What is nsf certification? A Clear Guide to Its Standards and Benefits

Think of NSF certification as a trusted seal of approval. It’s a clear signal to everyone—from the health inspector who walks through your door to the customers enjoying a meal—that your kitchen equipment is safe, built to last, and easy to keep clean. It's a tough, independent safety check for everything from your ice machine to your cutting boards, guaranteeing they meet some seriously strict public health standards.

Understanding NSF Certification in Your Kitchen

When you spot that small, circular blue NSF mark on a piece of gear, know that it’s much more than just a sticker. That seal means the product has been through a demanding evaluation by NSF International, an independent and globally respected public health organization. The whole point of this process is to make sure the item is designed and built in a way that champions food safety.

This has real-world consequences for your daily grind. The certification process digs into several critical parts of equipment design and performance, including:

- Material Safety: It confirms that the materials used won't leach any harmful chemicals into the food you’re prepping.

- Design and Construction: The product has to be a breeze to clean, with no tiny cracks or crevices where bacteria could throw a party.

- Performance: The equipment must do what it says it will do, like a refrigerator that consistently holds a safe temperature without fail.

A Mark of Trust and Safety

The NSF certification program is a formal third-party verification system that kicked off way back in 1944. It has since grown into a global benchmark used across the food, water, and health science industries. By 2024, NSF International was certifying products for clients in over 150 countries, cementing its role as a trusted authority that regulators all over the world rely on.

For restaurant owners, this mark simplifies one of the toughest parts of running a kitchen: making sure every single component helps create a safe environment instead of working against it. It’s a clear sign of your commitment to doing things the right way.

Why It Matters for Kitchen Equipment

Choosing certified equipment is a foundational step in building a kitchen that’s both compliant and efficient. When you're outfitting your commercial kitchen, it’s crucial to pick products that meet these tough public health standards. For instance, bringing in durable NSF Certified shelving solutions ensures even your storage areas meet these high marks.

Ultimately, getting what NSF certification is all about helps you make smarter buying decisions. These are the choices that protect your business, make health inspections smoother, and build lasting trust with every customer who walks through your door. For a deeper dive, you might want to check out our guide on NSF sanitation certification.

Decoding Key NSF Standards for Foodservice Equipment

So, you see that little blue NSF logo on a piece of equipment and think, "Great, it's safe." You're right, but there's a bit more to the story. Think of "NSF Certified" as the main title of a book. The specific standards are the individual chapters, and each one tells a detailed story about safety for a particular type of equipment.

Getting a handle on these specific codes is what separates the pros from the rookies. It's how the broad goal of public health gets translated into real-world, concrete rules for the gear you rely on every single day. These standards aren't dreamed up in a vacuum; they're built through teamwork between public health officials, industry experts, and operators like you, making sure they're strict but also practical for a fast-paced kitchen.

The Most Common Standards You'll Encounter

For anyone running a restaurant, a few key standards will pop up over and over again. Each one is designed to tackle the unique risks that come with different kitchen jobs, from keeping things cold to cooking them safely. Learning this language is learning the language of food safety compliance.

Here’s a quick rundown of the big ones you'll see in the foodservice world:

To make it even clearer, here's a simple table breaking down the most common NSF/ANSI standards you'll run into.

Common NSF/ANSI Standards in Commercial Kitchens

| Standard | Purpose and Focus | Examples of Certified Equipment |

|---|---|---|

| NSF/ANSI 2 Food Equipment | The foundation for most gear. Focuses on safe materials and a design that's smooth, easy to clean, and free of crevices where bacteria can hide. | Prep tables, cutting boards, mixers, slicers, carts |

| NSF/ANSI 7 Refrigerators | All about temperature control. Ensures a unit can hold food safely at or below 41°F, even in a hot, busy kitchen environment. | Reach-in refrigerators, walk-in coolers, prep tables |

| NSF/ANSI 4 Cooking Equipment | Applies to heating equipment. Certifies that the gear is built for cleanability and can cook or reheat food safely without contamination. | Ovens, ranges, griddles, fryers, steam kettles |

| NSF/ANSI 51 Materials | Zooms in on the materials themselves. Confirms that things like plastics and metals that touch food won't leach harmful chemicals. | Gaskets, tubing, plastic food containers, coatings |

Knowing these standards helps you make smarter, safer choices for every corner of your kitchen.

Here's why getting familiar with them is so important:

-

NSF/ANSI 2 Food Equipment: This is a big one. It's the foundational standard that covers the basic design and construction of almost all food equipment, from your stainless-steel prep tables to your meat slicers. It’s all about making sure materials are non-toxic and that every surface is smooth, easy to clean, and free of those tiny gaps where bacteria love to multiply. To dive deeper, check out our comprehensive guide to NSF/ANSI Standard 2.

-

NSF/ANSI 7 Commercial Refrigerators and Freezers: This standard is your best friend when it comes to temperature control. It certifies that a fridge or freezer can consistently maintain safe cold-holding temperatures (at or below 41°F for refrigerators) even when it's sweltering in your kitchen. This is your number one defense against food spoilage and bacterial growth.

-

NSF/ANSI 4 Commercial Cooking and Rethermalization Equipment: This one applies to all your hot-side gear like ovens, ranges, and fryers. It makes sure they're built to be cleaned easily and can do their job safely and effectively, without introducing any contaminants to the food.

-

NSF/ANSI 51 Food Equipment Materials: This standard gets down to the microscopic level. It zeroes in on the actual materials—the plastics, stainless steel, and other bits and pieces—that come into contact with food. It’s the final word confirming that these components are safe and won’t leach anything harmful into your ingredients.

Why This Specificity Matters

The level of detail in these standards directly impacts your kitchen's safety and how smoothly it runs. For instance, a cutting board certified under NSF/ANSI 2 is specifically designed to not have microscopic pores that can trap food particles and bacteria, a huge problem with cheap, non-certified boards.

A refrigerator that meets NSF/ANSI 7 has been put through the wringer. It's proven it can get back down to a safe temperature quickly even after the door has been swung open a hundred times during a chaotic dinner rush. That’s not just a cool feature; it's a critical food safety function that keeps food out of the "danger zone."

Wondering how to check if a product is legit? The NSF has a public database where you can look up any company or product to verify its certification.

You can search by keyword, the standard number itself, or the company name, making it super easy to confirm that the equipment you're about to buy has actually passed these tough tests. By understanding these key standards, you stop just buying equipment and start making strategic investments in the long-term health and reputation of your restaurant.

The Journey to Earning the NSF Mark

Getting that little blue NSF mark on a piece of equipment isn’t as simple as just filling out a form and cutting a check. It's a demanding, multi-stage journey that puts a product—and its manufacturer—under a serious microscope. Think of it less like a one-time event and more like a long-term commitment to public health, with ongoing oversight to make sure standards never, ever slip. The whole process is intentionally tough to protect the trust that comes with the NSF seal.

It all kicks off with a super detailed application, where the manufacturer has to hand over a mountain of documents. We’re talking about everything from product formulas and material specs to design schematics and how the equipment is meant to be used. It's the first step in a totally transparent process where every single component is laid bare for inspection.

From Application to Laboratory Testing

Once the application gets the green light, the real evaluation begins. NSF experts dive deep into a product review, checking it against the specific requirements of the relevant NSF/ANSI standard. They're on the lookout for any potential weak spots in the design—anything from hard-to-clean corners to materials that could pose a chemical risk down the line. This isn't just a paperwork check; it's a thorough examination of the product's very construction.

After that, the product heads to the lab for some serious hands-on testing. Here, scientists put the materials through rigorous analysis to confirm they are completely safe for food contact and won't leach any harmful substances. For equipment like a refrigerator, this stage also involves performance tests to make sure it can hold safe temperatures, even under the stress of a real-world kitchen rush.

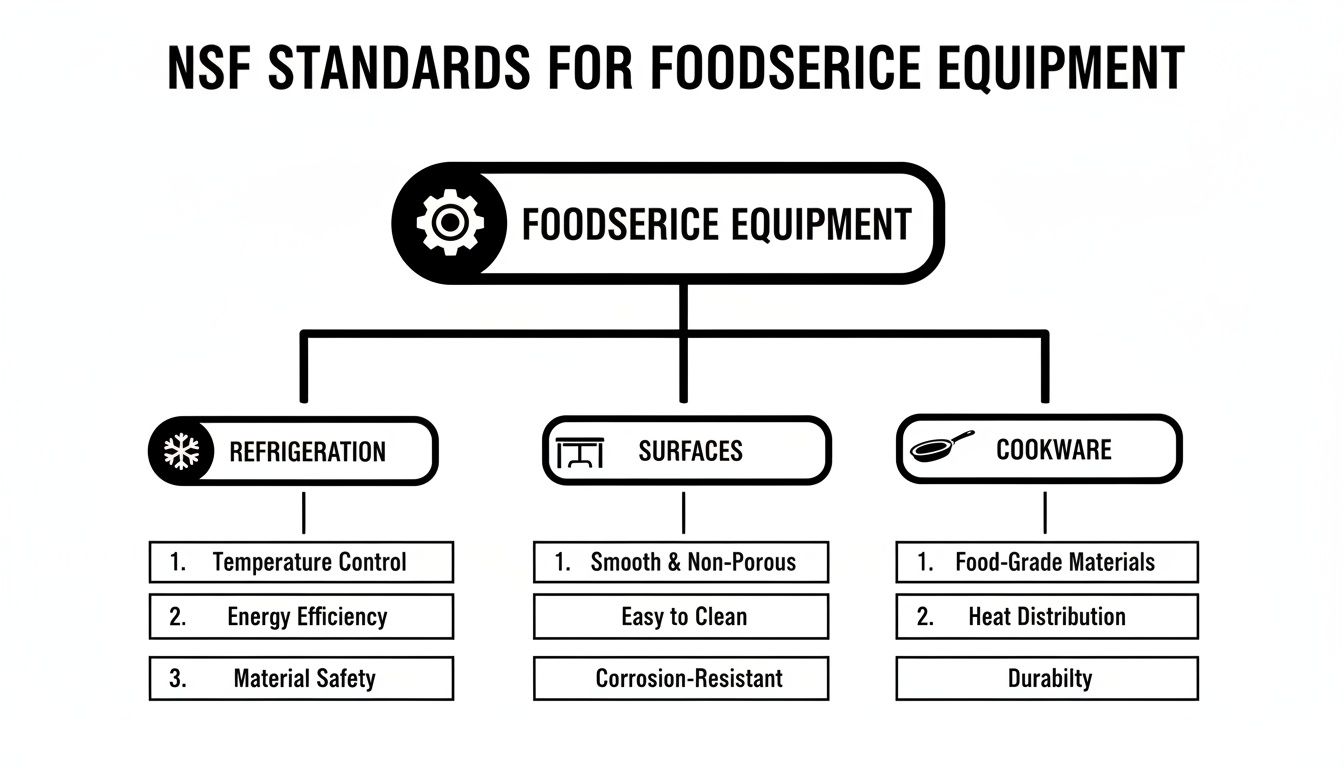

This diagram breaks down the main categories of foodservice equipment that go through this kind of strict evaluation.

As you can see, different standards apply to different types of equipment, making sure that the unique safety challenges of refrigeration, food surfaces, and cookware are all properly addressed.

The Unannounced Annual Inspection

Passing the initial tests is just getting through the front door. To actually keep the certification, a manufacturer has to agree to unannounced annual inspections of their production facilities. This is a critical piece of the puzzle. An NSF auditor can show up at any time to make sure the product rolling off the line today is the exact same one that was originally tested and certified.

This element of surprise is what gives the program its credibility. It guarantees that manufacturers are holding up their end of the bargain day in and day out, not just when they know an inspector is coming.

During these audits, the inspector will:

- Review quality control records and procedures.

- Confirm that only approved materials are being used.

- Pull products right off the line for re-testing if they see anything concerning.

This constant vigilance ensures that the NSF mark you see on a product today represents the same level of safety and quality as it did on day one. It’s this complete, cyclical process—from the initial review to the continuous monitoring—that has made the NSF certification the gold standard in kitchens all over the world.

Why NSF Certified Equipment Is a Smart Investment

Choosing equipment with that little blue NSF mark is so much more than just another line item on your budget. Think of it as a strategic business decision—one that pays you back long after you’ve swiped the card. Yes, compliance is a big part of it, but the real value is how this certification protects your brand, makes your operations run smoother, and ensures you’re buying gear that’s actually built to survive in a commercial kitchen.

It’s really all about getting ahead of risk. Take a certified meat slicer, for example. It's designed with fewer seams and parts that are easy to take off and clean. That’s not just for convenience. It’s a critical design choice that makes it incredibly simple to clean thoroughly, drastically cutting down the risk of cross-contamination. That simple feature is safeguarding both your customers and the reputation you've worked so hard to build.

Protect Your Customers and Reputation

The absolute foundation of any good restaurant is trust. Your customers trust that the food you serve isn't just delicious, but also completely safe to eat. NSF certification is your tangible proof that you’re committed to earning that trust every single day. It shows you've put your money into equipment that has been independently tested and proven to prevent foodborne illness, right down to the materials it's made from and its easy-to-clean design.

This isn't just about feeling good, either; it has a real commercial impact. The global demand for food certification is booming as everyone from retailers to regulators insists on seeing verifiable safety credentials. In fact, some analyses project the market to nearly double in a decade, which tells you that certified status is becoming a non-negotiable for market access and customer confidence.

Think of the NSF mark as a silent partner in your kitchen, working 24/7 to uphold your food safety standards. It’s a clear, visible promise to your customers that their well-being is your top priority.

Streamline Inspections and Ensure Longevity

Few things get a restaurant owner’s heart racing like an unexpected visit from the health inspector. But when that inspector walks in and sees a kitchen full of NSF-certified equipment, it immediately sets a positive tone. They recognize that mark as a shortcut to compliance, knowing the gear is already designed to meet public health codes. This can lead to much smoother, faster inspections with fewer interruptions to your service.

On top of that, NSF-certified equipment is just built tougher. The standards often require more durable materials and a more robust construction than what you’d find in non-certified alternatives. This means your investment is not only safer but will likely last a lot longer, lowering your total cost of ownership over the years. Making smart choices for your kitchen always comes back to health and safety, which is why understanding the importance of the best cookware for health and safe cooking is so crucial. When you choose certified products, you’re investing in durability, efficiency, and some much-needed peace of mind.

How to Verify Genuine NSF Certification

When you're shopping for new equipment, you'll come across a lot of official-looking claims. But be wary of phrases like “NSF compliant” or “built to NSF standards.” These are major red flags. More often than not, they’re used by manufacturers who haven’t actually put their products through the rigorous, independent testing required for a genuine NSF certification.

A true NSF seal is a guarantee, not a suggestion. An uncertified piece of equipment hasn't been put through the wringer by NSF International, which means you have zero proof it meets the critical benchmarks for public health and safety. Protecting your restaurant, your customers, and your investment means knowing how to spot the real deal.

Confirming a Product’s Official Listing

Verifying an NSF mark is surprisingly straightforward, and it's an essential step. Don't just take a salesperson's word for it—check it yourself directly from the source.

The easiest and most reliable method is to use the NSF Certified Products and Systems database. This free online tool is the ultimate source of truth, and it's available to everyone. Here’s how to use it:

- Find the Product Info: Grab the manufacturer’s name, brand, or the specific model number of the equipment you’re looking at.

- Go to the NSF Database: Navigate to the official NSF listings search page.

- Enter the Details: Type the information into the search bar. You can look up a company, a product category, or even the specific NSF standard number.

- Check the Results: If the product is genuinely certified, it will pop up in the search results with a detailed listing. This page confirms its certification is active and tells you exactly which standard it meets.

This simple check takes just a couple of minutes but gives you complete peace of mind. If a product isn't in that database, it isn't NSF certified—period. This step ensures you're buying legitimate, safe equipment for your kitchen.

Beyond the database, it's always a good idea to physically inspect the equipment. Look for the official NSF mark. It should be permanently stamped or affixed to the unit, not just a flimsy sticker that could be slapped on anything. This combination of a physical check and online verification is your best defense against misleading claims. For more tips on sourcing the right gear, check out our guide to understanding NSF-rated equipment.

Getting Your Certified Equipment into the Daily Grind

Bringing in a shiny new piece of NSF-certified equipment is a fantastic first step. But the real win comes from weaving it into the daily rhythm of your kitchen in a way that actually maintains its safety promise. Let's be honest, just having the gear doesn't magically make your kitchen safer. It's your day-to-day habits and maintenance routines that truly uphold the standards behind that little blue seal. This is all about connecting that initial investment to the reality of running a safe, efficient, and compliant kitchen every single day.

And this commitment to safety isn't just a local trend; it's a massive global movement. The demand for food safety certifications is a huge economic driver, with some reports estimating the global market to be somewhere between USD 6.0 billion and USD 12.2 billion for 2024–2025. This explosion shows just how vital trusted programs like NSF have become for modern food safety and trade. If you're curious, you can get more insights on this growing market over at Custom Market Insights.

A Quick Procurement Checklist

When you're buying new equipment, you're not just purchasing a machine—you're investing in a specific safety standard designed for a specific job. Here’s a simple checklist to help you match the right NSF certification to the right area of your kitchen:

- Hot Line (Grills, Fryers): You'll want to prioritize equipment certified to NSF/ANSI 4. This standard is all about easy cleanup of grease and cooked-on food, which is critical for preventing bacterial growth in those high-heat zones.

- Cold Line (Prep Tables, Coolers): Look for gear that meets NSF/ANSI 7. This is your guarantee of consistent temperature control, which is absolutely non-negotiable for keeping perishable ingredients safe.

- Warewashing (Dish Machines, Sinks): Make sure your equipment meets NSF/ANSI 3. This certifies that it can properly sanitize dishes and utensils, effectively killing off any harmful pathogens.

Keeping That Certification Strong with Good Maintenance

Your maintenance routine is every bit as important as your initial purchase decision.

An NSF-certified refrigerator can’t do its job if its seals are cracked or its coils are caked in dust. Regular upkeep is essential to preserving the built-in safety features of your equipment and ensuring it continues to perform as certified.

Stick to a strict cleaning schedule using manufacturer-approved, non-corrosive cleaning agents. Get in the habit of doing regular inspections for any wear and tear, and be quick to replace things like gaskets, seals, and other components. This proactive approach ensures the benefits of your NSF-certified equipment last for its entire lifespan.

Your Top Questions About NSF Certification, Answered

Jumping into the world of kitchen compliance can feel like learning a new language. As you start to get a feel for what NSF certification is all about, it’s only natural to wonder how it fits into the bigger picture with regulations, health inspections, and all the other seals you see on equipment. Let's clear up some of the most common questions restaurant owners have.

Getting these answers straight helps you make smarter buying decisions, stay a step ahead of health inspectors, and ultimately run a safer, more efficient kitchen.

Is NSF Certification Required by Law?

This is probably the biggest point of confusion, and it’s a great question. The short answer is no, NSF certification isn't a federal law. But that's where the nuance comes in.

While there's no nationwide mandate from Washington D.C., almost every single local and state health department has adopted food codes that require your commercial kitchen equipment to be certified by an accredited third-party organization. NSF International is far and away the most recognized and trusted of these organizations.

So, in practice? If you want to pass your health inspection without any headaches, you absolutely need to use NSF-certified equipment.

Think of it this way: The local health code is the law you have to follow. That law often says, "Use certified equipment," and the little blue NSF mark is the clearest, most common way to prove you’ve done exactly that.

What Is the Difference Between NSF and UL Marks?

It's easy to get the alphabet soup of seals on your equipment mixed up, but NSF and UL (that’s Underwriters Laboratories) are playing on completely different fields. They aren’t competitors; they are specialists focused on totally different aspects of safety.

- NSF is all about sanitation and public health. Its main job is to confirm that a piece of equipment is made from food-safe materials and designed to be cleaned easily, preventing the spread of foodborne illnesses.

- UL is all about electrical and fire safety. It tests products to make sure they won't cause electrical shocks, catch fire, or create other hazards when you plug them in.

You’ll notice that a lot of your kitchen equipment, like a refrigerator or an electric fryer, will actually have both marks. The UL seal tells you it’s safe to plug in, and the NSF seal tells you it’s safe for your food.

How Long Does NSF Certification Last?

NSF certification isn't a one-and-done deal. It’s an ongoing commitment that a manufacturer has to uphold to keep that seal on their products.

A product’s certification is only valid as long as the manufacturer continues to pass its unannounced annual facility audits and the product itself keeps meeting the standard it was tested against. If a manufacturer fails an audit, or if they change the product's design or materials without getting NSF's approval, the certification can be yanked.

This tough, continuous process is exactly why the NSF mark is so trustworthy. It guarantees that the equipment you buy today is held to the same high standards as the day it was first certified.

Ready to equip your kitchen with trusted, certified equipment? The Restaurant Warehouse offers a massive selection of NSF-certified products from top brands, all at competitive prices with fast shipping. Explore our inventory and get the gear you need to build a safe, compliant, and successful kitchen. Find everything you need at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment