Mastering HACCP Plans Templates

HACCP plan templates are essentially structured roadmaps for putting together your own Hazard Analysis Critical Control Point plan. They give you a solid, pre-built framework to work from, helping any foodservice business systematically spot, assess, and control food safety hazards without having to start from absolute scratch.

Why a HACCP Template is Your Food Safety Blueprint

Don't think of a HACCP plan as just another piece of regulatory paperwork. It's the core architecture for your entire food safety operation. Whether you're running a massive restaurant or a niche food truck, staring at a blank page when it comes to food safety can feel pretty intimidating. This is exactly where a good HACCP template becomes a game-changer, giving you a proven structure that can save you countless hours and, more importantly, prevent you from overlooking something critical.

Instead of trying to reinvent the wheel, a template guides you through a logical process, making sure you hit all the necessary components for a truly robust system. It prompts you to think through every single step of your food's journey—from the moment raw ingredients arrive at your back door to the final sale. This methodical approach is what helps turn complex food safety principles into actionable, everyday procedures your team can actually follow.

It's About More Than Just Compliance

Sure, meeting regulatory requirements is a big part of why you need a HACCP plan, but the benefits of a well-executed plan go so much further. A proactive food safety system, built from a solid template, is one of the most powerful tools you have for:

- Protecting Your Brand Reputation: It can take years to build a great reputation, but a single food safety incident can tear it down in a day. A HACCP plan is your frontline defense.

- Slashing Foodborne Illness Risks: By systematically identifying and controlling hazards, you are directly reducing the chances of ever making a customer sick.

- Improving Operational Consistency: The plan creates standardized procedures. This means every team member handles food safely and consistently, no matter how much experience they have.

The impact of this kind of systematic approach is well-documented. The worldwide adoption of HACCP plans has dramatically improved food safety. In countries where HACCP is mandatory, there have been huge reductions in foodborne illness outbreaks. Some regions have even reported decreases of up to 50% in certain types of food contamination incidents. This structured way of identifying critical control points—like cooking temperatures and storage time limits—has been incredibly effective at reducing the survival of harmful microorganisms like Salmonella.

The Seven Guiding Principles

At the heart of every HACCP plan are seven core principles. These are the building blocks that take a generic template and turn it into a living document that’s perfectly tailored to your unique operation. They give you a logical framework for analyzing risks and establishing controls right where they'll make the biggest difference.

Before we jump into building your plan, it’s really important to get a handle on what these principles are. For a deeper dive into the fundamentals, check out our guide on what HACCP food safety truly entails.

A HACCP plan isn't a static document you just file away. It's a dynamic system that should evolve with your menu, your processes, and your team. Think of it as a constant guardian of your food's integrity and your customers' trust.

Let's quickly walk through these seven principles. They'll set the stage for the practical steps we'll cover next. Each one builds on the last, creating a comprehensive safety net around your entire food production process.

The Seven Principles of HACCP at a Glance

This table breaks down the seven core principles of HACCP, giving you a quick overview of what each one does and how it might look in a real-world restaurant setting. Think of it as your cheat sheet for understanding the backbone of your food safety plan.

| Principle Number | Principle Name | Core Purpose | Restaurant Example |

|---|---|---|---|

| 1 | Conduct a Hazard Analysis | Identify potential biological, chemical, or physical hazards. | Finding Salmonella risk in raw chicken. |

| 2 | Determine Critical Control Points (CCPs) | Pinpoint steps where control can prevent or eliminate a hazard. | The cooking step for the chicken breast. |

| 3 | Establish Critical Limits | Set minimum/maximum values to control the hazard at a CCP. | Cooking chicken to an internal temp of 165°F. |

| 4 | Establish Monitoring Procedures | Plan how to consistently measure and track the critical limits. | Checking chicken temp with a calibrated thermometer. |

| 5 | Establish Corrective Actions | Predetermine steps to take if a critical limit is not met. | If temp is 155°F, continue cooking and re-check. |

| 6 | Establish Verification Procedures | Confirm that the HACCP system is working as intended. | A manager reviewing temperature logs weekly. |

| 7 | Establish Record-Keeping | Maintain documentation of the HACCP plan and all activities. | Keeping all temperature logs for at least 90 days. |

Understanding these seven principles is the first step. They provide the "why" behind the "what," transforming your template from a simple checklist into a powerful, proactive system that keeps your food safe and your customers happy.

Assembling Your Food Safety Team

Let’s get one thing straight: effective food safety is a team sport, not a solo mission. Before you even think about cracking open a HACCP template, your most critical first step is getting the right people in the room.

A plan cooked up by a single manager in an office is almost guaranteed to have blind spots. Why? Because it’s missing the real-world perspective from the folks on the ground. To build a system that actually works, you need a multidisciplinary team with a 360-degree view of your entire operation, from the delivery truck to the customer's plate.

This collaborative approach is everything. When you bring different roles together, you catch potential hazards from all angles, creating a plan that’s complete, realistic, and much easier to execute day-to-day.

Who Should Be on Your HACCP Team?

Building your team isn't about just picking names off a roster. It's a strategic move. You’re gathering a group of experts who can collectively map out every potential risk your food encounters on its journey.

A truly well-rounded HACCP team needs people from every key area of your business. Here’s a look at who you should pull into that first meeting and exactly why their input is so valuable:

- Kitchen Manager or Head Chef: This person lives and breathes the flow of your kitchen. They know the recipes, the cooking processes, and all the daily operational hurdles inside and out.

- Purchasing or Receiving Staff: Think of them as your first line of defense. They can speak to supplier reliability, the condition ingredients arrive in, and your initial storage protocols.

- Front-of-House Manager: They have direct contact with customers and see how food is held, plated, and served. They manage the final—and critical—steps before a dish reaches the table.

- Maintenance or Facilities Staff: This person holds the keys to equipment performance, sanitation systems, water quality, and pest control. Their knowledge is the foundation of a safe environment.

Getting these roles together does two things. First, it ensures no part of the food's journey gets overlooked. Second, it builds a culture of shared responsibility where food safety becomes everyone’s job, not just something a manager worries about.

Defining Your Product and Customer

Okay, team assembled. Now what? Your first task isn't to start listing hazards. It's to get crystal clear on what you’re making and who you’re serving. These two pieces of information will guide every single decision you make from here on out.

Start by creating detailed descriptions of your menu items. I'm talking more than just a name. You need to list all ingredients, every processing step (chopping, cooking, cooling), and how it's packaged or held. A "fresh tomato salsa" description, for example, would note that it's unpasteurized and stored in refrigerated display cases. This level of detail instantly flags potential risk areas.

Next, you have to identify your intended customer. Are you serving the general public, or do you have a more vulnerable population like kids, the elderly, or people with compromised immune systems? The risk level of a hazard can change dramatically depending on who is eating the food.

A HACCP plan for a gluten-free bakery, for instance, has to be intensely focused on preventing allergen cross-contact because its customers are highly sensitive. A university cafeteria’s plan, on the other hand, might put a greater emphasis on rapid cooling for large batches of food served to a generally healthy adult population.

Getting these elements right is non-negotiable, and proper training is key. Our guide on commercial kitchen equipment training can help your team understand the operational context behind these safety decisions. Your product description and consumer profile are the guiding stars for your entire hazard analysis, helping you focus on what matters most to your specific operation.

How to Conduct an Effective Hazard Analysis

This is where your HACCP plan really comes to life. The hazard analysis is the engine driving your entire food safety system, and getting it right is the very first principle of HACCP. It’s time to put on your detective hat and start thinking about every single thing that could possibly go wrong.

The main goal for your team is to identify any biological, chemical, or physical hazards that could reasonably pop up at any stage of your food's journey. This isn’t just about spotting the obvious stuff; it's about systematically picking apart your whole process, from the moment ingredients arrive at your back door to when a finished plate hits the table.

Honestly, the best way to tackle this is with a flow diagram of your production process. When you map out each step visually, you create a roadmap that helps ensure nothing gets missed. This methodical approach is perfect for pinpointing exactly where a hazard might be introduced, controlled, or even made worse.

Breaking Down the Three Hazard Types

To do a truly thorough analysis, you have to know what you’re looking for. Food safety hazards fall into three distinct categories. Let’s break them down with some real-world examples you'd find in almost any commercial kitchen.

-

Biological Hazards: These are the living organisms—bacteria, viruses, and parasites—that can cause foodborne illness. We're talking about things like Salmonella on raw chicken, E. coli in undercooked ground beef, or Listeria in deli meats. As you pinpoint potential biological hazards, effective pest management becomes a huge piece of the puzzle, especially when it comes to implementing comprehensive pest control for restaurants.

-

Chemical Hazards: This category covers harmful substances that can contaminate food. Common culprits include cleaning chemicals stored improperly near food prep areas, pesticide residue on produce that wasn't washed thoroughly, or food allergens like peanuts causing accidental cross-contact.

-

Physical Hazards: These are any foreign objects that can end up in food and cause an injury. This could be anything from a piece of broken glass, metal shavings from a can opener, a stray bone in a fish fillet, or even a bandage that fell off a finger.

The key to a great hazard analysis is to think about both the severity of a potential hazard and the likelihood of it occurring. A piece of glass in food is very severe but hopefully unlikely. Bacteria growing on food held at the wrong temperature is both severe and highly likely if controls aren't in place.

A Real-World Scenario: Grilled Salmon

Let’s walk through a simplified hazard analysis for a popular menu item: a grilled salmon dish. By following the salmon from receiving to plating, we can see how different risks emerge at each stage.

Receiving Fresh Salmon

Your supplier delivers a case of fresh salmon fillets.

- Biological Hazard: The fish could arrive at a temperature above 41°F, giving bacteria like Listeria a chance to multiply.

- Physical Hazard: The packaging could be torn or damaged, introducing dirt or other contaminants.

Storing the Salmon

The fillets are placed in the walk-in cooler.

- Biological Hazard: The cooler's temperature might fluctuate, dipping into the "danger zone" (41°F - 135°F). Cross-contamination is also a risk if raw chicken is stored on a shelf above the fish.

Prepping the Salmon

A line cook portions the salmon on a cutting board.

- Chemical Hazard: The cutting board was just used for shrimp (a common allergen) and wasn't properly sanitized, creating a risk for allergen cross-contact.

- Physical Hazard: The cook might miss a small pin bone while portioning the fillets.

Cooking and Plating

The salmon is grilled and served to the customer.

- Biological Hazard: The fish is undercooked, failing to kill potential parasites or bacteria that might be present.

- Chemical Hazard: The grill was cleaned with a harsh chemical, and some residue was left behind on the cooking surface.

This methodical, step-by-step evaluation is the heart of your HACCP plan. Once you’ve identified these potential hazards, your next move is to figure out which ones are significant enough to need a Critical Control Point (CCP)—the make-or-break moments we'll cover in the next section.

Identifying Your Critical Control Points

After mapping out every potential hazard, the next step is to separate the minor issues from the major threats. This is where you identify your Critical Control Points (CCPs), a cornerstone of any effective HACCP plan.

A CCP is a specific point in your workflow where you have the power to prevent, eliminate, or reduce a food safety hazard to an acceptable, safe level.

Think of it this way: not every safety check is a CCP. Regularly wiping down a counter is a vital sanitation practice (what we call a prerequisite program), but it doesn't eliminate a specific hazard in the same way that cooking chicken to the correct temperature does. That cooking step is the final, non-negotiable moment to destroy harmful pathogens like Salmonella. That's what makes it a CCP.

This crucial step helps you focus your resources and attention on the moments that truly make or break food safety. Your HACCP plan will have dedicated sections for these points, ensuring they get the intense focus they deserve.

Using a Decision Tree to Pinpoint CCPs

So, how do you decide what qualifies as a CCP? You don't have to guess. The most reliable method is to use a CCP decision tree.

This is a simple, logical tool—a series of "yes" or "no" questions—that helps you evaluate each identified hazard at every step of your process. It guides you to determine if a control is absolutely essential for safety.

Using a decision tree removes ambiguity and ensures consistency. It forces you to think critically about whether a later step could eliminate the hazard or if control at this specific point is the only opportunity you have to ensure the food is safe.

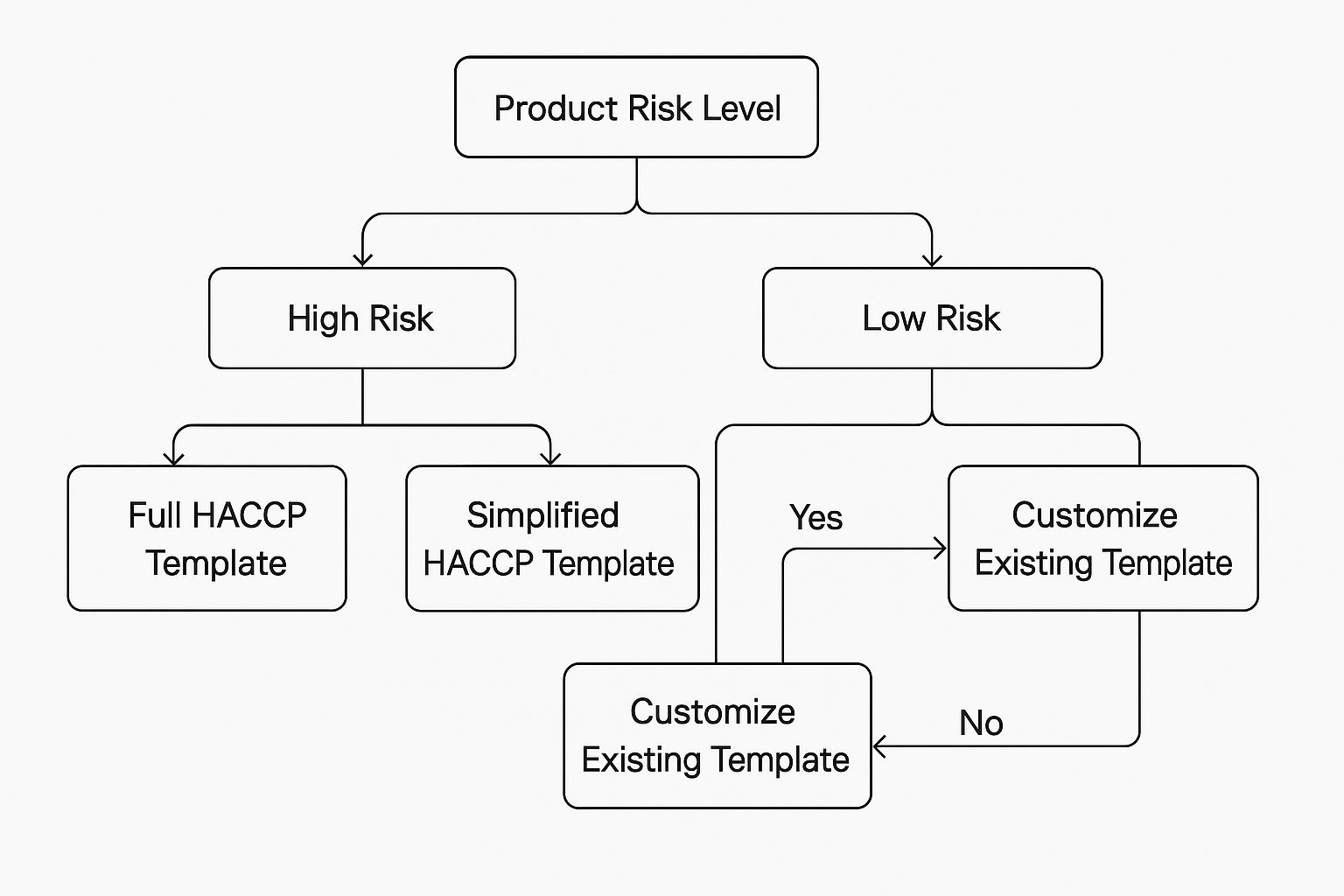

The infographic below shows a simple decision tree to help guide your choice of the right HACCP plan based on risk and existing documentation.

This visualization highlights how assessing risk levels and current record-keeping practices can steer you toward the most appropriate starting point for your safety plan.

Setting Non-Negotiable Critical Limits

Once you've identified a CCP, you have to establish its critical limits. A critical limit is a specific, measurable value that separates what's acceptable from what's unacceptable. This is where science, not guesswork, comes into play. These limits must be based on established food safety standards from regulatory bodies or scientific literature.

A critical limit cannot be vague. "Cook chicken thoroughly" is a suggestion, not a critical limit. "Cook chicken to a minimum internal temperature of 165°F for 15 seconds" is a powerful, measurable, and enforceable critical limit.

These clear boundaries are the foundation of your monitoring procedures. They give your team an exact target to hit every single time, leaving no room for interpretation or error. Without a precise critical limit, a CCP is essentially meaningless because you have no way to verify if control has been achieved.

Common Examples of CCPs and Their Limits

While every operation is unique, many foodservice businesses share common CCPs. Understanding these examples can help you recognize similar points in your own processes when you start building out your HACCP plan.

Here are a few classic CCPs you might identify:

-

Cooking: This is the most common CCP for raw animal products.

- Hazard: Survival of biological pathogens (e.g., Salmonella, E. coli).

- Critical Limit: Cooking ground beef patties to 155°F for 17 seconds.

-

Rapid Cooling: For foods that are cooked and then cooled for later use, like soups or sauces.

- Hazard: Growth of spore-forming bacteria.

- Critical Limit: Cooling food from 135°F to 70°F within 2 hours, and then to 41°F or below within the next 4 hours.

-

Hot-Holding: Keeping food on a steam table or in a warmer before service.

- Hazard: Growth of bacteria in the temperature "danger zone."

- Critical Limit: Maintaining a product temperature of 135°F or higher.

-

Cold-Holding: Storing ready-to-eat foods in a refrigerated unit.

- Hazard: Growth of pathogens like Listeria.

- Critical Limit: Holding food at 41°F or below. Managing the correct walk-in cooler temperature is a perfect example of a critical limit in action.

Pinpointing your CCPs and setting clear, science-backed limits transforms your hazard analysis into an actionable safety plan. These are the make-or-break points you’ll build your monitoring, corrective actions, and verification procedures around.

Building Your Monitoring and Verification System

A plan on paper is a great start, but it’s the consistent, day-to-day action that truly keeps food safe. Once you’ve pinpointed your Critical Control Points (CCPs) and set their limits, you need to bring your HACCP plan to life. That means building a solid system for monitoring, corrective actions, and verification.

This is the active, hands-on part of your plan. It’s how you confirm that your controls are actually working and, just as importantly, how you react in a split second when they aren’t. Without this system, a HACCP plan is just a document—not a living, breathing food safety culture.

Designing Effective Monitoring Procedures

Monitoring is really just the scheduled check-up you perform on a CCP to make sure it’s staying within its critical limits. It’s the task that tells you if your process is on track. When you’re designing these procedures from your HACCP plans templates, you have to be incredibly specific. Ambiguity is the enemy here.

For every single CCP, your monitoring plan needs to clearly spell out the answers to four key questions:

- What will be monitored? Is it temperature, time, a pH level, or a visual check for contaminants?

- How will it be monitored? Get specific. Name the exact equipment, like a calibrated digital probe thermometer, and outline the method for using it.

- Who will perform the monitoring? Assign the task to a specific role, like "Lead Line Cook" or "Shift Supervisor." Don't leave it to chance.

- How often will it be monitored? Define the frequency. Maybe it’s "every 30 minutes" for a steam table or "at the start and end of each shift" for cooler temps.

These details give your team clear, direct instructions. It removes the guesswork and ensures things are done the same way, every single shift.

Think of monitoring as taking your food's pulse. Regular, accurate checks ensure you can spot a problem before it escalates, protecting both your customers and your business.

Planning for When Things Go Wrong

Look, no system is foolproof. Deviations are going to happen. A cooler door will be left ajar, or a new cook might pull chicken off the grill a few degrees too early. That’s where corrective actions come in. These are the pre-planned steps you take the moment monitoring shows a critical limit has been breached.

Planning these actions ahead of time is absolutely crucial. You don’t want your team scrambling to figure out what to do in the middle of a chaotic dinner rush. A clear, pre-determined protocol eliminates panic and ensures a safe, consistent response every time.

For instance, a solid corrective action for a walk-in cooler CCP might look like this:

- Immediate Action: If the cooler's internal temperature is above 41°F, the shift manager immediately moves all time/temperature control for safety (TCS) foods to a working backup unit.

- Product Disposition: The manager then checks the product temperatures. Any food that has been in the temperature danger zone for more than two hours must be discarded and logged as waste.

- Root Cause Analysis: Maintenance is called to diagnose and repair the cooler.

- Documentation: The entire incident—the temperature reading, products moved, items discarded, and the maintenance call—is recorded in the corrective action log.

This level of detail ensures the immediate threat is neutralized and the root cause gets fixed so it doesn’t happen again.

Verifying That Your System Actually Works

So, how do you know if your entire HACCP system is actually effective? Through verification. These are the activities you perform—outside of routine monitoring—that confirm the validity of your HACCP plan and ensure the system is operating the way you designed it.

Verification is about taking a step back and asking the bigger question: "Are we still doing what we said we would do, and is it still working?" It provides that essential oversight layer.

Effective verification activities include things like:

- Record Reviews: A manager regularly reviews monitoring logs and corrective action reports, looking for trends or recurring problems.

- Equipment Calibration: Regularly checking thermometers against a known standard (like an ice-water bath) to ensure they are reading accurately.

- Direct Observation: Watching an employee perform a monitoring task to confirm they are following the correct procedure from start to finish.

Despite the clear benefits of a strong HACCP system, getting one up and running can be tough. Studies have pointed out some significant barriers, including high costs, a lack of staff expertise, insufficient training, and the sheer burden of all the documentation. For example, many firms in the meat industry struggle with the initial investment and finding skilled people. These hurdles highlight how important it is to find support through financial assistance, ongoing education, and better infrastructure. To get a better handle on these issues, you can discover more insights about barriers to HACCP adoption.

By building this robust system of monitoring, corrective actions, and verification, you transform your HACCP template from a static document into a dynamic, responsive shield for your business.

Modernizing Your HACCP Plan with Technology

Let's be honest, the old-school approach to HACCP—with mountains of binders, endless clipboard logs, and manual data entry—can feel like it’s stuck in the past. While paper-based haccp plans templates are a solid starting point, they can be a real headache. They’re cumbersome, prone to human error, and slow to give you any real insights.

Moving your system from paper to a digital platform isn't just about convenience. It’s about making your food safety program more powerful, responsive, and frankly, a whole lot more effective.

Specialized HACCP software is built to solve the biggest pain points of manual systems. Imagine replacing handwritten temperature logs with automated sensors that keep an eye on your coolers 24/7. Think about getting an instant alert sent straight to your phone the moment a critical limit is breached, instead of finding out hours later during a routine check. This is the real power of bringing technology into your food safety culture.

The Shift from Paper to Pixels

The move toward digital HACCP is more than a trend; it's a fundamental change in how the food industry manages safety. This transition is picking up serious steam, and the numbers back it up.

The global HACCP software market is projected to jump from USD 1.35 billion in 2025 to a whopping USD 3.5 billion by 2033. That's a growth rate of 12.5% a year. A key driver here is that over 60% of food businesses are actively moving to automated systems to keep up with both technology and regulatory demands. You can read the full research on the food safety software market to get a feel for this industry-wide shift.

This growth shows a clear understanding that digital tools offer huge advantages over their paper counterparts. They turn a static plan into a dynamic, real-time safety net for your entire operation.

Key Advantages of Digital HACCP Systems

Adopting technology for your HACCP plan brings a ton of benefits that directly impact your efficiency, accuracy, and overall peace of mind. Even a small café or food truck can see immediate improvements by integrating simple digital tools.

Here are some of the biggest reasons to make the switch:

- Reduced Human Error: Automated monitoring and digital checklists slash the risk of missed entries, illegible handwriting, and falsified records. The system ensures everyone follows the same process, on every shift.

- Real-Time Data and Instant Alerts: Digital sensors can ping you via text or email the second a cooler temperature goes haywire, letting you take immediate corrective action before any product is lost.

- Simplified Record-Keeping and Audits: Picture this: all your logs—monitoring, corrective actions, verification—neatly organized and instantly searchable. When an inspector shows up, you can pull up months of data in seconds instead of frantically digging through binders.

- Valuable Analytics and Insights: A digital system can crunch your data over time, helping you spot recurring issues you'd otherwise miss. You might discover a specific fridge consistently runs warm on weekends—a problem that's almost impossible to catch with manual logs.

By embracing technology, you're not just digitizing paperwork. You're building a smarter, more proactive food safety system that can identify risks before they become incidents, protecting your customers and your reputation.

To get a clearer picture of how these two approaches stack up, let's break down the key differences between a traditional paper-based system and a modern digital one.

Manual vs Digital HACCP System Comparison

| Feature | Manual System (Paper Templates) | Digital System (Software) |

|---|---|---|

| Data Collection | Manual, handwritten logs on clipboards. Prone to errors, gaps, and illegible entries. | Automated sensors and digital checklists on tablets or phones. Consistent and accurate. |

| Monitoring | Periodic checks performed by staff. Gaps between checks leave room for undetected issues. | Continuous, 24/7 monitoring for critical control points like temperature. |

| Alerts & Notifications | None. Issues are only discovered during the next manual check, often hours later. | Instant alerts via text, email, or app notification the moment a limit is breached. |

| Record-Keeping | Physical storage in binders. Time-consuming to organize, search, and retrieve. | Centralized, cloud-based storage. All records are instantly searchable and accessible. |

| Audit Preparation | Labor-intensive process of gathering and organizing months or years of paperwork. | Effortless. Generate and export comprehensive reports for any date range in minutes. |

| Corrective Actions | Manually recorded, with potential for inconsistent or incomplete documentation. | Guided digital forms ensure all necessary information is captured for every corrective action. |

| Analytics & Trends | Extremely difficult to analyze data to spot trends or recurring problems. | Built-in analytics provide valuable insights into operational performance and potential risks. |

This comparison really highlights how a digital system transforms HACCP from a reactive, paper-shuffling exercise into a proactive, data-driven food safety strategy.

To truly modernize your HACCP plan, you can even think about how other technologies can be integrated. For instance, some larger operations use augmented reality for manufacturing to enhance safety protocols and efficiency on the factory floor. This forward-thinking approach views your plan as an evolving system.

Taking the First Steps Toward Digital

You don't need a massive budget or a dedicated IT department to start modernizing. The transition can be gradual and scalable, even for the smallest businesses.

Start by picking your most labor-intensive monitoring task. Is it the hourly temperature checks on the hot-holding line? Or maybe the daily cooler and freezer logs? Begin by digitizing just that one process. This could be as simple as using a dedicated app with Bluetooth thermometers that sync data automatically.

As you get comfortable, you can expand to other areas, like digital supplier logs, automated sanitation schedules, and online employee training modules. The goal is to see your HACCP plan not as a static document, but as a living system that grows and improves with your business—powered by tools that make safety simpler and more reliable.

Got HACCP Plan Questions? We’ve Got Answers.

Even with a great template in hand, you’re bound to have questions as you start building and implementing your HACCP system. That’s perfectly normal. Getting clear, straightforward answers is the best way to move forward with confidence, so let's tackle some of the most common queries we hear from kitchen managers and restaurant owners.

Think of this as your quick-reference guide to help you nail down the finer points of your food safety plan.

How Often Should I Review My HACCP Plan?

This is a big one. Your HACCP plan isn't a "set it and forget it" document; it’s a living part of your operation. You need to give it a full, top-to-bottom review at least once a year. This annual check-in is your chance to make sure the plan still accurately reflects how your kitchen runs and is effectively controlling hazards.

But that’s just the minimum. You absolutely must review the plan anytime you make a significant change. What counts as significant?

- Rolling out a new menu item or changing a key recipe.

- Switching to a different supplier for your meat, produce, or dairy.

- Installing new equipment, like a high-capacity oven or a new walk-in cooler.

- Altering a major food prep process or redesigning your kitchen's workflow.

Regular reviews keep your plan relevant and effective as your business grows and changes. It's your primary defense against food safety risks.

Is a HACCP Plan Legally Required?

This is a common point of confusion because the answer is: it depends. The rules vary quite a bit based on where you are and what you're serving.

In the United States, the FDA and USDA require formal HACCP plans for specific high-risk food industries, like meat and poultry processing, seafood, and juice production. For many restaurants, cafes, and other foodservice spots, a local health department might not explicitly mandate a full-blown HACCP plan.

However, it is universally seen as the gold standard for managing food safety. Even if it's not required by law, putting a HACCP plan in place shows a serious commitment to protecting your customers. It can also reduce your liability and is a powerful way to safeguard your brand’s reputation.

Even when the law doesn't require it, a well-documented HACCP plan is your best defense if a food safety incident ever occurs. It proves you have a systematic, proactive approach to preventing foodborne illness.

Differentiating CCPs from Prerequisite Programs

It’s easy to get Critical Control Points (CCPs) and Prerequisite Programs (PRPs) mixed up, but they play very different—and equally important—roles.

Think of Prerequisite Programs (PRPs) as the solid foundation of your entire food safety system. These are the broad, facility-wide practices that create a safe and sanitary environment before you even start cooking. They manage general risks. Examples include:

- Your pest control program

- Employee hygiene policies (handwashing, uniforms, etc.)

- Sanitation Standard Operating Procedures (SSOPs)

- Supplier approval and verification programs

In contrast, a Critical Control Point (CCP) is a very specific step in your process where you can apply a control to prevent or eliminate a food safety hazard. A perfect example is cooking a chicken breast to an internal temperature of 165°F. That precise action is a CCP because it eliminates the biological hazard of Salmonella.

So, PRPs set the stage for safety, while CCPs are the critical actions you take during the performance itself.

Equipping your kitchen with reliable, modern equipment is the first step in building a robust food safety system. At The Restaurant Warehouse, we provide everything from high-performance commercial refrigeration to precise cooking equipment, all backed by expert support and flexible financing. Explore our catalog and build your HACCP-ready kitchen today at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment