What Is HACCP Food Safety and How Does It Work

So, at its core, what is HACCP food safety? It’s a systematic, science-based way of thinking that helps you stop foodborne illness before it ever has a chance to start. Think of HACCP not as a rigid rulebook, but more like a GPS for your kitchen—it helps you see potential dangers on the road ahead and steer clear of them before they become a real problem.

A Proactive Approach to Keeping Food Safe

HACCP, which stands for Hazard Analysis and Critical Control Point, completely changed the game for the food industry. Before it came along, food safety was mostly a reactive process. You'd inspect the final product and just hope for the best. That old-school method was like checking a car for damage after a crash has already happened.

HACCP, on the other hand, is all about prevention. It asks you to meticulously map out your entire food production journey, from the moment ingredients arrive at your back door to the second a dish is served.

Along that journey, you pinpoint the specific spots where hazards—whether biological, chemical, or physical—could pop up. These are your "Critical Control Points." By focusing your control and monitoring on these key steps, you stop problems from ever taking root.

The system was actually developed back in the 1960s for NASA to ensure the food for astronauts was 100% safe on space missions. If it was reliable enough for space travel, its value for kitchens back on Earth became crystal clear.

This fundamental shift from reaction to prevention has made a huge difference. Since its introduction in the United States, HACCP has been credited with helping reduce foodborne illnesses by around 20% in just seven years.

While it’s recognized globally, its adoption isn't universal. For example, despite rapid growth in meat production, fewer than 10% of China's meat facilities were certified as of recent data, highlighting the ongoing need for broader implementation. You can learn more about HACCP's international standards and impact.

HACCP vs Traditional Food Safety A Comparison

To really get what HACCP is all about, it helps to see how it stacks up against the older, less effective methods. The biggest difference is simple: it’s proactive and preventative, not reactive and inspection-based.

| Aspect | Traditional Food Safety (Reactive) | HACCP System (Proactive) |

|---|---|---|

| Focus | Inspecting the final product for defects or contamination. | Analyzing the entire process to prevent hazards from occurring. |

| Timing | Corrective action is taken after a problem is found. | Controls are implemented during production to stop problems. |

| Method | Relies on spot-checks and random sampling of products. | Uses continuous monitoring of specific Critical Control Points. |

| Responsibility | Often seen as the sole job of quality control inspectors. | Involves everyone in the food handling process, from chefs to managers. |

As you can see, the HACCP system integrates safety into every step, making it a shared responsibility and a much more reliable way to protect both your customers and your business.

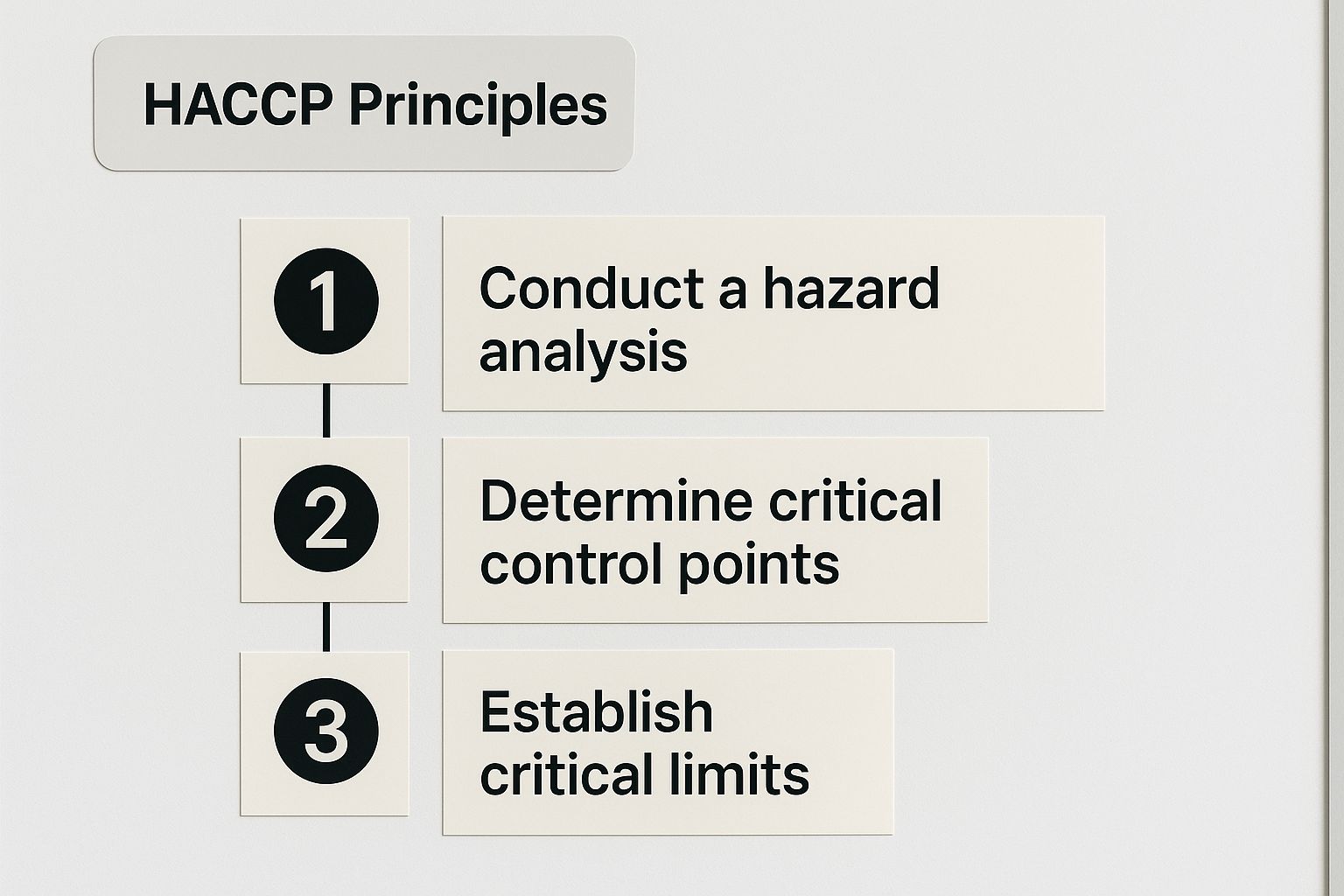

The Seven Principles That Power HACCP

A solid food safety plan isn’t built on guesswork. It’s a logical, step-by-step process, and the HACCP system gives us the framework. It’s powered by seven core principles that work together to create a powerful, preventative system. Think of them not as rigid rules, but as a roadmap for your food safety journey.

This visual guide breaks down the logical flow of the seven HACCP principles, showing how each step builds upon the last one.

As you can see, understanding HACCP is all about following a structured sequence, starting with identifying potential dangers and ending with rock-solid documentation. Let's walk through each of these essential steps.

Principle 1: Conduct a Hazard Analysis

This is the foundation of your entire plan. Before you can control any dangers, you have to know what they are. This first step is all about playing detective in your own kitchen.

You'll need to systematically review every single step in your food's journey—from the moment ingredients arrive to when a dish is served—and identify any potential biological, chemical, or physical hazards.

- Biological Hazards: These are the living organisms you worry about, like bacteria (think Salmonella on raw chicken) or viruses.

- Chemical Hazards: This category includes things like cleaning solution residue on a food prep surface or even undeclared allergens.

- Physical Hazards: These are foreign objects that have no business being in food, such as a piece of glass, a metal shaving, or a plastic fragment.

The goal here is to create a complete list of every realistic danger that could compromise food safety at each stage of your operation.

Principle 2: Identify Critical Control Points

Okay, you’ve mapped out all the potential hazards. Now what? You can't possibly control everything, everywhere, all the time. Instead, you focus your efforts where they matter most. This is where Critical Control Points (CCPs) come in.

A CCP is a specific point in the process where you can apply a control to prevent, eliminate, or reduce a food safety hazard to an acceptable level. It’s a genuine make-or-break moment.

For example, simply receiving a delivery of raw chicken isn't a CCP for eliminating bacteria. However, the cooking step absolutely is. This is the precise point where you can apply a control (heat) to kill the pathogen.

Think of it like this: If a hazard slips past a regular control point, you might still catch it later. But if a hazard gets past a Critical Control Point, there’s no turning back—the food is likely unsafe.

Principle 3: Establish Critical Limits

Identifying your CCPs is great, but how do you know if your control measure is actually working? That's what critical limits are for. For each CCP, you must establish a clear, measurable boundary that separates safe from unsafe.

These limits aren't vague guidelines; they are specific, science-backed numbers. They give your team a clear target to hit every single time.

Examples of Critical Limits:

- Cooking chicken to a minimum internal temperature of 165°F (74°C) for at least 15 seconds.

- Rapidly cooling a large batch of soup from 135°F (57°C) down to 70°F (21°C) within 2 hours.

- Holding cold food in a walk-in cooler at or below 41°F (5°C).

These precise numbers remove all ambiguity and give your staff an unmistakable pass/fail test for food safety.

Principle 4: Establish Monitoring Procedures

You've set your critical limits, but a plan on paper doesn't guarantee safety in the real world. The fourth principle requires you to create a system for actively monitoring your CCPs to ensure those limits are consistently met.

Monitoring is the scheduled observation or measurement of a CCP. It answers a few key questions:

- What will be measured? (e.g., temperature, time)

- How will it be measured? (e.g., with a calibrated food thermometer)

- Who is responsible for the measurement? (e.g., the line cook on duty)

- When will it be measured? (e.g., for every single batch of chicken)

This creates a system of accountability and provides the real-time data you need to confirm that your process is under control.

Principle 5: Establish Corrective Actions

Even with the best plans, things go wrong. A cook gets distracted, an oven's temperature drops, or a cooler door is left slightly ajar. When your monitoring shows that a critical limit has been missed, you need a pre-determined plan of action.

These corrective actions are the steps you take immediately to regain control and deal with any food that may have been affected. For instance, if a batch of chicken only reaches an internal temp of 155°F, the corrective action is clear: continue cooking it until it hits the critical limit of 165°F.

Having these actions defined in advance prevents panic and ensures a swift, effective response every time.

Principle 6: Establish Verification Procedures

How do you know your HACCP plan is actually working as intended over the long haul? That’s where verification comes in. This principle involves activities—other than your regular monitoring—that confirm the validity of your plan and ensure the system is operating correctly.

Think of it as the "trust, but verify" step. It’s about double-checking the system itself.

Verification Activities Can Include:

- Routinely calibrating thermometers and other monitoring equipment to ensure they're accurate.

- Reviewing monitoring logs and corrective action records to spot any troubling trends.

- Observing staff to make sure they are following procedures correctly.

- Occasionally sending product samples to a lab for microbiological testing.

Verification confirms that your plan is not only scientifically sound but is also being executed effectively day in and day out.

Principle 7: Establish Record-Keeping Procedures

The final principle ties everything together. In the world of food safety, if you don't document it, it didn't happen. Meticulous record-keeping is absolutely essential for a successful HACCP system.

Your records provide the proof that you are following your plan and maintaining control over food safety. This documentation is crucial during health inspections and is invaluable for troubleshooting if a problem ever pops up.

Key records to maintain include:

- Your written hazard analysis.

- Your complete HACCP plan, detailing CCPs, critical limits, and corrective actions.

- All logs from your monitoring activities (like temperature logs).

- Records of every corrective action taken.

- Documentation of your verification activities (like thermometer calibration logs).

These seven principles form a continuous loop of analysis, control, and improvement, creating a dynamic and effective system for keeping your food safe.

How to Conduct a Thorough Hazard Analysis

A rock-solid HACCP plan starts with knowing exactly what you’re up against. The very first principle—and the bedrock of the entire system—is conducting a thorough hazard analysis. It’s time to put on your food safety detective hat and meticulously examine every single corner of your operation to uncover potential dangers before they can ever cause harm.

This isn’t about guesswork or just looking for the obvious. It's a systematic evaluation of your entire process, from the moment an ingredient arrives on the delivery truck to the second it lands on a customer's plate. At every single step, you have to ask yourself one critical question: "What could possibly go wrong here?"

The Three Categories of Food Safety Hazards

To keep your investigation organized, it helps to break down all the potential dangers into three distinct categories. Thinking this way ensures you cover all the bases and don’t accidentally overlook a critical risk. Every hazard you identify will fit neatly into one of these groups.

-

Biological Hazards: These are the living organisms that can make people sick. We’re talking about bacteria like Salmonella and E. coli, viruses like Norovirus, and even parasites. These are, by far, the most common culprits behind foodborne illness.

-

Chemical Hazards: This group covers any harmful substance that can contaminate food. This could be anything from a splash of cleaning solution landing on a prep surface to pesticide residues on fresh produce, or even naturally occurring toxins in certain types of fish.

-

Physical Hazards: These are the foreign objects that have no business being in food. Think of a tiny piece of broken glass from a jar, a metal shaving from a can opener, or a sharp fragment of hard plastic from a cracked container.

By methodically working through these three categories at each stage of production, you can build a comprehensive list of every reasonably likely hazard.

A common mistake is only focusing on the obvious, like cooking temperatures. A true hazard analysis goes deeper, considering everything from the ice machine (biological) to the storage of sanitation chemicals (chemical) and the condition of your light fixtures (physical).

Mapping the Flow of Food

To pull this off effectively, you need a clear map of your process. Start by creating a simple flowchart that details every single step an ingredient takes once it enters your facility. Let’s use a grilled chicken sandwich as an example.

- Receiving: Raw chicken arrives from your supplier.

- Storing: It’s immediately placed in the walk-in cooler.

- Prepping: The chicken is unboxed, seasoned, and placed on a cutting board.

- Cooking: The chicken breast is grilled to the correct internal temperature.

- Holding: Cooked chicken is kept in a hot-holding unit until needed.

- Assembling: It’s placed on a bun with fresh lettuce and tomato.

- Serving: The finished sandwich is plated and delivered to the customer.

For each of these seven steps, you’d hunt for potential biological, chemical, and physical hazards. For instance, at the "Prepping" stage, a major biological hazard is cross-contamination from the raw chicken to the cutting board, while a physical hazard could be a piece of plastic from the original packaging.

This detailed, step-by-step approach is the foundation of your entire HACCP system. The global adoption of HACCP has led to incredible improvements in food safety, with some countries reporting up to a 50% drop in specific foodborne illness outbreaks. By zeroing in on critical steps like proper cooking and cooling, the system has dramatically reduced the spread of dangerous pathogens.

While we're focused on food-specific hazards here, the core idea of identifying, analyzing, and evaluating risks is universal. For a broader look at general risk assessment principles, you can explore resources that cover the topic more widely. This foundational analysis perfectly sets the stage for the next principle: identifying your Critical Control Points.

Finding and Managing Your Critical Control Points

After mapping out the hazards in your kitchen, you have a solid grasp of the potential dangers. But you can't watch everything all at once. The real genius of a HACCP plan is that it helps you focus your efforts where they'll have the biggest impact. This brings us to the next crucial step: identifying your Critical Control Points (CCPs).

A CCP is a make-or-break moment in your food prep process. It's a specific step where you have the power to control a hazard—to prevent it, eliminate it, or reduce it to a safe level. Think of it as your last line of defense. If a hazard gets past a CCP, there's often no way to fix it later.

Pinpointing Your Make-or-Break Moments

So, how do you separate a regular control point from a truly critical one? A simple "decision tree" mindset helps a lot. For each hazard you've identified, at every step of the process, just ask yourself: Is this the definitive point where I can control this specific hazard?

Let's use a classic example: cooking raw chicken.

- Hazard: Salmonella bacteria (a biological hazard).

- Step: Cooking the chicken breast on the grill.

- Question: Can this single step eliminate the hazard?

The answer here is a firm yes. Cooking chicken to the right internal temperature is the one moment you can effectively kill off harmful bacteria. That makes the cooking step a Critical Control Point for Salmonella. Seasoning the chicken, on the other hand, isn't a CCP for this hazard because it does nothing to get rid of the bacteria.

From CCPs to Critical Limits

Once you've zeroed in on a CCP, you need to define exactly what "safe" looks like in concrete, measurable terms. This is where you set Critical Limits. These are the specific, science-backed values that draw a clear line between safe food and potentially dangerous food. Vague goals like "cook thoroughly" just don't cut it.

Critical limits have to be clear and measurable. For our chicken example, the critical limit isn't just "hot." It's a minimum internal temperature of 165°F (74°C) for at least 15 seconds.

Establishing a precise critical limit transforms a general safety goal into an actionable, pass/fail test for your team. It removes all guesswork and ensures consistency.

Another vital CCP is cold holding. Keeping potentially hazardous foods at the right temperature is what stops bacteria from growing in the first place. For instance, maintaining the proper walk-in cooler temperature is non-negotiable for safety, with a critical limit typically set at 41°F (5°C) or below.

Monitoring and Taking Corrective Action

A plan is just paper until you put it into action. You need a system to make sure these critical limits are met every single time. This involves two more connected steps: creating monitoring procedures and defining your corrective actions.

-

Monitoring Procedures: This is the what, how, who, and when of your safety checks. What are you measuring (temperature)? How will you measure it (with a calibrated thermometer)? Who is responsible (the line cook)? And how often will they check (every single batch)?

-

Corrective Actions: This is your "what if" plan. What happens when a critical limit is missed? A pre-planned corrective action prevents panic and ensures a fast, safe response. If the chicken only temps at 160°F, the corrective action is simple: keep cooking it until it hits 165°F.

These interconnected steps are the engine of your daily food safety management. They turn abstract principles into concrete tasks your team can follow to actively keep risks in check.

Here’s a quick look at how these elements come together in a practical monitoring log.

Example CCP Monitoring Log For Cooked Chicken Breast

This table shows what a simple but effective monitoring log might look like for two common CCPs in a restaurant kitchen. It clearly outlines the hazard, the non-negotiable limits, and the exact steps to take for both monitoring and correction.

| CCP | Hazard | Critical Limit | Monitoring Procedure | Corrective Action |

|---|---|---|---|---|

| Cooking Chicken | Salmonella | Min. 165°F for 15 sec | Check internal temp of each breast with a calibrated thermometer. | Continue cooking until 165°F is reached. Discard if overcooked. |

| Cold Holding | Bacterial Growth | Hold at/below 41°F | Check cooler temp with a calibrated thermometer every 4 hours. | If temp is above 41°F, investigate cause. Move food to a working cooler. |

By documenting these points, you create a clear, repeatable process that empowers your team to maintain the highest safety standards consistently.

Putting Your HACCP Plan Into Action

A HACCP plan is a powerful roadmap, but it only starts making your kitchen safer when you bring it to life. This is where the theory hits the floor every single day. The final two principles—Verification and Record-Keeping—are what turn your plan from a document in a binder into a living, breathing system that actively protects your customers and your business. It’s all about building a culture of food safety that’s just part of how you operate.

Think of verification as the "trust, but verify" step for your entire process. It’s how you double-check that the system you’ve so carefully put together is actually working the way you intended. This isn't the same as your daily temperature checks; it's a higher-level review to make sure the whole plan is still sound.

Confirming Your System Works

Verification involves stepping back to look at the bigger picture and ensure your safety measures are truly effective. It’s the scheduled, periodic confirmation that your controls, limits, and procedures haven’t gone off track.

A few key verification activities include:

- Regular Equipment Calibration: You have to know your tools are accurate. This means making sure thermometers, scales, and other monitoring equipment are giving you the right readings. An off-kilter thermometer can throw your entire plan into chaos.

- Reviewing Records and Logs: Take a look at your monitoring logs and corrective action reports. Are you seeing the same problems pop up over and over? This is how you spot systemic issues before they become critical failures.

- Observing Staff Practices: Watch your team in action. Are they following the procedures correctly? Do they understand why they're doing it? This confirms that your training is sticking.

This process ensures your HACCP plan remains a reliable tool, not just a piece of paper filed away in an office.

The Power of Meticulous Record-Keeping

In the world of food safety, the golden rule is simple: if you didn’t write it down, it didn’t happen. That’s the core of the seventh and final HACCP principle. Consistent, accurate records are your ultimate proof that you’re diligently following your plan.

These records are so much more than a chore you have to do for compliance. They become your best tool for troubleshooting when something goes wrong and your primary evidence during a health inspection. A well-organized set of records shows a real, tangible commitment to keeping food safe.

Your documentation—from temperature logs to corrective action reports—tells the story of your food safety journey. It proves you are not just hoping for safety, but actively managing it every single day.

Effective record-keeping goes hand-in-hand with great kitchen hygiene. For a deeper look at keeping your whole environment spotless, our comprehensive restaurant kitchen cleaning checklist offers an excellent framework for those crucial daily and weekly tasks.

Building a Team-Driven Food Safety Culture

At the end of the day, a HACCP plan is only as strong as the people carrying it out. It takes a dedicated team and a culture where every single employee feels a sense of ownership over food safety. This all starts with solid training and clear communication from the top down.

The proof is in the results. When small and medium food businesses properly implement a HACCP system, the change is remarkable. They see huge improvements in hygiene, staff training, and compliance. This shift often comes with an over 80% improvement in management leadership and a stronger food safety culture overall. In fact, attitudes toward food security in these regions have seen a significant jump, rising from 53.1% to 78.1%. By making HACCP a shared responsibility, you make your entire operation safer and more resilient.

Common Questions About HACCP Answered

Even with the seven principles laid out, turning a HACCP plan from a document into a smooth, day-to-day reality in your kitchen can bring up some questions. It’s totally normal to wonder about the nitty-gritty details, from the initial cost to how it all fits in with your regular health inspections.

Let’s tackle some of the most common queries and clear up any confusion. My goal is to give you straightforward, practical answers so you can move forward with confidence.

Is HACCP Legally Required for My Business?

This is easily one of the first questions people ask, and the answer is: it depends on what you do and where you are. In the United States, HACCP is a federal mandate from the FDA for juice and seafood processors. The USDA also requires it for all meat and poultry plants.

Now, for most restaurants and other foodservice spots, a full, formal HACCP plan isn't always a legal requirement under local health codes. However—and this is a big however—most modern food safety regulations are built directly on HACCP principles. Your health inspector fully expects to see that you have active managerial control over food safety risks, which is exactly what a HACCP system helps you prove.

Think of it this way: Even if your local code doesn't use the word "HACCP," following its principles is the industry's gold standard. It's the most effective way to meet (and exceed) food safety standards and show everyone you're serious about protecting your guests.

How Much Does It Cost to Implement HACCP?

The cost can swing pretty widely depending on the size and complexity of your operation. A small café with a simple menu is going to have a much more straightforward plan—and fewer Critical Control Points—than a massive catering company juggling hundreds of different dishes.

The main costs usually fall into a few buckets:

- Training: Getting your team up to speed on the principles and what their specific roles are. This is non-negotiable.

- Equipment: You might need to invest in some new tools, like properly calibrated digital thermometers or better systems for logging data.

- Time: Honestly, this is often the biggest investment. It takes real time from you and your key staff to do the hazard analysis, build the plan, and keep up with the records.

But here’s the thing: the cost of not having a strong system is always far, far greater. A single foodborne illness outbreak can trigger lawsuits, massive fines, and do irreparable damage to your reputation. The upfront investment in HACCP is one of the smartest business decisions you can make.

Is HACCP the Same as a Health Inspection?

Nope, they're two different things, but they're very closely related. A health inspection is a snapshot in time. It’s an external audit by a health official to check your compliance with the local food code on one particular day.

A HACCP plan, on the other hand, is your own internal system for managing food safety 24/7. It's the proactive game plan you use every single day to stop problems before they can even start. A solid, well-documented HACCP plan makes passing health inspections much, much easier because you're already controlling the most critical risks an inspector is trained to look for.

What Is the Hardest Part of Implementing HACCP?

For a lot of operators, the toughest parts are the initial setup and then the ongoing commitment to record-keeping. That first step, conducting a thorough hazard analysis (Principle 1), requires some deep thinking and can feel a bit overwhelming at first.

After that, the next hurdle is maintaining consistent, accurate records (Principle 7). This takes real discipline from the entire team, day in and day out. It's where great training becomes absolutely essential. Proper instruction ensures everyone understands not just what they need to do, but why it's so critical for keeping food safe. For more on this, our guide on commercial kitchen equipment training offers key strategies to make those important lessons stick. When you build good habits from the start, documentation becomes a seamless part of your daily routine instead of a chore.

At The Restaurant Warehouse, we know that equipping your kitchen for success means more than just having the right hardware. It's about building safe, efficient systems. From high-quality refrigeration to maintain your critical limits to durable stainless steel tables for hygienic prep, we provide the tools you need to put your HACCP plan into action. Explore our extensive catalog of commercial kitchen equipment and supplies at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment