What is Cold Chain Management? A Practical Guide to Food Safety & Profitability

Cold chain management is basically a promise. It’s the promise that every temperature-sensitive ingredient, from a side of fresh salmon to a case of premium cheese, is kept perfectly chilled every single step of its journey.

Think of it like a relay race. The baton is your chilled or frozen product, and dropping it—even for a moment—means losing the race. A brief temperature spike on a warm loading dock or in a disorganized walk-in cooler can ruin an entire shipment, costing you thousands and putting your customers at risk.

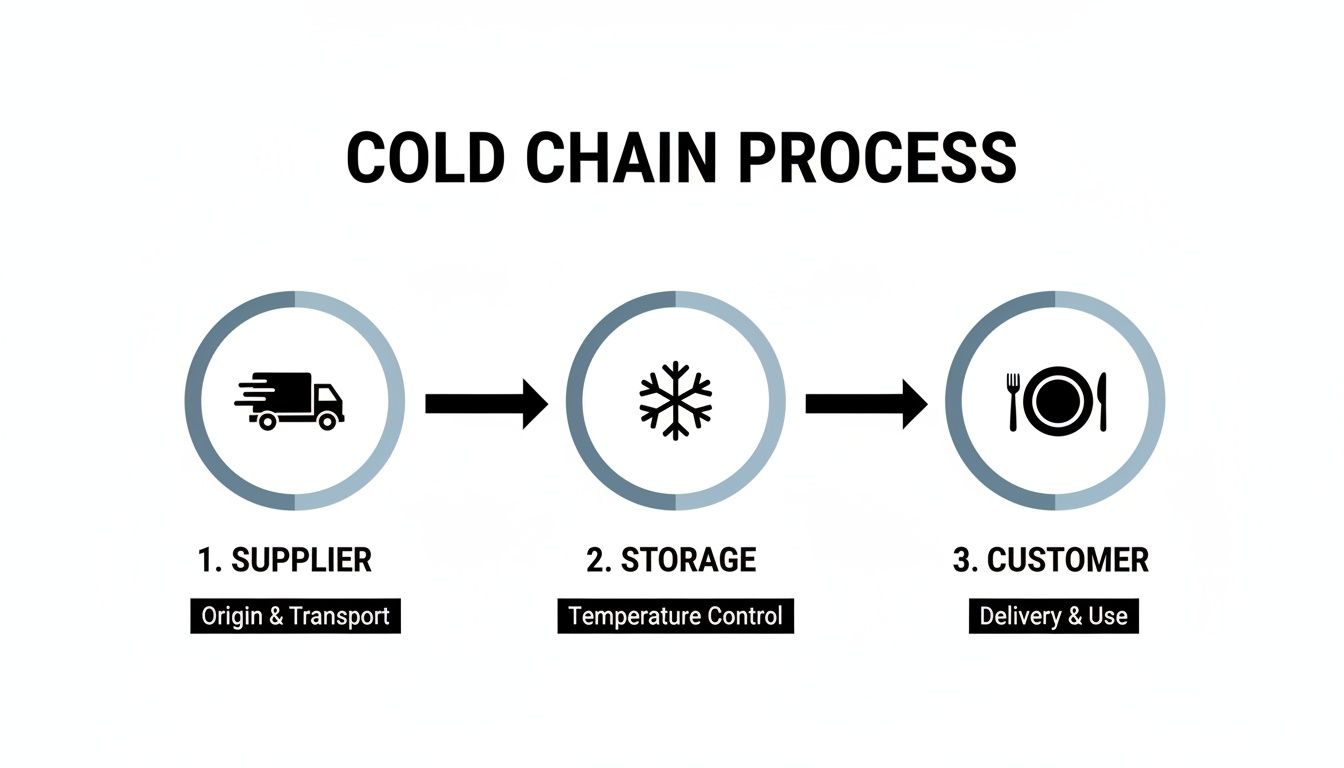

An Unbroken Chain, From Supplier to Your Customer's Plate

At its core, what is cold chain management is the critical process that protects your food, your finances, and your reputation. It’s not just some buzzword for logistics nerds; it's a fundamental part of running a smart, safe foodservice operation. Every link in this chain has to be strong and secure.

Let’s trace the journey of that fresh salmon. It leaves a chilled processing plant, travels in a specialized refrigerated truck, gets checked and immediately moved into your walk-in cooler, and finally lands in a refrigerated prep station before it's cooked to order. A single weak link—a truck's cooling unit failing, a staff member leaving a cooler door ajar—can break the chain. That's when quality plummets and dangerous bacteria get a chance to grow.

Maintaining that seamless cold environment is the entire game.

Keeping It Cool From Production to Prep

This whole process is designed to keep your temperature-sensitive products within their ideal "safe zone" from start to finish. This is what stops harmful pathogens from multiplying and preserves the incredible texture, flavor, and nutritional value your customers expect.

Here's how the links in the chain connect:

- Production and Sourcing: It all starts with your suppliers. They have to get products chilled down right after they're harvested or processed.

- Transportation: Specialized refrigerated trucks (often called "reefer trucks") are non-negotiable for moving ingredients between locations while holding a constant, monitored temperature.

- Storage: Once a delivery hits your back door, it's a race to get those items into the right commercial refrigerators or freezers, whether that's a big walk-in cooler or a smaller reach-in unit.

- Handling and Preparation: The chain doesn't end at the cooler door. During prep, those ingredients need to stay chilled, which is why refrigerated prep tables and undercounter coolers are so vital on the line.

This journey requires precision at every stage. The table below breaks down these critical steps.

Key Stages of the Restaurant Cold Chain

| Stage | Description | Primary Goal |

|---|---|---|

| Sourcing & Production | Ingredients are harvested or prepared and immediately brought to a safe, cold temperature. | Lock in freshness and prevent initial bacterial growth. |

| Refrigerated Transport | Products are moved from the supplier to the restaurant in temperature-controlled vehicles. | Maintain a consistent, safe temperature during transit. |

| Receiving & Inspection | Staff inspect deliveries for proper temperature and signs of spoilage before accepting them. | Prevent compromised products from ever entering the kitchen. |

| Cold Storage | Items are immediately transferred to the appropriate walk-in coolers, refrigerators, or freezers. | Keep inventory safe, organized, and fresh until needed. |

| Preparation & Handling | Ingredients are kept chilled on the line using refrigerated prep tables or by limiting time outside the cooler. | Minimize temperature exposure during the final prep stages. |

| Serving | The final dish is prepared and served, completing the food safety journey. | Deliver a high-quality, safe, and delicious meal to the customer. |

Each of these stages is a critical link. A failure at any one point can jeopardize the entire process.

As the diagram shows, one misstep in transport, storage, or handling can break the chain and compromise everything that follows.

The goal is simple: create a seamless cold environment from start to finish. A single weak link—like a thermostat that's off by a few degrees or a door that doesn't seal properly—can spoil thousands of dollars worth of inventory and put your entire operation at risk.

Ultimately, mastering your cold chain is all about controlling the variables you can control. It's a foundational piece of any successful restaurant and ties directly into building a resilient and efficient restaurant supply chain. When you understand and manage each link, you can be confident that every dish you serve is as safe, fresh, and delicious as you intend it to be.

The Three Pillars of an Effective Cold Chain

A successful cold chain doesn't happen by accident. It's a system that’s deliberately built on three essential pillars: the right equipment, constant monitoring, and crystal-clear procedures. If even one of these pillars gets shaky, the whole structure—along with thousands of dollars in inventory—is at risk of coming crashing down.

When we talk about cold chain management, it's best to see it as a complete system where every part supports the others. Think of it like a three-legged stool. Kick one leg out, and the whole thing becomes wobbly and useless. The same idea applies to protecting your perishable ingredients.

Let's break down each of these pillars to see how they work together to create an unbreakable chain of food safety and quality in your restaurant.

Pillar 1: The Right Commercial Equipment

The foundation of any cold chain is the hardware itself. This isn't just about having a refrigerator; it's about having the right commercial-grade units that can handle your specific workflow. Those consumer-grade appliances from the big-box store just can't keep up with the demands of a professional kitchen, from doors flying open constantly to holding precise temperatures under pressure.

Investing in proper equipment is completely non-negotiable. Key pieces include:

- Walk-In Coolers and Freezers: These are the workhorses for your bulk storage. A properly running walk-in ensures that huge quantities of produce, meat, and dairy are held at a stable, safe temperature from the moment they’re delivered.

- Reach-In Refrigerators and Freezers: Placed strategically throughout your kitchen, these units give your team quick access to ingredients during service, keeping the cold chain intact right up until it's time to cook.

- Refrigerated Prep Tables: These are critical for maintaining temperature control while your staff is actually working. They stop sensitive items like proteins and pre-cut veggies from hitting the temperature danger zone as your team assembles dishes.

Choosing the right equipment means matching the unit's capacity, power, and design to your menu and kitchen layout. An undersized walk-in leads to overcrowding and poor airflow, creating dangerous warm spots. A prep table without enough refrigerated wells forces staff to pull too much product at once, breaking the chain.

The global demand for these systems is growing fast. The cold chain market, which reached USD 405.0 billion, is projected to hit USD 452.8 billion, showing just how vital this infrastructure is for industries like foodservice. You can explore more on the global cold chain market growth and its drivers to see how these trends are shaping the industry.

Pillar 2: Constant and Accurate Monitoring

Having the best equipment is only half the battle. If you aren't constantly monitoring it, you’re basically flying blind. This pillar is all about shifting from a reactive approach—finding spoiled food after it's too late—to a proactive one where you can stop problems before they even start.

Traditionally, this meant manual temperature logs on a clipboard. While that's better than nothing, this method is wide open to human error—missed checks, inaccurate readings, or even "pencil-whipped" entries during a chaotic service.

Modern cold chain management relies on automated monitoring. This technology acts as a 24/7 guardian for your inventory, providing real-time data and instant alerts that a clipboard never could.

Imagine getting a text alert at 3 AM because a freezer door wasn't shut properly. That single notification lets you fix the problem immediately, saving your entire inventory from spoiling. That's the power of moving beyond manual checks. Automated systems provide an unbroken, accurate data trail that simplifies health inspections and gives you true peace of mind.

Pillar 3: Clear Standard Operating Procedures

The final pillar is the human element. Your state-of-the-art equipment and high-tech monitoring systems are only as effective as the people using them. Standard Operating Procedures (SOPs) are the clear, written instructions that turn best practices into consistent daily habits for your entire team.

Well-defined SOPs take the guesswork out of the equation and ensure every team member handles perishable goods the exact same way, every single time.

Your SOPs should cover every critical touchpoint in the cold chain:

- Receiving Deliveries: Detail the exact steps for inspecting incoming goods. This includes checking the delivery truck's temperature, visually inspecting products for signs of thawing, and using a probe thermometer to verify the internal temperature of key items before you accept them.

- Storage and Organization: Create rules for immediate storage. For instance, new deliveries should never be left sitting on the loading dock. Implement the First-In, First-Out (FIFO) system to ensure older stock is used before newer stock, which cuts down on waste and spoilage. Use clear labeling with delivery and use-by dates.

- Temperature Logging: If you’re using manual logs, specify who is responsible for checks and at what times (e.g., at the start of each shift and before closing). If it’s automated, outline the protocol for responding to alerts.

- Cleaning and Maintenance: Schedule regular cleaning for all refrigeration units to ensure proper airflow and efficiency. Also, create a calendar for preventative maintenance on compressors and seals to avoid unexpected breakdowns.

By strengthening each of these three pillars—equipment, monitoring, and procedures—you build a resilient and effective system. This comprehensive approach is the key to mastering what cold chain management really is and protecting your business from the massive costs of failure.

Why Digital Monitoring Is Now Essential

Let's play out two scenarios. In the first, a line cook, slammed during the dinner rush, scribbles a temperature reading on a clipboard tacked to the walk-in cooler door. He's in a hurry, the reading is a few minutes late, and he’s just hoping the old compressor doesn't decide to give up the ghost overnight. We've all been there.

Now, picture this: it’s 2 AM. Your phone buzzes with an alert. A tiny sensor has detected your freezer door is slightly ajar. You call your manager, they pop over and fix it, and you've just saved thousands of dollars in prime cuts and specialty ingredients. This isn’t some far-off futuristic idea anymore; it's the new standard for keeping your cold chain locked down.

Digital monitoring has quickly moved from a "nice-to-have" luxury to an absolutely essential tool for managing risk and making your operation more efficient. Think of it as your 24/7 guardian, watching over your most valuable assets when nobody else is around.

From Reactive Guesswork To Proactive Control

The old way of doing things—relying only on manual checks—is riddled with holes. A temperature log is only as trustworthy as the last person who filled it out, and it only captures a single snapshot in time. What happens in the hours between those checks is a complete mystery.

Automated systems, powered by what are known as Internet of Things (IoT) sensors, completely eliminate that guesswork. These small, often wireless devices are placed inside your refrigerators and freezers to continuously track temperature, humidity, and even whether a door is open or closed. They give you a constant stream of data, painting a full picture of your equipment's health.

This shift provides an ironclad data trail for health inspections, drastically reduces the potential for costly human error, and frees up your team to focus on serving customers instead of logging temperatures every few hours.

This proactive approach means you’re not just recording history; you’re getting ahead of disasters before they happen.

The Clear ROI Of Automated Monitoring

Investing in this technology isn't just another expense—it's one of the smartest financial moves a modern restaurant operator can make. The return on investment becomes crystal clear when you think about the staggering cost of a single failure. One busted compressor can wipe out thousands of dollars in inventory overnight.

Let's break down the difference between the old way and the new way.

Manual vs Automated Temperature Monitoring

The move from pen-and-paper logs to real-time digital alerts is a game-changer for any kitchen. It’s the difference between hoping for the best and knowing for sure. Here’s a side-by-side look at how the two methods stack up.

| Feature | Manual Monitoring (The Old Way) | Automated Monitoring (The New Way) |

|---|---|---|

| Data Accuracy | Prone to human error, missed entries, and "pencil-whipping." | Highly accurate, consistent, and recorded automatically. |

| Response Time | Reactive. A problem is often discovered hours later, after spoilage has already begun. | Proactive. Instant alerts are sent to your phone or computer the moment an issue arises. |

| Labor Efficiency | Requires staff members to stop their work multiple times a day to perform checks. | Completely passive, freeing up your team's valuable time for revenue-generating tasks. |

| Compliance | Creates paper-based records that can be lost, incomplete, or difficult to manage for health inspections. | Generates a perfect, time-stamped digital log that makes compliance effortless and verifiable. |

| Peace of Mind | Relies on hope that everything is running smoothly after hours. | Provides absolute certainty that your inventory is protected around the clock. |

As you can see, automated systems offer a massive upgrade in reliability and efficiency, turning a tedious chore into a powerful safety net for your business.

The core technology behind these systems isn't brand new; it's similar to what powers massive logistics fleets. If you're curious about the mechanics, you can check out this ultimate guide to vehicle GPS trackers to see how real-time tracking and sensor data work in another industry.

Smart Systems And The Future Of Kitchens

The market for these solutions is blowing up for a simple reason: they work. The cloud‑based cold chain management market was valued at USD 9.12 billion and is projected to skyrocket to nearly USD 28.9 billion by 2029. That explosive growth is all thanks to the technology's proven ability to slash spoilage and waste.

But today's systems do more than just send alerts when things go wrong. They analyze trends, helping you spot if a compressor is slowly failing or if a unit struggles to hold its temp during the dinner rush. This predictive insight lets you schedule maintenance before a catastrophic failure occurs, turning a potential emergency into a routine repair.

This means maintaining the ideal walk-in cooler temperature becomes an automated, data-driven process. For any foodservice business, putting digital monitoring in place is a direct investment in stability, safety, and your bottom line.

Identifying and Fixing Common Failure Points

Even the most buttoned-up cold chain has weak links. It only takes a single moment of distraction or an overlooked piece of equipment for a link to snap, leading straight to spoiled inventory, wasted cash, and serious food safety risks. The real trick isn't just reacting to disasters; it's about spotting these vulnerabilities ahead of time and shoring them up before they fail.

Think of it like inspecting a bridge. You don't wait for it to collapse to check for a few loose bolts. You actively look for the stress points and fix them. In your kitchen, these failure points are often hiding in plain sight, tucked away in your daily routines and equipment.

This proactive mindset is the difference between acing a health inspection and scrambling to explain a cooler full of ruined product. It’s all about building resilience right into your operations.

The Loading Dock Danger Zone

One of the most frequent breaks in the chain happens the second a delivery truck pulls up. Pallets of chilled or frozen goods get unloaded, and if that inventory sits on a warm loading dock for just 20 minutes while your crew is tied up, the temperature abuse has already started. This is often the first—and most critical—failure.

The fix? Treat every delivery like a well-drilled pit stop. Your team needs a clear, repeatable process that gets those temperature-sensitive products from the truck to the cooler in minutes, not hours.

Actionable Solution: A Simple Receiving Checklist

- Schedule Smart: Try to arrange deliveries for off-peak hours when your staff can give them their full, undivided attention.

- Inspect Immediately: Use a calibrated probe thermometer to spot-check product temperatures before you sign off. Don't hesitate to reject any delivery that falls outside the safe zone.

- Prioritize Unloading: Always, always move refrigerated and frozen items into storage first. The dry goods can wait.

The Slow Creep of Equipment Failure

Your refrigeration equipment is a true workhorse, running 24/7. But compressors, fans, and door seals don't last forever. A slow coolant leak or a tiny crack in a door gasket can gradually raise internal temperatures over weeks, silently compromising food safety until it’s way too late. This "slow creep" is a sneaky and costly point of failure.

Waiting for a total breakdown is just asking for trouble. Preventative maintenance is your absolute best defense here, turning a potential emergency into a manageable, planned expense.

A single overnight freezer failure can easily wipe out $5,000 to $10,000 in high-value inventory. The cost of a quarterly maintenance check is a tiny fraction of that potential loss, making it one of the highest-ROI activities in any kitchen.

Actionable Solution: A Preventative Maintenance Calendar

- Schedule Regular Inspections: Set calendar reminders for quarterly professional servicing of all your major refrigeration units.

- Create Daily Staff Checks: Task your team with simple daily checks, like listening for weird noises, checking for ice buildup, and making sure door seals are tight and clean.

- Keep a Log: Maintain a maintenance log for each piece of equipment. This helps you track performance over time and gives technicians valuable data to work with.

Human Error and The Overloaded Cooler

Your team is your greatest asset, but they can also be an unintentional source of failure. Simple mistakes—like propping a cooler door open during a rush or overloading a refrigerator—can have massive consequences. When you over-stuff a reach-in or walk-in, you block critical airflow, creating warm spots where bacteria can thrive, even if the unit's thermostat reads perfectly fine.

This isn't about placing blame; it's about smarter training and creating a better environment. To prevent these kinds of disruptions, a solid grasp of supply chain risk management strategies is crucial for spotting and heading off potential failures caused by human error.

Actionable Solution: Visual Guides and Consistent Training

- Use Visual Aids: Post simple, clear diagrams inside your refrigeration units showing proper stacking techniques. Remind staff to leave space for airflow between items and away from the walls.

- Train, Then Re-Train: Make cold chain protocols a non-negotiable part of onboarding. Follow up with brief refresher sessions every few months to keep best practices top of mind.

- FIFO Focus: Really hammer home the "First-In, First-Out" (FIFO) principle. Proper stock rotation not only cuts down on spoilage but also prevents the kind of overcrowding that causes airflow problems in the first place.

By systematically identifying and fixing these common weak spots—at receiving, with your equipment, and through your team—you transform your cold chain from a fragile system into a resilient one. This proactive troubleshooting is what cold chain management is really all about: a continuous process of control and improvement.

Navigating Food Safety and Compliance Rules

Keeping that cold chain intact isn’t just a good idea—it’s the law. A single violation can lead to hefty fines, a damaged reputation, or even having to close your doors for good. But here's the thing: compliance doesn't have to be some intimidating, complicated beast. Once you get the hang of a few core principles, you can turn complex regulations into simple, actionable habits for your team.

Think of food safety rules as the official rulebook for that relay race we talked about earlier. They're there to make sure every handoff is clean, every step is safe, and the final product is perfect for your customer. Mastering these rules not only protects the public but also acts as your best defense when a health inspector walks in.

Understanding The Temperature Danger Zone

The single most important rule in cold chain management is avoiding the Temperature Danger Zone. This is the temperature range between 40°F and 140°F (4°C and 60°C) where nasty bacteria like Salmonella and E. coli can go wild, sometimes doubling in number in just 20 minutes.

Every minute a perishable food item spends in this zone, its safety and quality start to nose-dive. The entire goal of your cold chain is to keep food either chilled below 40°F or, once you start cooking, heated above 140°F. This one concept is the bedrock of nearly all food safety compliance.

The Role of HACCP in Your Kitchen

To make sure kitchens follow this rule, health authorities use a system called HACCP (Hazard Analysis and Critical Control Points). It sounds super technical, but it’s really just a straightforward, preventative way to handle food safety. Instead of waiting for a problem to pop up, HACCP helps you pinpoint potential hazards in your workflow and set up control points to stop them before they start.

A perfect example is when you get a dairy delivery. The "hazard" is that the milk could show up at an unsafe temperature. Your "control" is having a team member use a probe thermometer to check the milk’s temp before you even think about accepting it. Our guide on what is HACCP food safety takes a much deeper dive into building a full plan for your operation.

A well-documented HACCP plan is more than just a piece of paper you have to fill out; it's your proof of due diligence. It shows an inspector you have a proactive system in place to protect your customers, which makes any inspection feel less like a test and more like a collaborative process.

Documentation Is Your Best Defense

When a health inspector stops by, the first thing they'll want to see is your records. Consistent, accurate documentation is the hard evidence that proves your cold chain is working exactly as it should. This includes things like:

- Temperature Logs: Daily records for every single refrigeration unit.

- Receiving Checklists: Proof that you inspect incoming goods for proper temperatures.

- Maintenance Records: A log showing when your equipment was serviced and repaired.

Not too long ago, this meant wrestling with binders full of paper logs that were easy to lose, damage, or fill out incorrectly. Thankfully, modern digital systems make record-keeping almost effortless. Automated monitoring tools can generate perfect, time-stamped logs that you can pull up on a tablet in seconds, providing an undeniable record of compliance. This shift is happening everywhere. As the global cold chain grows, so does the focus on solid regulatory standards. In the Asia-Pacific region, for instance, China's cold chain demand is already around 365 million tonnes, a huge number that signals a worldwide move toward verifiable safety protocols. By connecting your daily tasks to these legal requirements, you ensure your restaurant is always prepared, compliant, and—most importantly—safe.

Your Cold Chain Management Action Plan

Alright, theory is great, but turning that knowledge into action is what really protects your inventory and your profits. A solid cold chain isn't something you build overnight, but you can absolutely start laying the foundation today with a clear, step-by-step approach. This plan boils everything down into a straightforward checklist to get you moving.

Think of this as the blueprint for taking full control of your restaurant's temperature-sensitive ingredients. It's all about shifting from ideas to real, daily practices that protect your products, your customers, and your bottom line. Every step you take strengthens another link in the chain.

Audit and Assess Your Current Setup

Before you can improve, you have to know where you stand. A thorough audit is like turning the lights on—it shows you exactly where your biggest risks are and, just as importantly, what you're already doing right.

- Map Your Process: Seriously, trace the journey of an ingredient from the moment it hits your delivery dock to the final plate. Note every handoff, every storage point, and look for those little moments where delays or temperature exposure could creep in.

- Inspect Equipment Performance: Go beyond just glancing at the thermostat. Get hands-on. Check the door seals on your coolers for any cracks, listen for weird compressor noises, and look for a lot of ice buildup, which can be a red flag for a bigger problem.

- Review Staff Practices: Watch your team during a busy receiving window and throughout a service. Are they actually following FIFO (First-In, First-Out)? Are cooler doors being left open while people grab things? These simple observations will tell you exactly where your training needs to be focused.

Great cold chain management is not an expense; it is a direct investment in your business's safety, quality, and long-term profitability. Protecting your inventory is protecting your bottom line.

Develop and Implement Clear Standards

Once your audit gives you the lay of the land, the next step is to make your processes official. This isn't about creating a bunch of complicated rules; it's about ensuring everyone on your team is on the same page and accountable for keeping the chain strong.

- Create Simple Standard Operating Procedures (SOPs): Write down clear, bite-sized rules for receiving, storing, and handling all your perishable goods. Use checklists and maybe even some visual aids to make them super easy for a busy team to follow.

- Investigate Monitoring Technology: Look into automated temperature monitoring systems that fit your budget. Even a basic system is a massive upgrade from manual logs, giving you 24/7 protection and a whole lot of peace of mind.

- Establish a Review Cycle: Put it on the calendar. Schedule a quick monthly check-in to review your temperature logs and procedures. This regular habit helps you catch small issues before they blow up into costly failures and ensures your standards don't start to slip over time.

Frequently Asked Questions

Even with a solid plan, questions always come up when you start putting cold chain principles into practice. Here are some quick, clear answers to the things we hear most often from restaurant operators.

What Is The First Step To Improving My Restaurant's Cold Chain?

The best way to start is with a simple audit. Seriously, just take one full week and observe your current process with a critical eye.

Watch where that pallet of produce sits after a delivery before it makes it into the walk-in. Note how often the temperature logs are actually being filled out. Listen for any weird noises coming from your reach-in. This observation phase is powerful because it shows you your most immediate weaknesses without any guesswork, helping you prioritize what to fix first.

How Do I Get Staff To Take Temperature Logs Seriously?

This is a big one. To get real buy-in, you have to connect the task directly to the outcome. Explain that those logs aren't just "busy work"—they are your first line of defense against foodborne illness and the official proof you need for a health inspector. When they get the stakes, the task feels important.

Make the process dead simple with clear, accessible log sheets or an easy-to-use digital tool. Most importantly, lead by example. If your team sees you reviewing the logs and asking questions, they'll understand that you value the data.

The key is framing it as a shared responsibility. It's not about checking a box; it's about everyone upholding a standard of safety and quality that protects the business and its customers.

Is An Automated Monitoring System Worth It For A Small Business?

For most small businesses, the answer is a resounding yes. Take a second and just roughly calculate the total dollar value of the inventory in your main refrigerator or freezer right now. A single equipment failure overnight could easily wipe out thousands of dollars in product.

Think of an automated system as a 24/7 insurance policy against that kind of catastrophic loss. There are plenty of affordable subscription services now that send real-time alerts straight to your phone. The monthly cost is almost always far less than what you'd lose in a single major spoilage event, not to mention the damage to your hard-earned reputation. It’s a proactive investment in security.

Ready to fortify your cold chain with reliable, commercial-grade equipment? At The Restaurant Warehouse, we offer everything from walk-in coolers to refrigerated prep tables, all backed by expert support and flexible financing. Explore our full selection and secure your inventory today.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment