Commercial Kitchen Equipment Training: Your Ultimate Guide

Proper commercial kitchen equipment training is the critical investment that protects your staff, your customers, and your bottom line. It's the difference between a smoothly running kitchen and one plagued by costly breakdowns, inconsistent food quality, and dangerous safety hazards.

Why Smart Equipment Training Is a Game Changer

Let's be honest, viewing training as just another expense is a shortsighted mistake many restaurant owners make. In reality, it's the engine that powers a safe, efficient, and profitable kitchen.

Skimping on this crucial step directly leads to problems that can cripple an operation. When staff don't understand the nuances of a high-powered convection oven or a complex combi-steamer, the results are predictable and expensive.

Imagine a new line cook who hasn't been properly shown how to clean the fryer. They might use the wrong chemicals, damaging the unit, or fail to follow the correct procedure, creating a serious fire risk. Both outcomes lead to equipment downtime and repair bills that far exceed the cost of a 30-minute training session. This isn't just theory; it's a daily reality in under-trained kitchens.

The True Cost of Inadequate Training

The financial drain of poor training goes beyond simple repair invoices. It silently chips away at your profitability in multiple ways:

- Inconsistent Food Quality: An employee who doesn't know the proper settings on a charbroiler will produce inconsistent results, leading to customer complaints and wasted ingredients.

- Increased Food Waste: Improper cooking techniques, temperature mismanagement, and incorrect storage due to lack of equipment knowledge directly contribute to higher food costs.

- Higher Employee Turnover: Staff who feel unequipped and unsupported are more likely to become frustrated and leave. Investing in their skills shows you value their contribution, boosting morale and retention.

- Safety and Compliance Risks: Failure to train staff on safety protocols can result in serious injuries and costly violations.

This isn't just about a single piece of equipment. You can find detailed breakdowns in a comprehensive commercial kitchen equipment guide, which shows how each appliance, from refrigerators to griddles, has its own set of best practices for safety and efficiency.

The following table breaks down how investing in a solid training program delivers real, measurable business outcomes.

The Business Impact of Comprehensive Equipment Training

| Training Benefit | Operational Impact | Business Outcome |

|---|---|---|

| Correct Equipment Use | Reduced user-error breakdowns and consistent cooking results. | Lower repair bills, less equipment downtime, and fewer customer complaints. |

| Enhanced Safety Knowledge | Fewer workplace accidents and a safer kitchen environment. | Reduced liability, lower workers' compensation claims, and improved staff morale. |

| Improved Cleaning Protocols | Longer equipment lifespan and better hygiene. | Maximized return on investment (ROI) for equipment and higher health inspection scores. |

| Boosted Staff Confidence | Increased employee engagement and reduced turnover. | Lower hiring and onboarding costs, and a more experienced, efficient team. |

| Efficient Operation | Optimized energy and utility consumption. | Reduced monthly overhead and a more profitable, sustainable operation. |

As you can see, the benefits ripple across the entire operation, turning what seems like an expense into a powerful driver of profitability and stability.

More Than a Manual, It's a Mindset

Effective commercial kitchen equipment training transforms how your team interacts with their tools. It shifts their perspective from simply "using" a machine to truly understanding its capabilities and limitations.

A well-trained chef knows how to coax the best performance out of a temperamental piece of equipment, turning a potential liability into a reliable asset.

A seasoned kitchen manager once shared, "I can tell within five minutes of watching a new hire if they've had real training. It's in the way they respect the machine—the pre-checks, the cleaning, the shutdown. That respect saves me thousands a year in what I call 'stupid repairs.'"

The industry itself is constantly advancing. The commercial kitchen equipment market, valued at around $13.7 billion in 2023, is projected to grow significantly as smart technology and automation become standard. This evolution makes continuous, high-quality training more important than ever to keep up.

Ultimately, framing training as a strategic advantage is key. It's not a chore to be completed but a core operational pillar that protects your most valuable assets: your people, your reputation, and your equipment. It's the foundation upon which a truly excellent culinary program is built.

Building Your Foundational Training Framework

Let's be honest, designing a training program from the ground up can feel like a massive task. But it doesn't have to be. A strong foundation isn't about complexity; it’s about practicality. The real goal is to build a clear, repeatable system that gives your staff genuine competence, ensuring everyone operates with the same high standards you expect.

Forget trying to teach them everything at once. The first move is to figure out which pieces of equipment are the true workhorses of your kitchen. Which machines are humming along all day? Which ones pose the biggest safety risk or have the most influence on food quality? This isn't just about the expensive, shiny stuff—it's about what is truly central to your daily grind.

Identifying Mission-Critical Equipment

Start by making a simple list of every major appliance in your kitchen. Then, you'll want to rank them. This little exercise forces you to focus your energy where it will have the most immediate and meaningful impact on your commercial kitchen equipment training.

To figure out your priorities, consider these factors for each machine:

- Frequency of Use: How often is this piece of equipment actually used during a typical shift?

- Impact on Quality: How much does this machine dictate the final product's consistency and quality?

- Safety Risk: What's the potential for injury if this is misused?

- Cost of Error: What’s the price tag—in repairs or food waste—if someone operates it incorrectly?

A busy pizzeria, for instance, would put its deck oven and dough mixer right at the top of that list. A high-volume café? Their espresso machine and high-speed panini press are non-negotiable priorities. This simple activity immediately tells you where to start.

Defining Clear and Actionable Learning Goals

Once you have your priority list, you need to define what "trained" actually looks like for each piece of equipment. Vague goals like "learn the oven" are totally useless in a real kitchen. Instead, you need to create specific, observable outcomes that a manager can look at and say, "Yes, they can do that."

A great learning goal is always an action. For a combi oven, the training isn't one monolithic task but a series of smaller, digestible skills.

The most effective training programs break down complex operations into simple, verifiable steps. A new hire isn't trained on the 'combi oven'; they are trained on how to properly preheat it, how to run a steam cycle for vegetables, and how to execute the nightly cleaning procedure.

This approach makes training far less intimidating for new staff and gives managers a straightforward checklist to follow. For that combi oven, a basic skills checklist might look something like this:

Combi Oven Skills Checklist

- Startup & Preheating: Can the employee power on the unit and correctly set it to a specific temperature and mode?

- Core Cooking Functions: Can they successfully run a convection-only cycle and a combination steam/convection cycle?

- Basic Cleaning: Does the employee know how to safely use the spray hose and initiate the correct cleaning cycle?

- Shutdown Procedure: Can they power down the unit safely according to the manufacturer's guidelines?

This simple, task-based structure is the backbone of an effective framework. It's easy for everyone to understand, simple to track, and tied directly to the real-world needs of your kitchen.

Building a Flexible Curriculum for All Skill Levels

Here’s a crucial point: your training framework has to work for two very different people. You've got the brand-new hire who has never laid eyes on a commercial fryer, and you've got the veteran line cook who just needs a quick refresher on a new feature. A one-size-fits-all program will fail both of them.

The solution is to make your foundational plan modular. Create a core curriculum that covers the absolute must-knows for a new employee's specific role. This ensures they can start contributing safely and effectively without feeling buried under an avalanche of information.

For your experienced crew, training shifts to a focus on continuous improvement. This could mean short, targeted sessions on things like:

- Advanced features of an existing machine they rarely use.

- New energy-saving techniques for the griddle.

- Updated cleaning protocols based on a new health code advisory.

This layered approach respects the knowledge your veterans already have while giving new hires the scaffolding they need to succeed. The key is to see commercial kitchen equipment training not as a one-time event, but as an ongoing process. To build a truly robust learning environment, it helps to understand general staff training best practices which can seriously elevate your entire framework. This broader knowledge ensures your equipment-specific training is built on solid educational ground.

Getting Your Hands Dirty: Mastering Practical Equipment Training

Let's be honest. Reading a manual is one thing; wrestling with a new combi oven during a chaotic dinner rush is something else entirely. This is where theory gets thrown out the window and real competence is built. The most effective commercial kitchen equipment training gets your team’s hands on the actual machines they’ll be using every single day.

Forget just handing someone a binder and hoping for the best. The most powerful learning happens by doing. Studies on how we retain information have shown, time and again, that active participation blows passive methods like reading or listening out of the water. In a kitchen, that means supervised, hands-on experience is non-negotiable.

The Power of "See One, Do One, Teach One"

One of the most powerful training models I've ever used is borrowed from the world of medical education: "See One, Do One, Teach One." It’s a beautifully simple framework for building genuine confidence and a deep understanding of the equipment. It breaks the process into three logical steps that are a perfect fit for a kitchen.

-

See One: First, the trainee just watches. An experienced mentor performs a task correctly, from start to finish. This isn't a rushed, 30-second demo. The mentor needs to explain the why behind each action—why the fryer is set to exactly 350°F, why a specific chemical is used for cleaning, or why the shutdown sequence has to be followed in that exact order.

-

Do One: Now, it's the trainee's turn. Under the watchful eye of the mentor, they perform the same task. This is the crucial practice stage. The mentor provides real-time feedback, corrects small mistakes before they become bad habits, and answers questions as they pop up. This is how you build muscle memory.

-

Teach One: This is the final and, in my opinion, most important step. The trainee has to explain and demonstrate the process back to the mentor or another team member. This step forces them to organize their thoughts and truly own the knowledge. If you can teach it, you really know it.

This method transforms new hires from passive observers into active, engaged participants, dramatically improving skill retention and ensuring procedures are followed precisely every time.

A seasoned executive chef I know put it perfectly: "I never consider someone fully trained on a piece of equipment until they can confidently and accurately teach the basics to a new hire. It's the ultimate test of their own competence and my best tool for creating a culture of shared responsibility."

Simulating Real-World Scenarios

Your training shouldn't just happen when the kitchen is quiet. To truly test your team’s skills, you need to simulate the pressure of a real service. This is your chance to spot weaknesses in a controlled setting before they turn into full-blown disasters during a live rush.

A great way to do this is to run a "mock rush" during a pre-service meeting. Fire off a series of orders that require the team to use multiple pieces of key equipment in quick succession. This doesn't just test their individual skills; it tests their ability to communicate and move around each other in tight spaces.

Proactive Troubleshooting Drills

Equipment will fail. It’s an unavoidable part of running a kitchen. The only question is whether your team will panic or handle it with poise. The answer lies in proactive troubleshooting drills, which are far more memorable than a boring list of error codes.

Intentionally create small, controlled, and completely safe issues for your staff to solve. For example:

- Unplug a low-temp dishwasher and see if the team can diagnose the "power issue" before calling for service.

- Set a slicer to a slightly incorrect thickness to see if they notice the inconsistent product.

- Use a known-bad extension cord (clearly marked for training purposes) to trip a circuit breaker.

These mini-challenges build critical thinking and empower your staff to perform basic diagnostics. This can prevent costly service calls for simple fixes like a tripped breaker or a loose connection. This hands-on approach should also include getting them familiar with a comprehensive kitchen equipment maintenance checklist to promote longevity and safety.

Ultimately, this turns reactive panic into proactive problem-solving, saving you time, money, and a whole lot of stress when it matters most.

You don't have to build your training program from scratch. In fact, some of the most effective programs I've seen are the ones that smartly blend in-house coaching with modern tools and a little outside help. Doing this can save you a ton of time and give your team access to top-notch, industry-approved practices.

You probably have powerful training tools in your pocket right now. One of the simplest yet most effective tricks I’ve seen is the humble QR code. Imagine this: you stick a small, laminated QR code on your combi oven or walk-in cooler. When a new cook needs to know the daily cleaning steps, they just scan it with their phone. Instantly, they’re watching the manufacturer's 5-minute tutorial or looking at a PDF of the quick-start guide.

This simple step provides immediate answers right where they're needed, empowering your staff to solve minor problems without having to track down a busy manager.

Weaving Together Digital and Physical Training

This blend of a physical prompt (the QR code) and a digital resource makes training an ongoing, accessible part of the workday. No more digging through a cluttered binder in the office to find a manual. Your team gets the official information they need, right now. This is a game-changer for new hires who might be shy about asking questions and a great quick refresher for veteran staff tackling a task they don't do every day.

Here are a few practical ways to weave technology into your hands-on training:

- Curate Video Libraries: Most big equipment brands have YouTube channels packed with detailed videos on operation, cleaning, and basic upkeep. Create a simple playlist for the models in your kitchen and make watching them a standard part of onboarding.

- Go Digital with Checklists: Use a simple app or a shared document to create interactive checklists for opening, closing, and deep-cleaning procedures. Staff can check off tasks on a tablet, giving managers a live look at what's been done.

- Tap into Your Suppliers: Don't overlook your food and chemical suppliers. They often provide free training on best practices for things like produce storage or the safe use of cleaning agents—both critical for proper equipment care.

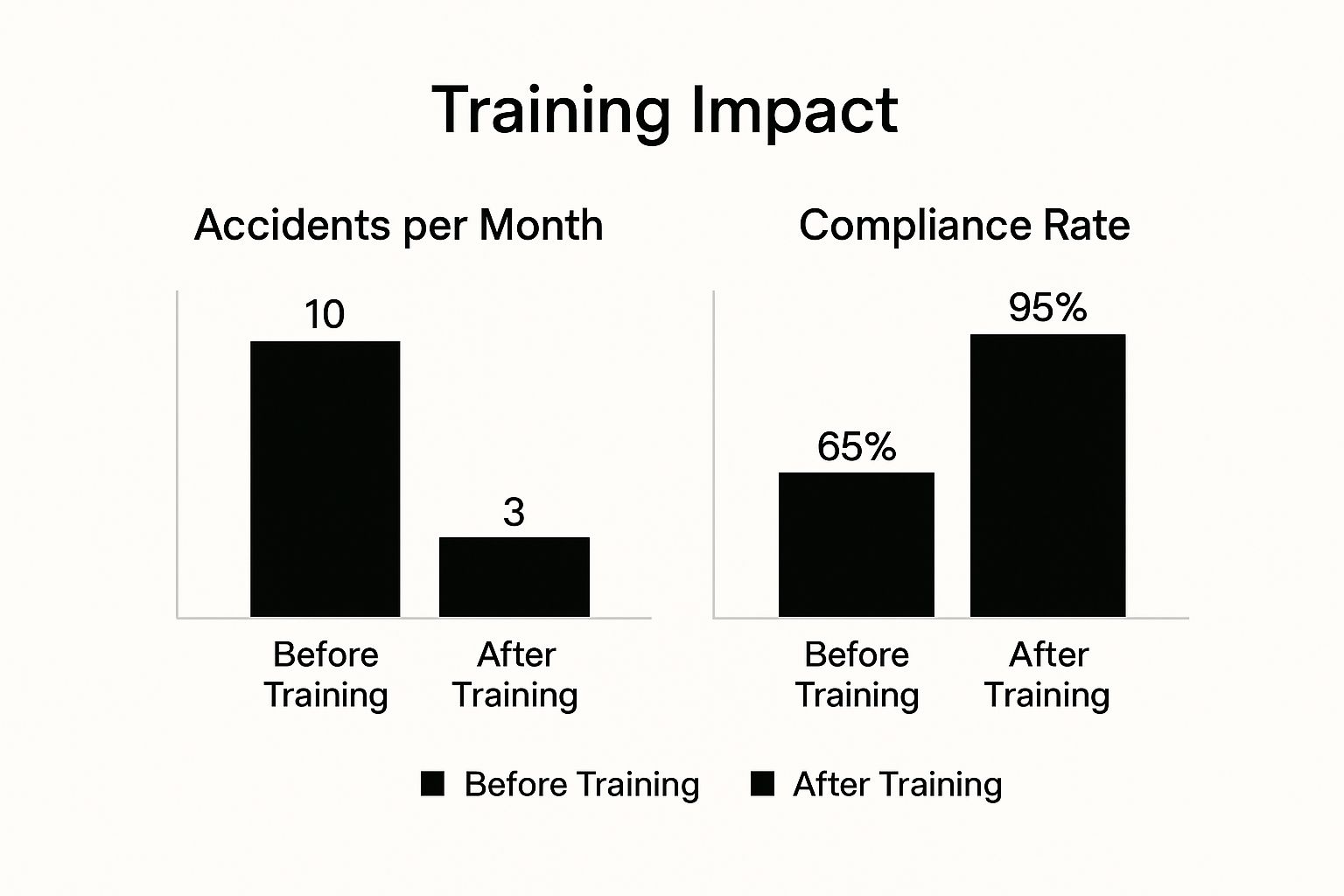

The data backs this up. A structured training program can have a huge impact on safety and compliance. Using a mix of your own coaching and these outside resources can help you get these tangible results even faster.

As you can see, a focused training plan doesn't just check a box—it dramatically improves how safely and effectively your team operates.

Knowing When to Call in the Pros

While your day-to-day training is essential, sometimes the smartest move is to bring in an expert. For highly complex or specialized equipment, investing in professional training can prevent incredibly expensive mistakes and add years to the life of your machinery.

One of the best resources out there is the Certified Food Equipment Service Association (CFESA). They offer rigorous certification programs that are the gold standard for servicing all kinds of kitchen tech. While your team probably doesn't need to get certified, just knowing this level of expertise exists highlights how important specialized knowledge can be.

Bringing in a manufacturer-certified technician to train your key kitchen leaders on a new, high-tech oven is an investment, not an expense. That expert knowledge then trickles down through your team, creating a higher standard of operation for everyone.

This is especially true when you're buying new gear. Always try to negotiate a training session into the purchase price—it’s a huge win. Likewise, if you're trying to figure out the best way to acquire that new equipment, it pays to understand all your options. For anyone weighing how to handle those big upfront costs, our guide to restaurant equipment leasing offers some great insights into more flexible financing.

Internal vs. External Training Resources

Deciding whether to develop your training materials in-house or look for outside help is a key strategic choice. Each path has its own set of benefits and drawbacks. An internal approach gives you complete control over the content, ensuring it's perfectly aligned with your kitchen's unique procedures. However, it can be time-consuming to create from scratch. On the other hand, leveraging external resources like manufacturer videos or certified trainers can provide expert-level knowledge and save you time, but might not feel as personalized.

This table breaks down the pros and cons to help you decide on the best mix for your restaurant.

| Training Resource | Pros | Cons | Best For |

|---|---|---|---|

| Internal (In-House) | - Fully customized to your specific kitchen and workflow. - Builds a culture of internal expertise and mentorship. - Cost-effective if you have knowledgeable senior staff. |

- Time-consuming to create materials from scratch. - May lack the polished quality of professional resources. - Can perpetuate bad habits if not carefully managed. |

- Reinforcing your restaurant’s unique operational standards. - Onboarding new hires into your specific culture. - Daily and weekly procedure refreshers. |

| External (Providers/Tech) | - Access to expert-level, industry-vetted information. - Saves significant time on content creation. - High-quality videos and digital tools can improve engagement. |

- Can be more expensive (e.g., hiring a trainer). - May be too generic and not specific to your setup. - Less control over the content and delivery. |

- Complex or high-tech equipment training. - Introducing new safety or compliance standards. - Supplementing in-house knowledge with expert-led tutorials. |

Ultimately, the most successful training programs aren't purely internal or external—they're a hybrid. By thoughtfully combining your own hands-on coaching with the wealth of knowledge available from manufacturers, suppliers, and certified experts, you create a powerful and resilient commercial kitchen equipment training program. This blended strategy ensures your team isn't just competent, but truly confident and up-to-date.

Measuring Success and Driving Continuous Improvement

A training program is only as good as the results it delivers. Simply running your staff through the motions isn't enough; you need to know if the commercial kitchen equipment training is actually making a tangible difference in your day-to-day operations. This means moving beyond "training complete" checkboxes and focusing on measurable outcomes that directly impact your bottom line.

Measuring success isn't about pointing fingers. It's about figuring out what’s working, what isn’t, and where you can make smart, targeted improvements. The goal is to create a living, breathing training program that evolves right alongside your team, your menu, and your equipment.

Looking Beyond Simple Checklists

To truly gauge how effective your training is, you have to connect it to the key performance indicators (KPIs) in your kitchen. These are the hard numbers that tell the real story about your operational health. The trick is to establish a baseline before you roll out a new training program, then track these metrics over time to see the impact.

Your most valuable data points will almost always tie back to cost control and efficiency. For example, a well-trained team should make fewer user errors, which naturally leads to more reliable equipment performance.

Key metrics to keep an eye on include:

- Maintenance and Repair Costs: Start tracking the frequency and cost of service calls. A noticeable drop is a strong signal that your staff is using and cleaning the equipment correctly.

- Food Waste Percentages: When cooks truly master their equipment, they produce more consistent results. That means fewer re-fires and less product spoilage.

- Safety Incident Reports: This one is critical. A reduction in cuts, burns, or slips related to equipment use is a direct and immediate win for your training program.

- Utility Bills: Proper use, like shutting down fryers correctly or using a convection oven’s energy-saving mode, can lead to measurable decreases in your energy consumption.

By tracking these numbers, you transform the idea of training from a "soft skill" into a hard, financial benefit. It gives you concrete data to justify the time and resources you invest.

Gathering Honest Feedback from Your Team

Hard data tells one part of the story, but the other, equally important part comes from your staff. They’re on the floor every single day, and they know what’s practical and what’s just not working. Creating a safe and easy way for them to share their thoughts is absolutely essential for making your program better.

Anonymous surveys are a fantastic tool for this. Ask direct questions that get to the heart of their experience.

The most insightful feedback often comes from asking simple, open-ended questions like, "What is one thing about the fryer training that is still confusing?" or "Which piece of equipment do you feel least confident using?" This pinpoints specific knowledge gaps you can address immediately.

Regular, informal check-ins are also incredibly powerful. During a pre-shift huddle, just ask if anyone has run into any equipment issues or has a new tip to share. This helps build a culture where knowledge is shared freely and problems get solved as a team. This approach to measurement is a universal principle; when you're evaluating the success of corporate training programs, gathering both data and human feedback is key, no matter the industry.

Creating a Cycle of Refinement

The final, most important step is to actually use all this data and feedback to make your program better. Measurement without action is pointless. I recommend setting up a regular review cycle—maybe quarterly—to sit down and really dig into what you've found.

Based on your review, you might decide to:

- Develop a targeted micro-training session on the specific slicer that your repair logs show is breaking down frequently.

- Update your cleaning checklists to be clearer after staff feedback indicated a certain step was confusing. To make sure your lists are thorough, you can reference a detailed restaurant equipment checklist as a guide.

- Invest in professional training for that new, complex combi oven that multiple team members still feel shaky about using.

This iterative process ensures your commercial kitchen equipment training never gets stale. It remains a relevant, effective tool that supports your team, protects your expensive assets, and drives operational excellence every single day.

Frequently Asked Training Questions

Even with the best-laid plans, questions always come up. That’s just part of running a busy kitchen. Getting clear, straightforward answers to common training concerns can make all the difference, helping you move forward with confidence. Here are the questions we hear most often from restaurant managers, along with some practical, real-world advice.

How Often Should We Conduct Refresher Training?

As a good rule of thumb, shooting for semi-annual refresher sessions on your major equipment is a smart move. It’s enough to keep best practices fresh in everyone's mind and stop that slow drift away from standard procedures that inevitably happens over time.

But this isn't a hard-and-fast rule. Some situations demand immediate attention.

You should always schedule a training session when:

- A new piece of equipment rolls into your kitchen.

- The manufacturer releases an updated user guide or a new safety bulletin.

- You have a safety incident or even just a near-miss. That's a clear signal something needs to be reinforced.

For your really complex machines, like a combi oven or a high-tech blast chiller, try this: hold short, quarterly huddles. Focus on just one feature each time, like a specific cooking mode or a deep cleaning cycle. It’s an incredibly effective way to build deep, lasting expertise without overwhelming your team.

What Is the Biggest Mistake in Training New Hires?

The single biggest mistake we see? Throwing too much at them all at once. A new line cook’s first week is absolutely not the time to teach them the ins and outs of every single appliance. This fire-hose approach just leads to anxiety, terrible information retention, and a much higher risk of accidents.

Instead, zero in on the one or two pieces of equipment they'll use most in their specific role. For a prep cook, that’s probably the food processor and the vacuum sealer. Let them get comfortable and confident on those tools first.

Once a new team member builds confidence on their primary equipment, they become much more receptive to learning additional skills. This phased approach turns training from a stressful ordeal into an empowering process of gradual skill-building.

Are Digital Training Tools Actually Effective?

Yes, but there’s a critical catch: they work best as part of a blended approach, not as a standalone fix. Digital tools like videos, e-learning modules from companies like Schoox, or even simple QR codes linked to tutorials are fantastic for delivering standardized information efficiently.

They’re great at explaining the "what" and the "why." A manufacturer’s video, for instance, can perfectly lay out the technical reasons for a specific cleaning procedure.

But they can't replace the need for supervised, hands-on practice. The "how" is learned by doing, with an experienced mentor right there to offer immediate feedback and correct mistakes. The most successful commercial kitchen equipment training programs weave together digital resources for consistency with in-person coaching for true competence.

How Can I Measure the ROI of My Training Program?

Tracking the return on your training investment comes down to monitoring key operational numbers before and after you roll out your program. You’re looking for tangible improvements in areas directly tied to cost and efficiency.

Here are the key metrics to watch:

- A reduction in equipment repair costs: Fewer user errors mean fewer service calls. It’s that simple.

- Lower food waste percentages: Better cooking technique leads to fewer mistakes and less product in the trash.

- A decrease in workplace accidents: Proper training is your best defense against safety incidents and worker's comp claims.

- Faster ticket times and improved output: A confident, well-trained team is an efficient team.

When you track these numbers, you can draw a straight line from your investment in training to a healthier bottom line. It proves the value of your program beyond any doubt.

Equipping your kitchen is a major investment, and at The Restaurant Warehouse, we believe in protecting that investment with smart operational practices. From high-performance Atosa ovens to reliable True refrigeration, we provide the durable equipment and flexible financing you need to build a successful kitchen from the ground up. Explore our extensive catalog and see how we can help you at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment