Is an ENERGY STAR Commercial Dishwasher Worth It?

As a restaurant owner, you deal with constant uncertainty. Ingredient prices fluctuate, staffing presents daily challenges, and you can never be sure how busy a Tuesday night will be. So, what if you could make one of your largest operating costs completely predictable and significantly lower? That’s the stability an ENERGY STAR commercial dishwasher brings to your business. By cutting energy and water use by up to 40%, these machines deliver consistent, measurable savings on every utility bill. This guide breaks down the real-world numbers, showing you how to calculate your return on investment and choose a model that turns a volatile expense into a reliable source of savings.

Why Your Restaurant Needs an ENERGY STAR Commercial Dishwasher

An energy star commercial dishwasher doesn't just clean—it controls one of your highest back-of-house costs. With utility rates rising across the nation, the fastest path to dependable savings is a machine that uses dramatically less energy and water without sacrificing performance. Restaurant operators face mounting pressure to control costs while maintaining quality standards, and the dishwashing station represents a critical opportunity for measurable improvement.

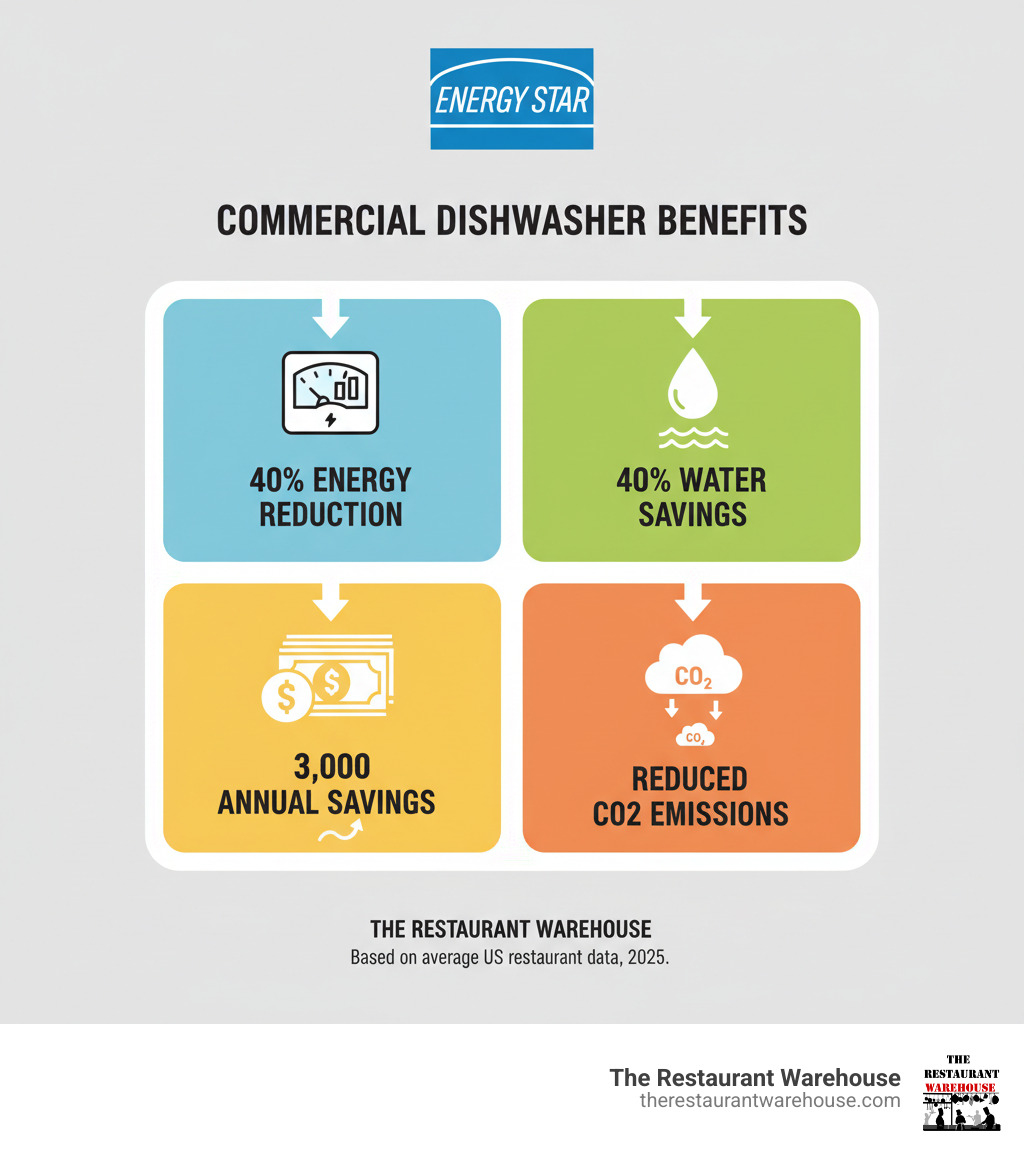

At-a-glance benefits:

- Uses about 40% less energy than standard models

- Uses about 40% less water than conventional machines

- Delivers up to $3,000/year in utility savings, depending on usage and rates

- Saves roughly 2,400 kWh annually

- Reduces greenhouse gas emissions equivalent to removing cars from the road

- Extends equipment lifespan through efficient operation

The blue label is more than green marketing—it's third-party verification that you'll get consistent results with lower operating costs. The ENERGY STAR program, administered by the Environmental Protection Agency, sets rigorous standards that manufacturers must meet through independent testing. This certification process ensures that every approved model delivers genuine efficiency gains, not just marketing promises.

In this comprehensive guide you'll see how an ENERGY STAR model improves margins, what to look for when evaluating options, and how to stack rebates with best-practice operation to maximize ROI. We'll explore the technical specifications that matter most, break down the financial calculations that justify the investment, and provide actionable strategies for getting the most from your equipment.

I'm Sean Kearney from The Restaurant Warehouse. We help operators cut overhead with smart, affordable choices, and an ENERGY STAR-certified dishwasher is often the quickest win. Our team has helped thousands of restaurants, cafes, bars, and institutional kitchens find the right balance between upfront investment and long-term savings.

Want pricing or a fast quote? Visit https://therestaurantwarehouse.com/ to get started. Our specialists can analyze your current usage patterns and recommend models that align with your volume, space constraints, and budget parameters.

The Most Trusted Environmental Label in the U.S.

When it comes to making environmentally responsible choices for your restaurant, the ENERGY STAR label is the most trusted symbol in the United States. Nearly 90% of American households recognize the blue label, which signifies that a product meets rigorous energy efficiency standards set by the Environmental Protection Agency (EPA). For a restaurant owner, this isn't just about being eco-friendly; it's about making a smart financial move. Choosing an ENERGY STAR-certified commercial dishwasher demonstrates your commitment to sustainability while directly lowering your utility bills—a tangible benefit you'll see on every statement.

The trust in the ENERGY STAR label is built on its strict certification process. This isn't just a marketing sticker; every approved model undergoes independent testing to verify its efficiency claims. This third-party validation provides confidence that you are investing in a product that delivers genuine savings and consistent performance. It takes the guesswork out of purchasing and ensures the efficiency gains you're promised are the ones you'll actually see, protecting your investment and your bottom line from the start.

By opting for ENERGY STAR products, restaurant owners can reduce energy and water consumption by up to 40% compared to standard models. This translates directly to lower utility bills and a smaller carbon footprint by reducing greenhouse gas emissions. In a busy kitchen, these savings add up quickly, improving your profit margins without compromising the cleaning power your operation depends on. Incorporating ENERGY STAR-certified equipment is a smart, practical choice that aligns financial goals with environmental responsibility, making it a clear win for your restaurant.

How You'll Save Money (and the Planet)

When you invest in an energy star commercial dishwasher, you reduce two major costs—energy and water—every single cycle. Operators routinely see immediate drops in utility bills, and those savings compound month after month. The impact extends beyond the monthly statement: reduced utility consumption means more predictable operating costs, easier budgeting, and improved cash flow management.

Consider the broader financial picture. A typical restaurant spends between 3-10% of its total revenue on utilities, with dishwashing operations accounting for a significant portion of water heating and consumption costs. By cutting these expenses by 40%, you're not just saving money—you're improving your competitive position in a market where margins often determine survival.

You also lighten your environmental footprint substantially. Lower energy demand and reduced water use mean fewer greenhouse gas emissions and less strain on local water systems—without compromising clean, sanitized results. This environmental responsibility increasingly matters to customers, particularly younger demographics who factor sustainability into their dining decisions. According to data from the National Restaurant Association, over 70% of consumers say they're more likely to visit restaurants with strong environmental practices.

The efficiency gains translate into operational advantages beyond utility savings. Faster cycle times mean dishes return to service quicker during peak periods. Lower water temperatures in some models reduce steam and humidity in the dish room, creating a more comfortable working environment for staff. Reduced heat output can also lower air conditioning loads in warmer climates, creating secondary energy savings.

How Much Energy and Water Will You Save?

- About 40% less energy used vs. non-certified machines

- About 40% less water used, often 5,600+ gallons saved annually

- Around 2,400 kWh saved per year

- Reduced water heating costs by approximately 25-30%

- Lower detergent and rinse aid consumption due to optimized water usage

- Decreased maintenance costs from reduced mineral buildup and component wear

Across the lifecycle, these reductions translate to thousands in avoided utility spend, with some operations reporting five-figure savings over time. The cumulative effect becomes particularly pronounced in high-volume operations where dishwashers run continuously during service hours. A busy restaurant running its dishwasher 8-10 hours daily can see monthly savings exceeding $250, which adds up to over $3,000 annually.

Water savings deserve special attention in regions facing drought conditions or high water costs. Many municipalities now charge escalating rates for commercial water usage, making efficiency improvements increasingly valuable. Some areas also impose sewer charges based on water consumption, effectively doubling the cost of each gallon used.

Potential Savings for Your Entire Kitchen

The savings from an efficient dishwasher ripple out across your entire kitchen. When one major appliance uses 40% less energy and water, it directly lowers your total utility bill—a line item that can account for a significant chunk of your revenue. This isn't just about the dish pit; it's about creating a more financially sound operation from the back of the house out. A more efficient machine often runs cooler and produces less steam, which can reduce the strain on your HVAC system during a busy service, creating another layer of savings. This single upgrade is a great first step. Applying the same efficiency mindset to other workhorses like your refrigerators and deep fryers can completely transform your operating costs and improve your bottom line.

Making Your Kitchen More Sustainable

Choosing an energy star commercial dishwasher cuts your kitchen's carbon footprint and supports broader energy-reduction goals. If widely adopted, these models would prevent significant greenhouse gas emissions nationally—proof that operational efficiency can be good business and good stewardship. The EPA estimates that if every commercial dishwasher in the United States met ENERGY STAR standards, the energy savings would prevent greenhouse gas emissions equivalent to those from over 100,000 vehicles annually.

Beyond the direct environmental benefits, efficient dishwashers contribute to improved local water quality. Less water usage means reduced strain on municipal treatment facilities, while lower chemical consumption (in the case of optimized low-temp models) means fewer pollutants entering the wastewater stream. These factors become increasingly important as communities implement stricter environmental regulations and sustainability requirements for businesses.

Ready to reduce your operational costs? Contact The Restaurant Warehouse today at https://therestaurantwarehouse.com/ for a personalized equipment consultation.

How a Dishwasher Earns the ENERGY STAR Label

The ENERGY STAR mark signals independent, third-party verification that a dishwasher delivers strong cleaning while using significantly less energy and water. It’s proof—not a promise—that you’ll get consistent performance with lower operating costs.

For a broader overview of selecting, sizing, and integrating a machine, visit our Commercial Dishwasher Restaurant Guide.

The Standards for ENERGY STAR Certification

Energy and water targets are strict—and practical:

- Low idle energy rate so the machine sips power between rushes

- Efficient energy per rack (kWh/rack) during active washing

- Tight water consumption (gallons per rack) thresholds

- Verified by independent third-party testing

- Must meet NSF/ANSI 3 food safety standards

Ready to compare current models? Use the official ENERGY STAR database: Find a list of ENERGY STAR certified commercial dishwashers.

Which Commercial Dishwashers Qualify?

- Undercounter models: Space-saving options for bars, cafes, and compact kitchens

- Single tank door-type: A common choice for many restaurants

- Conveyor machines (rack and flight-type): Built for high-volume operations

- Pot, pan, and utensil (PPU) washers: For heavy soil loads and cookware

Gas, steam, and residential-style units are not included in the program’s scope.

High-Temp vs. Low-Temp: Which Is Right for You?

- High-temperature sanitizing: Final rinse at about 180°F (often with a built-in booster) uses heat to sanitize; no chemical sanitizer cost, but higher heat energy input.

- Low-temperature sanitizing: Uses approved chemical agents at lower rinse temps (around 140°F); typically lower heat energy but requires ongoing chemical spend.

Both meet food safety requirements; choose based on utility rates, chemical preferences, and staff workflow.

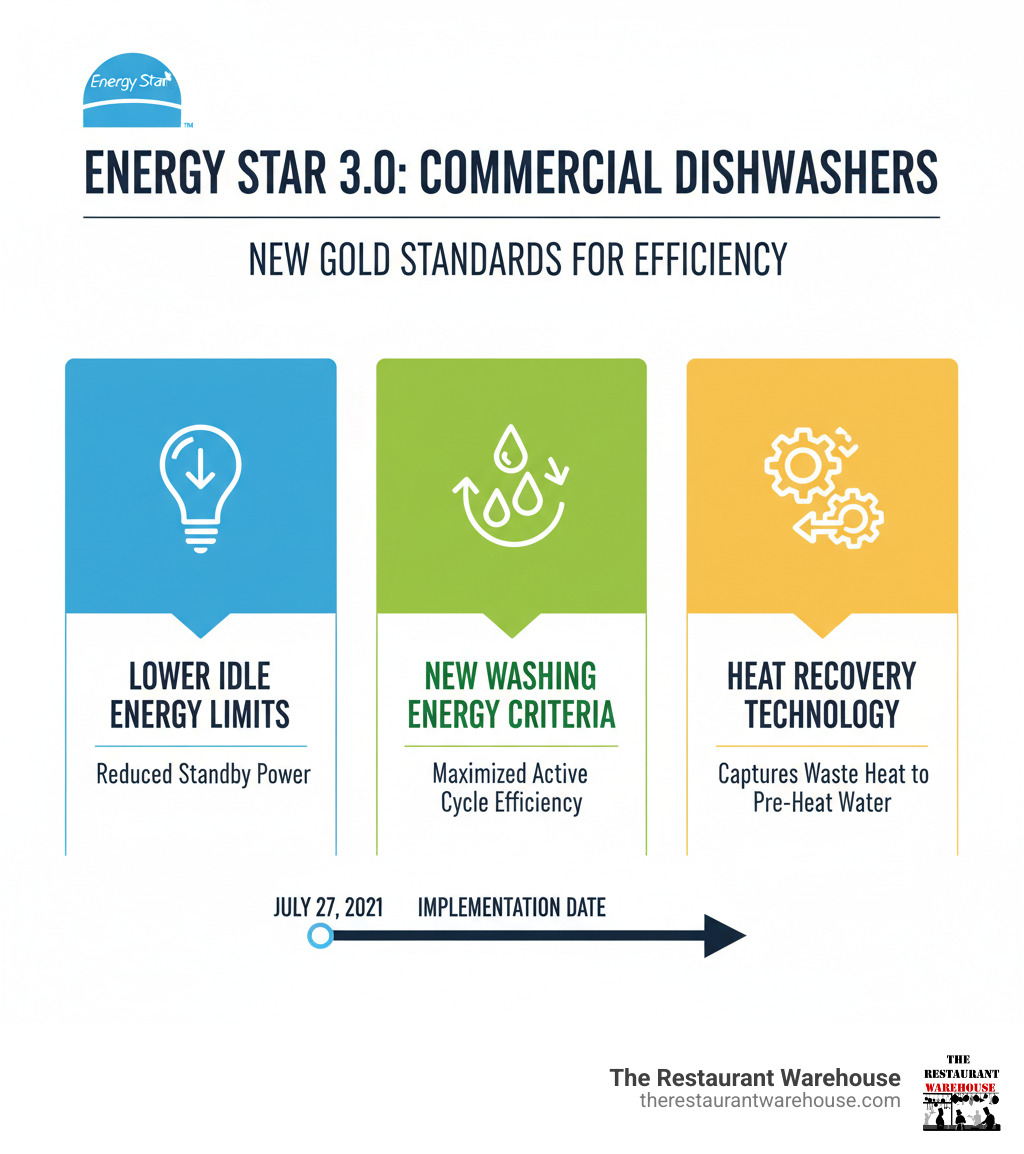

What's New with ENERGY STAR Version 3.0?

ENERGY STAR 3.0 tightened the bar for efficiency, emphasizing real-world cost drivers: lower idle energy use, refined washing energy thresholds, and recognition of heat-recovery designs that reclaim waste heat to pre-warm incoming water. The result is better day-to-day efficiency without sacrificing cleaning power. This latest iteration of the standard, which took effect in July 2021, represents years of collaboration between the EPA, manufacturers, and industry stakeholders to identify achievable yet meaningful efficiency improvements.

The new standards address a critical inefficiency in commercial dishwashing: idle energy consumption. Research showed that many dishwashers consume substantial energy even when not actively washing, maintaining water temperatures during periods between cycles. Version 3.0 sets strict limits on this idle energy draw, forcing manufacturers to implement better insulation, more efficient heating elements, and smarter control systems that reduce energy waste during standby periods.

Heat recovery technology, now formally recognized in the certification process, represents a significant advancement in dishwasher efficiency. These systems capture the heat from wastewater and steam exhaust, using it to preheat incoming cold water. This recovered energy would otherwise be lost to the drain or vented outside, representing pure waste. By reclaiming this thermal energy, heat recovery systems can reduce water heating requirements by 15-20%, creating substantial additional savings beyond the baseline ENERGY STAR requirements.

Compared with older non-certified machines, operators can see double-digit percentage savings—often around the high teens—thanks to decreased idle draw and smarter energy use during cycles. If you're replacing an aging unit, stepping up to a 3.0-certified model is one of the clearest paths to lower operating costs. The efficiency gains become even more pronounced when replacing dishwashers that are 10 or more years old, as technology improvements compound over time.

The Version 3.0 standards also introduced more stringent testing protocols to ensure real-world performance matches laboratory results. Manufacturers must now demonstrate efficiency across a range of operating conditions, including partial loads and varying water temperatures. This comprehensive testing gives operators confidence that advertised savings will translate to actual utility bill reductions.

For operations considering equipment upgrades, the timing has never been better. The combination of mature technology, competitive pricing, and available rebates makes ENERGY STAR 3.0 dishwashers an exceptional value proposition. Many manufacturers have expanded their certified product lines, offering models suited to every operation size and budget.

The environmental impact of widespread Version 3.0 adoption would be substantial. The EPA projects that if all commercial dishwashers sold in the United States met these new standards, the energy savings would equal the annual electricity consumption of over 40,000 homes. Water savings would exceed one billion gallons annually, enough to supply a mid-sized city for months.

Looking ahead, the ENERGY STAR program continues to evolve. Future versions may incorporate smart technology features, such as load sensing and automated optimization, to further reduce resource consumption. Operators who invest in current Version 3.0 models position themselves well for these future developments, as the fundamental efficiency improvements in today's certified dishwashers provide a solid foundation for additional improvements.

Beyond the Dishwasher: The Full ENERGY STAR Program

The savings don’t have to stop at the dish station. The ENERGY STAR program is a comprehensive initiative designed to help businesses reduce energy consumption across the board. Think of it as a roadmap for creating a high-performance, low-cost kitchen. By looking for the blue label on all major equipment purchases, you can create a network of efficiency that compounds your savings. The program helps businesses find products that save energy and money while protecting the environment. This holistic approach moves beyond single-point solutions and transforms your entire operation into a model of financial and environmental responsibility.

From refrigeration to cooking, nearly every major piece of equipment in your kitchen has an ENERGY STAR certified counterpart. Outfitting your entire kitchen with these certified models ensures that every station is contributing to lower utility bills. This strategy not only reduces your monthly overhead but also creates a more resilient business that is less vulnerable to rising energy costs. It’s a smart, systematic way to build a more profitable and sustainable restaurant from the ground up. Let's look at how you can extend these benefits throughout your kitchen and even to your entire building.

Outfit Your Entire Kitchen with Certified Equipment

While a dishwasher is a great start, the real power of the ENERGY STAR program comes from a kitchen-wide strategy. You can find certified models for nearly every major appliance category, allowing you to build an entire back-of-house operation designed for peak efficiency. When your refrigerator, fryer, and oven all meet these high standards, the combined savings on your utility bills become substantial. This approach turns energy management from a single decision into a core operational principle. You can shop restaurant equipment that meets these standards to ensure every part of your kitchen is working to lower your costs and support your bottom line.

Refrigerators and Freezers

Your refrigeration units are some of the hardest-working pieces of equipment in your kitchen, running 24/7 to keep ingredients safe. They are also major energy consumers. ENERGY STAR certified commercial refrigerators and freezers are designed to cut that consumption significantly, often by 20% or more. They achieve this through features like high-efficiency compressors, advanced insulation, and smarter temperature controls. This not only lowers your electricity bill but also reduces wear and tear on the equipment, potentially extending its service life and reducing maintenance costs over time.

Ovens, Fryers, and Griddles

Cooking appliances are another key area for energy savings. ENERGY STAR certified commercial ovens, for example, often feature better insulation and door gaskets, which means they heat up faster and maintain temperature more accurately with less energy. Certified commercial deep fryers use advanced burner and heat exchanger designs to transfer heat to the oil more efficiently, reducing idle energy consumption and shortening cook times. These improvements don't just save gas or electricity; they can also lead to more consistent food quality and a cooler, more comfortable kitchen environment for your staff.

Improving Your Building's Overall Efficiency

True operational efficiency extends beyond the kitchen equipment to the building itself. The ENERGY STAR program provides a framework for commercial buildings to measure, track, and improve their energy performance. This big-picture view helps you identify systemic issues and opportunities that you might miss when focusing only on individual appliances. By managing your building’s energy use, you can uncover hidden costs in your HVAC, lighting, and water systems. The program outlines a clear path to better performance: benchmark your usage, implement savings strategies, and earn recognition for your achievements.

Benchmarking with the ENERGY STAR Portfolio Manager

You can’t manage what you don’t measure. That’s where the ENERGY STAR Portfolio Manager comes in. This free, online tool allows you to track your building's energy and water consumption and compare your performance against similar facilities nationwide. By entering your utility data, you can get a clear picture of your building’s efficiency, identify underperforming areas, and set realistic goals for improvement. It’s an essential first step for any business serious about controlling utility costs and reducing its environmental impact. The data provides the insights you need to make informed decisions about upgrades and operational changes.

Earning EPA Recognition for Your Building

Performing in the top tier of energy efficiency can earn your building official ENERGY STAR certification. This isn't just a plaque for the wall; it's a powerful marketing tool. The ENERGY STAR label is the most trusted environmental symbol in the country, signaling to customers, staff, and the community that your business is a leader in sustainability. This recognition can enhance your brand reputation, attract environmentally conscious patrons, and even help with employee morale. It validates your hard work and demonstrates a public commitment to responsible business practices, turning your cost-saving measures into a competitive advantage.

Finding the Right Machine and Getting the Best Deal

An energy star commercial dishwasher is a predictable, measurable cost reducer. Unlike volatile food prices or labor fluctuations, efficiency savings are trackable each billing cycle, which helps tighten budgets and smooth cash flow.

For purchasing guidance, see our Buy Commercial Dishwashers Guide.

Figuring Out Your Return on Investment (ROI)

With typical lifespans around 15 years, many operators see a 2–4 year payback depending on usage and local rates. Annual savings can approach $3,000, and total lifecycle savings for many models can exceed $17,214, with some high-efficiency units reaching $20,000+ in avoided costs.

After payback, the machine becomes a quiet profit-center—returning savings every month it runs.

How to Find Rebates and Save on Your Purchase

Many utilities and regional programs offer cash incentives for efficient models. A few minutes of research can reduce your upfront cost by hundreds—sometimes more.

Start here: Find rebates in your area.

Exploring Federal Tax Deductions for Energy Efficiency

Beyond rebates and lower utility bills, your investment in an ENERGY STAR dishwasher can contribute to significant federal tax benefits. The government offers the Energy Efficient Commercial Buildings Deduction to reward business owners who make their properties more efficient. To qualify, your upgrades must help reduce your building's total annual energy and power costs by at least 25% compared to a standard building. The deduction starts at $0.50 per square foot and increases as your energy savings go up. Thanks to recent changes, this incentive is more generous than ever. While you should always consult a tax professional for advice, you can review the official rules to see how upgrading equipment throughout your kitchen—from dishwashers to high-efficiency refrigerators and freezers—can help you qualify for these valuable savings.

Choosing the Perfect ENERGY STAR Commercial Dishwasher

- Use the ENERGY STAR Product Finder (linked in the section above) to compare certified models

- Prioritize gallons per rack and idle energy—small differences add up over thousands of cycles

- Size for peak demand to avoid bottlenecks without oversizing

Want help picking the right machine for volume, footprint, and budget? Explore our selection of commercial dishwashers today!

CTA: Need a fast quote or procurement help? Visit https://therestaurantwarehouse.com/ and our team will get you options and pricing right away.

Getting the Most Out of Your Dishwasher

An efficient machine performs best with efficient habits. Train your team on these quick wins and you'll amplify savings while extending machine life. Proper operation can increase your energy savings by an additional 10-15% beyond the baseline efficiency of your ENERGY STAR dishwasher, while poor practices can negate much of the benefit you've paid for.

The foundation of efficient dishwashing starts before the first dish enters the machine. Establishing clear procedures for dish handling, from the dining room to the dish pit, ensures consistent results and prevents the need for rewashing. This systematic approach not only saves resources but also improves kitchen workflow and reduces labor costs.

Essential Daily Operating Procedures:

Run full racks only. Partial loads equal full-price cycles. Train staff to accumulate dishes until a full rack is ready, using a staging area if necessary. Consider purchasing additional racks to facilitate this practice during slower periods.

Pre-scrape, don't pre-rinse. Modern machines handle soils effectively; pre-rinsing wastes water and energy while providing no cleaning benefit. Use a rubber scraper or disposable paper to remove food debris. This single change can save 1,000+ gallons monthly.

Load racks properly. Incorrect loading leads to poor cleaning and the need for rewashing. Face soiled surfaces toward spray arms, don't overcrowd, and ensure water can reach all surfaces. Proper loading also prevents damage and extends dish life.

Monitor and maintain water temperature. Verify that wash and rinse temperatures meet specifications. Too low, and dishes won't sanitize properly; too high, and you're wasting energy. Check temperatures at the start of each shift.

Clean and de-lime on schedule. Mineral buildup reduces heat transfer and flow, driving up costs and reducing cleaning effectiveness. Follow manufacturer recommendations for cleaning frequency, typically daily for wash arms and weekly for deep cleaning.

Shut down during long idle periods. Especially important for high-temp models with booster heaters. If the dishwasher won't be used for more than an hour, turn it off. Modern units heat up quickly, so the energy saved far exceeds any convenience lost.

Verify water pressure. Low pressure extends cycle times and reduces cleaning effectiveness, while excessive pressure can damage dishes and increase water consumption. Install a pressure gauge if not already present.

Replace worn door gaskets promptly. Damaged seals allow heat and moisture to escape, forcing the machine to work harder. Check gaskets weekly and replace at the first sign of wear.

Advanced Efficiency Strategies:

Beyond basic operation, several advanced strategies can further reduce costs. Consider implementing a dish sorting system that groups similar items together, allowing you to adjust cycle settings appropriately. Lightly soiled glassware doesn't need the same intensive cycle as heavily soiled pots and pans.

Install a water softening system if you're in a hard water area. Soft water improves cleaning effectiveness, reduces detergent usage, and prevents mineral buildup that degrades efficiency over time. The investment typically pays for itself within 12-18 months through reduced chemical costs and extended equipment life.

Train multiple staff members on proper operation and maintenance procedures. Cross-training ensures consistent practices regardless of who's working and prevents knowledge loss when employees leave. Create a simple checklist posted near the dishwasher to reinforce proper procedures.

Monitor your utility bills closely to track the impact of your efficiency efforts. Many utilities offer online tools that show daily or hourly usage patterns, helping you identify opportunities for additional savings. Some operators have finded significant waste during off-hours due to equipment being left on unnecessarily.

For daily/weekly procedures that keep your operation sharp, use our Restaurant Cleaning Checklist.

Schedule your free efficiency assessment with The Restaurant Warehouse at https://therestaurantwarehouse.com/ and find additional ways to reduce operating costs.

Frequently Asked Questions about ENERGY STAR Commercial Dishwashers

How much can I realistically save with an ENERGY STAR model?

Most operators see about 40% less energy and 40% less water use versus standard models. Depending on your rates and volume, that can approach $3,000 in annual savings. Over a typical 15-year lifecycle, total utility savings for many models can exceed $17,214, and some high-efficiency machines reach $20,000+.

Are ENERGY STAR dishwashers as powerful as standard models?

Yes. Certification requires rigorous, independent testing. Every certified model must meet performance standards—including NSF/ANSI 3—while hitting strict energy and water targets. In practice, you get the clean and sanitation outcomes you expect with less resource use.

Where can I find a complete list of all certified models?

Use the EPA’s official Product Finder to browse, filter, and compare current listings: see the link in the “Decoding the Blue Label” section above.

Making the Switch to a More Efficient Kitchen

Switching to an energy star commercial dishwasher is a straightforward way to cut operating costs and reduce environmental impact—without changing your menu or guest experience. Expect about 40% less energy and water use, thousands saved each year, and long-term lifecycle savings that can surpass $17,000 in many operations. These savings represent pure profit improvement, flowing directly to your bottom line without requiring increased sales or reduced staff.

The decision to upgrade becomes even more compelling when you consider the broader operational benefits. Improved reliability means fewer service calls and less downtime during critical service periods. Improved cleaning performance reduces rewashing and improves customer satisfaction. Better working conditions in the dish room can improve employee retention, reducing turnover costs in a notoriously challenging position to fill.

With ENERGY STAR 3.0, you also benefit from tighter idle and washing energy standards—and, on certain models, heat-recovery features that reclaim waste heat to trim costs further. These technological advances represent real engineering improvements, not incremental tweaks, delivering measurable benefits in real-world conditions.

The financial case for upgrading strengthens when you factor in available rebates and incentives. Many operators reduce their upfront investment by 20-30% through utility programs and tax incentives. Combined with the operational savings, payback periods often fall below two years, after which the savings become pure profit improvement.

Timing matters in equipment decisions. Waiting until your current dishwasher fails forces you to make a rushed decision, often accepting whatever model is immediately available. Planning your upgrade allows you to research options thoroughly, secure the best pricing, and coordinate installation during slower periods to minimize disruption.

Consider the competitive advantage of operational efficiency. While your competitors struggle with rising utility costs, your efficient operation maintains stable expenses. This cost control provides flexibility to invest in other areas of your business, whether that's ingredient quality, staff training, or marketing initiatives.

The Restaurant Warehouse stands ready to support your efficiency upgrade. Our team understands the unique challenges facing food service operators and can guide you through the selection process, from initial assessment through installation and training. We maintain relationships with leading manufacturers and can often secure pricing advantages not available to individual buyers.

Beyond the immediate transaction, we provide ongoing support to ensure you maximize the value of your investment. This includes operational training for your staff, maintenance guidance to extend equipment life, and updates on new rebate programs or efficiency opportunities.

The path to improved profitability doesn't always require increasing sales or cutting staff. Sometimes the smartest move is simply operating more efficiently with better equipment. An ENERGY STAR commercial dishwasher represents one of the clearest opportunities to reduce costs while maintaining or improving service quality.

If you're ready to evaluate models, pricing, and rebates, we can help you move fast. Contact us for expert guidance on selecting the perfect dishwasher for your needs.

Take action today—every day you delay costs you money in unnecessary utility expenses. Visit https://therestaurantwarehouse.com/ and our team will respond quickly with recommendations custom to your volume and budget. Let us show you how much you could be saving with an ENERGY STAR certified dishwasher.

Key Takeaways

- Control Your Utility Bills: An ENERGY STAR dishwasher provides a reliable way to lower operating costs, reducing energy and water use by about 40%. These consistent savings, which can top $3,000 annually, flow directly to your bottom line.

- Amplify Savings with Smart Habits and a Full-Kitchen Approach: Get the most from your machine by training staff to run full loads and avoid pre-rinsing. Extend this efficiency mindset to other equipment like refrigerators and fryers to create a system of savings across your entire operation.

- Lower Your Upfront Cost with Rebates and Incentives: Don't pay full price for your upgrade. A few minutes of research can uncover utility rebates and federal tax credits that significantly reduce the initial investment, making a new, efficient dishwasher more affordable today.

Related Articles

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment