Natural Gas vs Propane for Commercial Kitchens

When you're outfitting a commercial kitchen, the fuel source you choose is a huge decision. It often boils down to one simple, unavoidable factor: location.

If your restaurant has access to a municipal utility line, natural gas is almost always the more straightforward and budget-friendly choice. But for kitchens in more rural spots or buildings without that existing infrastructure, propane steps in as a powerful and reliable on-site fuel source.

Choosing Your Commercial Kitchen Fuel Source

Picking the right fuel is one of the most fundamental choices you'll make as a restaurant owner. It impacts everything from your daily operating costs to how well your cooking equipment actually performs. The real difference in the natural gas vs. propane debate comes down to how they're delivered and stored.

Think of natural gas as a utility, just like your water or electricity. It’s delivered continuously through a network of underground pipelines right to your kitchen. Propane, on the other hand, is stored on-site in tanks that you either own or lease, which means you'll need scheduled deliveries to keep your supply topped up.

This single distinction means your restaurant's physical address is often the biggest decider. A bistro in a busy downtown area will almost certainly have access to natural gas lines. A countryside wedding venue? That's classic propane territory. Beyond just availability, each fuel has its own unique profile when it comes to energy output, cost structure, and the infrastructure you'll need.

Before you commit, a smart first step is to list out the essential commercial kitchen equipment you plan on using. High-demand appliances can perform differently depending on the fuel, and this choice really sets the stage for your kitchen's efficiency and budget. The conversation also goes beyond just these two options, as many operators weigh the pros and cons we cover in our guide on choosing between electric or gas restaurant equipment.

Quick Comparison Natural Gas vs Propane

To give you a quick, at-a-glance summary of the key differences, we've put together this simple comparison table. Use it to quickly weigh the trade-offs.

| Factor | Natural Gas | Propane |

|---|---|---|

| Availability | Limited to areas with pipeline infrastructure | Available virtually anywhere |

| Energy Output | ~1,030 BTUs per cubic foot | ~2,490 BTUs per cubic foot |

| Storage | Delivered via pipeline; no on-site storage | Requires on-site storage tanks |

| Cost Structure | Priced per therm or cubic foot; monthly utility bill | Priced per gallon; requires tank purchase/lease |

| Convenience | "Set and forget" continuous supply | Requires monitoring and scheduled refills |

Ultimately, this table highlights the core decision: the effortless convenience of a utility versus the powerful, go-anywhere flexibility of stored fuel.

Comparing Fuel Properties and Energy Output

To really get to the bottom of the natural gas versus propane debate, you have to start with the fuels themselves. We need to look at what they are, how they generate heat, and what that means for your kitchen's performance. While both are fossil fuels, their chemical makeup and how they get to your equipment create some very real differences that you’ll feel during a busy service.

Natural gas is mostly methane. It’s lighter than air and gets delivered through a huge network of underground city pipelines. The big win here is convenience; it's a continuous supply you never have to think about. For a busy restaurant in a service area, it's a "set-it-and-forget-it" fuel source.

Propane, on the other hand, comes from natural gas processing and oil refining. You'll know it as Liquefied Petroleum Gas (LPG), and it’s compressed into a liquid for storage and transport. It's kept in tanks right on your property, giving restaurants powerful and reliable fuel, even if they're nowhere near a natural gas line.

The Critical Role of Energy Density

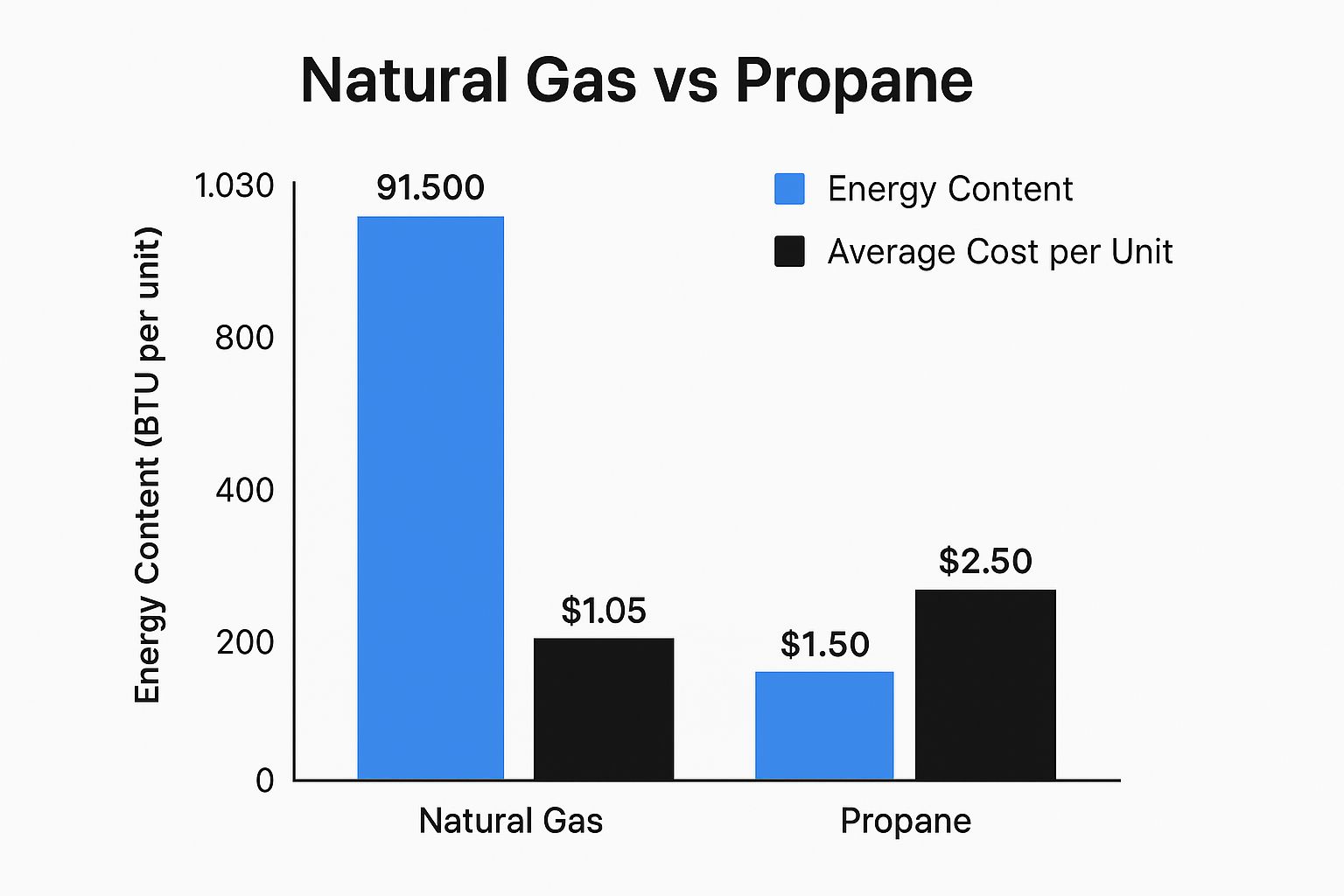

For a high-output kitchen, the single most important technical difference is energy density. This number, measured in British Thermal Units (BTUs), tells you exactly how much heat you get from a specific amount of fuel. And in this department, there's a clear winner.

- Natural Gas: Gives you about 1,030 BTUs per cubic foot.

- Propane: Packs a punch with roughly 2,490 BTUs per cubic foot.

That means propane delivers more than double the energy in the same amount of space. In the real world, this translates directly to faster preheating for your ovens, more intense flames on the charbroiler, and quicker recovery times for your deep fryers when you're slammed with orders.

Key Takeaway: Propane's higher energy density means your equipment can hit and hold its target temperatures faster. While natural gas is perfectly capable for most tasks, propane gives you a performance edge when speed and raw power are what you need most.

From Storage to Burner Tip

The journey each fuel takes to get to your cooking equipment is also completely different. Natural gas flows straight from the main line to your appliances at a low, steady pressure. Once you have that initial connection, the setup is pretty simple.

Propane’s journey is a bit more hands-on. It stays in its liquid state in your storage tank and only turns into a gas when it's drawn out and the pressure is lowered by a regulator. That step is essential because your kitchen equipment is built to run on a specific gas at a specific pressure.

This is exactly why you can't just flip a switch and go from one fuel to the other. If you're thinking about making a change, it's vital to understand what the conversion involves. We break down the necessary adjustments for orifices and regulators in our detailed guide on gas stove conversion from natural gas to propane.

Market Dynamics and Fuel Availability

While natural gas availability is tied to geography, propane's market is much more dynamic. The global propane market is set to grow significantly, from 187.5 million tons in 2024 to an expected 252.8 million tons by 2033. This growth is fueled by things like increased use in transportation to cut emissions and lower costs.

For a restaurant owner, this robust market means propane will be a widely available fuel for years to come, especially in places where natural gas lines aren't likely to expand.

Ultimately, the choice comes down to this: you have to weigh the uninterrupted convenience of pipeline-supplied natural gas against the superior heating power and go-anywhere availability of on-site propane.

A Practical Breakdown of Costs and Efficiency

When you're trying to decide between natural gas and propane, your budget is always top of mind. It’s tempting to just look at the price per unit and call it a day, but the real financial story is a lot more layered than that. To get a true picture, you have to look beyond the sticker price and consider service fees, infrastructure costs, and the all-important role of energy efficiency.

This deeper look often reveals that the "cheaper" option isn't always the one with the lower price tag. The fuel that costs less on paper might not be the most economical choice once you factor in how much energy it actually delivers to your commercial kitchen equipment.

Unpacking Natural Gas Costs

Think of natural gas like any other utility—it’s billed on a regular schedule, creating a predictable, recurring operational expense. When you get your monthly statement, the costs are generally broken down into a few key areas.

- Cost per Therm: This is the main charge for the fuel itself. Natural gas is usually measured in cubic feet or therms (a unit of heat energy), and the price can shift with market conditions.

- Monthly Service Fees: You’ll also pay a fixed monthly fee to the utility for account maintenance and access to the gas grid. This is a consistent cost, no matter how much or how little gas you use.

- Initial Connection Charges: If your building isn't already hooked up to the municipal gas line, this is a big one-time expense. It can involve trenching, laying pipe, and getting permits, potentially running you thousands of dollars upfront.

This setup offers convenience and steady billing, but it does tie you to a single provider and whatever their pricing structure happens to be.

Analyzing Propane Expenses

Propane's cost structure is a different animal because it's a delivered product, not a utility service. This gives you more control over your supplier, but it also introduces other variables into your financial planning.

- Cost per Gallon: Propane is sold by the gallon, and its price tends to be more volatile, often influenced by seasonal demand and global oil prices.

- Tank Fees: You’ll need a storage tank on your property. You can either buy one outright or lease it from your propane supplier for a recurring fee.

- Delivery Costs: Your supplier will charge a fee for each delivery, which might be bundled into the per-gallon price or listed as a separate line item on your bill.

Getting a handle on these components is crucial for accurately forecasting your kitchen's fuel budget. For a deeper dive, our propane cookstove guide offers some valuable insights for commercial kitchen operators.

How Energy Density Impacts Your Bottom Line

This is where the financial comparison gets really interesting. While natural gas often has a lower price per unit, propane’s superior energy density can totally level the playing field. Propane packs a much bigger punch, delivering over twice the heat energy (~2,490 BTUs) per cubic foot compared to natural gas (~1,030 BTUs).

A Key Financial Insight: Because propane burns hotter, your equipment uses less fuel to reach and hold the same temperature. This means that even if propane costs more per unit, its efficiency can lead to a comparable—or sometimes even lower—total annual fuel cost.

Let's run the numbers for a real-world scenario to see how this actually plays out.

Real-World Scenario: A Pizzeria's Annual Fuel Bill

Imagine you're opening a busy pizzeria with two high-output deck ovens running for 10 hours a day. Let’s calculate the potential annual fuel costs, keeping in mind these numbers are just for illustration.

Natural Gas Calculation:

- Assume a cost of $1.50 per therm.

- Your ovens use a combined 5 therms per day.

- Daily Cost: 5 therms x $1.50 = $7.50

- Annual Cost (360 days): $7.50 x 360 = $2,700

Propane Calculation:

- Assume a cost of $2.50 per gallon.

- Thanks to higher efficiency, the same ovens use 2.5 gallons per day.

- Daily Cost: 2.5 gallons x $2.50 = $6.25

- Annual Cost (360 days): $6.25 x 360 = $2,250

In this specific case, even with propane's higher per-gallon price, its energy efficiency results in an annual saving of $450. This is a perfect example of why you have to look at both price and performance to make the smartest financial decision for your kitchen.

Sorting Out Installation and Infrastructure

Choosing between natural gas and propane goes way beyond the fuel itself. It’s a nuts-and-bolts decision about infrastructure. One option tethers you to an underground municipal grid, while the other requires you to manage fuel storage right on your property. Getting a handle on these differences is key to planning your kitchen's layout, budget, and timeline because the setup for each is a completely different ballgame.

With natural gas, everything boils down to a single question: is there a gas main already running to your building? If so, you're in good shape. A licensed pro can simply run the necessary pipes from that main line to your equipment. The whole process is usually pretty straightforward and won't break the bank.

But if your restaurant is in a location without an existing connection, things get a lot more complicated—and expensive. Tapping into a new natural gas line means working with the local utility, pulling permits, and paying for some serious construction, like trenching from the street to your building. This isn't a quick job; it can take weeks or even months and tack on thousands of dollars to your initial setup costs.

Getting Connected to Natural Gas

If you discover you need a brand-new natural gas line, the process involves a few critical steps. Every stage needs professional oversight to make sure the installation is safe and up to code.

- Talk to the Utility: Your first call should be to the local gas company to check if service is even available and to get a quote for a new connection.

- Permits and Inspections: You'll need to secure the right permits from your city or county. Expect inspections at various points to ensure everything meets safety regulations.

- Trenching and Pipework: This is where the heavy lifting happens. A trench will be dug to lay the new gas line from the street to your building’s meter.

- Plumbing and Hookups: Once the meter is set, a qualified plumber takes over, running the interior gas lines to each piece of your commercial kitchen equipment.

To ensure your fuel delivery system is both durable and safe, referring to a good guide to stainless steel pipe and fittings is a smart move when you're sorting out these installation details.

Managing Your Own Propane Setup

Propane flips the script entirely, offering a self-contained installation built around on-site storage. This makes it a fantastic option for almost any location, but it comes with its own set of logistical hurdles and strict safety rules you absolutely must follow. The biggest piece of the puzzle is the storage tank itself.

Picking the right tank size is a crucial first step. You need one large enough to handle your kitchen’s busiest days without needing constant refills, but not so big that it’s a waste of space and money. Your propane supplier will be your best friend here; they can help you calculate your expected usage based on your equipment and hours to recommend the perfect tank.

Crucial Consideration: Local zoning laws and fire codes are very specific about where a propane tank can be placed. These rules dictate minimum distances from buildings, property lines, and potential ignition sources to ensure everyone's safety.

Let's break down the key differences in infrastructure and setup for natural gas versus propane systems.

Installation and Infrastructure Requirements

A comparative look at the installation process, logistical needs, and key considerations for natural gas and propane systems.

| Consideration | Natural Gas Setup | Propane Setup |

|---|---|---|

| Source | Supplied by a public utility via an underground pipeline network. | Stored on-site in a dedicated tank refilled by a supplier. |

| Availability | Limited to areas with existing municipal gas line infrastructure. | Available almost anywhere, ideal for rural or off-grid locations. |

| Installation Complexity | Simple if a connection exists; complex and costly if a new line is needed. | Involves tank placement, trenching for lines, and professional setup. |

| Upfront Cost | Can be very high ($5,000 - $20,000+) if a new main line is required. | Primarily the cost of the tank (rent or buy) and installation ($1,500 - $5,000). |

| Space Requirement | Minimal, as the infrastructure is mostly underground. | Requires significant outdoor space for the tank, adhering to safety codes. |

| Ongoing Management | Little to none; the utility handles supply and maintenance. | Requires monitoring fuel levels and scheduling regular deliveries. |

As you can see, the decision isn't just about the fuel—it’s about the entire support system behind it.

Once the tank is in place, a licensed technician runs gas lines from the tank's regulator to your kitchen appliances. While it’s a similar process to plumbing for natural gas, it’s all contained on your property. This gives you more control over the installation schedule since you aren’t waiting on a public utility.

The image above really drives home a key point: while propane might cost more per unit, it packs a much bigger energy punch (more BTUs). This is a huge factor in its efficiency during day-to-day operations.

Evaluating Safety Protocols and Maintenance

In the controlled chaos of a commercial kitchen, safety is the one thing you can't afford to get wrong. When you're weighing natural gas against propane, getting a handle on their physical properties is the first step to building a rock-solid safety plan. Both fuels are incredibly safe when handled with respect, but their differences call for unique protocols and maintenance routines.

The most critical distinction is their density. Natural gas is lighter than air. If a leak springs in a well-ventilated kitchen, the gas will rise and dissipate, making it less likely to build up to dangerous levels near the floor.

Propane, on the other hand, is heavier than air. If there's a leak, that gas is going to sink and pool in low-lying spots like basements, floor drains, or right along the floor. This creates a serious ignition risk, as the concentrated gas could easily find a pilot light or an electrical spark.

Critical Safety Systems for Your Kitchen

Because of these properties, the safety gear and procedures for each fuel aren't quite the same. Your kitchen’s layout and your team’s training have to be tailored to the specific fuel you’re using. A comprehensive safety strategy is non-negotiable.

For any gas system, these are the absolute must-haves:

- Professional Installation: All gas lines, fittings, and connections have to be installed and inspected by a licensed pro. This ensures everything is leak-free and up to local code.

- Automatic Shut-Off Valves: These devices are lifesavers, designed to instantly cut the fuel supply in an emergency, like when a fire suppression system goes off.

- Proper Ventilation: A powerful, well-maintained ventilation system is vital for pulling unburnt gas, heat, and combustion fumes out of the kitchen, no matter which fuel you use.

Where things really differ is the placement of your gas detectors. Natural gas detectors need to be installed up high, near the ceiling, where the lighter gas will collect first. For propane, detectors must be placed near the floor to catch the heavier, pooling gas before it becomes a hazard.

"Your first line of defense is always prevention, but your second is detection. Placing detectors correctly based on your fuel type—high for natural gas, low for propane—is one of the most critical and often overlooked safety details in a commercial kitchen."

Comparing Maintenance Routines

Day-to-day maintenance is what keeps your fuel system running safely and efficiently. While both fuels require you to be diligent, their maintenance checklists look a little different, mostly because of how they’re delivered and stored. A proactive approach here stops small issues from turning into big, dangerous problems.

Natural Gas Maintenance: With natural gas, the main focus is on the integrity of the pipelines inside your building.

- Periodic Line Inspections: Get a professional to regularly inspect all your interior gas lines, connections, and appliance hookups to check for any corrosion or potential leaks.

- Appliance Servicing: Make sure all your equipment is serviced on a regular schedule to keep it burning efficiently and to check for any issues with the burners or pilot lights.

Propane System Maintenance: For propane, the maintenance checklist extends outside the kitchen to the on-site storage tank and all its components.

- Tank and Regulator Checks: The storage tank, regulators, and gauges need to be inspected regularly for any signs of damage, rust, or malfunction.

- Fitting and Hose Inspection: All the fittings and hoses that connect the tank to your main line require routine checks to make sure they’re secure and free of any cracks or wear.

- Supplier Coordination: You'll want to work closely with your propane supplier. They often handle a good chunk of the tank and regulator maintenance as part of your service agreement.

Let's Talk About the Environmental and Sustainability Side

As more and more restaurant owners get serious about sustainability, the environmental impact of their fuel choice has become a huge part of the conversation. When you're weighing natural gas against propane, it's important to look past simple labels. Sure, both are fossil fuels, but their emission profiles are different in ways that could steer your decision, depending on your green goals.

Both fuels are widely seen as cleaner-burning alternatives to other fossil fuels like coal or oil. Natural gas is known for its relatively low carbon dioxide (CO2) output, while propane is officially listed as an approved clean alternative fuel under the Clean Air Act. For any business owner, this means choosing either one is a definite step up from older, less efficient fuel sources.

The real difference comes into focus when you look at the specific emissions each one produces during combustion. It’s a nuanced comparison that goes way beyond just a single greenhouse gas.

A Deeper Look at Emissions Profiles

While both are considered "clean," their chemical makeup means they burn a little differently. Natural gas is mostly methane, whereas propane is a distinct hydrocarbon (C3H8). This fundamental structural difference directly affects what gets released into the atmosphere from your kitchen equipment.

From an environmental standpoint, natural gas produces significantly lower emissions than other traditional fossil fuels. Its carbon dioxide (CO2) emission factor averages 2.2 tonnes per tonne of primary energy—that's about 20% less than oil and a whopping 43% less than coal. It also kicks out 50% fewer nitrogen oxides than coal and 85% less than oil, and it nearly eliminates sulfur dioxide emissions completely. You can explore more detailed natural gas statistics to see the full picture.

Propane has a strong environmental record, too. It produces very little sulfur dioxide and has low carbon content. While natural gas might produce slightly less CO2 per unit of energy, some analyses point out that it can emit more methane—a potent greenhouse gas—during its extraction and transportation process.

Key Sustainability Insight: This isn't a choice between a "dirty" and a "clean" fuel. It's a trade-off between different emission profiles. Natural gas generally offers lower direct CO2 emissions from your kitchen, while propane is known for its minimal particulate matter and sulfur content, which contributes to better local air quality.

Aligning Your Fuel Choice with Your Green Initiatives

For a restaurant aiming to shrink its carbon footprint, both fuels offer a solid path forward, but the best choice might hinge on your specific priorities. Understanding these nuances helps you make a decision that genuinely lines up with your brand's environmental commitments.

Here’s how you can frame the decision based on different green goals:

- Prioritizing Carbon Reduction: If your main goal is to minimize direct CO2 emissions from your kitchen's day-to-day operations, natural gas often has a slight edge due to its lower carbon content per BTU.

- Focusing on Air Quality: For businesses in dense urban areas worried about local air pollution, propane's near-zero sulfur and low particulate emissions can be a really compelling advantage.

- Off-Grid Sustainability: For a rural or remote spot committed to sustainable practices without access to utility lines, propane provides a clean-burning fuel that supports both operational independence and environmental responsibility.

At the end of the day, both natural gas and propane are far more sustainable choices for a commercial kitchen than heating oil or coal. The natural gas vs propane debate from an environmental perspective shows that both are strong contenders in the clean fuel category. Your final decision can be confidently based on which fuel’s specific environmental benefits best match your restaurant's location, operational needs, and long-term sustainability vision.

Answering Your Final Questions About Kitchen Fuels

Okay, even after you've weighed the costs, installation headaches, and performance specs, a few practical questions might still be lingering. Choosing between natural gas and propane isn't just about the big picture; it's about the day-to-day realities that will shape your kitchen's workflow. Let's tackle some of the most common questions restaurant owners have before they make the final call.

Getting these last details sorted out will help you move forward with confidence, knowing you’ve picked the fuel that truly fits your kitchen.

Can I Use the Same Equipment for Both Fuels?

Not right out of the box, no. Commercial kitchen gear is built with specific orifices and regulators designed for either natural gas or propane. Propane is a different beast—it's delivered at a higher pressure and packs more energy. If you tried to run propane through a natural gas appliance, you’d get dangerously large flames. It’s a serious safety issue.

The good news is that most manufacturers offer conversion kits. A qualified technician can easily swap out the necessary parts to safely switch a piece of equipment from one fuel to the other, ensuring it runs exactly as it should.

Key Insight: Always factor in conversion costs if you plan on switching fuels or buying used equipment. Getting a professional to handle the conversion isn't just a recommendation—it's an absolute must for the safety of your kitchen and your team.

Which Fuel Is More Reliable During a Power Outage?

Propane is the clear winner when the lights go out. Because it’s stored in a self-contained tank right on your property, your propane system doesn't need the electrical grid to work. As long as your appliances have standing pilot lights or a backup power source for their igniters, your kitchen can keep cooking through a blackout.

Natural gas, on the other hand, relies on a pipeline network that often uses utility-run compression stations. Those stations need electricity. While it's a rare event, a widespread and lengthy power outage could potentially disrupt the natural gas supply.

How Volatile Are Propane Prices?

Propane prices can definitely bounce around more than natural gas rates. They are often tied to seasonal demand and the price of crude oil. When cold weather hits, demand for residential heating spikes, and that can drive up costs for everyone.

For example, in January 2025, U.S. propane consumption hit 1.48 million barrels per day—the highest January level since 2005—mostly because of a severe cold snap. This shows just how directly weather can make prices swing. You can dive deeper into these propane consumption trends on EIA.gov to get a feel for the market.

At The Restaurant Warehouse, we provide the high-performance cooking equipment you need, no matter which fuel you choose. Equip your kitchen with top-tier, energy-efficient appliances by exploring our extensive catalog at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment