The Ultimate Reach In Freezer Buying Guide

A reach in freezer is the unsung hero of a professional kitchen. It's the upright, self-contained unit that stands ready to store and protect your perishable goods at safe, frozen temperatures. Unlike the freezer you have at home, this one is built like a tank, with powerful components designed to handle the constant open-and-close chaos of a busy service, ensuring your ingredients stay perfectly frozen.

Why a Reach In Freezer Is Your Kitchen's Workhorse

Think of it this way: your freezer at home is like a family sedan, reliable for daily trips. A commercial reach in freezer, on the other hand, is a high-performance race car—engineered for power, endurance, and consistency under the most extreme conditions. It's the silent guardian that protects your valuable inventory and, ultimately, your profits.

This isn't just a cold box; it’s a cornerstone of operational efficiency and food safety in your restaurant. Its main job is to hold a consistently frigid environment, typically somewhere between 0°F and -10°F, which is critical for stopping bacterial growth in its tracks and preventing spoilage.

So, what are the key components that make these units so essential? Let's break down the core features.

| Core Features of a Commercial Reach In Freezer |

| :--- | :--- |

| Feature | Why It Matters to Your Operation |

| Heavy-Duty Compressor | This is the engine. A powerful compressor ensures the freezer recovers its temperature lightning-fast after the door is opened, protecting food safety. |

| Durable Construction | Built with materials like stainless steel, these freezers are designed to withstand the dents, dings, and spills of a busy professional kitchen. |

| Precise Temperature Control | Digital thermostats allow you to set and monitor the exact temperature, ensuring ingredients are held in the optimal state for quality and safety. |

| Efficient Air Circulation | Internal fans ensure cold air is distributed evenly, eliminating warm spots and keeping every item, from top to bottom, perfectly frozen. |

| Adjustable Shelving | Heavy-duty, adjustable shelves give you the flexibility to organize everything from large boxes of protein to smaller, delicate items, maximizing your storage space. |

These features all work together to create a reliable piece of equipment you can count on, shift after shift.

The Engine of Kitchen Efficiency

The real magic of a commercial reach in freezer lies in its recovery speed. In a hectic kitchen, that freezer door gets opened dozens, if not hundreds, of times during a single shift. A residential freezer would completely struggle to pull the temperature back down, creating dangerous fluctuations that can ruin your food.

A commercial model, however, is built to snap back to its set temperature almost instantly.

This rapid recovery isn't just a nice-to-have feature—it's a critical tool for food safety. It guarantees that your inventory, from prime cuts of steak to delicate pastries, stays perfectly frozen, preserving its texture, flavor, and quality.

Protecting Your Bottom Line

A reliable reach in freezer has a direct and immediate impact on your profitability. Here’s how:

- Cuts Down on Food Waste: By holding precise temperatures without fail, it dramatically reduces spoilage. That means less of your expensive inventory ends up in the trash.

- Speeds Up Your Workflow: Placing freezers strategically along the prep line gives your chefs instant access to ingredients, which helps get plates out to customers faster.

- Guarantees Menu Consistency: Properly frozen products ensure that every dish you serve meets the same high-quality standard your customers have come to expect.

It's no surprise that the demand for these workhorse units is on the rise. In fact, the commercial freezer market is projected to see its fastest growth from 2025 to 2032, driven by the expansion of food retail and logistics. You can read more about these global freezer market trends on Data Bridge Market Research. This just goes to show how essential this equipment is for any modern foodservice business.

Choosing Your Ideal Freezer Configuration

Picking out a reach-in freezer isn’t just about how big it is; it’s about finding a design that fits the unique rhythm and flow of your kitchen. Get this right, and you’ll speed up service. Get it wrong, and you’ve got a constant bottleneck on your hands. Think of it like organizing a toolbox—having the right compartments in the right places makes every job faster.

Just like a mechanic needs specific tools for different jobs, your kitchen needs a freezer that matches its operational demands. This means really thinking about everything from the door style to where the cooling system lives. These choices directly impact your energy bills, your staff's efficiency, and even how quickly you can grab key ingredients during a chaotic dinner rush.

Let's break down the essential configuration choices you'll need to make to ensure your new freezer is a perfect fit for your workspace.

Solid Doors Versus Glass Doors

Your first big decision is the door style, and it's a classic trade-off between energy efficiency and inventory visibility. There’s no single “best” option here; the right one depends entirely on how you and your team actually use the freezer day-to-day.

-

Solid Doors: The Efficiency Champions. A reach-in with solid doors is like a well-insulated thermos. Its biggest strength is holding onto cold air. Thanks to superior insulation, the compressor doesn’t have to kick on as often, leading to significant energy savings over the unit's lifespan. This makes solid doors the clear winner for back-of-house storage where ingredients are accessed less frequently but need to stay at a rock-solid temperature.

-

Glass Doors: The Visibility Experts. On the flip side, a glass door freezer is all about quick access. Its main advantage is letting your staff see what’s inside without ever opening the door. This simple feature saves precious seconds during a hectic service and cuts down on how often the door is opened, which helps keep the internal temperature more stable. They’re perfect for busy prep lines or even customer-facing areas in cafes and markets.

The trade-off is clear: Solid doors give you maximum energy efficiency for long-term storage, while glass doors provide at-a-glance convenience that boosts workflow speed in active work zones.

Top Mount Versus Bottom Mount Compressors

The compressor is the heart of your reach-in freezer, and where it’s located—either on top of the unit or at the bottom—has real-world consequences for maintenance, ergonomics, and performance in different kitchen environments.

A top-mount compressor sits above the storage cabinet. This design is a lifesaver in kitchens with a lot of dust, flour, or other debris on the floor, since it pulls in cleaner air from higher up. That can mean less frequent cleaning for the condenser coils. The downside? The heat it generates rises toward the ceiling, which can make an already hot kitchen feel even warmer.

On the other hand, a bottom-mount compressor is at the base of the unit. This raises the lowest shelf, making it easier for staff to grab items without constantly bending over—a small but significant ergonomic win. This design can work a bit harder in greasy or dusty environments because it pulls air from floor level, but it tends to be more efficient in hotter kitchens since it isn't sucking in the warmest air rising to the ceiling.

| Compressor Placement | Key Advantages | Best For... |

|---|---|---|

| Top-Mount | Pulls cleaner air, reducing coil cleaning. | Bakeries, pizzerias, or kitchens with lots of floor debris. |

| Bottom-Mount | Ergonomic access to lower shelves; better efficiency in hot ambient air. | Standard kitchens where ergonomics are a priority and floors are kept clean. |

Finding the Right Number of Doors

The final piece of the configuration puzzle is deciding between a one, two, or three-door reach-in freezer. This choice is directly tied to your storage volume and the physical space you have available in your kitchen.

-

One-Door Models: These are the compact solution for small cafes, food trucks, or for a supplementary freezer at a specific kitchen station. They offer a small footprint without sacrificing commercial-grade power.

-

Two-Door Models: This is the industry workhorse and by far the most popular choice. It strikes a great balance between capacity and physical space, fitting well in most small to medium-sized restaurants.

-

Three-Door Models: Built for high-volume operations, these units offer maximum storage capacity. They are essential for busy restaurants, catering companies, and institutions that need to keep large quantities of frozen goods on-site.

How To Select The Right Freezer Size And Capacity

Choosing the right size for your reach-in freezer is easily one of the most important equipment decisions you'll make. It’s a tricky balance. Go too small, and you’ll constantly be fighting for space, unable to take advantage of bulk deals. Go too big, and you're just throwing money away on higher utility bills and eating up precious kitchen real estate.

It's about more than just cubic feet. The right capacity is a moving target, depending entirely on your menu, how often your suppliers show up, and what your kitchen looks like during an absolute madhouse of a dinner rush.

Calculating Your True Capacity Needs

You have to think about freezer capacity in terms of operational demand, not just physical space. A small coffee shop that gets daily deliveries of frozen pastries has completely different needs than a high-volume catering company that has to store a whole week's worth of event ingredients at once. Your mission is to find that sweet spot that keeps your kitchen humming without creating waste.

Here’s a practical way to think through your needs:

- Menu Complexity: The more frozen components you have—from proteins and veggies to pre-made sauces and desserts—the more organized, separate storage space you’re going to need.

- Delivery Frequency: If you get deliveries multiple times a week, you can probably get by with a smaller unit. But if your supplier only comes once a week, you'll need a bigger freezer to hold enough stock to get you through.

- Peak Volume: Always, always plan for your busiest days. Figure out how much frozen stock you need to survive your most slammed holiday weekend without running out of anything.

For a deeper dive, our guide on determining commercial refrigerator and freezer space offers a detailed way to map out your specific requirements and turn your kitchen's data into a solid number.

Matching Freezer Size To Your Business Type

To make things a little easier, let's connect common freezer sizes to real-world kitchens. This gives you a solid starting point for figuring out which model will best serve your crew and your customers.

Here's a quick reference table to get you started.

Reach In Freezer Sizing Guide

| Freezer Type | Typical Capacity (Cubic Feet) | Best For (Examples) |

|---|---|---|

| 1-Door Reach-In | 12-29 cu. ft. | Small cafes, coffee shops, concession stands, or as a dedicated station freezer in a larger kitchen. |

| 2-Door Reach-In | 30-55 cu. ft. | Mid-volume restaurants, bars, pizzerias, and most full-service kitchens. |

| 3-Door Reach-In | 56-80+ cu. ft. | High-volume restaurants, catering operations, cafeterias, and institutional kitchens. |

This table helps you visualize where your operation might fit, but remember to always consider your unique menu and workflow.

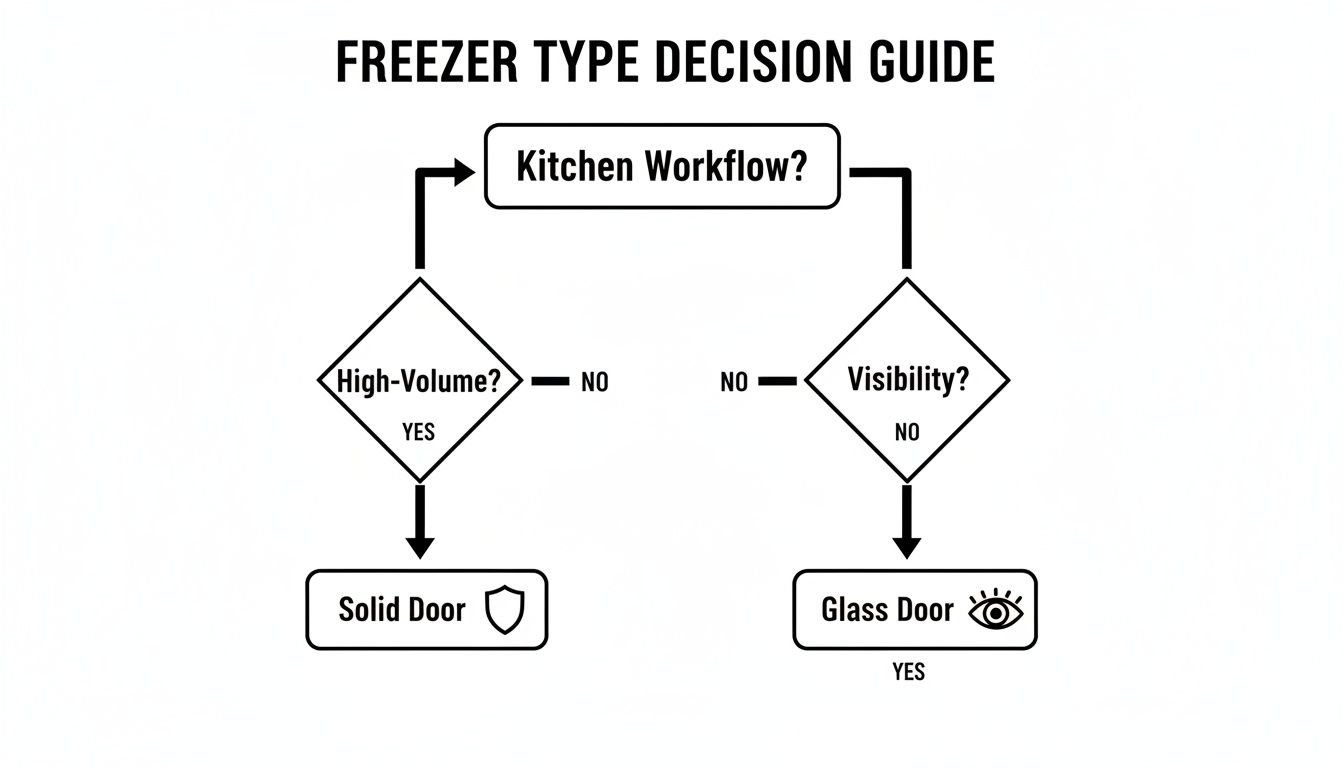

The flowchart below can also help you make that initial call based on what's most important in your kitchen's daily grind.

This really boils it down to a key decision: Solid doors are your best bet for high-volume, back-of-house workhorses where energy efficiency is king. Glass doors are perfect when your team needs to see inventory instantly to keep a fast-paced line moving.

A critical mistake I see people make is buying a freezer for their needs today without thinking about tomorrow. A reach-in freezer is a long-term investment. Always factor in a buffer of at least 15-20% more capacity than you think you need right now to handle menu changes or a sudden boom in business.

That bit of foresight will save you the massive headache and cost of outgrowing your equipment just a year or two down the road. It ensures your freezer stays a valuable tool, not a logistical bottleneck.

Performance and Energy Efficiency: The Real Cost of a Freezer

The sticker price on a new reach in freezer? That's just the down payment. The real, long-term cost of that machine shows up on your monthly utility bill and in its day-to-day performance. Investing in an efficient, high-performance unit isn't just a "green" choice; it's a critical business decision that directly protects your inventory and your bottom line.

A commercial freezer has one primary job: to hold a brutally cold, stable temperature. For most health departments, the gold standard is a consistent 0°F to -10°F (-18°C to -23°C). This isn't just a suggestion—it's the temperature range that slams the brakes on bacterial growth, locking in the flavor, texture, and quality of your food.

The Make-or-Break Metric: Temperature Recovery

In the heat of a dinner rush, your freezer door is swinging open and shut constantly. Every time it opens, that precious cold air spills out, and warm, humid kitchen air rushes in. This is where a crucial performance metric called temperature recovery time becomes your best friend or your worst enemy.

This metric measures how fast the freezer can battle its way back to its set temperature after the door closes. Think of it like your home AC on a sweltering day—if you leave a window open, it has to work overtime. A top-tier reach-in has a powerful compressor and smart air circulation designed to knock down those temperature spikes instantly, making sure your food never even gets close to the danger zone.

A fast recovery time isn't a luxury; it's a non-negotiable feature in a commercial kitchen. It's what stands between you and thousands of dollars in spoiled inventory, ensuring you stay compliant with food safety regs, even when you're slammed.

How to Read the Efficiency Labels

Beyond raw power, energy efficiency is where you'll find the biggest long-term savings. An energy-efficient model might cost a bit more upfront, but it pays you back every single month on your utility bill.

The most important sticker to look for is the ENERGY STAR certification. An ENERGY STAR freezer is, on average, 20% more energy-efficient than a standard model. They pull this off with a trio of smarter components:

- High-Efficiency Compressors: These are the modern engines of the freezer, using less juice to generate the same cooling power.

- Electronically Commutated (EC) Fan Motors: Instead of running at full blast all the time, these smart motors adjust their speed based on need, sipping energy instead of guzzling it.

- Better Insulation: Thicker, higher-quality insulation in the walls and doors means less cold air escapes, so the compressor doesn't have to kick on as often.

These pieces work together to shrink your operating costs day after day. For a deeper dive into calculating these savings, check out our guide on commercial freezer sizes and energy savings.

Eco-Friendly Refrigerants and Smart Tech

The type of refrigerant a freezer uses also has a huge impact on its efficiency and environmental footprint. Old-school refrigerants have been phased out, and the industry has shifted to natural, eco-friendly options.

The new king is R290 (propane), a hydrocarbon refrigerant with an incredibly low Global Warming Potential (GWP). Not only is it kinder to the planet, but it's also a more efficient coolant, which can trim your energy use even further.

Modern freezers are also packed with other smart features that chip away at your energy bill. For instance, bright LED lighting is now standard in most quality units. It uses up to 90% less energy than old-school incandescent bulbs and gives off almost no heat, meaning the compressor doesn’t have to work harder to compensate. Every component is designed to work smarter, not harder.

Installation and Maintenance Best Practices

Your reach-in freezer’s lifespan and performance really hinge on what happens after it’s delivered. Proper setup and consistent care aren't just suggestions—they're the secret to preventing costly emergency repairs, ensuring food safety, and keeping your energy bills in check. Think of it like a car: you can get regular oil changes, or you can drive it until the engine seizes. We both know which one is the smarter, cheaper choice.

Getting the installation right from day one sets the stage for years of reliable service. So many performance headaches can be traced back to a sloppy initial setup, making this a critical first step you can't afford to get wrong.

A Solid Foundation: The Keys to Proper Installation

Before you even think about plugging that new freezer in, take a moment to plan its home. A few simple checks here will save you from major issues down the road. The goal is simple: give the unit an environment where it can work efficiently without putting extra strain on its components.

To guarantee safe operation and the long life of your reach-in freezer, always follow proper installation procedures and consult resources like the electrical safety guidelines like NFPA 70E. This ensures your setup meets professional standards from the get-go.

Here are the non-negotiable installation steps:

-

Give It Room to Breathe: Your freezer's compressor is its engine, and it needs to breathe. Without proper airflow, it can't get rid of heat, causing it to overheat and work way too hard. Always leave at least 3-4 inches of space on all sides and on top of the unit.

-

Level the Unit: A wobbly, unlevel freezer puts unnecessary stress on the frame and can keep the doors from sealing properly. Use a level to make sure it's perfectly flat, adjusting the feet as needed. A tight door seal is crucial for holding temperature and saving energy.

-

Use a Dedicated Circuit: A commercial reach-in is a powerful piece of equipment. It needs its own dedicated electrical circuit, period. Plugging it into an overloaded circuit isn't just a performance killer—it's a serious fire hazard.

Your Preventative Maintenance Checklist

Once your freezer is up and running, a simple, repeatable maintenance routine is your best defense against those dreaded middle-of-the-night breakdowns. These tasks are easy and can add years to your equipment's life. Trust me, being proactive is far less stressful than being reactive.

Think of this checklist as a health plan for your freezer. A few minutes of care each month can save you from a catastrophic failure that could cost thousands in lost inventory and emergency repair bills.

This routine doesn't have to be complicated. Just build these tasks into your kitchen's regular cleaning schedule to make it a habit.

Monthly Tasks:

- Inspect Door Gaskets: Check the rubber seals around the doors for any rips, cracks, or brittleness. A leaky gasket lets cold air escape, forcing the compressor to run nonstop.

- Wipe Down the Interior: Clean up any spills or debris inside. This prevents funky odors, cross-contamination, and keeps things looking professional.

- Check Temperature Accuracy: Use a separate, reliable thermometer to confirm the freezer's digital display is telling the truth.

Quarterly Tasks:

- Clean the Condenser Coils: This is the single most important thing you can do. Dirty coils clogged with dust and kitchen grease will slowly choke your cooling system. Carefully vacuum or brush the coils clean every 90 days to keep air flowing freely.

- Clear the Drain Lines: Make sure the defrost drain lines are clear of any ice or gunk. A blockage can cause water to back up and freeze solid inside the unit.

For more hands-on advice, exploring expert guides on commercial freezer repair and maintenance can give you even deeper insights. Following these best practices will ensure your reach-in freezer remains a reliable kitchen workhorse for years to come.

Got Questions About Reach-In Freezers? We've Got Answers.

Stepping into the world of commercial refrigeration can feel a bit overwhelming, whether you’re buying your first piece of equipment or you’re a seasoned pro managing a busy kitchen. Getting straight answers is the key to making a smart investment and keeping your operation humming. This section is your quick-reference guide, tackling the most common questions we hear about the absolute workhorse of the modern kitchen—the reach-in freezer.

We’ve pulled together the top queries from operators just like you to give you direct, practical advice. Think of this as your friendly roadmap for filling in any gaps, solving common headaches, and feeling confident as you choose and manage this essential piece of equipment.

What Is The Difference Between A Reach In Freezer And A Walk In Freezer?

This is easily one of the most common points of confusion, but it becomes crystal clear once you picture your kitchen's daily flow. Just think of it as the difference between a small pantry right beside your stove and a massive storage closet down the hall.

A reach-in freezer is your day-to-day player. It's an upright, self-contained cabinet designed to be right in the action, positioned near your prep line. It gives your chefs instant access to the ingredients they need in the middle of a busy service. Its entire purpose is built around speed and convenience.

A walk-in freezer, on the other hand, is all about bulk, long-term storage. This is where you keep pallets of frozen goods and the deep inventory you won't touch for days or even weeks. Because of its size, it’s almost always located away from the main kitchen. While most kitchens absolutely need a reach-in for their active workflow, high-volume businesses often need both to manage their inventory efficiently.

How Often Should I Clean My Freezer's Condenser Coils?

If you only remember one piece of maintenance advice, let it be this. Cleaning your freezer's condenser coils is the single most important thing you can do to keep it running efficiently and extend its life.

For a typical commercial kitchen, cleaning the coils every 90 days is the bare minimum. But this isn't a hard-and-fast rule.

- High-Grease Environments: In kitchens with fryers or griddles, airborne grease can quickly blanket the coils. You'll want to inspect and clean them monthly.

- Bakeries or Pizzerias: Flour and dust are just as bad as grease. A monthly cleaning schedule is a must in these spots.

Dirty coils are like a thick wool blanket wrapped around your freezer's engine. They trap heat, forcing the compressor to work much harder. This not only spikes your energy bills but also weakens its cooling power and dramatically shortens the life of your freezer. A few minutes of cleaning can genuinely save you thousands in future repair costs.

Can I Use A Residential Freezer In A Commercial Kitchen?

It's tempting to look at the lower price tag of a residential freezer and think you've found a bargain. But trust us, putting one in a professional kitchen is a costly mistake just waiting to happen. There are a few critical reasons why this is a terrible idea, affecting everything from your food quality to your legal standing.

First off, residential units simply aren't built for the grind of a commercial kitchen. Their compressors, door hinges, and seals are designed for a family opening the door a dozen times a day—not a kitchen staff swinging it open hundreds of times during a single shift. The components will fail, and they will fail fast.

Second, they just don't have the muscle. They lack the raw cooling power and quick temperature recovery needed to keep food safe in a busy environment. Every time that door opens, warm air rushes in. A residential freezer can't bring the temperature back down fast enough, putting your valuable inventory at serious risk of spoilage.

Finally, and maybe most importantly, using a non-commercial freezer will almost certainly violate your local health codes. And if there's ever an electrical issue or fire, it could also void your business insurance policy. It's a gamble that's never worth taking.

What Certifications Should I Look For On A Reach In Freezer?

Think of certifications as your guarantee that a freezer meets strict national standards for safety and cleanliness. When you're shopping, there are two main seals of approval you should always look for. Seeing them ensures you'll pass health inspections and are running a safe, compliant kitchen.

These certifications are usually displayed on a sticker or a small metal plate, often on the inside of the door jamb or on the unit's exterior.

Key Certifications to Verify:

-

NSF (National Sanitation Foundation): This one is all about food safety. An NSF mark means the freezer is built with materials and a design that are easy to clean and resist bacterial growth. It confirms that all surfaces are smooth, non-porous, and constructed to prevent food contamination.

-

UL (Underwriters Laboratories) or ETL (Intertek): These marks are focused on electrical safety. A UL or ETL listing certifies that the freezer's wiring, components, and overall design have been rigorously tested to meet tough safety standards, protecting your business from fire and electrical hazards.

Seeing both of these certifications on a reach-in freezer gives you peace of mind that you're investing in equipment that is both safe for your food and safe for your staff.

At The Restaurant Warehouse, we provide top-tier, certified commercial refrigeration designed to meet the demands of any professional kitchen. Explore our extensive selection of reach-in freezers and find the perfect unit to power your operation.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment