From Food Trucks to Fine Dining: Commercial Hand Wash Basins Reviewed

Why Proper Handwashing Stations Are the Foundation of Food Safety

Every successful foodservice operation, from a busy food truck to a fine dining restaurant, relies on a critical element for success: a hand wash basin commercial kitchen setup that meets health codes and promotes impeccable hygiene. This isn't just about passing inspections; it's about protecting your customers and building a reputation for safety that fosters trust.

Quick Answer for Commercial Kitchen Hand Wash Basins:

- Size: 14-18" wide, 10-14" deep, with a 5-6" bowl depth.

- Material: Durable 18-gauge, Type 304 stainless steel is the standard.

- Placement: At least one sink per food prep area, located within 20 feet of workstations.

- Water: Hot water between 100-120°F and cold water below 85°F.

- Features: Hands-free faucets, soap and paper towel dispensers, and clear signage.

- Plumbing: A backflow prevention device is mandatory.

The CDC estimates that proper handwashing can prevent millions of foodborne illnesses each year. Yet, many operators struggle with choosing the right equipment while navigating tight budgets and complex health regulations. From compact wall-mounted units to robust pedestal models, the right hand wash basin is your first line of defense against contamination. Investing in quality handwashing stations early on saves money, reduces risk, and secures your business's reputation for the long term.

The Cornerstone of Kitchen Hygiene: Why Hand Washing is Crucial

The connection between clean hands and safe food is absolute. Throughout a shift, your team handles everything from raw ingredients to ready-to-eat garnishes, making their hands a primary vehicle for potential contamination. Every touch creates an opportunity for harmful bacteria and viruses to transfer from one surface to another.

Cross-contamination can happen in an instant. A staff member might handle raw poultry and then move on to slicing vegetables for a salad. Without proper handwashing between these tasks, dangerous pathogens like Salmonella can transfer directly from the raw meat to the fresh produce. This invisible threat can turn a perfect dish into a serious health hazard.

This is why accessible, well-equipped hand wash basin commercial kitchen stations are not just a recommendation—they are essential. The CDC consistently emphasizes that promoting hand hygiene is a key public health measure. In a kitchen environment, this translates directly to protecting every customer who trusts you with their health.

HACCP (Hazard Analysis and Critical Control Points) guidelines identify handwashing as a critical control point for a reason. By fostering a culture where frequent handwashing is second nature, you build the foundation of your entire food safety program. Your team must wash their hands:

- Before starting work

- After handling raw meat, poultry, or fish

- After using the restroom

- After touching their face, hair, or clothing

- After handling cleaning chemicals or taking out the trash

One contaminated pair of hands can spread bacteria to cutting boards, utensils, prep surfaces, and ultimately, the food your customers consume. Preventing foodborne illness begins with the simple act of using soap, water, and proper technique. However, this is only effective when staff can easily access proper handwashing facilities. If an employee has to walk across a busy kitchen or wait in line, they are far less likely to wash their hands as often as required, increasing the risk of an outbreak.

Creating a culture of diligent handwashing is about more than just following rules—it's about protecting your reputation, your customers, and your business. When you invest in the right infrastructure and provide thorough training, you build a defense system that works around the clock to keep your food safe.

Ready to upgrade your kitchen's handwashing stations? Contact us today to explore our selection of compliant, durable hand wash basins that make proper hygiene convenient for your entire team.

Decoding Health Codes: Essential Requirements for a Hand Wash Basin Commercial Kitchen

Navigating health department regulations can seem daunting, but the requirements for a hand wash basin commercial kitchen are straightforward. These rules are designed to make handwashing so convenient and effective that it becomes an automatic part of your staff's routine. While specific codes may vary by jurisdiction, the core principles are consistent nationwide.

Sink Placement and Quantity

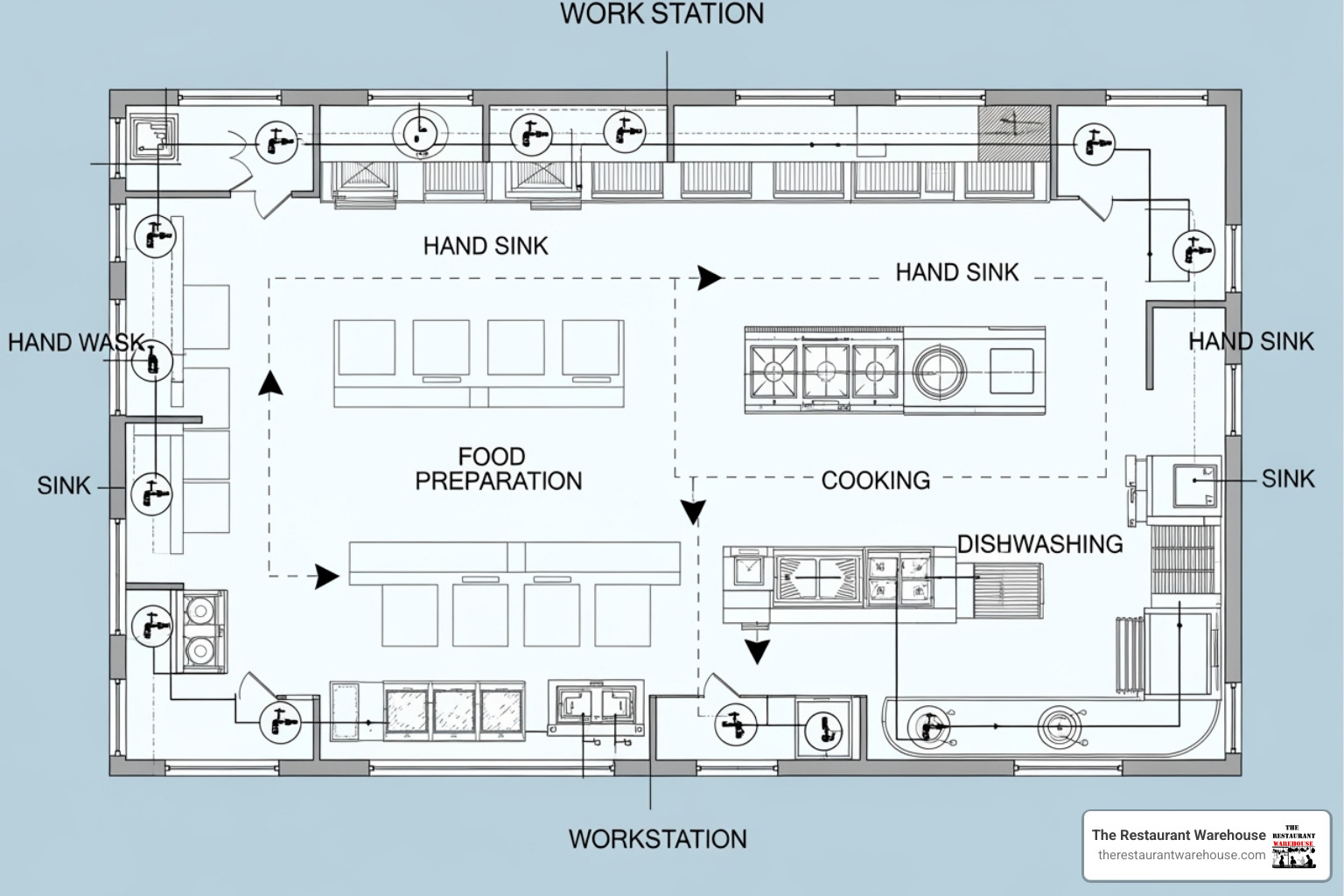

The primary rule for sink placement is accessibility. Staff should never have to cross a busy kitchen or steer obstacles to wash their hands. Health departments typically require at least one dedicated hand wash basin commercial kitchen unit in every food preparation, dispensing, and warewashing area. This ensures that a sink is always within easy reach.

Many inspectors use the 20-foot rule, meaning a hand sink must be located within 20 feet of any food handling workstation. Some local codes may also specify a ratio, such as one sink per five employees. The goal is to eliminate any barrier to frequent handwashing. A critical point that trips up many new owners is that hand sinks must be used exclusively for handwashing. They cannot be used for rinsing food, dumping liquids, or washing equipment. This exclusive use prevents cross-contamination and ensures the station remains sanitary and available.

For a complete overview of different sink types and their roles, our resource on industrial sink types can help you plan your entire kitchen layout effectively.

Water Temperature and Supply

Water temperature is a key factor in effective cleaning. Your hand wash basin commercial kitchen must provide a continuous supply of hot and cold running water. Health codes mandate that the hot water temperature be maintained between 100°F and 120°F (38°C to 49°C). This range is warm enough to help soap lather and remove grease, but not so hot as to discourage use or pose a burn risk. The cold water should be below 85°F (29°C).

A mixing valve or combination faucet is required to allow users to temper the water to a comfortable temperature. This makes the process quicker and encourages proper technique, as staff won't have to struggle with separate hot and cold taps.

Backflow Prevention

This technical requirement is crucial for protecting your potable water supply. Backflow prevention stops contaminated water from your sink drain from being siphoned back into the clean water lines, a phenomenon known as back-siphonage. This can occur during sudden changes in water pressure and poses a significant health risk.

Every hand wash basin commercial kitchen must be equipped with a backflow prevention device. The most common types are air gaps and vacuum breakers. An air gap is a physical space between the faucet outlet and the sink's flood level, making it impossible for water to flow backward. A vacuum breaker is a mechanical valve that achieves the same goal. These devices are mandated by plumbing codes to prevent waterborne disease outbreaks and must be installed by a professional.

Ready to upgrade your handwashing stations? Our team at The Restaurant Warehouse can help you find compliant, affordable solutions that meet all health department requirements.

Designing for Durability and Safety: Key Sink Features

In a kitchen, your hand wash basin commercial kitchen must be built to last. The materials and design you choose will affect daily cleaning routines, long-term maintenance costs, and overall hygiene. A well-designed sink not only meets health codes but also makes proper hygiene effortless for your staff.

The Superiority of Stainless Steel

There's a reason stainless steel is the dominant material in professional kitchens. For a hand wash basin commercial kitchen, its benefits are best:

- Hygienic Surface: Stainless steel is non-porous, meaning it provides no place for bacteria, mold, or other pathogens to hide and multiply. This makes it inherently more sanitary than other materials.

- Exceptional Durability: Commercial kitchens are demanding environments. Stainless steel resists rust, corrosion, and dents from daily use, ensuring your investment lasts for years.

- Easy to Clean: The smooth surface of stainless steel makes it incredibly easy to clean and sanitize. A quick wipe-down is often all that's needed to maintain a clean and professional appearance.

For the best combination of durability and value, look for sinks made from 18-gauge, Type 304 stainless steel. The gauge refers to the thickness (a lower number is thicker), while Type 304 indicates an alloy with superior corrosion resistance. This is the industry standard for reliable, restaurant-grade equipment. For more details on materials, see The ultimate guide to industrial sinks.

Choosing the Right Size for Your Hand Wash Basin Commercial Kitchen

Size is crucial for functionality. A sink that is too small will lead to splashing and an inadequate wash, while one that is too large wastes valuable space and water. The ideal size for most operations is between 14-18 inches wide and 10-14 inches front-to-back, with a bowl depth of at least 5-6 inches. These dimensions provide enough room for staff to lather and scrub their hands and forearms thoroughly without making a mess.

A common and effective size is a 14" x 10" bowl with a 5-inch depth, which fits well in most layouts. Smaller options are available for tight spaces, but they must still allow for proper handwashing technique.

Pay attention to the backsplash. Most commercial hand sinks include an integrated backsplash that rises several inches up the wall. This functional feature protects the wall from water damage, which can lead to mold growth and costly repairs. It also simplifies cleaning and contributes to a more professional look that health inspectors appreciate. For space-constrained areas, wall-mounted units are an excellent solution, as they provide adequate washing space while keeping the floor clear.

For help selecting the perfect size and style, read our guide on how to Sink smart when choosing your commercial kitchen hand wash sink.

Beyond the Basin: Essential Accessories and Maintenance

A high-quality hand wash basin commercial kitchen is only the foundation of an effective handwashing station. To ensure compliance and maximize hygiene, you must complete the setup with essential accessories and a consistent maintenance routine. These components work together to promote safety and reduce contamination risks.

Faucets and Fixtures for a Hand Wash Basin Commercial Kitchen

The faucet you choose is critical for preventing the re-contamination of clean hands. The goal is to avoid touching dirty handles after washing. Hands-free faucets are the gold standard and are highly favored by health inspectors. Common options include:

- Foot Pedals: Allow users to control water flow with their feet.

- Knee Levers: Activated by a push with the knee.

- Electronic Sensors: Use infrared technology to automatically turn water on and off.

If budget constraints require manual faucets, choose wrist-blade handles. These longer handles are designed to be operated with the wrist or forearm, keeping clean hands from touching potentially contaminated surfaces. Additionally, gooseneck faucets are a popular choice due to their high-arched design, which provides ample clearance for thorough washing and helps prevent splashing.

Soap, Drying, and Signage

Every hand wash basin commercial kitchen station must include three key elements:

- Soap: A dispenser stocked with liquid, foam, or powder soap must always be available. Antibacterial formulations are a popular choice. Regularly checking and refilling dispensers is crucial for maintaining hygiene standards during busy services.

- Hand Drying: Single-use paper towels are the most hygienic option for drying hands, as they are discarded after one use, removing moisture and pathogens. Dispensers should be kept full, with a waste receptacle placed nearby. Warm-air dryers are also permitted in many areas but require regular cleaning.

- Signage: A clear and conspicuous "Employees Must Wash Hands" sign must be posted at every handwashing sink. This serves as a constant visual reminder, reinforcing the importance of hand hygiene for all staff.

Cleaning and Maintenance

Even the best equipment becomes ineffective without proper upkeep. A dirty sink can become a breeding ground for bacteria, defeating its purpose. A strict cleaning and maintenance schedule is non-negotiable.

- Daily Cleaning: The basin, faucet, handles, and dispensers should be cleaned and sanitized every day using appropriate solutions to eliminate pathogens.

- Regular Checks: Inspect drains frequently for clogs and address any blockages immediately to prevent stagnant water. Check all plumbing connections for leaks, as even small drips can lead to water damage, mold, and slip hazards.

A clean, well-maintained station is more inviting for staff to use and sends a clear message about your commitment to food safety. For more on maintaining all types of sinks, explore our complete guide to commercial sinks for restaurants.

Contact us today to find the perfect sink for your kitchen! Our team can help you create handwashing stations that fit your workflow and budget.

Frequently Asked Questions about Commercial Hand Wash Basins

Navigating the requirements for a hand wash basin commercial kitchen can bring up many questions. Here are straightforward answers to some of the most common concerns from restaurant owners.

How many hand sinks are required in a commercial kitchen?

The exact number depends on your kitchen's size, layout, and local health codes. However, the guiding principle is accessibility. You generally need at least one dedicated hand wash basin commercial kitchen unit in each distinct work area, including food preparation, cooking, and warewashing zones. A common rule of thumb is that no employee should have to travel more than 20 feet to reach a hand sink. The goal is to make handwashing convenient enough that it becomes a frequent, natural part of the workflow.

Does a commercial hand sink need a grease trap?

No, a dedicated hand wash sink does not require a connection to a grease trap. Grease traps are designed to capture fats, oils, and grease (FOG) from warewashing sinks and floor drains where food and cooking residues are washed away. A hand sink only handles soap, water, and soil from hands, so it does not generate the type of waste that would necessitate a grease trap. Connecting one would be an unnecessary expense.

Can I use a 3-compartment sink for handwashing?

Absolutely not. This is a critical health code violation that can lead to immediate penalties. A three-compartment sink is exclusively for the three-step process of washing, rinsing, and sanitizing equipment and utensils. Using it for handwashing introduces a severe risk for cross-contamination. Pathogens from hands can contaminate the water used for sanitizing, and vice-versa. Handwashing must always be performed in a separate, dedicated hand wash basin with no exceptions.

The good news is that dedicated hand sinks are an affordable and essential investment. Contact us today to find the perfect sink for your kitchen! We help operators find compliant solutions that fit their budget.

Conclusion

When building a successful foodservice operation, it's clear that the humble hand wash basin commercial kitchen setup plays a monumental role. From food trucks to full-service restaurants, these essential fixtures are the silent guardians of public health and your business's reputation. Investing in proper hand hygiene infrastructure is a direct investment in the future and integrity of your brand.

This is about more than just avoiding citations from a health inspector. It's about building genuine trust with your customers. While they may never see your handwashing stations, they experience the results with every safe and delicious meal. When your staff has convenient access to well-equipped sinks, you create an invisible shield of protection that builds a reputation for quality and care.

The regulations regarding placement, water temperature, and backflow prevention are not arbitrary problems; they are science-backed standards designed to ensure safety. By adhering to these guidelines and choosing durable equipment, like 18-gauge stainless steel sinks, you ensure your investment pays dividends in safety and reliability for years to come.

At The Restaurant Warehouse, we have seen how a commitment to hygiene can lift a kitchen's entire safety culture. When handwashing is convenient, it becomes second nature. That is the difference between simple compliance and true excellence.

We understand that every dollar counts. That's why we are committed to providing high-quality, compliant hand wash basin commercial kitchen solutions at wholesale prices. By eliminating unnecessary overhead, we help you achieve professional-grade hygiene standards without breaking your budget. Your commitment to hand hygiene reflects your values as a professional—it shows respect for your craft, care for your community, and pride in your brand.

Browse our extensive collection of commercial sinks today and find how affordable professional-grade hygiene can be!

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment