Explore refrigerated sandwich prep tables: Essential guide for kitchens

Refrigerated sandwich prep tables are the absolute command center for any kitchen that lives and dies by speed, consistency, and food safety. Think about it: these units brilliantly combine cold storage, an ingredient rail, and a sanitary workspace into a single, hyper-efficient hub. This setup is designed to streamline every single step of making a sandwich, salad, or wrap, ensuring every order goes out looking and tasting perfect.

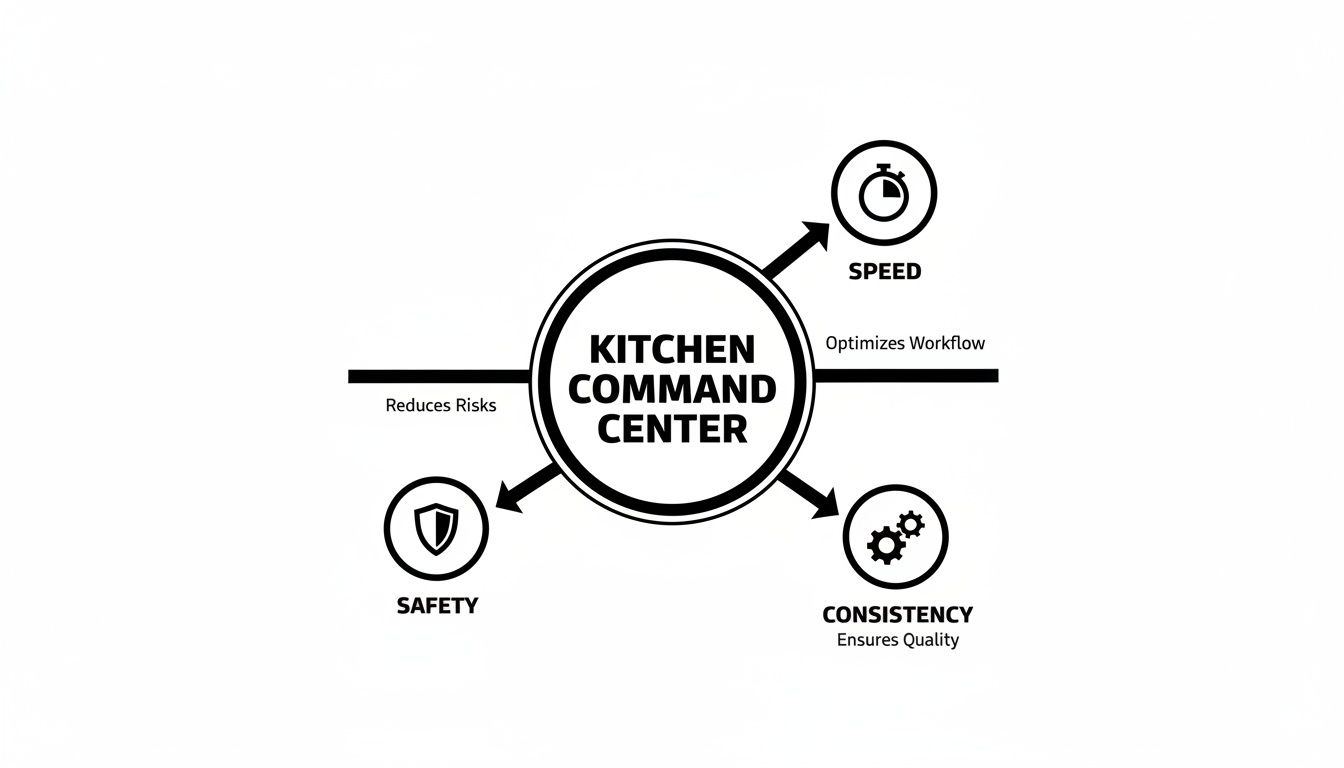

The Command Center of Your Kitchen

Imagine your craziest lunch rush. Now, picture it transforming from controlled chaos into a smooth, profitable machine. That’s not just about having a great team; it’s about mastering your kitchen’s workflow, and the right prep table is the linchpin holding it all together. It’s the central spot where fresh, chilled ingredients meet quick, efficient assembly, turning individual components into finished meals with incredible speed.

This piece of equipment is so much more than just a refrigerated counter. It's a purpose-built station designed from the ground up to minimize wasted movement and maximize your output.

Streamlining Your Assembly Line

The real magic of a refrigerated sandwich prep table is its ability to create a powerful assembly line in a surprisingly compact space. Here’s how it breaks down:

- Refrigerated Base: This is your bulk storage. It keeps your backup supplies of meats, cheeses, and produce perfectly chilled and ready to restock the line in seconds.

- Top Ingredient Rail: This is your immediate arsenal. It holds pans of prepped ingredients at food-safe temperatures, literally right at your fingertips.

- Integrated Cutting Board: This is your sanitary workspace where the magic happens—from slicing bread to adding the final touches and wrapping it up.

By bringing these three critical functions together, your team can build orders without taking a single unnecessary step to a separate fridge or prep counter. This efficiency boost directly translates to faster service, a higher capacity for orders, and less staff fatigue during those critical peak hours.

A well-organized prep table can slash order assembly time by up to 30%. That means serving more customers and boosting revenue when it matters most.

More Than a Purchase—It’s an Investment

Putting your money into the right unit from a trusted brand like Atosa or True isn't just buying equipment; it's a cornerstone investment in your success. The design of these tables directly shapes your kitchen's efficiency and overall flow. In fact, proper placement is just as important as the unit itself, a concept that's also vital when designing your entire kitchen layout.

For a deeper dive into optimizing your workspace for maximum productivity, you can explore our detailed guide on how to create a commercial kitchen floor plan. Whether you're running a bustling deli, a nimble food truck, or a high-volume café, understanding how this equipment functions as your command center is the first step toward operational excellence.

Understanding Your Prep Table Inside and Out

To really get the most out of your kitchen, you need to understand what makes a refrigerated sandwich prep table tick. Think of these units as having three distinct zones, all working together to make your workflow seamless from start to finish.

First up is the refrigerated base. This is your bulk storage—the deep reserve of meats, cheeses, and produce that keeps your line stocked. It's the foundation of your prep station, ensuring you have backup ingredients ready to go without a trip to the walk-in.

Next, you have the top rail. This is your immediate-access arsenal. It holds food pans filled with all your fresh, prepped ingredients, kept at a precise, food-safe temperature. This is where your team lives during a rush, grabbing toppings and fillings with zero wasted motion.

Finally, there's the cutting board, which acts as your assembly line. This durable, sanitary surface is where orders come to life, transforming individual ingredients from the top rail into perfectly crafted sandwiches, salads, and wraps.

The Anatomy of an Efficient Kitchen

Getting a handle on this basic anatomy is a great start, but digging a little deeper into the key features will empower you to look at product listings and see not just specs, but direct solutions to your kitchen’s challenges.

This diagram shows how these three zones combine to create a true kitchen command center, driving speed, safety, and consistency with every order.

As you can see, a well-organized prep table directly impacts everything from reducing ticket times to ensuring every customer gets the same high-quality product, every single time.

This foundational knowledge is key, especially as these units become more and more essential. In fact, the market for sandwich and salad prep tables was valued at USD 1.2 billion and is projected to hit USD 1.71 billion by 2032. That growth just highlights how critical they are for any spot that depends on made-to-order menu items.

A Buyer's Guide to Key Features

When you start comparing different refrigerated sandwich prep tables, you'll come across a few key terms that define a unit's performance. Let's break down what the most important ones mean for you and your kitchen.

The features below are what separate a good prep table from a great one. Understanding what they are and why they matter will help you choose a unit that feels like it was custom-built for your workflow.

| Feature | What It Is | Why It Matters for Your Business |

|---|---|---|

| Pan Capacity | The number of food pans the top rail can hold. This is often described by the size of the pans (e.g., 1/6-size). | A higher pan capacity, like in a "Mega Top" model, allows for more ingredient variety, supporting complex menus without slowing down service. |

| Compressor Location | The placement of the refrigeration system's "engine." It can be rear-breathing or side-breathing. | A rear-breathing unit needs clearance behind it, while a side-breathing model can be pushed against a wall but needs space on the side for airflow. |

| Refrigerant Type | The chemical used to cool the unit. Modern tables use eco-friendly options. | Look for R-290 (propane). It's highly efficient, meaning lower energy bills, and has a low impact on global warming compared to older refrigerants. |

Thinking through these specs helps you match a machine to your reality. You’ll know instantly if a unit’s pan capacity can support your "build-your-own" salad bar or if its compressor will fit into that tight corner of your kitchen.

Understanding the difference between a standard top and a mega top isn't just about pan count—it's about menu flexibility. A mega top can support a more complex menu without slowing down your assembly line, directly impacting your potential revenue.

This knowledge turns you from a casual buyer into a strategic operator. For those looking to dive even deeper, our complete restaurant prep table buying guide offers more detailed comparisons and tips to help you find the perfect match. Ultimately, investing in the right unit is an investment in your kitchen's future success.

How to Choose the Right Prep Table for Your Business

Picking the right refrigerated prep table is one of the most important gear decisions you'll make for your kitchen. This isn't just about buying a hunk of stainless steel; it's about investing in the very heart of your operation. Get it right, and you’ll streamline your workflow, lock down food safety, and set your business up for growth for years to come.

This choice directly impacts how fast your team can pump out orders during a chaotic dinner rush. A table that’s too small will create instant bottlenecks and drag down ticket times. On the other hand, one that’s too big will just eat up precious floor space and waste energy. The goal is to find that perfect sweet spot for your unique needs, creating a seamless bridge between your fresh ingredients and the finished plate.

Size and Capacity: The First Big Decision

The first question you have to ask is, "How much space do I actually have, and how much food am I going to be making?" Refrigerated prep tables come in a huge range of sizes, from little 27-inch units perfect for a food truck or a cozy café to massive 72-inch or even 93-inch models built for high-volume delis.

Before you do anything else, grab a tape measure. Know your exact footprint, but don't forget to leave some breathing room. Most units need at least a few inches of clearance around them for proper ventilation—this is absolutely critical for the compressor's health and efficiency.

Next, think about your menu. A simple, straightforward menu might only need a standard top with eight 1/6-size pans. But if you’re offering tons of customization with dozens of toppings, you'll want to look at "Mega Top" models. These tables pack in an extra row of pans, giving you way more ingredient capacity without needing a wider table.

A classic rookie mistake is buying for today's needs instead of planning for tomorrow's growth. If you even think you might expand your menu or volume, investing in a slightly larger unit now can save you from a very expensive upgrade down the road.

Compressor Placement and Airflow

The compressor is the engine of your prep table, and where it’s located matters more than you’d think. It dictates where the unit can be placed in your kitchen and how it breathes.

- Rear-Breathing Compressors: These are the most common. They pull in air and push it out from the back of the unit. This design means you have to leave several inches of space between the table and the wall, which can be a real pain in a tight kitchen.

- Side-Breathing Compressors: These units give you more flexibility. Since they ventilate from the side, you can push them right up against a wall, saving valuable floor space.

- Front-Breathing Compressors: This is your most space-efficient option. These tables pull air from the front, allowing them to be fully enclosed on the back and sides. They’re perfect for being built right into a counter line.

Figuring out the right configuration from the get-go prevents future headaches from overheating and poor performance. It ensures your investment runs smoothly, even in the heat of a busy kitchen.

Materials and Long-Term Value

While most prep tables look pretty similar on the surface, the quality of their construction can vary wildly. Look for units made with a high grade of stainless steel, especially for the exterior and interior. This material isn't just tough and resistant to rust; it's also a breeze to clean and sanitize, which is non-negotiable for passing health inspections.

Another huge factor in long-term value is energy efficiency. An ENERGY STAR certified model might have a higher sticker price, but it can save you hundreds of dollars a year on your utility bills. These units use better components, eco-friendly R-290 refrigerant, and superior insulation to cut down on energy use without sacrificing performance.

When selecting a prep table, especially for a busy commercial kitchen, consider if your setup requires a three-phase power installation to handle the electrical load of multiple heavy-duty appliances running at once.

Investing in a well-built, efficient model is just a smart financial move. This decision tracks with the broader food prep tables market, which shows strong growth potential. The global market was valued at USD 1.18 billion in 2023 and is expected to hit USD 1.62 billion by 2029. This growth highlights a clear industry-wide commitment to investing in quality kitchen infrastructure. You can learn more about the growing demand for quality prep tables and see these trends for yourself.

Ultimately, choosing the right refrigerated prep table boils down to a clear-eyed assessment of your space, your menu, and your budget. By focusing on size, compressor design, and material quality, you can pick a unit that will serve as a reliable and profitable command center for your kitchen.

Mastering Your Workflow for Safety and Speed

Getting the right refrigerated sandwich prep table is a great start, but its real value comes alive when it’s woven seamlessly into your kitchen’s daily rhythm. Think of it less as a standalone appliance and more as the central hub of your assembly line. Your goal is to get the most out of your investment by mastering your workflow for both safety and speed.

This all begins with smart placement. A poorly positioned table can create traffic jams, forcing staff to take extra steps and creating bottlenecks during your busiest hours. The ideal spot minimizes movement, creating a logical flow from bulk storage (like a walk-in cooler) to the prep station, and finally to the service or pickup area.

When you position your prep table strategically, you can transform your kitchen into a model of efficiency, where every action is purposeful and every second counts.

Your Critical Control Point for Food Safety

Beyond just speed, your refrigerated sandwich prep table is a critical control point for food safety and Hazard Analysis and Critical Control Points (HACCP) compliance. This is where your raw ingredients are handled and assembled, making it a hotspot for potential risks if you don't manage it correctly. Using it properly directly protects your customers and, by extension, your hard-earned reputation.

The most fundamental rule is maintaining precise temperatures. Ingredients held in the top rail absolutely must stay at or below 41°F (5°C) to stop harmful bacteria from growing. This takes more than just setting the thermostat; it means building consistent habits:

- Regular Monitoring: Use a calibrated food thermometer to check ingredient temperatures at the start of every shift and periodically throughout the day.

- Proper Loading: Don't overfill the pans. Air needs to circulate freely around the ingredients to keep them properly chilled.

- Night Covers: Always use insulated night covers when the unit is not in use. This helps maintain temperature and shields ingredients from contaminants.

These simple habits are non-negotiable for any professional kitchen and form the backbone of a safe operation.

Preventing Cross Contamination at the Source

Organizing your ingredients is about more than just speed—it's a powerful way to prevent cross-contamination. A messy station where raw meats are right next to ready-to-eat vegetables is a health code violation just waiting to happen.

Implementing a color-coded system is one of the simplest yet most effective ways to bolster food safety. Using different colored cutting boards and utensils for different food groups—such as red for raw meat, green for produce, and yellow for poultry—drastically reduces the risk of transferring pathogens.

This visual cue system makes it second nature for staff to grab the right tool for the job, even during a chaotic lunch rush. It’s a best practice that aligns perfectly with HACCP principles. For a more complete look at kitchen safety, our commercial kitchen safety checklist provides actionable steps to protect your staff and customers.

Implementing a Bulletproof Cleaning Routine

Finally, operational excellence depends on a strict and consistent cleaning schedule. A pristine station not only looks professional but is absolutely essential for preventing foodborne illness.

Your daily cleaning routine should be thorough and cover every part of the unit. Make sure it includes these steps:

- Empty and Sanitize Pans: At the end of each day, all food pans should be removed, emptied, washed, and sanitized.

- Clean the Cutting Board: The cutting board must be scrubbed and sanitized. Removable boards make this process much easier.

- Wipe Down All Surfaces: Clean the interior and exterior of the table, paying close attention to door handles and gaskets.

A well-managed prep station is a clear indicator of a well-run kitchen. It translates directly to higher quality food, faster service, and a healthier bottom line. In contrast, a poorly managed station is inefficient, risky, and ultimately, a drain on your business.

Keep Your Investment Safe with Smart Maintenance

A refrigerated prep table is a big-ticket item, and how long it lasts has a real impact on your bottom line. Let’s be honest: smart installation and proactive maintenance aren't just chores. They’re essential moves to protect your asset, dodge those nightmare emergency repair bills, and make sure your unit hums along efficiently for years.

Think of it as a wellness plan for your equipment. A little attention now saves you from a world of hurt later.

This commitment starts before you even plug the unit in. The right setup sets the stage for everything that follows. You have to make sure the location has plenty of ventilation, because a compressor that can’t breathe will work itself to death, guzzling energy and failing way too soon. It’s also critical to connect it to the right electrical circuit—improper power can fry sensitive parts and, you guessed it, void your warranty.

Build a Proactive Maintenance Schedule

Long-term care is so much more than a daily wipe-down. An effective maintenance plan is all about being proactive, not reactive. By creating a simple schedule for a few key tasks, you can catch tiny issues before they snowball into a full-blown crisis that shuts down your sandwich line during the lunch rush.

A simple checklist can empower any kitchen manager to get more life out of their equipment. The goal here is to shift from a "fix it when it breaks" mindset to a "prevent it from breaking" approach. This is how you ensure your refrigerated sandwich prep tables perform at their best, day in and day out.

Here’s a practical schedule you can put to work right away:

- Daily: Clean and sanitize the cutting board, interior, and exterior surfaces. Don't forget to empty and sanitize all the food pans.

- Weekly: Check the door gaskets for any cracks or tears. A bad seal makes the compressor run constantly, which is a huge energy-waster.

- Monthly: Clean the condenser coils. This is, without a doubt, the single most important maintenance task you can perform.

- Quarterly: Calibrate the thermostat. Use a reliable thermometer to make sure your temperature readings are accurate for food safety.

The Most Important Task: Cleaning Condenser Coils

If you only do one thing on this list, make it this: clean the condenser coils regularly. These coils work like a radiator, pushing heat away from the refrigeration system. When they get clogged with grease, dust, and flour, the unit simply can't cool itself effectively.

An overworked compressor from dirty coils is the number one reason for premature equipment failure. A simple 15-minute cleaning every month can prevent a repair bill that could easily run you hundreds, if not thousands, of dollars.

This one habit protects your bottom line by cutting down on energy use and extending the life of your unit's most expensive component. Investing in this kind of simple care has become standard practice for successful operators, and you can see that value reflected in the market's growth. The industry was valued at around USD 2.8 billion and is projected to hit USD 4.6 billion by 2034. You can discover more insights about the refrigerated prep table market to see just how much value operators place on this crucial equipment.

By following these straightforward installation and maintenance steps, you’re not just cleaning—you’re safeguarding your investment, ensuring HACCP compliance, and keeping your kitchen’s command center operating at full strength.

Matching Prep Table Configurations to Your Menu

Choosing the right refrigerated sandwich prep table is never a one-size-fits-all deal. Think about it: the ideal unit for a small corner café would just create bottlenecks in a slammed downtown deli, and a massive three-door table would be complete overkill in a food truck. When you match the equipment's features directly to your menu and business style, you turn a simple purchase into a strategic asset that actually makes your kitchen run smoother.

To make this super practical, let's walk through a few common scenarios. We’ll look at four different businesses and figure out the perfect prep table for each, explaining the logic behind the choice. This should help you visualize how specific features solve real-world problems on the line.

The Cozy Independent Café

A small café usually has a tight, focused menu—classic sandwiches, a few salads, maybe some wraps. The flow of customers is steady but not overwhelming, and kitchen space is almost always at a premium.

- Recommendation: A 48-inch, two-door refrigerated prep table is the perfect fit here.

- Why It Works: This size gives you enough refrigerated storage for the day's needs without hogging the whole kitchen. The top rail can hold 12 to 16 pans, which is more than enough for a curated menu, while the two doors below let you organize backup meats and produce. It's the ideal balance of capacity and footprint.

The High-Volume Urban Deli

An urban deli lives and dies by speed, variety, and customization. The menu is a beast, with dozens of meats, cheeses, and toppings for signature subs and build-your-own creations. The line is always moving.

- Recommendation: A 72-inch, three-door mega-top prep table is pretty much essential.

- Why It Works: It's all about volume. A 72-inch unit provides a massive cutting board for multiple staff to work elbow-to-elbow. But the real game-changer is the mega-top design, which adds a third row of pans. This boosts your immediate ingredient capacity by up to 30% over a standard top, letting you offer endless customizations without constantly stopping to restock.

For a business built on variety, a mega-top isn’t a luxury—it’s a necessity. It’s what keeps the line moving during the lunch rush, preventing those constant trips to the walk-in and maximizing how many customers you can serve.

The Versatile Food Truck

Food trucks are the definition of tight quarters, where every single inch of space has to pull its weight. The menu is streamlined for speed, and the equipment has to be compact, durable, and multifunctional.

- Recommendation: A 27-inch, one-door prep table is the go-to solution.

- Why It Works: Its compact footprint is everything. A 27-inch model rolls refrigeration, ingredient access, and a prep surface into one efficient station. This size is perfect for a focused menu, giving you just enough pan space and under-counter storage to power through a service without tying up precious real estate.

The Large-Scale Catering Operation

Catering kitchens are all about bulk production and getting food ready for transport. They need equipment that supports preparing huge quantities of sandwiches and wraps efficiently for off-site events.

- Recommendation: Multiple 60-inch roll-top or dual-sided prep tables.

- Why It Works: Caterers need flexible, high-capacity workstations. A 60-inch model offers a big prep surface, and having multiple units allows for dedicated stations (one for sandwiches, one for salads, etc.). A roll-top lid is a key feature here; it provides better insulation, keeping ingredients fresher for longer during those extended prep sessions, which is crucial for maintaining quality.

To make it even easier to see how these choices align, here's a quick-reference table matching business types with their ideal prep table setups.

Recommended Prep Table by Business Type

| Business Type | Recommended Size | Key Feature Focus | Why It Works |

|---|---|---|---|

| Small Café | 48 inches | Balanced Footprint | Provides enough storage and prep space for a curated menu without dominating a small kitchen. |

| Urban Deli | 72 inches | Mega-Top Design | The extra row of pans supports a massive, customizable menu and high-volume service. |

| Food Truck | 27 inches | Compact Design | Combines refrigeration, prep, and ingredient access into the smallest possible footprint. |

| Catering | 60+ inches (Multiple Units) | Roll-Top Lid & Large Surface | Supports bulk production with better insulation for long prep times and ample workspace. |

Ultimately, looking at these examples shows there's a perfect configuration for every kind of operation. Taking the time to analyze your menu, volume, and workflow will lead you to the right piece of equipment that works for you, not against you.

Got Questions? We’ve Got Answers.

Jumping into a major equipment purchase always brings up a few last-minute questions. It’s completely normal. To help you feel confident you’re making the right call, we’ve put together some straightforward answers to the practical concerns we hear most often from operators just like you.

Sandwich Prep Table vs. Pizza Prep Table: What's the Real Difference?

It really boils down to two things: the depth of the cutting board and how the ingredient rail is set up. A sandwich prep table is designed with a narrower cutting board, usually around 8-12 inches deep, which is just right for lining up subs, wraps, and sandwiches. The ingredient rail is built to hold standard hotel pans perfectly flush with the work surface.

A pizza prep table, on the other hand, needs a much bigger stage. Its cutting board is significantly deeper, often 16-20 inches, to give you plenty of room to work with large pizza doughs. The ingredient rail is also raised, designed to hold oversized pans so you can grab big handfuls of cheese and toppings without any hassle. Sure, you can make a sandwich on a pizza table, but a dedicated sandwich unit is just way more comfortable and efficient for that specific job.

How often Should I Clean the Condenser Coil?

For most kitchens, giving the condenser coil a good cleaning every 90 days is a solid plan. But—and this is a big but—if your kitchen has a lot of grease in the air from fryers or flour dust from a baking station, you need to check it monthly.

When that coil gets clogged, it forces the compressor to work way harder than it should. That means higher energy bills and a serious risk of the whole unit failing way before its time.

Think of it this way: regular coil cleaning is the single most important maintenance task you can do to protect your investment. It’s a 15-minute job that can save you from a multi-thousand-dollar repair bill.

This simple habit is the key to keeping your refrigerated prep tables running smoothly for years.

Can I Just Use a Regular Power Strip for My Prep Table?

Absolutely not. Please don't do this—it's a critical safety issue. Commercial prep tables are powerful machines that pull a lot of electricity. They need their own dedicated circuit that is rated for the specific voltage and amperage listed on the unit's data plate.

Plugging an appliance like this into a standard power strip or a household extension cord is a major fire hazard. It can also fry the compressor and will void your warranty in a heartbeat. Always bring in a licensed electrician to make sure your wiring is up to code and ready to handle the equipment you're installing.

Ready to find the perfect command center for your kitchen? The team at The Restaurant Warehouse offers a wide selection of high-quality refrigerated sandwich prep tables from trusted brands like Atosa, all at competitive prices. Explore our collection and get expert advice today.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment