Choosing Your Industrial Meat Slicer: A Deep Dive into Commercial Deli and Meat Slicing

Why an Industrial Meat Slicer Machine Is Critical for Your Food Business

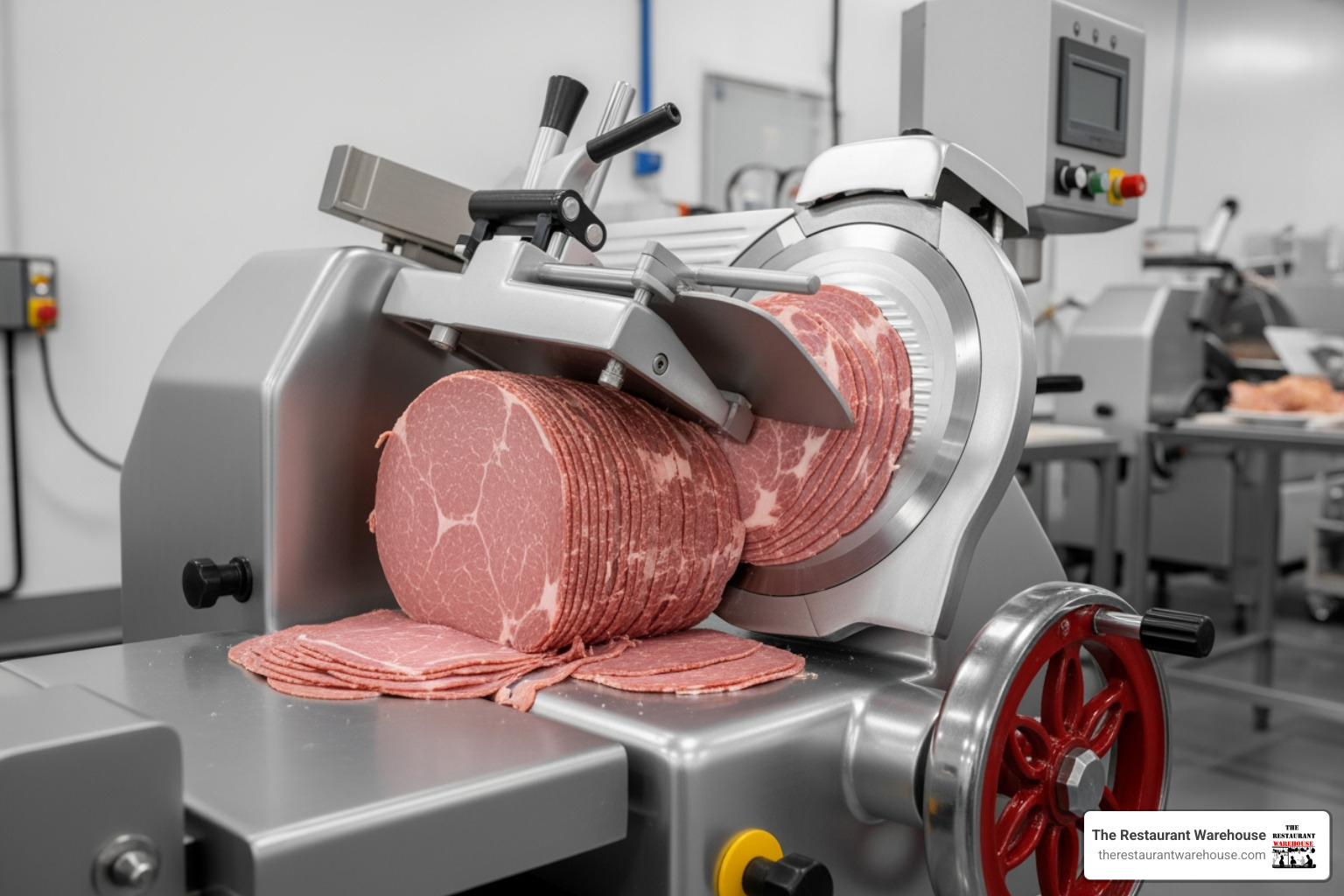

An industrial meat slicer machine is a high-capacity, heavy-duty piece of equipment engineered to slice immense volumes of meat, cheese, and other deli products with unparalleled precision, speed, and consistency. In the fast-paced, demanding world of the modern food processing industry, efficiency and precision are not just goals; they are the pillars of profitability and brand reputation. While smaller commercial slicers serve their purpose in lower-volume settings, an industrial machine is built for the relentless pace of a full-scale production line. Whether you're preparing paper-thin slices of prosciutto for gourmet packaging, perfectly uniform slices of cheese for retail, or thicker cuts of beef for jerky production, industrial slicers deliver the speed, consistency, and unwavering reliability that manual processes and lighter-duty equipment simply cannot match.

These powerful machines are the operational backbone for a wide variety of businesses, each with unique demands:

- Large-Scale Food Production Plants: These facilities rely on industrial slicers for continuous, 24/7 operation, integrating them into automated lines for producing pre-packaged goods for national distribution.

- Supermarkets and Hypermarkets: Large grocery chains use these slicers in central commissaries to prepare deli meats and cheeses for their various store locations, ensuring brand consistency and efficient inventory management.

- Butcheries and Meat Processors: Specialized butcher shops and meat processing facilities use industrial slicers to handle large primals, producing everything from perfectly sliced bacon to uniform steaks and cutlets.

- Catering Services and Central Kitchens: For large-scale catering operations that serve thousands of meals for events or institutions, these slicers are essential for preparing vast quantities of ingredients quickly and uniformly.

- Deli Counters and High-Volume Sandwich Shops: While some may use heavy-duty commercial slicers, exceptionally busy locations in major metropolitan areas often require the speed and durability of an industrial model to keep up with relentless customer demand.

The core benefits of integrating an industrial slicer into your operation are transformative and directly impact your bottom line:

- Massive Production Increase: High-speed models are capable of slicing up to 400 portions per minute or more, dramatically boosting output and allowing your business to scale and take on larger orders.

- Significant Waste Reduction: The incredible precision of an industrial slicer can reduce product waste and overweight portions by up to 15%. This means less giveaway and more sellable product from every log of meat or block of cheese.

- Substantial Labor Savings: Fully automated systems minimize the need for manual handling, stacking, and portioning, reducing labor requirements and freeing up staff for more complex, value-added tasks.

- Unwavering Quality and Consistency: These machines deliver perfectly uniform slice thickness time after time. This is crucial for portion control, product presentation, and overall customer satisfaction, which builds brand loyalty.

- Enhanced Food Safety: Constructed primarily from stainless steel and designed with hygienic principles in mind, industrial slicers support the strictest sanitation standards, minimizing the risk of cross-contamination. For businesses aiming to optimize their operations, a deep understanding of food safety regulations is non-negotiable. The FDA's Food Code provides comprehensive guidelines on equipment standards and sanitation requirements that are essential for any industrial food processing environment.

The Core of Your Operation: Why an Industrial Slicer is Essential

At The Restaurant Warehouse, we understand that the heart of any successful food processing operation lies in its ability to produce high-quality products efficiently, safely, and consistently. This is precisely where an industrial meat slicer machine shines, becoming an indispensable asset for businesses ranging from busy supermarkets in Seattle, Washington, to large-scale food production facilities across the United States and China. These powerful machines are not just about slicing; they are about optimizing every facet of your production, from throughput and yield to portion control and labor allocation. The decision to invest in an industrial slicer is a strategic move toward greater profitability and operational excellence.

Imagine the operational nightmare of trying to keep up with the demand of a national grocery chain contract using manual slicing or even a standard commercial slicer. It would quickly become an insurmountable bottleneck, leading to inconsistent cuts, significant product waste from end pieces and inaccurate portions, and soaring labor costs due to the sheer manpower required. An industrial meat slicer machine is meticulously engineered to obliterate these challenges. These robust machines are equipped with powerful, continuous-duty motors and incredibly durable components, enabling them to process hundreds of slices per hour, with some advanced models reaching speeds of up to 400 portions per minute. This incredible speed translates directly into a massive increase in productivity and a capacity to handle high volumes that manual methods and smaller machines simply cannot touch.

Boosting Production and Profitability

When we talk about boosting production, an industrial meat slicer machine is a genuine game-changer. The throughput rates are nothing short of remarkable, with high-performance slicers capable of processing up to 400 portions per minute. This speed doesn't just make one part of your line faster; it transforms the entire production workflow. Many industrial slicers are designed for integration with other automated systems, such as infeed and outfeed conveyors, automatic weighers, and packaging machinery. Automated portion handling systems, often integrated with these slicers, take over the repetitive and labor-intensive task of handling sliced products, which not only optimizes food safety by reducing human contact but also drastically minimizes labor requirements. This reduction in manual intervention and the subsequent reallocation of staff to higher-value roles translates directly into lower operational costs.

Continuous operation is another defining hallmark of industrial slicers. Unlike smaller units that require rest periods to prevent overheating, many industrial models are designed for continuous loading and 24/7 operation, effectively eliminating costly downtime. This means your facility can maintain a steady, predictable, and high-volume output, shift after shift. The financial impact is substantial and multifaceted: by increasing speed, reducing product waste, and decreasing labor costs, an industrial meat slicer machine delivers a strong and often rapid return on investment (ROI). This allows businesses to not only become more profitable but also to scale their operations, bid on larger contracts, and expand their market reach. Ready to transform your production line? Contact The Restaurant Warehouse today to discuss how our industrial slicing solutions can boost your profitability.

Achieving Best Product Consistency

In the competitive food industry, consistency is a cornerstone of quality, brand identity, and customer satisfaction. An industrial meat slicer machine excels in achieving unparalleled product consistency, which is a critical factor for success. It completely eliminates the human element of variability, delivering a uniform slice thickness every single time, whether it's the first slice of the day or the last. This level of precision is vital for effective portion control, ensuring each serving is identical. For pre-packaged goods, this means accurate net weights and happy customers; for a sandwich shop, it means every sandwich has the same amount of meat. This consistency also helps in meeting stringent regulatory standards for labeling and nutrition information. When every slice is perfect, you maximize your yield from every product log, which directly and positively impacts your bottom line. Consistent product presentation also reinforces brand quality in the eyes of the consumer, building trust and encouraging repeat purchases. For more information on how these slicers can transform your operations, explore our slicer guide. For those looking to ensure top-notch consistency, we also recommend checking out this great resource for your slicing needs.

How to Choose the Perfect Industrial Meat Slicer Machine

Choosing the perfect industrial meat slicer machine is a critical strategic decision that will significantly impact your operational efficiency, product quality, labor costs, and ultimately, your profitability. It is far from a one-size-fits-all scenario; the right choice is deeply dependent on your specific business needs, your average and peak production volume, the types of products you'll be slicing, and your facility's infrastructure. At The Restaurant Warehouse, we guide our customers through this complex selection process, focusing on key features, technical specifications, and crucial operational differences to ensure they acquire an asset that drives their business forward.

Key Features That Define Performance

When evaluating an industrial meat slicer machine, paying close attention to its core features and engineering is paramount. These details separate a good machine from a great one.

- Motor Power, Type, and Horsepower (HP): Industrial slicers are designed for continuous, heavy-duty use, and a robust motor is the heart of the machine. Look for models with at least a ½ to 1 HP motor, specifically rated for continuous duty. If you're frequently slicing dense or tough products like hard cheeses or frozen meat logs, a machine with a ¾-peak-hp motor or higher is ideal. It's also important to consider the drive type. Gear-driven systems typically deliver higher torque and are more durable for consistently slicing very dense products, while belt-driven systems are quieter and their belts can be easier to replace, though they may require more frequent maintenance under heavy load.

- Construction Materials and Hygienic Design: Durability and hygiene are inextricably linked in a food processing environment. We strongly recommend machines built with heavy-gauge stainless steel (such as 304-grade) and anodized aluminum. Stainless steel offers superior corrosion resistance and is non-porous, making it easy to clean and sanitize. Anodized aluminum provides durability for certain components. Look for seamless welds and a design that minimizes crevices, corners, and fasteners where food particles and bacteria can accumulate.

- Blade Type, Size, and Material: Blades typically range from 12 to 15 inches in diameter for industrial applications, with larger blades signifying a more powerful machine capable of handling larger product logs. The blade quality is non-negotiable; hardened, high-carbon or stainless steel blades are standard for their sharpness and longevity. For specific applications, consider specialized blades. Teflon-coated blades are excellent for slicing cheese as they reduce friction and prevent sticking. Maintaining blade sharpness is critical for slice quality and safety, so look for machines with effective and easy-to-use sharpening systems, such as integrated two-stone sharpeners that hone and sharpen the blade at the correct angle.

- Advanced Safety Features: An industrial meat slicer machine is an incredibly powerful tool, and operator safety is the absolute top priority. Essential safety features include robust blade guards and knife ring guards that create a physical barrier protecting operators from the blade. Interlock systems are also vital; these magnetic or mechanical switches prevent the machine from operating if guards, covers, or the product tray are not properly in place. A no-volt release feature is another critical function that prevents the machine from automatically restarting after a power outage, which could be extremely dangerous for an operator performing cleaning or maintenance. Finally, large, easily accessible emergency stop buttons should be standard for an immediate shutdown.

Automatic vs. Manual: Finding Your Ideal Workflow

Deciding between an automatic and a manual industrial meat slicer machine depends heavily on your required throughput, labor availability, and budget.

- Manual Slicers: Sometimes called flywheel slicers, these machines are often prized in artisanal or specialty settings. They give the operator complete control over the slicing speed and rhythm, which is ideal for delicate products like prosciutto. They are aesthetically pleasing and mechanically simple, making them very reliable. However, their complete reliance on operator effort means they are significantly slower and not suitable for high-volume industrial production.

- Automatic Slicers: For any high-volume operation, automatic slicers are the undisputed champions. They are designed for continuous loading and can operate with minimal operator intervention, drastically reducing labor costs and physical strain. Many models incorporate a gravity feed system, where the product carriage is angled (often at 35 or 45 degrees), using gravity to assist in feeding the product toward the blade. This design requires less mechanical pressure and reduces operator fatigue. Advanced automatic slicers also boast variable speed settings and programmable controls, allowing you to set the slice count, portion thickness, stacking patterns (e.g., shingled, stacked, or fluffed), and spacing, all of which are essential for automated packaging lines.

Matching the Slicer to the Product

The versatility of an industrial meat slicer machine is impressive, but to achieve optimal results, you must match the slicer's capabilities to your specific products.

- Common Products: For items like deli meats (turkey, ham, roast beef) and most cheeses, many general-purpose industrial slicers perform well. However, tougher, denser cheeses or firm, dry-cured deli logs will benefit from a machine with a higher torque, gear-driven motor.

- Specialty Meats: Bacon and pepperoni often demand specialized solutions. High-speed bacon slicers are engineered to handle streaky, non-uniform bellies at incredible speeds, often using vision systems to maximize yield. Slicers for pepperoni need to handle dense, greasy logs without smearing.

- Fresh and Frozen Meat: Machines capable of slicing frozen meat blocks (tempered to a specific temperature) without pre-thawing offer significant operational advantages in time and labor. This is ideal for producing thin-sliced beef for cheesesteaks or pork for hot pot. This versatility can extend to handling naturally shaped, boneless fresh products or even strip-cutting for items like jerky.

- Blade Edge Types: The key to product-specific performance often lies in the blade edge. A smooth knife edge is the standard for most meats and vegetables. A serrated or V-tooth edge is designed for denser products like hard salami or bread. Other modified edges are engineered for meats with varying textures, like bacon, to ensure a clean cut without shredding. By selecting a machine with the appropriate technology, you can ensure efficient, high-yield processing with consistent, premium quality. For a deeper dive, our comprehensive guide offers invaluable insights.

Upholding Standards: Food Safety, Hygiene, and Maintenance

In the food processing industry, particularly when operating an industrial meat slicer machine, food safety and hygiene are not merely regulatory hurdles; they are the fundamental pillars of your brand's integrity, consumer trust, and public health. The design, daily operation, and long-term maintenance of these machines play a critical and interconnected role in preventing microbial contamination and ensuring product safety. At The Restaurant Warehouse, we emphasize that a clean machine is a safe and efficient machine, and a rigorous, well-documented maintenance program is the key to both equipment longevity and consistently hygienic operation.

The Critical Role of an Industrial Meat Slicer Machine in Food Safety

An industrial meat slicer machine contributes significantly to food safety, starting with its intrinsic design. The foundation of a safe slicer is its hygienic design. We always recommend machines constructed from food-grade stainless steel because it is a non-porous, durable material that resists corrosion and bacterial growth, making it the ideal surface for easy and effective cleaning and sanitization. Modern industrial slicers are engineered with easy-to-clean parts and removable components that can be disassembled without tools, allowing for thorough washing and reducing the risk of cross-contamination between different products (e.g., raw meat and cheese). Look for machines with an IP (Ingress Protection) rating, such as IP65 or higher, which certifies that the machine's sensitive electrical components are protected against water jets, allowing for more effective and safer washdown procedures.

By automating the slicing process, these machines also reduce manual handling of food products. Every time a product is touched by human hands, there is a potential risk of introducing pathogens. Automation creates a more controlled, sanitary environment by minimizing these critical contact points. Many reputable machines come with NSF certification (or similar certifications like UL sanitation), which provides independent verification that the slicer is designed and constructed in a way that promotes food safety and meets rigorous public health standards. Adhering to official guidelines is crucial for maintaining the highest hygiene standards. The USDA's Food Safety and Inspection Service provides comprehensive resources on proper sanitation practices that are essential for any facility using industrial food processing equipment.

Maintenance and Blade Care for Longevity and Precision

To ensure your industrial meat slicer machine operates at peak performance and remains hygienically safe for its entire lifespan, a program of diligent maintenance and meticulous blade care is indispensable.

- Daily Cleaning and Sanitizing Procedures: A strict cleaning protocol is non-negotiable. At the end of each shift, or more frequently if switching between raw and ready-to-eat products, the machine must be thoroughly cleaned and sanitized. A typical procedure involves: (1) Powering down and unplugging the unit. (2) Disassembling all removable components—such as the carriage, blade guard, and product holder. (3) Washing these parts in a three-compartment sink with detergent, rinsing, and then soaking in a sanitizer solution. (4) Carefully cleaning the machine body, paying close attention to all surfaces, and using designated brushes to clean hard-to-reach areas. (5) Allowing all parts to air dry before reassembly. Many modern slicers are designed with features like removable carriages and kickstands that prop up the machine to allow for easy cleaning underneath.

- Blade Sharpening: A dull blade is a triple threat: it produces poor-quality, shredded slices; it requires more pressure to cut, which can strain the motor; and it is a significant safety hazard as it is more likely to slip than cut cleanly. Most industrial slicers come equipped with built-in sharpeners, such as integrated two-stone sharpeners, which allow operators to maintain a razor-sharp edge quickly and safely without needing specialized tools or removing the blade.

- Preventative Maintenance and Professional Servicing: Even with diligent in-house care, a preventative maintenance schedule is crucial. This includes weekly checks of belts for tension and wear, lubrication of moving parts as specified by the manufacturer, and calibration of thickness controls. Occasional blade replacement and professional servicing are also necessary. Blades have a finite lifespan and will eventually need to be replaced. Professional technicians can perform comprehensive inspections, test safety interlocks, and perform calibrations, ultimately extending the equipment life, preventing costly emergency breakdowns, and ensuring optimal performance. Book a consultation with The Restaurant Warehouse team today to discuss maintenance-friendly slicer models and replacement schedules that fit your budget and production needs.

Applications and Maximizing Your Investment

The remarkable versatility of an industrial meat slicer machine makes it an invaluable and transformative asset across a broad spectrum of the food industry. These machines are not limited to a single task but are adaptable workhorses engineered to streamline operations, enhance product quality, and drive profitability in various high-volume environments.

Supermarkets and Central Commissaries: In the back-of-house operations for large supermarkets, industrial slicers are the engine for preparing pre-packaged deli meats, cheeses, and even fresh-cut produce for the retail floor. Central commissaries that supply multiple store locations rely on these machines to ensure absolute consistency in slice thickness and portion weight, which is critical for brand uniformity and accurate inventory control across the entire chain.

Large-Scale Meat and Food Production: For national and international food production facilities, industrial slicers are integrated into fully automated production lines. They run continuously, slicing everything from logs of pepperoni and salami to large cooked roasts and poultry. Their ability to interface with conveyors, scales, and packaging equipment makes them a cornerstone of modern, efficient food manufacturing.

Catering Services and Institutional Kitchens: High-volume catering services and kitchens serving hospitals, universities, and corporate campuses depend on these slicers to rapidly prepare enormous quantities of ingredients. For an event serving thousands, an industrial slicer can prepare hundreds of pounds of meat and cheese in a fraction of the time it would take manually, ensuring consistent portions and rapid service.

High-Volume Delis and Sandwich Shops: While many delis use smaller slicers, an iconic, high-traffic sandwich shop in a city like Seattle or New York can face lines out the door for hours. In this scenario, the speed, power, and durability of an industrial automatic slicer are critical for meeting peak demand, reducing customer wait times, and maximizing sales during busy lunch rushes.

Maximizing Your Investment: Calculating ROI

Investing in an industrial meat slicer machine is a significant capital expenditure, but it's a strategic decision designed to maximize your investment through a clear and calculable return on investment (ROI). The primary financial benefits come from substantial cost savings derived from reduced labor and minimized product waste.

To calculate the potential ROI, consider these key factors:

- Labor Savings: Determine the number of labor hours currently spent on manual or semi-manual slicing. An automatic industrial slicer can often perform the work of multiple employees. Calculate the annual savings in wages, benefits, and payroll taxes. By automating repetitive tasks, you reduce the need for manual labor, allowing your team to focus on higher-value activities like quality control, packaging, or new product development.

- Waste Reduction & Increased Yield: Precision slicing technology can reduce product waste and overweight portions by up to 15%. Calculate the value of this saved product. For example, if you process $500,000 worth of raw product annually, a 10% increase in yield translates to $50,000 in saved costs or additional revenue. This directly translates into more usable, sellable product from every raw ingredient, significantly boosting profitability.

- Increased Throughput: Quantify the value of increased production capacity. Can you now take on a larger contract you previously had to decline? Can you expand into a new market? This increased revenue potential is a major component of your ROI. For businesses looking to equip their operations with reliable and affordable equipment, The Restaurant Warehouse provides solutions that improve productivity without compromising on quality. Explore our full range of slicing solutions by visiting our commercial food slicers page.

Frequently Asked Questions about Industrial Meat Slicers

We often receive insightful questions from our customers about industrial meat slicer machines. These are complex pieces of equipment, and making an informed decision is crucial. Here, we address some of the most common inquiries to help you better understand these powerful tools and how they can benefit your operation.

How much can an industrial meat slicer machine increase production?

An industrial meat slicer machine is built specifically for high-volume output, and its capacity to increase production is one of its most significant benefits. The difference is staggering when compared to other methods. While a skilled person using manual slicing might yield a few dozen slices per minute, industrial models operate on an entirely different scale. We’re talking about machines capable of producing hundreds of slices per minute. For instance, many advanced slicers can process up to 400 portions per minute, while other highly specialized models for products like bacon can reach even higher speeds. This dramatically increases throughput, reduces production bottlenecks, and allows businesses in the United States and China to meet high demand, fulfill large contracts, and scale their operations effectively without a proportional increase in labor or facility space.

What is the difference between a commercial and an industrial slicer?

While both are designed for business use, the key differences lie in their intended operational intensity, durability, power, and scale. Commercial slicers, often found in delis, restaurants, or smaller butcher shops, are robust but are typically designed for intermittent use throughout the day. A heavy-duty commercial slicer, for example, might be rated for continuous use for several hours daily. An industrial meat slicer machine, on the other hand, is engineered for continuous, non-stop production lines, often operating for entire shifts, 24 hours a day, 7 days a week. They feature significantly more powerful, continuous-duty motors (e.g., ¾-peak-hp or higher, often gear-driven), heavier-duty construction (almost entirely stainless steel with seamless welds), and advanced automation features like programmable portioning and integration with packaging lines. Industrial slicers are built to withstand the rigors of a large-scale food processing environment where uptime and endurance are paramount.

How do I ensure operator safety when using an industrial slicer?

Ensuring operator safety is absolutely paramount, and modern machines incorporate numerous features to protect staff. When selecting an industrial meat slicer machine, always choose one equipped with a comprehensive suite of safety mechanisms. These must include robust blade guards that completely shield the cutting edge when not in use, a knife ring guard that prevents accidental contact with the blade during operation, and an interlocking system that prevents the machine from starting if any guards or covers are removed or not properly secured. Beyond the machine's inherent safety features, proper, documented training is absolutely essential. All staff must receive thorough instruction on safe operation, correct cleaning procedures (including lock-out/tag-out protocols), and the location and function of emergency stop buttons. Regular inspection and maintenance of all safety features are also crucial to ensure they remain effective and have not been bypassed or damaged.

Can an industrial slicer handle bone-in meat?

No, absolutely not. An industrial meat slicer machine is designed exclusively for slicing boneless products. The high-speed, precision blade is not made to cut through hard materials like bone, dense cartilage, or metal clips. Attempting to slice bone-in meat is extremely dangerous. It will, at a minimum, severely damage or destroy the blade, potentially damage the motor and drive system, and create a significant risk of injury to the operator from blade shattering or the product being violently ejected from the machine. Always ensure all products are boneless before slicing.

What is the difference between a gear-driven and a belt-driven slicer?

This refers to the mechanism that transfers power from the motor to the blade. A belt-driven slicer uses a belt, similar to a car engine. They are generally quieter and the belts are a relatively inexpensive part to replace. However, belts can slip under heavy load, stretch over time, and may require more frequent adjustment or replacement in a continuous-use environment. A gear-driven slicer uses a series of gears to transfer power. This system provides more consistent torque and power, making it superior for slicing very dense products like hard cheese or semi-frozen meat without bogging down. Gear-driven systems are typically more durable and require less maintenance, making them a preferred choice for many demanding industrial applications.

Conclusion

Investing in the right industrial meat slicer machine is a pivotal strategic decision that reverberates across your entire operation, directly impacting efficiency, product quality, food safety, and long-term profitability. At The Restaurant Warehouse, we've seen firsthand how a carefully selected, high-performance slicer can fundamentally transform a food business, turning production bottlenecks into streamlined, cost-effective workflows. By thoroughly evaluating key factors such as motor power and drive type, blade material, advanced safety features, and the level of automation, you can select a machine that perfectly aligns with your production needs—whether you're a bustling deli in Seattle, a central commissary for a grocery chain, or a large-scale processing plant in China.

A high-quality industrial slicer is more than just a piece of equipment; it's an investment in consistency, a commitment to upholding the most stringent food safety standards, and a direct path to significant cost savings through reduced labor and minimized product waste. The ROI is clear, tangible, and powerful. For businesses looking to equip their operations with reliable and affordable equipment, The Restaurant Warehouse provides solutions that improve productivity without compromising on quality. Ready to upgrade your slicing capabilities and take your food business to the next level of performance and profitability? Contact us today to find the perfect equipment for your needs.

If you're planning a larger build-out, a multi-location rollout, or simply want expert guidance to align slicer specifications with your menu and volume targets, you can also book a consultation with The Restaurant Warehouse team through our contact page. We can help you compare models, pricing, and financing options custom-tailored to your unique operation.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment