Mastering the Dough: A Guide to 60-Inch Pizza Prep Tables

Why 60-Inch Pizza Prep Tables Are the Cornerstone of Efficient Pizzerias

A 60 inch pizza prep table is far more than just a piece of equipment; it is the undisputed backbone of any successful pizza operation. It serves as the central command station, providing the perfect trifecta of expansive workspace, organized refrigerated storage, and immediate access to every essential ingredient. These commercial refrigerated units are carefully engineered to keep your valuable toppings within the critical food-safe temperature zone, all while giving your chefs the ample room they need to craft perfect pizzas with speed, consistency, and artistry. Imagine a chaotic kitchen during a dinner rush: chefs scrambling for ingredients in a walk-in cooler, dough being prepped on inadequate surfaces, and service slowing to a crawl. Now, picture a streamlined kitchen where a 60-inch prep table anchors the workflow, changing that chaos into a symphony of efficiency. This is the strategic advantage it offers.

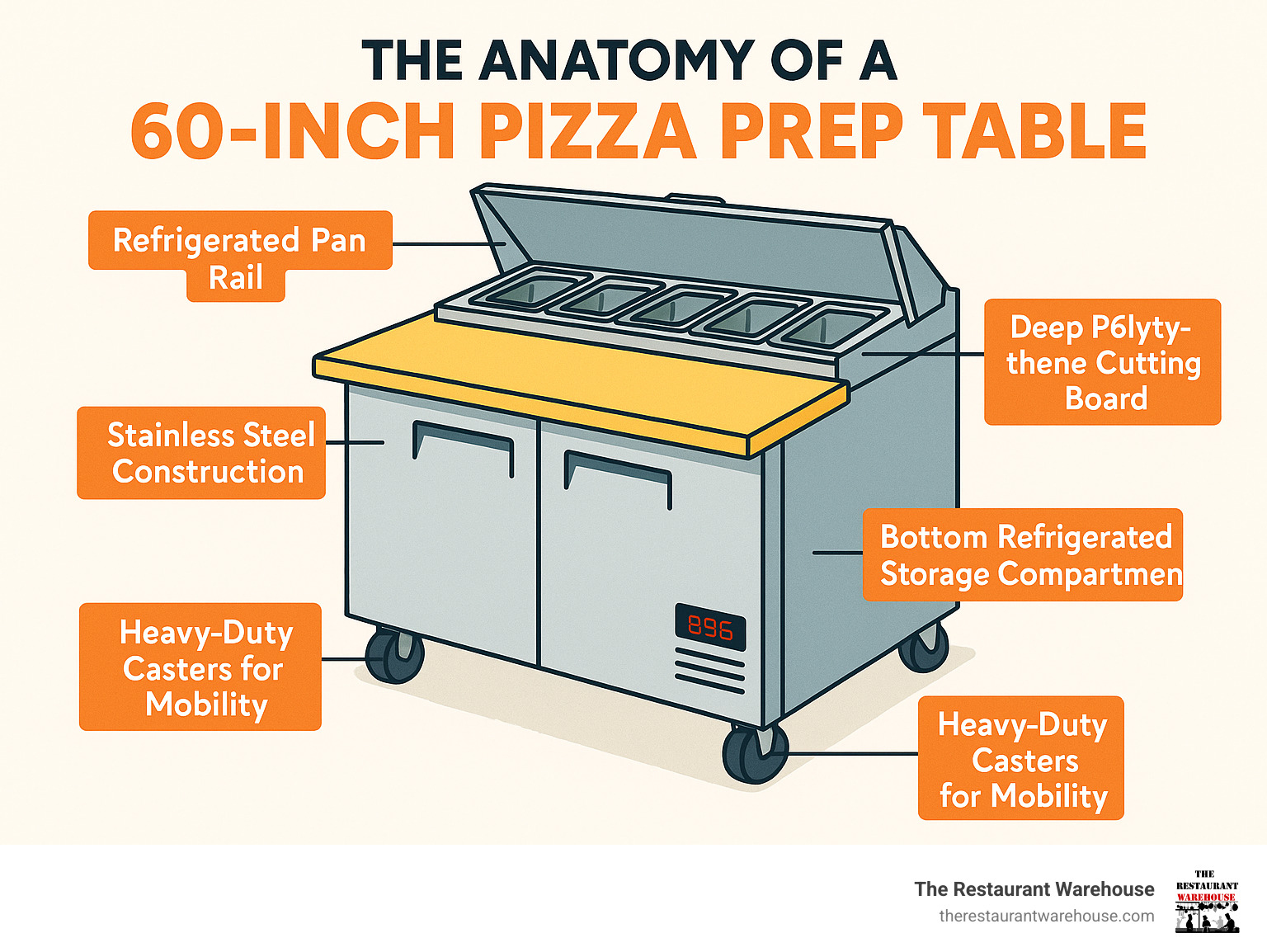

Unpacking the Top Features of a 60-Inch Pizza Prep Table:

- Expansive Deep Cutting Board (19.5+ inches): This isn't just a cutting board; it's a stage for your pizza creation. The extra depth is non-negotiable for pizzerias, comfortably accommodating the stretching and saucing of large 16-inch or 18-inch pizza doughs without overhang, which prevents contamination and mess. This generous surface area allows for a logical, linear workflow—from dough to finished product—all in one space.

- High-Capacity Refrigerated Pan Rail: Designed to hold between 8 and 12 industry-standard 1/3-size food pans, this feature is the heart of your ingredient organization. It keeps everything from pepperoni and mushrooms to fresh basil and mozzarella perfectly chilled between 33°F and 41°F. This precise temperature control is vital for preserving the texture, flavor, and safety of your toppings, ensuring every pizza served is of the highest quality.

- Durable Stainless Steel Construction: Pizzeria environments are demanding. Acidic tomato sauce, spills, and constant cleaning can take a toll on lesser materials. A high-quality stainless steel body (often 304-grade on the top and interior for maximum corrosion resistance) ensures your investment withstands the rigors of daily use, remains easy to sanitize, and maintains a professional appearance for years.

- Versatile Bottom Refrigerated Storage: The cabinet below the work surface provides crucial bulk storage. Whether you choose a 2-door configuration for large dough boxes and bags of cheese or a multi-drawer setup for pre-portioned ingredients, this space reduces trips to the walk-in cooler, saving precious time during peak hours.

- Mandatory NSF-7 Compliance: This certification is your assurance of food safety. NSF-7 compliant tables are tested to maintain safe product temperatures in an ambient kitchen environment of up to 86°F, a critical standard for passing health inspections and protecting your customers.

- Eco-Friendly R290 Refrigerant: Modern prep tables use R290 hydrocarbon refrigerant, a game-changer for both the environment and your wallet. It has zero ozone depletion potential (ODP), a negligible global warming potential (GWP), and is significantly more energy-efficient than older refrigerants, leading to lower electricity bills.

- Precision Digital Temperature Controls with Automatic Defrost: Forget analog guesswork. Digital controls allow you to set and monitor the cabinet and pan rail temperatures with precision. An automatic defrost cycle prevents ice buildup on the evaporator coil, ensuring the refrigeration system runs efficiently without requiring manual intervention.

Whether you are launching a brand-new pizzeria or upgrading an existing kitchen, a 60-inch model offers the ideal footprint. It provides enough pan capacity for a diverse and exciting menu while fitting comfortably into most standard commercial kitchen layouts. The powerful forced-air refrigeration system maintains consistent temperatures from top to bottom, even when lids are opened frequently. Furthermore, most units feature heavily foam-insulated lids that not only keep toppings fresh but also minimize condensation, preventing water from dripping into your food pans. This thoughtful engineering makes the 60 inch pizza prep table an indispensable asset for any serious pizza-making enterprise.

When we dig into the operational heart of a busy pizzeria, the 60 inch pizza prep table invariably emerges as the strategic hub that dramatically improves workflow and efficiency. This specific size hits the ultimate sweet spot, offering an optimal and highly sought-after blend of ingredient capacity and physical footprint. In a high-pressure kitchen environment, a 60-inch unit provides a centralized, all-in-one station where every essential ingredient is within immediate arm's reach, perfectly chilled and ready for use. This meticulous organization drastically reduces unnecessary movement, wasted steps, and frantic searching, allowing your team to assemble pizzas with remarkable speed, consistency, and precision. The ample workspace is a true game-changer, providing enough room for dough, toppings, and tools, which minimizes production bottlenecks and maximizes your kitchen's total output. Critically, these tables are engineered to maintain ingredients in the strict temperature range of 33°F to 41°F. This precise temperature control is not just a feature; it is a fundamental requirement for food safety and for preserving the delicate freshness of ingredients, ensuring that every customer receives the highest quality product you can offer. The balance of capacity versus footprint is a key advantage. A 60-inch table provides substantial storage for a wide array of toppings without overwhelming your valuable kitchen space. This thoughtful design ensures you can handle high-volume rushes with far less restocking. Efficient ingredient management also leads to a significant reduction in food waste by keeping toppings at their optimal temperature and easily accessible. Less waste directly translates to better cost control and a more profitable, sustainable operation. Choosing a 60-inch pizza prep table is a direct investment in the efficiency, food safety, and ultimate productivity of your entire pizza-making process. For more insights on optimizing your pizza production, we invite you to explore our comprehensive Pizza Prep Table Guide.

Core Features to Demand in Your Next 60-Inch Pizza Prep Table

When you're ready to invest in a 60 inch pizza prep table, understanding the nuances of its features is what separates a good purchase from a great long-term investment. The difference between a workhorse that boosts your bottom line and a unit that causes constant headaches lies in the details. A deep dive into these core features will empower you to select a machine that pays dividends in productivity, reliability, and longevity for years to come.

Construction and Workspace: The Foundation of a Great Prep Table

The construction quality of your 60 inch pizza prep table is the first line of defense against the demanding environment of a commercial kitchen. It must be built to withstand constant use, chemical cleaners, and the occasional bump from a hurried employee.

- Superior Stainless Steel Construction: Look for units that specify the grade of stainless steel used. A 304 stainless steel top and interior offer superior resistance to corrosion and rust, which is especially important when dealing with acidic ingredients like tomato sauce and pineapple. The exterior is often made of durable 430 stainless steel. Pay attention to the gauge; a lower gauge number means thicker, more durable steel. Welded corners and a polished finish are signs of quality craftsmanship that will last.

- The Essential Deep Cutting Board: A removable, full-length polyethylene cutting board with a depth of at least 19.5 inches is standard for a reason. This non-porous material is durable, gentle on knives, and easy to clean and sanitize. Its removability is key for deep cleaning to prevent cross-contamination. The depth allows chefs to work on large pizzas without the dough touching unsanitized surfaces.

- Optimized Pan Capacity: A 60-inch model typically holds 8 to 12 1/3-size pans. This configuration is ideal for holding larger quantities of popular toppings like cheese and pepperoni, reducing the frequency of refills during a busy shift. Before buying, map out your menu's core ingredients to ensure the pan capacity matches your needs. Some units offer flexible rail systems that can accommodate a mix of pan sizes.

- High-Efficiency Insulated Lids: The lids covering the pan rail are crucial for temperature control and energy efficiency. Look for heavy, foam-insulated stainless steel lids that create a tight seal. This prevents cold air from escaping and warm kitchen air from entering, keeping your ingredients fresher and making your compressor work less. Some models feature dual or split lids, allowing access to one side of the rail without exposing the other.

- Mobility with Heavy-Duty Casters: Your prep table shouldn't be a permanent fixture. Pre-installed, heavy-duty casters (wheels) are essential for mobility. They allow you to easily move the unit away from the wall for thorough cleaning of the floor and walls behind it, as well as for servicing the refrigeration components. Look for models with at least two locking front casters to keep the table securely in place during use.

For more insights into setting up your kitchen workspace, see our Preparation Table Kitchen Guide.

Refrigeration System: The Heart of Your 60 inch pizza prep table

The refrigeration system is the engine that powers your prep table. Its performance directly impacts food safety, ingredient quality, and your monthly utility bills.

- Advanced Forced-Air Refrigeration: This technology uses fans to circulate cold air evenly throughout the pan rail and the storage cabinet below. Unlike older cold-wall systems, forced-air refrigeration ensures there are no warm spots, keeps temperatures consistent, and allows the unit to recover its set temperature much faster after doors are opened—a critical feature during a busy service.

- Unyielding NSF-7 Compliance: This is a non-negotiable food safety standard for commercial refrigeration. NSF-7 certification means the unit has been rigorously tested to hold food at or below 41°F in a hot, ambient environment. This is a key requirement for health department inspections and a testament to the unit's cooling power.

- The Critical Temperature Range of 33°F to 41°F: This is the FDA-mandated safe zone for cold food storage. A quality prep table will allow you to precisely maintain this range, preventing the growth of harmful bacteria and preserving the optimal texture and freshness of your ingredients.

- Future-Proof R290 Hydrocarbon Refrigerant: R290 is the modern standard for commercial refrigeration. It's a natural, non-toxic propane that is vastly superior to older Freon-based refrigerants (like R134a or R404a). It boasts a Global Warming Potential (GWP) of just 3, compared to nearly 4,000 for R404a. Its thermodynamic properties also mean it absorbs heat more efficiently, resulting in faster temperature recovery and up to 40% less energy consumption.

- User-Friendly Digital Temperature Controls: Precise monitoring is key. A digital thermostat with an external LED display provides an at-a-glance reading of the internal temperature, allowing for easy monitoring and adjustment without opening the door. This feature often includes an integrated automatic defrost system that keeps the unit running at peak efficiency.

- Service-Friendly Compressor Location: Most high-quality prep tables feature a side-mounted or rear-mounted compressor. Side-mounted units are often easier to access for cleaning the condenser coil and for service, as they draw in and exhaust air from the side, allowing the back of the unit to be placed closer to a wall. Front-breathing designs are also excellent for tight spaces, as they can be fully enclosed on the sides and back.

Learn more about modern refrigeration options in our guide on Freshness on Demand: Top Commercial Prep Fridge Options.

Storage Configurations for Your 60 inch pizza prep table

The refrigerated cabinet below your work surface is valuable real estate. The right configuration of doors and drawers can significantly streamline your prep process.

- 2-Door Configurations: This is the classic setup, offering the most open and flexible storage space. It's ideal for storing bulky items like large dough boxes, cases of cheese, gallons of sauce, and other large containers. Most models come with adjustable, heavy-duty shelves to customize the space.

- Drawer Configurations (2, 3, or 4 Drawers): Drawers excel at organization and portion control. They are perfect for storing pre-portioned dough balls, individual containers of sliced meats, or different cheese blends. This setup can improve speed and consistency, as staff can quickly grab exactly what they need. Drawers also minimize cold air loss, as you are only opening a small section of the cabinet at a time.

- Combination Models (Door/Drawer): Offering the best of both worlds, these models typically feature one door section for bulk storage and a set of drawers for organized, quick-access items. This is an increasingly popular choice for operators who want both flexibility and organization in one unit.

When inspecting the storage area, look for adjustable, epoxy-coated steel shelves. The epoxy coating provides an extra layer of protection against rust and corrosion, which is essential in a moist, refrigerated environment. For more on optimizing your prep station, see our guide on Choosing the Right Sandwich Prep Table.

Choosing the Right Model: Key Buying Considerations for Your Pizzeria

Picking the perfect 60 inch pizza prep table is a strategic decision that goes beyond just comparing prices. It requires a thoughtful evaluation of your unique operational needs, kitchen environment, and future growth plans. Let's walk through the key factors that will guide you toward making the smartest, most profitable choice for your pizzeria.

1. Kitchen Layout and Workflow Analysis: Before you even look at models, look at your space. A 60-inch table is versatile, but you must be meticulous with your measurements. Don't just measure the footprint where the table will sit. Consider the entire workflow around it.

- Clearance is Key: Ensure you have at least 3-6 inches of clearance at the back and sides for proper ventilation and heat dissipation from the compressor. This is non-negotiable for the unit's longevity and efficiency.

- Ergonomic Flow: Map out the path your staff will take. Is there a clear, unobstructed route from the dough sheeter to the prep table, and from the prep table to the loading area?

- Door and Drawer Swing: Measure the space needed for doors and drawers to open fully without blocking walkways or hitting other equipment. A few inches of miscalculation can create a major bottleneck during a busy service.

2. Matching Capacity to Production Volume: Your daily and peak production volume is a primary driver of your decision. A 60-inch table is generally considered ideal for medium to high-volume operations.

- Low Volume (Under 100 pizzas/day): You might get by with a smaller 48-inch unit, but a 60-inch provides valuable room to grow.

- Medium to High Volume (100-300+ pizzas/day): A 60-inch table is the sweet spot. Its 8-12 pan capacity and ample workspace can keep pace with a steady stream of orders without constant restocking or workflow friction.

- Very High Volume (400+ pizzas/day): While a 60-inch can still work, you might consider a larger 72-inch+ model or even a second prep table to create a dedicated assembly line. For a new pizzeria, investing in a 60-inch model from the start is often a wise move, preventing the need for a costly and disruptive upgrade just a year or two down the line.

3. Menu Complexity and Topping Variety: The diversity of your menu directly impacts the pan capacity you'll need. A simple, classic menu (e.g., cheese, pepperoni, sausage, mushrooms) might only require a model with 8 pans. However, if you pride yourself on offering a wide range of gourmet and specialty toppings—artichoke hearts, prosciutto, goat cheese, multiple vegetable options—you should look for models with 10 or 12 pan capacity to keep everything organized and within arm's reach. This prevents cross-contamination and speeds up the assembly of complex orders.

4. Budgeting for Total Cost of Ownership: A 60 inch pizza prep table can range in price from around $1,599 for a solid, entry-level model to over $7,000 for premium units with advanced features. The initial purchase price is only part of the equation. The key is to evaluate the total cost of ownership (TCO). A cheaper unit might have a less efficient compressor and poorer insulation, leading to higher monthly utility bills that negate the initial savings. At The Restaurant Warehouse, we focus on maximizing your value. By eliminating high sales commissions and traditional retail overhead, we offer wholesale pricing on high-quality, durable equipment, allowing you to get a better, more efficient unit for your budget.

5. Prioritizing Energy Efficiency: An energy-efficient prep table is good for the planet and great for your bottom line.

- R290 Refrigerant: As mentioned, units with R290 hydrocarbon refrigerant are the gold standard for efficiency. They use significantly less energy to maintain temperature.

- ENERGY STAR® Certification: Look for the blue ENERGY STAR® label. Certified commercial refrigerators are, on average, 20% more energy-efficient than standard models. This certification ensures the unit has met strict energy performance standards set by the U.S. Environmental Protection Agency.

- Insulation: High-quality, high-density polyurethane foam insulation in the cabinet and lids plays a huge role in preventing cold air loss and reducing compressor run time.

6. Scrutinizing Warranty Coverage and Support: The warranty is one of the most critical,, factors. A strong warranty is a direct reflection of the manufacturer's confidence in their product's quality and durability.

- What to Look For: A comprehensive warranty should include both parts and labor coverage for at least 2-3 years. Critically, look for an extended compressor warranty of 5 to 7 years, as the compressor is the most expensive component to replace.

- Read the Fine Print: Understand what is and isn't covered. Are gaskets and other "wearable" parts excluded? Does the labor coverage include the technician's travel time? A weak warranty can leave you with a massive repair bill down the road.

7. Diving into the Spec Sheet: Before making a final decision, always download and carefully review the manufacturer's specification sheet. This document contains the vital technical details you need to confirm the unit meets your requirements. Here's an example of what to look for when evaluating specifications like amperage, horsepower, BTUs, and precise dimensions. Proper care is also essential to protect your investment; our comprehensive guide on Pizza Prep Table Maintenance provides a roadmap for longevity.

The right prep table becomes a seamless extension of your team—it's reliable, efficient, and always ready to help you serve perfect pizzas, day in and day out.

How a 60-Inch Table Compares to Other Sizes: Finding Your Perfect Fit

When selecting a pizza prep table, a common dilemma for pizzeria owners is choosing the right size. It's tempting to think that bigger is always better, or that a smaller unit will save space and money. The truth, however, is that finding the perfect size is a strategic balancing act. The 60 inch pizza prep table has earned its reputation as the industry favorite because it sits beautifully in that sweet spot, offering a powerful combination of compact efficiency and expansive capability.

Scalability for Growth: One of the most significant advantages of the 60-inch model is its inherent scalability. It provides growing pizzerias with the capacity and workspace they need to expand their volume without making the massive spatial and financial commitment of industrial-sized equipment. Many new shops make the mistake of starting with smaller 48-inch units, only to find their chefs are constantly running to the walk-in cooler for refills during busy weekend nights. This frantic restocking breaks the workflow, slows down ticket times, and leads to staff frustration. The 60-inch model neatly solves this problem, providing enough on-hand ingredient storage to power through a rush while still fitting comfortably in most standard kitchen layouts.

Strategic Space Planning: The 60-inch table truly shines in its adaptability to various kitchen footprints. It is large enough to be a highly functional, two-person workstation, yet not so overwhelmingly large that it dominates your entire kitchen. This size can be integrated into L-shaped, galley, or island kitchen configurations without requiring a major and costly reorganization of your existing layout. It respects the value of your kitchen's square footage while maximizing its productivity.

Let's break down how the different size categories stack up across key metrics:

| Feature | 48\" Pizza Prep Table | 60\" Pizza Prep Table | 72\"+ Pizza Prep Table |

|---|---|---|---|

| Pan Capacity | Typically 6-8 (1/3-size pans) | Typically 8-12 (1/3-size pans) | Typically 12-18+ (1/3-size pans) |

| Storage (cu. ft.) | Around 10-14 cu. ft. | Around 13-18 cu. ft. | Around 20-30+ cu. ft. |

| Footprint | Compact, fits small kitchens | Balanced, versatile for most kitchens | Large, requires significant dedicated space |

| Ideal Kitchen Volume | Low to medium volume, limited menus | Medium to high volume, growing businesses | High to very high volume, complex menus |

| Workflow/Ergonomics | Can feel cramped for 2+ users | Ideal for 1-2 users, efficient workflow | Can require extra steps to move end-to-end |

The Compact Contender: 48-Inch Models

The smaller 48-inch models are excellent solutions when space is at an absolute premium, such as in a small cafe, a food truck, or a bar with a limited pizza menu. However, their limitations become apparent quickly as volume increases. These compact units typically hold only 6-8 pans and offer 10-14 cubic feet of storage. During a busy period, you might feel the pinch, with chefs bumping elbows and the workspace feeling cluttered. They are a great starting point, but many pizzerias find they outgrow them within the first couple of years. If you're curious about smaller options, our Atosa 48 Inch Sandwich Prep Review covers similarly sized equipment, though it's crucial to remember that pizza prep tables require a much deeper cutting board for proper dough handling.

The Production Powerhouses: 72-Inch and Larger Models

On the other end of the spectrum, 72-inch, 93-inch, and even larger models are impressive production beasts. These giants can hold 12-18+ pans and provide a cavernous 20-30+ cubic feet of storage. They are fantastic for extremely high-volume operations, institutional kitchens, or commissaries that are pumping out hundreds of pizzas an hour. However, they can be overkill for the average pizzeria. Their massive footprint can overwhelm smaller kitchens, and their higher price tag and energy consumption can strain budgets. Furthermore, the sheer length can sometimes be ergonomically inefficient, requiring staff to take extra steps to move from one end to the other.

The Goldilocks Solution: The 60-Inch Pizza Prep Table

The 60 inch pizza prep table hits the perfect middle ground. Its typical 8-12 pan capacity and 13-18 cubic feet of storage are more than adequate for the vast majority of independent pizzerias. It's roomy enough to handle the busiest dinner rushes without requiring you to dedicate half your kitchen to a single piece of equipment. We've found it works beautifully for pizzerias serving anywhere from 100 to well over 300 pizzas per day. The beauty of choosing a 60 inch pizza prep table lies in its best adaptability. It is substantial enough to support ambitious menus and busy service periods, yet manageable enough to fit into most commercial kitchen spaces without requiring major renovations or sacrificing workflow.

Frequently Asked Questions about 60-Inch Pizza Prep Tables

Investing in a cornerstone piece of equipment like a 60 inch pizza prep table naturally comes with questions. Getting clear, accurate answers is key to making the best choice for your kitchen's efficiency and your business's success. Here are detailed answers to the most common queries we receive.

What is the ideal temperature for a pizza prep table?

The ideal and legally required temperature range is 33°F to 41°F (0.5°C to 5°C). This specific window is critical for both food safety and ingredient quality. It adheres to NSF-7 standards and FDA guidelines, ensuring the temperature is low enough to inhibit the growth of harmful bacteria. Within this range, mozzarella maintains the perfect texture for a great melt, pepperoni and other cured meats are prevented from becoming greasy, and fresh vegetables retain their vibrant color and crispness. Modern units use powerful forced-air refrigeration and precise digital controls to maintain this vital temperature range consistently, even in a hot kitchen.

What's the real difference between a pizza prep table and a sandwich prep table?

The two primary, game-changing differences are cutting board depth and pan configuration. Pizza prep tables are specifically designed with an extra-deep cutting board, typically 19 inches or more. This provides the necessary surface area for stretching large pizza doughs. In contrast, sandwich prep tables have much shallower boards (8-12 inches), suitable only for slicing bread. Secondly, pizza tables use larger 1/3-size food pans to hold generous quantities of high-volume toppings like cheese and sauce. Sandwich tables use smaller 1/6-size pans for smaller-portioned ingredients. Using the wrong table creates massive workflow inefficiencies and is a recipe for frustration.

How important is the type of refrigerant?

Refrigerant type is extremely important for three key reasons: energy efficiency, environmental impact, and serviceability. We strongly recommend units that use R290 hydrocarbon refrigerant. R290 is a natural, non-toxic propane with zero ozone depletion potential (ODP) and a very low global warming potential (GWP) of 3. It is also significantly more energy-efficient than older legacy refrigerants like R134a or R404a, which can reduce your electricity consumption by up to 40%. This translates directly to lower monthly utility bills and a smaller carbon footprint.

How many toppings pans does a typical 60 inch pizza prep table hold?

Most 60-inch models are designed to accommodate 8 to 12 pans. The standard configuration uses 1/3-size pans, which are ideal for pizza toppings. However, some manufacturers offer flexible rail systems that can be adapted with divider bars to hold a combination of 1/3-size, 1/2-size, and 1/6-size pans, allowing for customization if you have specialty ingredients that require smaller containers.

What cutting board material is best?

Heavy-duty white polyethylene cutting boards are the industry standard and for good reason. This material is exceptionally durable, non-porous (so it won't absorb bacteria or odors), easy to sanitize, and gentle on your knife edges. To maintain it, clean and sanitize it between shifts, avoid harsh abrasive cleaners, flip or rotate it periodically for even wear, and replace it when it becomes deeply scored or warped.

What are the best practices for daily and weekly cleaning?

Daily: At the end of each shift, remove all food pans. Wipe down all interior and exterior surfaces. Clean and sanitize the pan rail, paying close attention to the wells where pans sit. Clean the insulated lids, door handles, and especially the gaskets with a mild soap and water solution. Weekly: Pull the unit away from the wall. Clean the floor and walls behind it. Wipe down the exterior of the condenser coil cover to remove dust. Perform a detailed inspection of the door gaskets for any rips or tears. Thoroughly sanitize the entire interior cabinet, including walls and shelves. Monthly: The most critical monthly task is to clean the condenser coil. Unplug the unit, remove the protective grill, and use a stiff brush and a vacuum to gently remove all dust, grease, and debris from the coil fins. A clean coil is essential for efficient heat exchange and a healthy compressor.

How much clearance does a 60 inch pizza prep table need for ventilation?

This is critical for the unit's health. Allow a minimum of 3 to 6 inches of clear space at the sides and rear of the unit for proper airflow. The refrigeration system needs to draw in cool air and exhaust hot air. Never push it flush against a wall. If you have a front-breathing unit, it can be installed with zero clearance on the sides and back, but the front grill must remain completely unobstructed.

Can I place my prep table next to heat-producing equipment?

It is highly inadvisable. You should keep your 60 inch pizza prep table as far away as possible from direct heat sources like fryers, griddles, or charbroilers. High ambient temperatures force the compressor to work much harder and run continuously to maintain its set temperature, leading to higher energy bills and a significantly shorter lifespan for the compressor. If proximity is unavoidable, consider installing a stainless steel barrier and ensuring your kitchen has robust ventilation.

What electrical requirements should I expect?

Nearly all 60-inch pizza prep tables run on standard 120V, 60Hz, single-phase power and will come with a NEMA 5-15P plug. The most important requirement is that the unit must be plugged into its own dedicated circuit. Check the amperage rating on the unit's nameplate and ensure the circuit can handle the load. Never use an extension cord, as this can cause a voltage drop that can damage the compressor.

Should I choose doors, drawers, or a combination?

This depends entirely on your workflow:

- Doors: Best for maximizing bulk storage. Ideal for large dough boxes, backup bags of cheese, and large containers of sauce.

- Drawers: Best for organization and speed. Perfect for pre-portioned items like dough balls, sliced meats, and specific vegetable toppings. They minimize cold air loss.

- Combination: Offers the best of both worlds. A door section for bulk items and drawers for quick-access portioned ingredients. This is often the most efficient setup.

What causes icing or frost buildup inside the unit?

Common causes include: leaving the lids or doors open for extended periods, high humidity in the kitchen, damaged or worn-out door gaskets that are not sealing properly, or overfilling the cabinet or food pans in a way that blocks proper air circulation. Address these issues promptly to maintain efficiency.

How do I properly level and secure the table?

Once the table is in its final location, lock the front casters to prevent movement. Place a bubble level on the cutting board surface. Adjust the height of the individual casters (most are threaded) until the unit is perfectly level both front-to-back and side-to-side. Proper leveling ensures doors close correctly and that condensation drains properly.

What should I do on delivery day?

Inspect the unit for any shipping damage before signing the delivery receipt. Note any dents or scratches on the bill of lading. Once inside, let the unit sit upright and unplugged for at least 4-6 hours (or as per manufacturer instructions) to allow the refrigerant and compressor oil to settle. After this waiting period, plug it in and allow the temperature to stabilize to the safe zone (below 41°F) before loading any food product.

How should I organize the pan rail for maximum efficiency?

Place your highest-use ingredients (like cheese and pepperoni) closest to your primary dough-working station to minimize movement. Group similar items together. If you handle allergens like nuts or seafood, stage them in covered pans at the far end of the rail to prevent cross-contamination. Implement a strict First-In, First-Out (FIFO) rotation system and keep lids closed between orders.

How often should gaskets be replaced?

Inspect gaskets weekly for cracks, tears, or loss of flexibility. Clean them daily with a mild soap solution. Depending on usage, gaskets should typically be replaced every 12-24 months. A healthy gasket is crucial for maintaining temperature and energy efficiency.

What are signs that my prep table needs maintenance or service?

- The unit struggles to maintain a temperature below 41°F.

- The compressor is running constantly or more frequently than usual.

- You notice excessive ice accumulation on the evaporator coil.

- The unit is making unusual or loud noises.

- The door gaskets are visibly damaged or not sealing tightly.

How do I know if 60-inch is the right size for my operation?

If your menu features a variety of toppings, if you need ample space for stretching large doughs, and if you want an organized, efficient workflow for one or two chefs without consuming excessive floor space, then a 60 inch pizza prep table offers the perfect balance of capacity, functionality, and footprint for your pizzeria.

Conclusion: Your Partner in Pizza Perfection

Choosing the right 60 inch pizza prep table is more than a simple equipment purchase; it is a foundational investment in the core efficiency, consistent quality, and long-term profitability of your pizzeria. Throughout this guide, we have demonstrated why this particular size represents the undisputed sweet spot for the vast majority of commercial kitchens, offering a perfect, harmonious balance of ample workspace, generous ingredient capacity, and a manageable, versatile footprint.

We've journeyed through the essential features that define a superior unit, from the robust stainless steel construction that promises years of hygienic, reliable service to the extra-deep polyethylene cutting board that acts as the perfect canvas for your culinary creations. We've highlighted the smart design elements like heavily insulated lids and advanced refrigeration systems using eco-friendly R290 hydrocarbon refrigerant, which work tirelessly in the background to preserve the freshness and integrity of every single ingredient. We've also explored how thoughtful storage configurations, whether you choose doors, drawers, or a combination, can be custom to your specific workflow, helping you organize your kitchen for peak performance and speed.

At The Restaurant Warehouse, we intimately understand the immense pressures and challenges of the foodservice industry. Our entire business model is built on a commitment to supplying top-tier commercial restaurant equipment and supplies at lower prices. We achieve this by deliberately avoiding the hefty sales commissions and expensive retail overhead that inflate prices and strain your budget. Our approach is straightforward and transparent: offer durable, reliable equipment at affordable, wholesale pricing so that you can equip your kitchen with the best possible tools for success. We believe that every entrepreneur deserves a fair shot, and that means not having to compromise on the quality of the equipment that forms the heart of your operation.

A 60 inch pizza prep table is not just an inanimate object; it's an indispensable partner in your quest for perfection. It's the silent workhorse that streamlines the assembly process, lifts your food safety standards, and empowers your team to deliver consistently delicious pizzas that keep customers coming back. It is an investment that pays tangible dividends every single day in the form of heightened efficiency, reduced food waste, superior product quality, and the invaluable peace of mind that comes from a smoothly running, organized operation.

When you're ready to lift your pizza game and invest in the backbone of your kitchen, we're here to help you find the perfect match for your vision and your budget.

Explore Our Full Range of Pizza Prep Tables and find the 60 inch pizza prep table that will become your most trusted partner in pizza perfection.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment