Kitchen Nightmares? Call the Pros for Restaurant Equipment Service

Why Restaurant Equipment Service Can Make or Break Your Business

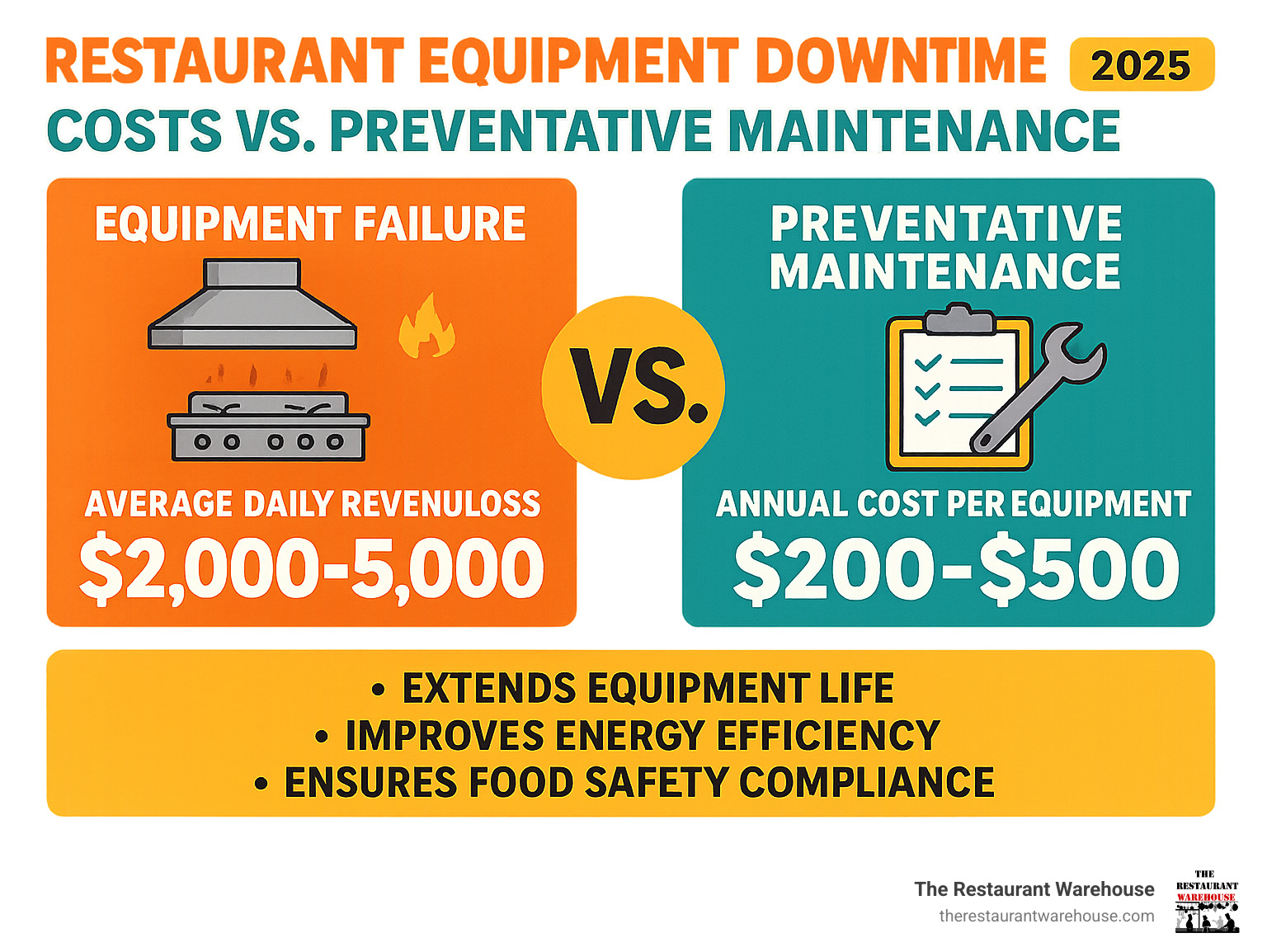

When your restaurant equipment service needs arise, every minute of downtime costs you money. A broken fryer during a lunch rush or a failed walk-in cooler on a busy weekend can turn a profitable day into a financial disaster. The numbers tell the story: a single day of equipment failure can cost a restaurant $2,000-$5,000 in lost revenue and spoiled food. In contrast, a planned maintenance program typically costs just $200-$500 per piece of equipment annually.

Your kitchen equipment works harder than almost any other business asset. Commercial ranges, coolers, and dishwashers run for hours on end, making them prone to breakdowns at the worst possible moments. Professional service is about more than fixing what's broken; it's about preventing failures, extending equipment life, and protecting your investment.

Why Professional Service is Non-Negotiable

In commercial kitchens, your equipment is your lifeline. Malfunctions aren't just inconveniences; they are kitchen nightmares that impact your bottom line and reputation. Professional restaurant equipment service is non-negotiable for maximizing uptime and ensuring customer satisfaction. When equipment fails, it can lead to negative reviews and a damaged reputation that takes years to rebuild.

Reliable service is crucial for a wide array of businesses, including:

- Restaurants, hotels, and hospitality venues

- Healthcare facilities and retirement homes

- Schools and university cafeterias

- Grocery stores, delis, and bakeries

- Banquet halls and food service companies

For all these operations, the principle is the same: efficiency, safety, and satisfaction hinge on well-maintained equipment. Investing in expert restaurant equipment service is a smart business decision, not just an expense.

Key terms for restaurant equipment service:

The Lifeline of Your Kitchen: Understanding Commercial Equipment Service

What is Commercial Restaurant Equipment Service and Why is it Crucial?

In a busy commercial kitchen, every piece of equipment plays a vital role. Restaurant equipment service is the unsung hero that keeps your operation running smoothly. It's a comprehensive approach to maintaining your kitchen's health, much like preventative medicine is better than emergency surgery.

Professional service goes beyond simple repairs. A qualified technician takes a holistic view, not just fixing today's problem but preventing tomorrow's disasters. This proactive approach ensures kitchen safety, protecting staff and customers from hazards like gas leaks or electrical faults. It also boosts efficiency; a well-maintained refrigerator uses less energy, lowering utility bills while ensuring food safety.

The financial impact of proper service cannot be overstated. Consider the cascading effects of equipment failure: lost revenue from inability to serve customers, spoiled inventory, emergency repair costs often double or triple regular rates, potential health code violations, and damage to your reputation from disappointed customers. A single refrigeration failure can cost thousands in spoiled food alone, while a broken dishwasher can force you to close early or turn away customers.

Most importantly, professional service prolongs equipment life. Commercial kitchen equipment is a major investment, and regular servicing can add years to the lifespan of your machines, maximizing your return. The ultimate goal is to prevent catastrophic failures that can shut down your business. For more insights, see our guide on restaurant equipment repair.

Common Equipment That Needs Professional Attention

Commercial kitchen equipment endures demanding conditions, often running 12-16 hours a day. Each type requires specialized attention and understanding of its unique maintenance needs.

Cooking Equipment: Ranges, fryers, and griddles are the heart of your kitchen. They face extreme temperatures and constant use. Regular service of heating elements, gas lines, and thermostats is essential for reliable performance. Grease buildup, calibration drift, and wear on moving parts are common issues that professional technicians address during routine maintenance.

Refrigeration Equipment: Working 24/7, walk-in coolers, freezers, and ice machines are critical. A failure can mean thousands of dollars in lost inventory within hours. Service focuses on compressors, refrigerant levels, and door seals to prevent costly breakdowns. Temperature monitoring systems, condenser coil cleaning, and gasket replacement are routine maintenance tasks that prevent major failures. For specific issues, see our troubleshooting tips for a commercial ice machine not making ice.

Warewashing Equipment: Commercial dishwashers are complex machines managing high-pressure water, chemicals, and heat. If they fail, your entire operation can grind to a halt without clean dishes. These systems require regular descaling, pump maintenance, and chemical dispenser calibration to function properly.

Food Preparation Equipment: Mixers, slicers, and processors are the workhorses of your prep line. Their motors, blades, and moving parts need regular service to ensure safety and keep prep work flowing smoothly. Blade sharpening, motor lubrication, and safety guard inspection are critical maintenance tasks.

Ventilation Systems: Often overlooked, exhaust hoods and ventilation systems are crucial for safety and compliance. Grease buildup in these systems creates fire hazards and can lead to health code violations. Regular cleaning and filter replacement are essential.

A professional restaurant equipment service provider understands the unique needs of each piece of equipment, keeping your kitchen in perfect harmony.

What to Expect from a Professional Restaurant Equipment Service

When your walk-in cooler fails at 2 AM, you realize the true value of a professional restaurant equipment service partner. A dedicated provider understands that your business can't afford to wait.

Core Offerings of a Restaurant Equipment Service Provider

Our service rests on three pillars to keep your kitchen running smoothly.

Emergency Repairs: Breakdowns don't keep business hours. That's why 24/7 availability is essential. Our emergency response focuses on minimizing downtime with rapid, same-day service whenever possible. Our on-site service brings the solution to you, fixing equipment where it sits to get you back in business fast.

Equipment Installation: Proper setup is more than just plugging something in. It involves ensuring every connection and calibration meets manufacturer specifications and local codes. We handle the commissioning process, testing every function to guarantee performance from day one.

OEM Parts: Using Original Equipment Manufacturer (OEM) parts is critical. Generic parts can compromise performance and safety. OEM components are designed to fit perfectly and perform reliably. We maintain extensive sourcing and inventory to provide the right part without delay, which is often the difference between a quick fix and days of downtime. For cost-effective options, we also offer guidance on used restaurant equipment.

The Proactive Approach: Planned & Preventative Maintenance

While emergency repairs are reactive, planned and preventative maintenance is proactive. It stops problems before they start.

This approach is built on scheduled check-ups. Our technicians visit on a predetermined schedule to create customized programs based on your specific equipment and usage. During each visit, they perform thorough cleaning and calibration, as grease and mineral buildup can reduce efficiency.

The real value is in identifying potential issues early. A technician can spot a fraying belt or a failing gasket and fix it during a scheduled visit rather than an emergency call. This proactive approach extends equipment life, improves efficiency, and lowers energy bills. Most importantly, it provides peace of mind, preventing critical failures during your busiest hours.

For specific guidance, explore our resources on cleaning restaurant equipment and Atosa refrigerator and freezer maintenance. Preventative maintenance isn't an expense—it's an investment in your bottom line.

Choosing Your Service Partner: What Separates the Best from the Rest

Finding the right restaurant equipment service partner is about building a relationship with a team that understands your business. When equipment fails during a dinner rush, you need a trusted partner who will be there when it matters most. The difference between an average and an exceptional service provider often comes down to their people and processes.

Technician Qualifications and Expertise to Look For

The heart of any great service company is its technicians. When evaluating partners, look for specialized professionals with factory training from equipment manufacturers. This ensures they know your specific equipment inside and out, leading to faster, more accurate repairs. Proper licensing and insurance are non-negotiable, confirming that technicians are up-to-date on safety protocols and industry standards.

Years of experience and professional communication are also key. An experienced technician can diagnose problems quickly, while clear communication ensures you understand the issue, the solution, and the cost.

The Importance of OEM Parts

Using Original Equipment Manufacturer (OEM) parts is the only smart choice for repairs. OEM parts are designed specifically for your equipment, ensuring they meet strict safety standards and perform reliably. Generic parts might look similar, but they lack the same validation and can compromise both safety and efficiency. Using non-OEM parts can also void your warranty protection, leaving you responsible for expensive future repairs. To ensure you're getting genuine components for specific brands, you can find More info about Atosa parts.

Key Differentiators of a High-Quality Provider

Beyond technical skill, several operational factors distinguish the best restaurant equipment service providers:

- Rapid Response Times: In foodservice, urgency is everything. Look for providers offering 24/7 emergency availability and same-day service for critical issues.

- Technology-Driven Service: GPS-tracked service fleets and digital work order systems streamline the process, providing accurate arrival times, real-time updates, and clear service records.

- Broad Coverage: A large service area with multiple locations ensures that help is never too far away, regardless of where your business operates.

- Transparent Billing: Quality providers offer detailed estimates upfront and explain all charges clearly, avoiding surprise fees.

- Loaner Programs: A loaner program can be a lifesaver, providing temporary equipment to keep your kitchen running during extended repairs.

- Excellent Communication: From appointment confirmations to post-repair follow-ups, clear and consistent communication is the hallmark of a true service partner.

The Long-Term Value of Preventative Restaurant Equipment Service

Preventative restaurant equipment service is about building a highly efficient and reliable kitchen operation. The most successful businesses invest in prevention rather than scrambling for fixes. This strategic approach transforms your kitchen from a source of constant worry into a well-oiled machine that supports your business goals.

The Financial and Operational Benefits

The numbers clearly favor preventative maintenance over a reactive approach. Industry studies show that businesses with comprehensive maintenance programs experience 40% fewer equipment failures and 25% lower overall maintenance costs. The following table illustrates the difference:

| Feature | Reactive Repairs | Planned Maintenance Program |

|---|---|---|

| Cost | Higher, unpredictable emergency repair costs; rush fees; potential for complete equipment replacement. | Lower, predictable annual costs; preventative fixes are cheaper. |

| Downtime | Unscheduled, often lengthy; significant loss of revenue; business disruption. | Minimal, scheduled downtime; equipment often serviced during off-hours. |

| Equipment Life | Shorter lifespan; increased wear and tear; premature failure. | Extended lifespan; consistent performance; maximized ROI. |

| Energy Efficiency | Decreased; malfunctioning equipment consumes more power, leading to higher utility bills. | Optimized; equipment runs efficiently, reducing energy consumption and utility bills. |

| Food Spoilage | High risk, especially for refrigeration failures, leading to significant product loss. | Minimal risk; consistent temperature control and proper functioning prevent spoilage. |

| Safety | Increased risk of accidents, fires, and health hazards due to faulty equipment. | Improved safety; regular checks identify and mitigate potential dangers. |

| Staff Morale | Low; frustration from working with unreliable equipment; increased stress. | High; confident in reliable tools; reduced stress. |

By maximizing equipment uptime, you ensure consistent revenue and happy customers. Equipment failures during peak hours can result in lost sales that are impossible to recover. Extending equipment life through regular maintenance protects your investment and delays major capital expenditures. A well-maintained piece of equipment can last 50% longer than one that receives only reactive repairs.

Furthermore, well-maintained equipment is more energy-efficient. Optimizing energy efficiency through regular cleaning and calibration can lead to significant savings on utility bills. Dirty condenser coils, clogged filters, and misaligned components can increase energy consumption by 15-30%. Over time, these savings can offset the entire cost of your maintenance program.

Building Operational Excellence Through Service

A comprehensive maintenance program does more than prevent breakdowns—it creates operational excellence. When equipment runs reliably, your kitchen staff can focus on food quality and customer service instead of worrying about malfunctions. This leads to improved productivity, better food consistency, and improved customer satisfaction.

Regular maintenance also provides valuable data about your equipment's performance trends. Professional technicians can identify patterns that indicate when equipment might need replacement, allowing you to plan capital expenditures strategically rather than making emergency purchases at premium prices.

Enhancing Safety and Food Quality

Beyond the financial benefits, preventative restaurant equipment service is crucial for safety and quality. Equipment failures can create dangerous situations, from gas leaks to electrical hazards. Regular inspections identify these risks before they become emergencies.

Regular maintenance helps improve employee safety, creating a workplace where your team can focus on their tasks without worrying about equipment malfunctions. This leads to better morale, as no one wants to work with unreliable tools. When staff are confident in their equipment, they take more pride in their work and are more productive.

Perhaps most importantly, reliable equipment ensures consistent food quality. Your reputation depends on serving the same great meal every time. Precise temperatures and predictable performance lead to the consistency that builds customer loyalty. Temperature fluctuations in refrigeration can compromise food safety, while inconsistent cooking temperatures affect taste and presentation.

Finally, proper maintenance makes it easier to maintain adherence to health codes, as inspectors look closely at equipment condition. Well-maintained equipment demonstrates your commitment to food safety and professional operation. Health code violations can result in fines, temporary closures, and lasting damage to your reputation.

For more guidance, see our commercial kitchen cleaning tips and our Essential Daily Cleaning Guide for Commercial Fryers.

Frequently Asked Questions about Restaurant Equipment Service

When it comes to keeping your commercial kitchen in top shape, many questions arise. Here are the most common inquiries we receive about restaurant equipment service.

How often should my equipment be serviced?

This depends on equipment type, usage, and environment. High-use equipment in a busy restaurant, like fryers and walk-in coolers, should be serviced every three to six months. Moderate-use equipment, such as specialty mixers or slicers, may only need annual service. Always consult the manufacturer's manual for specific recommendations to maintain your warranty.

Environmental factors like high humidity or a dusty kitchen can also increase service frequency. As a general rule, a semi-annual or annual preventative maintenance plan is a wise investment for most critical equipment to catch small problems before they become costly emergencies.

Can I perform my own equipment maintenance?

Yes, for certain tasks. Daily cleaning (wiping surfaces, cleaning filters) and basic operational checks (monitoring temperatures, listening for odd noises) are essential and should be handled by your staff. For guidance, see our tips on how to Maintain Commercial Refrigerators.

However, complex technical maintenance should always be left to certified professionals. Attempting to fix electrical components, gas lines, or pressurized systems yourself can void manufacturer warranties, cause more damage, and create serious safety hazards. Professionals have the diagnostic tools, OEM parts, and training to perform these jobs safely and correctly. The rule is simple: handle daily cleaning and monitoring, but call a pro for anything technical.

What's the difference between a service warranty and a manufacturer's warranty?

Understanding this distinction is key. A manufacturer's warranty comes from the company that built the equipment. It covers defects in materials and workmanship for a set period (e.g., one year for parts and labor). If a new fryer fails due to a faulty part, the manufacturer covers the repair. This warranty does not cover issues from misuse or lack of maintenance.

A service warranty comes from the company that performs a repair. It's a guarantee on their workmanship and the parts they installed, typically for 30 to 90 days. If a motor they replaced fails again within that period due to the repair itself, they will fix it at no charge. The manufacturer's warranty protects you from product defects, while the service warranty protects you from poor repair work. Always choose a provider that offers a clear service warranty.

Conclusion

Keep Your Kitchen Humming with Reliable Service

In the foodservice industry, your kitchen equipment is the heartbeat of your operation. The key takeaway is simple: proactive maintenance beats reactive repairs every time. While emergency service is a necessary lifeline, a planned preventative maintenance program transforms worry into confidence.

Regular service extends equipment life, reduces energy costs, ensures food safety, and boosts staff morale. This level of care depends on qualified technicians who use their training and experience to not just fix problems, but prevent them. Using genuine OEM parts is a critical part of this process, as it protects your warranties and ensures your equipment performs as designed.

At The Restaurant Warehouse, we supply commercial restaurant equipment and food service supplies at wholesale prices, helping you make smart investments. We believe that reliable restaurant equipment service isn't an expense—it's insurance for your business's future. It keeps your kitchen humming, your staff safe, and your customers coming back.

Don't wait for a breakdown to learn this lesson. Establish a relationship with a professional service provider today to protect your business for years to come.

Ready to take your commercial kitchen to the next level? Explore our comprehensive commercial kitchen equipment guide to find how the right equipment, paired with expert service, creates the foundation for lasting success.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment