Freshness on Demand: Top Cold Prep Tables for Restaurants and Delis

What is a Cold Prep Table and Why Your Kitchen Needs One

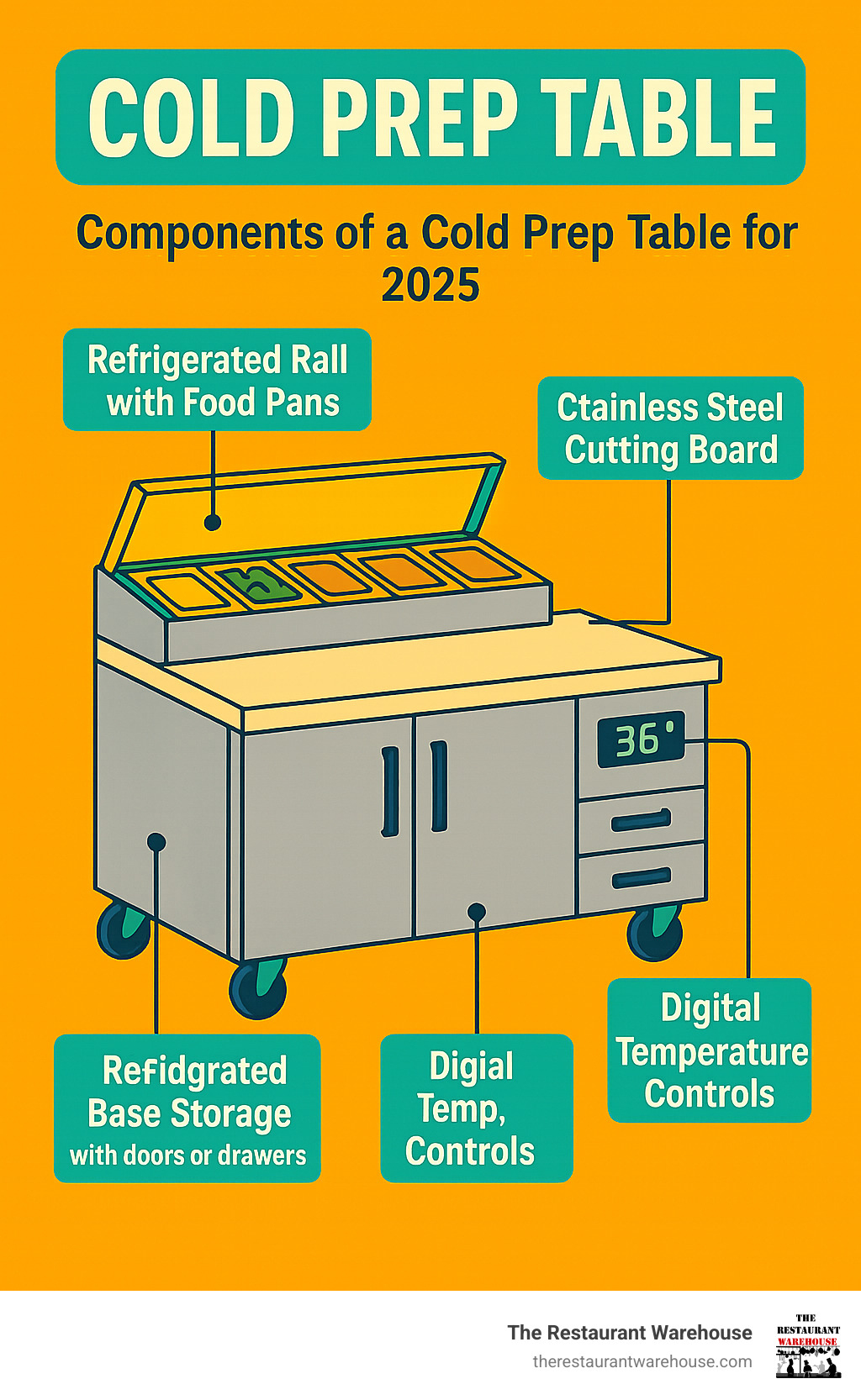

A cold prep table is a hybrid workstation combining a food preparation surface with refrigerated storage. This essential piece of equipment is designed to keep ingredients fresh and within arm's reach, streamlining food assembly, boosting workflow efficiency, ensuring food safety, and improving ingredient organization.

Quick Answer: Cold Prep Tables Essentials

- Temperature Range: 33°F to 41°F for food safety

- Main Types: Sandwich prep, pizza prep, and mega-top models

- Key Features: Refrigerated rail, cutting board surface, refrigerated base storage

- Ideal For: Restaurants, delis, pizzerias, sandwich shops, salad bars

- Benefits: Faster service, reduced waste, better organization, food safety compliance

Cold prep tables are the unsung heroes of commercial kitchens. They create a centralized station where fresh ingredients stay at safe temperatures in the refrigerated rail above, while backup supplies are stored in the refrigerated base below. This setup guarantees that ingredients remain at a regulated temperature, preserving freshness all day, which is crucial for serving quality products and meeting health codes.

Whether you're running a busy deli, a pizzeria, or any restaurant with a made-to-order menu, these versatile units eliminate the constant trips to a walk-in cooler. The beauty of a cold prep table is its simplicity: it puts cold storage exactly where you need it most.

The Unsung Hero: Why Every Food Business Needs a Cold Prep Table

In a busy kitchen, efficiency is everything. Scrambling between a walk-in cooler and prep stations costs time, creates unnecessary traffic, and can compromise food safety. This is where a cold prep table becomes a kitchen's secret weapon. These units are the backbone of successful food operations, from sandwich shops to pizzerias, because they bring order to the chaos of a lunch or dinner rush. They embody the culinary principle of mise en place—everything in its place—by creating a self-contained universe of preparation where every necessary ingredient is chilled, organized, and within arm's reach.

By keeping chilled ingredients organized and at your fingertips, a cold prep table creates a foundation for workflow efficiency that is critical during peak hours. This smart ingredient organization not only speeds up service but also leads to reduced food waste and consistent product quality. When ingredients are held at their optimal temperature, they maintain their freshness, texture, and flavor, meaning less spoilage and better food for your customers. This consistency is key to building a loyal customer base that trusts the quality of every dish you serve.

Most importantly, cold prep tables are essential for food safety compliance. They are engineered to maintain a temperature range of 33°F to 41°F, keeping perishable ingredients out of the temperature danger zone where harmful bacteria multiply. This is fundamental for meeting health department standards and protecting your patrons. You'll find these versatile units in sandwich shops, pizzerias, salad bars, delis, cafes, and catering companies—anywhere speed and freshness are paramount.

For a deeper dive into selecting the perfect unit, our comprehensive Restaurant Prep Table Guide covers everything you need to know.

Enhancing Kitchen Workflow and Organization

A cold prep table acts as a centralized workstation, eliminating the constant, time-wasting movement between prep areas and distant refrigeration. With everything in its place and within arm's reach, your staff can focus on assembling orders instead of searching for ingredients. This reduced staff movement is especially valuable during busy periods, leading to smoother order flow, shorter wait times, and less staff fatigue. It reduces the cognitive load on your team, allowing them to build muscle memory and assemble complex orders with greater speed and accuracy. The result is a calmer, more productive kitchen environment, even during the most intense service periods.

The organized ingredient pans in the refrigerated rail provide a clear visual inventory, which helps with restocking and portion control. This transparency results in faster order fulfillment and fewer mistakes. When ingredients are easily accessible, staff can work more precisely, ensuring every dish meets your quality standards. This visual organization also simplifies training for new employees, as they can quickly learn the station's layout and the location of all necessary components for each menu item.

For more insights on optimizing your prep station, check out our detailed Prep Table Kitchen Guide.

Upholding Food Safety and Quality

A cold prep table is your kitchen's guardian of temperature control. By keeping ingredients below 41°F, it creates an environment where harmful bacteria like Salmonella, E. coli, and Listeria cannot thrive. The temperature danger zone, as defined by health codes, is between 41°F and 135°F. A quality prep table is engineered to stay firmly and consistently below this threshold. Most quality units maintain temperatures between 33°F and 41°F, adhering to the strict requirements of health departments and providing a buffer against temperature fluctuations from opening and closing lids.

Many cold prep tables are built to meet NSF-7 standards, the benchmark for commercial refrigeration. This certification is not just a label; it's a guarantee that the unit has been rigorously tested for performance and safety. NSF-7 compliance means the unit is designed with materials that are non-toxic and corrosion-resistant, has passed performance tests to hold temperature in a hot kitchen environment, and is constructed for easy cleaning and sanitation, with coved corners and minimal crevices where bacteria could hide. This commitment to quality helps preserve freshness and the integrity of your ingredients. The design also aids in preventing cross-contamination, as separate food pans keep ingredients isolated, and the non-porous stainless steel surface is easy to sanitize. This systematic organization promotes better food handling practices.

Consistent temperature control also means your ingredients maintain their peak quality. Lettuce stays crisp, tomatoes remain firm, and meats retain their texture and color. The ability to cover the pans and lower the lid for overnight storage is another food safety benefit, as it reduces handling and saves valuable prep time by keeping ingredients protected and ready for the next day's service.

For more information on how proper refrigeration supports food quality, explore our guide on Freshness on Demand: Top Commercial Prep Fridge Options.

Decoding the Features: How to Choose the Perfect Cold Prep Table

Selecting the right cold prep table is a crucial decision that impacts your kitchen's efficiency, food quality, and budget. It's not a one-size-fits-all solution, so understanding the key features will help you make an informed choice that serves your operation for years to come. We help customers focus on several critical factors:

- Size and capacity: How much space do you have and how many ingredients do you need?

- Material: What level of durability and ease of cleaning do you require?

- Refrigeration system: What cooling performance and energy efficiency are you looking for?

- Doors vs. drawers: Which storage configuration best suits your workflow?

- Cutting board depth: What type of food will you be prepping?

- Pan capacity: How many different ingredients do you need available?

By carefully considering these points, you can ensure your investment pays off. For a comprehensive guide on choosing the best cold prep table, we recommend reviewing our specialized resource: Choose Sandwich Prep Station.

Size and Configuration: Finding the Right Fit

The physical dimensions of your cold prep table are a primary consideration. Widths range from compact 27-inch models for smaller kitchens to expansive 72-inch units for high-volume production lines. Common sizes include 28-inch, 48-inch, 60-inch, and 72-inch models, each designed for different operational scales. Before you buy, measure your space carefully. Account for not only the unit's footprint but also for necessary ventilation clearance (typically 3-4 inches at the back and sides) and the swing radius of the doors. Assess your available kitchen layout to ensure the table fits without impeding traffic flow, and consider your production volume to match the unit's capacity to your needs.

Beyond width, the refrigerated base configuration is crucial. You'll typically choose between doors or drawers:

- Doors are excellent for bulk storage, allowing you to keep larger containers of backup ingredients, full-size hotel pans, or pre-prepped items. They are generally more cost-effective and offer flexibility for storing items of various shapes and sizes.

- Drawers offer superior organization and easier access to smaller, frequently used items, improving efficiency for specific tasks. They pull out, providing a top-down view of contents, which eliminates the need to bend down and rummage through a cabinet. This makes them ideal for holding pre-portioned items or specific pan sizes.

The choice between doors, drawers, or a combination depends on your menu and prep style. A high-volume sandwich station might benefit from drawers holding portioned meats and cheeses, while a salad station might prefer the bulk storage of a door cabinet for large bins of lettuce. For a versatile mid-size option, our 48 Inch Sandwich Prep Refrigerators offer a popular balance of capacity and footprint.

Material Matters: The Advantages of Stainless Steel

Commercial kitchen equipment needs to be durable, which is why stainless steel is the industry standard for cold prep tables. However, not all stainless steel is the same. You'll often see different grades used, such as 304 and 430. Type 304 stainless steel has a higher nickel content, making it more resistant to corrosion from salt and acidic foods, and is typically used for high-contact surfaces like the tabletop and interior. Type 430 is more economical and is often used for the sides and back of the unit. This combination provides durability where it's needed most while keeping the unit affordable. The advantages are numerous:

- Durability: Stainless steel is robust and resistant to dents, scratches, and impacts, withstanding the rigors of a busy kitchen.

- Hygiene and Ease of Cleaning: Its non-porous, smooth surface doesn't absorb liquids or bacteria and is incredibly easy to wipe down and sanitize. Many models are NSF certified, attesting to their sanitary design.

- Resists Corrosion: It is highly resistant to rust and corrosion, even when exposed to moisture and acidic foods.

- Professional Appearance: A gleaming stainless steel kitchen looks professional, clean, and bright.

The cutting board is another critical material. Most are made from high-density polyethylene, which is durable, non-absorbent, and won't dull your knives. They are also typically removable for easy and thorough cleaning.

Stainless steel construction is a hallmark of quality and reliability in cold prep tables. It’s an investment that pays dividends in cleanliness and longevity. To learn more, check out our Stainless Steel Prep Table Guide.

The Heart of the Unit: Understanding Refrigeration Systems

The refrigeration system is the heart of your cold prep table, keeping ingredients fresh and safe between 33°F and 41°F. Many modern units use advanced forced-air systems that circulate a blanket of cool air above, below, and over the food pans. This ensures even cooling across all ingredients, preventing warm spots that could compromise food safety, even when pans are frequently accessed. This is superior to older cold-wall systems, which can be prone to uneven cooling.

Most cold prep tables feature self-contained refrigeration systems, with the compressor, condenser, and evaporator integrated into the unit. This makes them easy to install—just plug them in—and simplifies maintenance. When choosing a unit, consider its breathing direction. Front-breathing units pull in and exhaust air from the front, allowing them to be installed flush against a wall or other equipment, saving valuable space. Rear-breathing models require several inches of clearance at the back.

In terms of refrigerants, the industry is shifting towards environmentally friendly options like R290. This natural hydrocarbon refrigerant is highly efficient, non-toxic, and has a very low Global Warming Potential (GWP), making it a greener and more energy-efficient choice than older refrigerants like R134a. This can lead to lower electricity bills over the life of the unit.

Precise temperature is managed by digital thermostats, allowing you to easily monitor and adjust settings to ensure your ingredients are always held in the optimal, food-safe range. For a deeper dive into the technical aspects, we invite you to View a detailed product reference guide.

A Guide to Different Cold Prep Table Types

Not all cold prep tables are created equal. While they all keep ingredients chilled during prep, specialized versions exist to cater to different culinary needs. The main types are sandwich prep tables, pizza prep tables, and mega-top prep tables. Understanding their distinct designs—from cutting board depth to pan capacity—is crucial for choosing the unit that will best optimize your specific operation.

A busy deli has different requirements than a pizzeria, and these specialized designs address those unique needs. For a comprehensive look at all our options, check out our main Restaurant Prep Table page.

The Classic: Standard Sandwich & Salad Prep Tables

Standard sandwich and salad prep tables are the workhorses of countless delis, cafes, and sandwich shops. Their design is perfected for assembling sandwiches, wraps, and salads with speed and efficiency. Beyond these classics, their versatility makes them perfect for modern fast-casual concepts like burrito bowls, poke bowls, and yogurt parfait stations.

The key feature is a shallow cutting board, typically 8 to 10 inches deep. This provides enough room to work without requiring awkward stretching to reach the pans. Above the work surface, the refrigerated rail is designed to hold 1/6-size food pans, which are ideal for organizing ingredients like sliced tomatoes, onions, cheeses, and deli meats. A key benefit is pan flexibility; you can often swap two 1/6-size pans for a single 1/3-size pan to accommodate bulkier items like mixed greens.

Many of these tables include a hinged, insulated lid that covers the ingredient pans. This is a game-changer for maintaining temperature during service and for safe overnight storage. Atosa models are particularly popular in this category, offering reliability for busy operations. These units are ideal for delis and cafes where customized orders need to be made quickly and consistently.

If you're ready to select the perfect unit for your sandwich operation, our Sandwich Prep Table Guide has all the details. For those interested in the reliable Atosa line, check out our Atosa Sandwich Prep Table options.

The Specialist: Dedicated Pizza Prep Tables

The pizza prep table is the heart of any pizzeria. These units are engineered specifically for the art of pizza making. The most noticeable feature is the extra-deep cutting board, often 16 to 20 inches deep. This provides a generous workspace to stretch dough and assemble large pizzas without the dough hanging over the edge or feeling cramped.

Above the workspace sits a raised refrigerated rail. This design lifts the pans higher and often angles them toward the user, which serves two purposes: it creates an air buffer to keep ingredients consistently cold even in a hot kitchen environment, and it improves ergonomics. The rail is designed to accommodate 1/3-size pans, which are larger than those in sandwich prep tables. This is practical for holding high-volume toppings like pepperoni, mushrooms, and cheese, reducing the need for frequent refills during a rush.

Another thoughtful feature is the dedicated space for large dough balls or dough boxes in the refrigerated base, eliminating trips to a separate cooler. The refrigeration system is often more robust to handle the constant opening and closing in a high-temperature environment. These tables are built tough to perform flawlessly order after order, making them ideal for pizzerias of all sizes. To learn more, explore our Pizza Prep Table Guide and find reliable options like the Atosa Pizza Prep Table.

The High-Capacity Option: Mega-Top Prep Tables

For high-volume kitchens in catering, campus dining, or restaurants with extensive menus, the mega-top prep table is the ultimate solution. These units offer significantly more ingredient capacity without a massive increase in floor space, making them a smart choice for maximizing output in a limited area.

The defining feature is the extra row of pans in the refrigerated rail. While a standard 48-inch table might hold twelve 1/6-size pans, a 48-inch mega-top can hold eighteen, a 50% increase. This allows you to stock more ingredient varieties or larger quantities of popular items. This increased ingredient capacity boosts efficiency by dramatically reducing the time spent refilling pans during busy periods.

The deeper refrigerated rail is engineered with powerful, directed airflow to ensure all pans, even those in the back row, maintain consistent, safe temperatures. These tables are indispensable for operations with complex menus, such as build-your-own bowl concepts or sandwich shops with dozens of toppings. They are incredibly versatile, allowing you to offer more customization to your customers without slowing down the line. You get significantly more working capacity in a relatively compact footprint, which is crucial for maintaining speed and quality. Explore our Sandwich Prep Tables page to see various mega-top units.

Maximizing Your Investment: Cleaning and Maintenance Essentials

Your cold prep table is a cornerstone of your kitchen's success and a significant investment. Proper care is essential to ensure its longevity, peak performance, and the food safety standards your business depends on. A well-maintained unit will serve you reliably for years, while a neglected one can lead to inefficient cooling, costly repairs, and compromised safety.

Establishing a routine of daily, weekly, and monthly maintenance is the best way to protect your investment. It prevents small issues from becoming major problems and keeps the unit running efficiently. For practical tips that apply across different models, our Pizza Prep Table Maintenance guide offers valuable advice.

Daily Cleaning Routine

Good daily habits are essential for hygiene and performance. These simple steps should be part of your closing routine:

- Wipe down all surfaces, including the stainless steel exterior, interior, and lid. Use a food-safe cleaner and a soft cloth, wiping in the direction of the steel's grain to prevent scratching. Follow with a sanitizer.

- Clean and sanitize the cutting board. If it's removable, take it to a three-compartment sink for a full wash, rinse, and sanitize. If fixed, scrub it thoroughly in place. This prevents flavor transfer and bacterial buildup.

- Empty, wash, and sanitize all food pans from the refrigerated rail to prevent cross-contamination and ensure ingredients start fresh the next day.

- Check for and clean any spills in the refrigerated cabinet below. This prevents odors, mold growth, and potential pest issues.

- Empty and clean any drip trays and check drain lines for any blockages to maintain a hygienic workspace.

Periodic Maintenance Checklist

Deeper maintenance tasks keep your cold prep table running smoothly long-term. Schedule these checks to ensure optimal performance and energy efficiency.

Weekly Tasks:

- Deep Clean the Interior: Remove all shelves and supports and wash them thoroughly. Wipe down the entire interior cabinet, including corners and crevices.

- Inspect Door/Drawer Gaskets: Check the gaskets for any tears, cracks, or loss of flexibility. A poor seal lets cold air escape, forcing the compressor to work harder. Clean them with warm, soapy water and wipe dry. Most gaskets are removable for easy replacement if damaged.

Monthly Tasks:

- Clean the Condenser Coil: This is one of the most critical maintenance tasks. Dust and grease buildup on the coils act as an insulator, forcing the unit to work harder and use more energy. Unplug the unit and use a stiff brush or vacuum to gently clean the coils. For greasy kitchens, a degreasing agent may be necessary.

- Calibrate the Thermostat: Use an external, calibrated food thermometer to check the internal temperature. Place it in a glass of water in the unit for several hours. If the reading differs significantly from the unit's display, you may need to adjust the thermostat or call for service.

- Check and Clean Casters: Inspect the casters for debris buildup, ensure they roll smoothly, and test that the brakes engage properly for safety.

When to Call a Professional: While regular cleaning and maintenance can be handled by staff, some issues require a qualified refrigeration technician. Call a professional if you notice the unit is not holding temperature, the compressor is running constantly, you hear unusual noises like grinding or knocking, or if you suspect a refrigerant leak.

Frequently Asked Questions about Cold Prep Tables

Investing in a cold prep table is a big decision, and it's natural to have questions. This equipment will be a workhorse in your kitchen, so it's important to have all the facts. Based on our experience helping countless food service operators, these are the most common questions we hear.

How do cold prep tables ensure food safety?

Food safety is the core principle behind the design of a cold prep table. They ensure safety in several key ways:

- Consistent Temperature Control: The most critical feature is maintaining a temperature between 33°F and 41°F. This keeps ingredients out of the temperature danger zone where bacteria multiply rapidly. Advanced forced-air systems ensure even cooling in every part of the unit, from the cabinet below to the top rail.

- Sanitary Construction: The use of stainless steel provides a non-porous surface that doesn't harbor bacteria and is easy to clean and sanitize. NSF-certified units have coved corners and seamless welds to eliminate crevices where food particles could get trapped.

- Preventing Cross-Contamination: Separate compartments and food pans in the refrigerated rail keep different ingredients, like raw proteins and fresh vegetables, from coming into contact.

- Protective Lids: Most models include insulated lids that cover the ingredient pans, protecting them from airborne contaminants and helping maintain a consistent temperature, especially overnight.

Can I store ingredients in the prep table overnight?

Yes, and it's one of the biggest time-saving benefits of a cold prep table. When done properly, it's completely safe and means your ingredients are ready to go for the next shift. The key is to lower the insulated lid to create a sealed, temperature-controlled environment. You should also use any individual covers for the food pans if you have them.

Before closing, do a quick check of the digital thermostat to confirm the unit is holding its temperature within the safe range (33°F to 41°F). This practice not only saves prep time but also reduces food handling, which further minimizes the risk of contamination. It's a standard, approved practice in commercial kitchens across the country.

What is the difference between a cold prep table and a worktop refrigerator?

This is a common point of confusion. While they look similar, their function is different. A worktop refrigerator provides a refrigerated base with a durable, flat stainless steel top for general prep work or for placing countertop equipment. It does not have the refrigerated top rail for holding pans of ingredients. A cold prep table is a specialized version of a worktop refrigerator that includes the refrigerated pan rail, making it a complete, all-in-one station for assembling dishes like sandwiches, salads, or pizzas.

What is the typical price range for a commercial cold prep table?

The price of a cold prep table varies widely based on several factors, ensuring there's an option for nearly every budget.

- Size and Capacity: This is the biggest price driver. A compact 27-inch unit might start around $900-$1,500, while a large 72-inch mega-top for a high-volume operation could be $3,000-$5,000 or more.

- Features and Brand: Units with advanced refrigeration systems, digital controls, or special certifications like Energy Star will cost more. The configuration also matters, as drawers typically add to the cost compared to standard doors.

- Configuration: A simple two-door base will be less expensive than a unit with multiple drawers.

Most standard 48-inch to 60-inch units, which suit the majority of restaurants, fall in the $1,500 to $3,000 range. At The Restaurant Warehouse, we focus on wholesale pricing, cutting out retail overhead to provide professional-grade equipment at more affordable prices.

While used equipment can seem cheaper upfront, a new cold prep table comes with a manufacturer's warranty, the latest energy-efficient technology, and the peace of mind of knowing its history. An Energy Star certified model, for example, can save you hundreds of dollars in electricity costs over its lifespan, making the initial investment more valuable. Given the importance of food safety, many operators find the reliability of new equipment to be a worthwhile investment.

Conclusion

Choosing a cold prep table is a strategic investment in your kitchen's future. These units are the unsung heroes of the foodservice industry, working to keep your operation efficient, safe, and profitable. They are efficiency boosters that centralize workflow, safety guardians that maintain precise temperatures, and quality keepers that ensure every dish meets your high standards.

From the durable stainless steel construction to the sophisticated refrigeration systems, every feature is designed to deliver value. Whether you need a standard sandwich prep table, a specialized pizza prep table, or a high-capacity mega-top model, you are investing in a tool that will transform how your team works.

Proper cleaning and maintenance are key to maximizing the return on your investment for years to come. A well-maintained unit is a reliable partner in your success.

At The Restaurant Warehouse, we've seen how the right equipment can revolutionize a kitchen. We are passionate about providing affordable, wholesale pricing on high-quality units without the high retail markup. Your customers deserve fresh, safe food, and your staff deserves tools that make their jobs easier. A quality cold prep table delivers on all fronts.

Ready to take the next step? We're here to help you find the perfect match for your operation. For deeper insights into selecting the ideal unit, Explore our complete guide to Sandwich Prep Tables. Your kitchen's efficiency revolution starts here.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment