Kitchen Zones

Once you’ve got a handle on the materials, you can start matching specific pieces of equipment to their jobs within your kitchen layout. Every piece plays a role in creating a logical and efficient flow. For a deeper dive into all the different types, check out our guide on commercial kitchen shelves.

Dunnage racks are those low-profile, heavy-duty platforms designed to keep bulk items like 50-pound bags of flour or big boxes safely off the floor. You absolutely need these in your receiving and dry storage areas to comply with that universal health code rule: everything must be stored at least six inches off the ground.

Choosing the right commercial kitchen storage solutions is increasingly vital. The global kitchen storage market is projected to reach $208.97 billion by 2032, driven by a growing demand for efficient, clutter-free environments. This trend underscores the importance of maximizing every square inch of your kitchen.

Wall-mounted shelves are the perfect answer for maximizing vertical space in cramped prep areas. By getting ingredients, spices, and small tools off the countertops, you create a more organized and expansive work surface. That directly improves your staff's efficiency and cuts way down on clutter.

Designing a Smarter Kitchen Workflow

Buying the right equipment is only half the battle. The real magic happens when you arrange your shelving and racks in a way that actually makes sense for your kitchen's rhythm. A smart layout can transform your kitchen from a chaotic space into a well-oiled machine.

Think of your kitchen not as one big room, but as a series of interconnected workstations, each with a specific job. This is the core idea behind kitchen zoning, a fundamental concept for creating an efficient workflow. The goal is simple: map out a clear path that your ingredients follow from the delivery door to the pass, cutting down on wasted steps and preventing those frustrating bottlenecks during a dinner rush.

Creating Your Kitchen Zones

The first step is to carve out dedicated areas for each stage of the food's journey. This isn't just about being organized; it's a critical strategy for boosting speed and, most importantly, preventing dangerous cross-contamination.

You'll want to establish a few key zones:

- Receiving Area: This is the first stop for all deliveries. It should be equipped with scales and a clear surface for inspecting everything that comes in.

- Dry Storage: Your home for non-perishables like flour, pasta, and canned goods, all organized on sturdy shelving.

- Cold Storage: Walk-in coolers and freezers for your meats, dairy, and produce, where rust-proof polymer shelving is your best friend.

- Prep Stations: Designated spots for chopping, mixing, and assembling, with essential ingredients stored neatly within arm's reach.

By placing your storage solutions logically within these zones, you drastically reduce the distance your staff has to travel. That translates directly to faster prep times and a smoother service. For a deeper dive into integrating storage into your layout, our guide to building a commercial kitchen floor plan has some fantastic insights.

Implementing Core Storage Practices

Once your zones are set, there are two non-negotiable habits that will bring your system to life and keep you in the clear with the health inspector. These practices are the bedrock of a safe, cost-effective kitchen.

The First-In, First-Out (FIFO) system is your best defense against food waste. Simply place new inventory behind older items, ensuring everything gets used before it expires. This one habit can slash your spoilage costs. In fact, some studies show poor storage practices can be responsible for up to 35% of a restaurant's food waste.

On top of that, always stick to the 6-inch rule. Every food item must be stored at least six inches off the floor on approved shelving or dunnage racks. This is a universal health code requirement that keeps pests away and makes cleaning underneath a whole lot easier.

Don't Let Your Storage Fail a Health Inspection

Let's be honest, the first thing a health inspector looks at is your storage system. It's the frontline of your kitchen's reputation, making your storage choices a critical part of keeping your operation safe and legal. Getting this right means you can breathe easy when that inspection clipboard comes out.

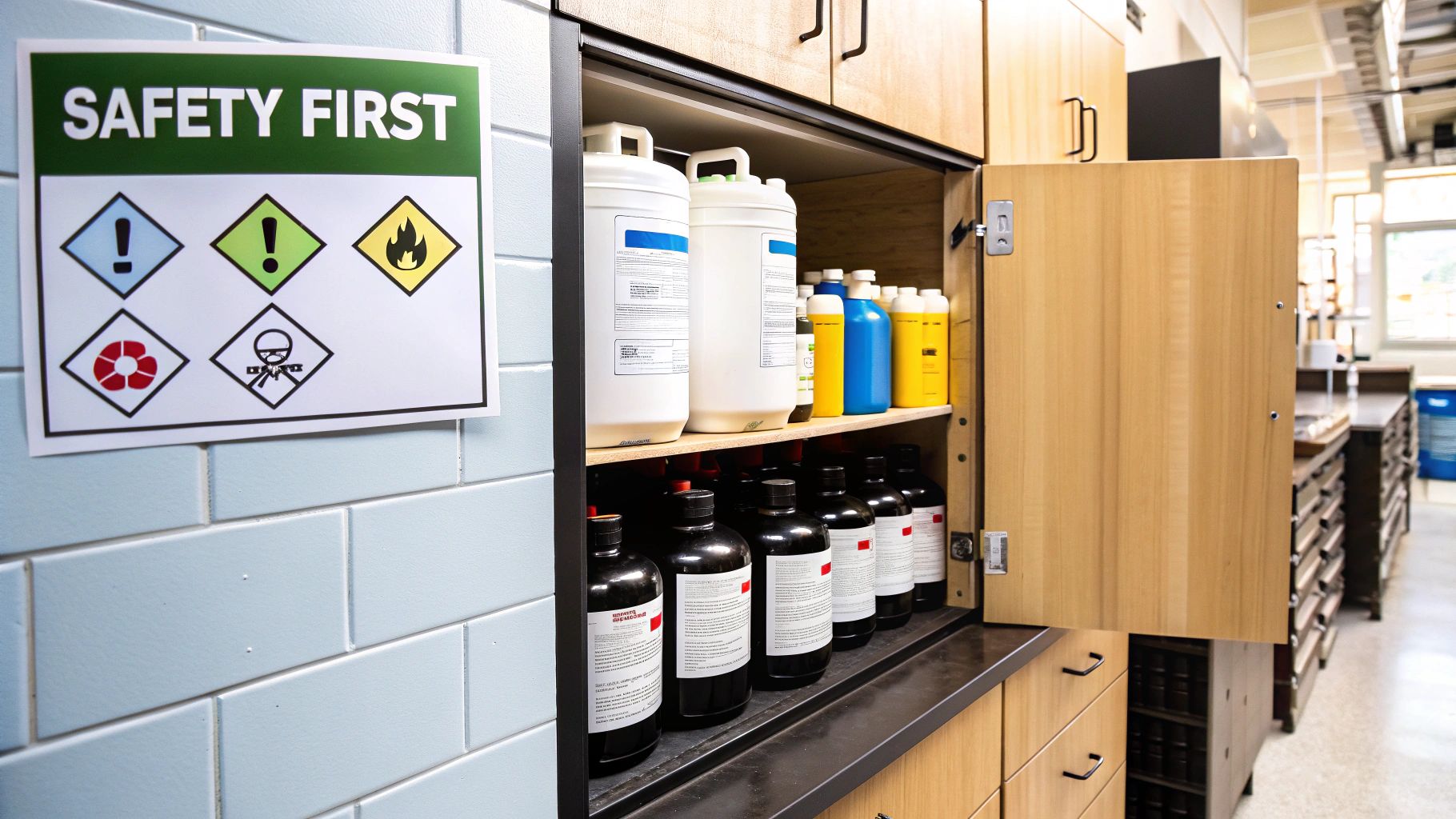

The absolute best place to start is with NSF-certified equipment. This isn't just a fancy sticker; it's a guarantee that your shelving and racks are made from materials that are non-porous and easy to sanitize—meaning they won't become a breeding ground for bacteria. Using the wrong stuff, like uncertified shelves or especially wood, is one of the fastest ways to rack up violations.

The Rules You Can't Ignore

Beyond the materials themselves, inspectors are trained to spot specific storage habits that directly impact food safety. These aren't just arbitrary rules; they're designed to stop contamination before it ever has a chance to start.

-

The 6-Inch Rule: All food and equipment must be stored at least six inches off the floor. This simple rule is a game-changer for pest control and makes it much easier to clean underneath your dunnage racks and shelving units.

-

Prevent Cross-Contamination: It's all about stacking smart. Always store ready-to-eat foods, like fresh produce, on shelves above raw meats. This common-sense hierarchy prevents dangerous juices from raw items dripping down and contaminating everything below.

-

Choose the Right Material for the Job: In wet areas like walk-in coolers or dish pits, your shelving absolutely must be rust-proof. Polymer or epoxy-coated units are essential here to prevent rust from flaking off and getting into your food supply.

Following these standards isn’t just about dodging fines. It's about building a rock-solid foundation of safety that protects your customers, your crew, and your brand's credibility.

This focus on compliance is a huge driver in the industry. The market for commercial kitchen storage is expected to grow at a 5.3% CAGR from 2024 to 2030, largely because restaurants are investing in better, safer systems to keep up with strict health codes. You can learn more about this market growth on GrandViewResearch.com.

Advanced Strategies for Maximum Space

Alright, you’ve got your main shelving and racks in place. Now it’s time to level up. These are the pro tactics that make every single square inch of your kitchen work harder, turning a good layout into a truly great one.

One of the most powerful tools in our arsenal is high-density mobile shelving. Think about those rolling stacks you see in a library, but built tough for your walk-in cooler or dry storage room. By mounting shelving units on tracks, you get rid of the need for multiple, permanent aisles. It’s a game-changer. This one move can nearly double your storage capacity in the exact same footprint.

Leverage Vertical and Specialized Solutions

Squeezing the most out of your space also means looking up and bringing in the specialists. Every kitchen has its quirks and unique needs, and believe me, there's a specific rack for just about everything you can think of.

-

Go Vertical: Don't let that space above your head go to waste. Install tall shelving units to use the full height of your storage areas. The top shelves are perfect for stashing less-frequently used items or bulk backstock.

-

Wall-Mounted Organizers: Get clutter off your valuable prep surfaces. Things like wall-mounted magnetic strips for knives and simple spice racks free up counter space while keeping essential tools right where you need them.

-

Purpose-Built Racks: Stop stacking things precariously. Use dedicated racks for sheet pans, glassware, and wine bottles. They’re designed to hold items securely and efficiently, which prevents costly breakage and makes taking inventory a whole lot faster.

Here's a simple but incredibly effective tip: use clear, properly labeled food storage containers. When staff can see what’s inside at a glance, inventory checks become faster and more accurate, which cuts down on ordering errors and food waste.

This whole idea of smart, visible organization is just as vital inside your coolers and freezers. To dive deeper into optimizing your refrigerated spaces, check out our complete guide on commercial refrigerator and freezer storage. Mastering these advanced storage solutions isn’t just about being tidy—it’s about giving your kitchen a real competitive edge.

Your Commercial Kitchen Storage Questions Answered

Even with the best plans laid out, you're always going to have a few specific questions pop up when it comes to outfitting your kitchen storage. Getting solid answers to these common hurdles is the key to making decisions you feel good about. This section is all about tackling those frequent queries we hear from kitchen managers and owners just like you.

Think of this as your go-to reference. We’ve boiled down the most practical advice for commercial kitchen storage solutions to help you navigate the tricky spots and get your operation running smoothly.

What Is the Most Important Factor When Choosing Kitchen Shelving?

Hands down, the single most critical factor is matching the material to its environment. It's a lot like choosing the right tires for a car; what works perfectly on a dry road is a total disaster in the snow. Stainless steel is your best all-around bet for durability and heat resistance, especially for anything near the hot cooking line.

But for walk-in coolers and warewashing areas, polymer or epoxy-coated shelving is a much smarter choice. Why? Because it will not rust or corrode in those constantly damp, humid conditions. No matter which material you land on, make absolutely sure any shelving you pick is NSF-certified—that’s a non-negotiable for meeting health code standards.

How Can I Maximize Storage in a Small Commercial Kitchen?

In a small kitchen, you've got to think vertically. Go for tall, narrow shelving units to store your less-frequently used items on higher shelves, which frees up precious floor space. Wall-mounted shelves and magnetic racks are also your best friends for getting items off your countertops, where every inch is prime real estate.

If you're ready for a serious upgrade, look into high-density mobile shelving. These systems run on tracks and let you compact shelves together, which gets rid of the need for multiple aisles. It’s a game-changer for dramatically increasing storage capacity in a tight footprint.

What Is the FIFO Method and Why Is It So Important?

FIFO is short for ‘First-In, First-Out.’ It’s a simple but brilliant stock rotation system where you place new inventory behind the existing inventory. This ensures that the older products always get used up first. This is absolutely crucial for cutting down on food spoilage, which studies show can account for up to 35% of a restaurant's food waste.

Putting FIFO into practice helps you maintain food quality, keep costs in check, and it’s a standard practice that health inspectors will be looking for. The key to making it work? Use clear, dated labels on absolutely everything. Without them, even the best FIFO system will fall apart.

Ready to build a smarter, more efficient kitchen? The Restaurant Warehouse offers a wide selection of NSF-certified shelving, dunnage racks, and essential storage equipment to meet your needs and budget. Explore our durable and affordable solutions at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment