Beyond the Burner: A Comprehensive Guide to Commercial Countertop Ranges

Why Commercial Countertop Ranges Are Essential for Modern Foodservice

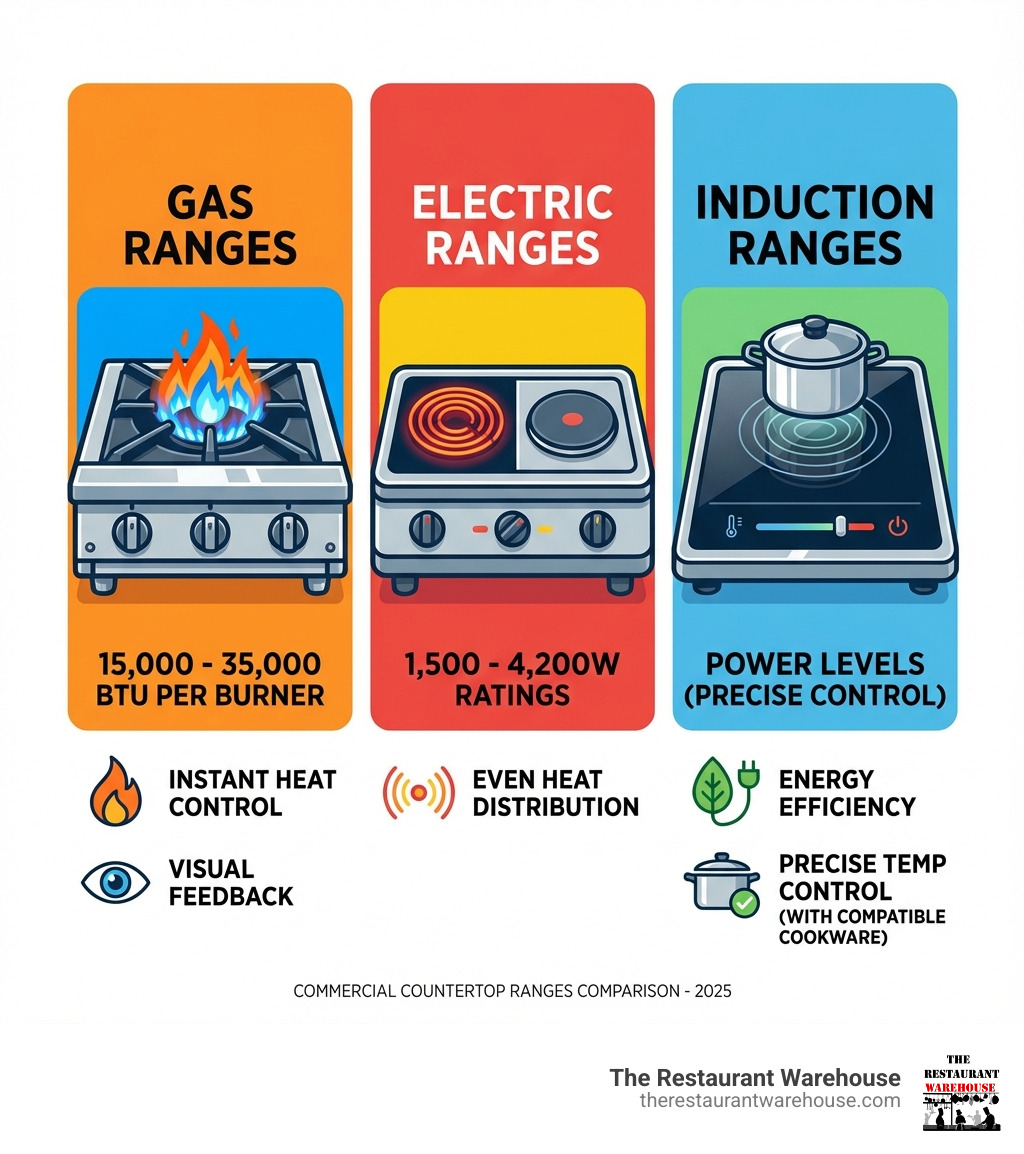

A commercial countertop range is a gas, electric, or induction-powered cooking appliance meticulously engineered to sit on workstations in professional kitchens. These versatile units provide powerful, restaurant-grade cooking capabilities without the large footprint, high cost, or complex installation of a full-size floor model range. In today's competitive foodservice landscape, where space is a premium and adaptability is paramount, these compact powerhouses are essential for maximizing kitchen efficiency and menu potential.

Key benefits extend beyond simple cooking. They include a space-efficient design that can transform an underutilized counter into a high-output production station, restaurant-grade power (with gas models reaching up to 35,000 BTU per burner or electric units exceeding 4,200W), flexible placement options, and heavy-duty construction designed for relentless use. With choices for gas, electric, or induction fuel, they are perfectly suited for a wide spectrum of operations. This includes bustling food trucks, agile catering businesses, cozy cafes, large-scale hotel kitchens, institutional dining halls, and as crucial auxiliary cooking stations in established restaurants.

Whether you're launching a new food truck concept, strategically adding capacity to handle peak dinner rushes, or equipping a mobile catering operation for off-site events, these ranges deliver professional power in a portable, compact format. It is critical to understand that these are not simply more powerful versions of residential models. Unlike home appliances built primarily for aesthetics and intermittent use, commercial units are engineered from the ground up for high-volume output, extreme durability, and rapid, easy cleaning to meet stringent sanitation standards.

A well-chosen commercial countertop range is a strategic asset that can fundamentally transform your kitchen's efficiency, menu flexibility, and labor flow. It is a tool that empowers your culinary team to:

- Drastically reduce ticket times during the busiest service periods by adding dedicated sauté or finishing stations.

- Introduce new, profitable menu items like sautéed dishes, pan-seared proteins, or complex stir-fries without the need for a costly and disruptive full kitchen remodel.

- Seamlessly support seasonal specials, limited-time offers, or pop-up concepts on the existing line, allowing for greater creativity and responsiveness to market trends.

- Facilitate expansion into new business models like ghost kitchens or satellite locations with minimal construction and capital investment.

This comprehensive guide will cover everything you need to know, from the nuances of different fuel types to selecting the proper size and power for your specific menu, along with critical installation, safety, and maintenance considerations.

I'm Sean Kearney from The Restaurant Warehouse, and I've spent years helping operators find the right commercial countertop range solutions. My experience has consistently shown that a deep understanding of your specific operational needs—from the intensity of high-heat searing to the delicacy of gentle simmering—is the absolute key to selecting an appliance that truly serves your business, delivering professional performance without inflated prices.

If you already know you need to upgrade or expand your cooking capacity, you can browse commercial countertop ranges at The Restaurant Warehouse while you read this guide, then come back to compare features and specifications with your newfound knowledge.

Understanding the Fundamentals of Commercial Cooking Power

A commercial countertop range is a specialized cooking appliance designed specifically for the rigorous, non-stop demands of professional kitchens. Unlike their residential counterparts, these units are purpose-built for continuous, high-volume use, offering superior durability, immense power, and unmatched efficiency for fast-paced environments ranging from busy urban cafes to high-output food trucks.

Commercial vs. Residential Countertop Ranges

The chasm between commercial and residential countertop ranges is substantial and goes far beyond mere appearance. While many home units are designed to mimic a professional aesthetic, true commercial models prioritize raw performance, unwavering resilience, and operational safety above all else.

- Durability and Construction: This is a non-negotiable distinction. Commercial ranges are constructed with heavy-duty materials designed to endure the harsh realities of a professional kitchen. The body is typically made from thicker gauge, corrosion-resistant stainless steel, such as Grade 430, with continuously welded seams for added strength and easier cleaning. Grates are made of heavy-duty cast iron to withstand extreme thermal shock and the weight of heavy stockpots. In contrast, residential models use lighter-gauge metals and often feature plastic components that would quickly fail under commercial-level stress.

- Power Output (BTU/Watts): This is the heart of a commercial unit's performance. Commercial gas burners deliver a staggering 15,000 to 35,000 BTUs per burner, an output that allows a chef to achieve a hard sear on a steak in seconds or bring a large pot of water to a rolling boil in minutes. Electric models can reach 4,200 watts or more, providing intense, consistent heat. This power enables rapid cooking and, crucially, quick recovery times—the ability of the burner to return to its set temperature immediately after cold food is added to a pan. A standard 6-burner commercial gas unit can produce a combined output of over 132,000 BTUs, a level of thermal energy that far exceeds the capacity of even high-end residential ranges.

- Safety and Sanitation Standards: Commercial countertop ranges are legally required to meet stringent safety and sanitation standards, verified by certifications from organizations like NSF International or ETL. These certifications are not optional; they are critical for passing health inspections in the United States. They ensure the appliance is designed for safe operation in a public setting and can be thoroughly cleaned and sanitized to prevent foodborne illness. Residential units are not subjected to these same commercial-grade protocols and are therefore unsuitable and often illegal for use in a commercial foodservice business.

Key Features and Common Applications

Understanding the core features of a commercial countertop range illuminates its immense value across a diverse array of foodservice settings.

- Heavy-Duty Construction: Beyond the materials, this includes robust frames, reinforced control knobs, and durable internal components. The use of Grade 430 stainless steel provides excellent durability, resistance to corrosion from spills and cleaning chemicals, and a hygienic, non-porous surface. Heavy-duty cast iron grates and burners offer superior heat retention and create a stable, level platform for large and heavy cookware.

- High-Efficiency Burners: These are not just powerful; they are engineered for maximum heat transfer and fuel efficiency. This ensures quick, consistent results while helping to manage utility costs. Gas models often feature standing pilots, which provide instant ignition and eliminate the delay of electronic igniters, a critical feature for streamlining workflow in a high-pressure environment.

- Precise and Responsive Temperature Control: Whether it's the immediate, visual feedback and nuanced control of a gas flame or the precise, repeatable digital settings of an electric or induction unit, commercial ranges empower chefs to execute a vast range of cooking techniques—from aggressive pan-frying and sautéing to delicate simmering and shallow poaching—with consistency and confidence.

- Portability and Simplified Cleaning: Many models are designed with portability in mind, a significant advantage for catering companies and mobile food vendors. Features like removable grates, lift-off burner heads, and full-width, slide-out crumb trays are engineered to simplify daily cleaning, saving valuable time and labor while ensuring compliance with health codes.

These features make the commercial countertop range an indispensable tool for:

- Limited-Space Kitchens: They are the workhorses of food trucks, concession stands, kiosks, and small cafes, where every square inch of counter space must be maximized for cooking power.

- Supplemental Cooking Stations: Larger restaurants frequently use them to add extra burner capacity during peak hours, create a dedicated station for gluten-free or allergen-free cooking, or handle specific menu items like sauces or appetizers without tying up the main range.

- Mobile and Off-Premise Operations: Caterers and pop-up kitchens depend on their portability and quick setup to bring professional-grade cooking capabilities to any venue, from wedding receptions to farmers' markets.

- Demonstration and Educational Cooking: Their compact size and powerful performance make them perfect for culinary schools, cooking classes, and front-of-house chef demonstrations.

If you want tailored advice based on your space, fuel availability, and menu, you can contact The Restaurant Warehouse for a free appliance planning consultation and get a recommendation checklist before you buy.

Fueling Your Kitchen: A Deep Dive into Gas, Electric, and Induction Models

Choosing the right fuel type for your commercial countertop range is a foundational decision that profoundly impacts performance, operating costs, and the daily workflow of your kitchen. Each of the three primary options—gas, electric, and induction—offers a distinct set of advantages and considerations that must be weighed against your menu, location, and operational style.

The Power and Precision of Gas Countertop Ranges

Gas ranges are the traditional workhorse and a long-standing favorite in commercial kitchens, prized for their raw power and incredibly responsive control. They operate on either natural gas (NG) from a utility line or liquid propane (LP) from tanks, with most commercial units offering conversion kits for fuel flexibility.

-

Pros:

- High BTU Output: Gas burners deliver intense, powerful heat, with commercial ratings typically falling between 15,000 and 35,000 BTUs/hr per burner. This makes them the undisputed champion for high-heat cooking techniques like searing, blackening, stir-frying, and bringing large volumes of liquid to a boil quickly.

- Instant & Visual Control: Chefs overwhelmingly value the immediate temperature adjustments and intuitive visual feedback provided by a gas flame. The ability to instantly go from a roaring heat to a delicate simmer by turning a knob allows for unparalleled control and artistry on the fly.

- Fuel Flexibility and Reliability: Natural gas provides a continuous and often more cost-effective fuel source in areas where it's available. Propane (LP) offers excellent portability, making gas ranges the go-to choice for food trucks, outdoor events, and catering operations. The use of standing pilots in most commercial models allows for instant burner ignition, a crucial time-saver in a fast-paced service environment.

-

Cons & Considerations:

- Ventilation & Safety: Gas combustion produces significant heat and byproducts like water vapor, carbon dioxide, and other particulates. Therefore, you must install and operate these units under a proper commercial ventilation hood. According to the U.S. Environmental Protection Agency, proper ventilation is critical for maintaining indoor air quality and reducing staff exposure to combustion pollutants. Always consult your local authority having jurisdiction (AHJ) for specific fire and mechanical code requirements.

- Maintenance: Standing pilot lights require regular monitoring and can sometimes be extinguished, requiring relighting. Burner ports can become clogged with grease and food debris, necessitating routine cleaning to ensure an even flame and efficient operation.

- Best For: High-volume, high-heat cooking methods like searing, sautéing, and wok cooking that benefit from direct, powerful, and instantly adjustable heat.

The Consistency and Simplicity of Electric Countertop Ranges

Electric countertop ranges are celebrated for their reliable, consistent, and evenly distributed heat, making them an excellent choice for specific cooking styles and kitchen setups where precision and stability are more important than raw power.

-

Pros:

- Even Heat Distribution: Electric elements, whether they are solid cast iron plates (French tops) or exposed coils, provide steady and even heat across the entire cooking surface. This is ideal for simmering sauces for long periods, melting chocolate, holding delicate items at a consistent temperature, or braising.

- Simple Installation: In kitchens with adequate electrical infrastructure, installing an electric range can be significantly simpler and less expensive than running a new gas line. However, it's crucial to note that powerful commercial units often require a 240V connection, not a standard 120V wall outlet.

- Cleaner Operation: Electric units do not produce combustion byproducts, which can result in a slightly cooler and more comfortable kitchen environment. This also makes them a viable option for front-of-house or demonstration cooking where extensive ventilation may be impractical.

-

Cons & Considerations:

- Slower Response Time: Compared to gas or induction, electric elements have a slower response time. They take longer to heat up and cool down, which can require more foresight from the culinary team and may be less ideal for techniques requiring rapid temperature changes.

- Utility Costs: The operational cost of electric ranges is directly tied to local electricity rates, which can be higher than natural gas in many regions. Analyze your utility costs carefully before committing.

- Power Requirements: High-wattage models (4,200W or more) are necessary for heavy-duty performance and can place a significant load on your kitchen's electrical system. Ensure your circuits and panels are rated to handle the demand.

- Best For: Tasks requiring stable, consistent, low-to-medium heat, such as simmering, braising, holding, finishing dishes, and preparing delicate sauces.

The Efficiency and Safety of Induction Countertop Ranges

Induction technology represents the cutting edge of countertop cooking, offering unparalleled energy efficiency, precision, and safety. It functions by using a powerful electromagnetic field to heat the cookware directly, while the cooktop surface itself remains relatively cool.

-

Pros:

- Superior Energy Efficiency: By heating the pan directly, almost no energy is wasted into the surrounding air. This translates to significantly lower utility bills and a dramatically cooler, more comfortable kitchen environment, reducing the strain on your HVAC system.

- Rapid and Precise Heating: Induction is one of the fastest heating methods available, capable of boiling water much quicker than many gas or electric counterparts. It also offers extremely accurate and instantaneous temperature regulation, making it invaluable for delicate tasks like tempering chocolate, creating stable emulsions, or holding sauces at a precise temperature for service.

- Improved Safety: The cool-to-the-touch glass-ceramic surface drastically reduces the risk of burns, creating a safer workspace for busy staff. Spills are also much easier to clean, as they don't bake onto the hot surface.

-

Cons & Considerations:

- Cookware Compatibility: This is the most significant limitation. Induction requires ferromagnetic cookware—pans that a magnet will stick to, such as cast iron or magnetic stainless steel. Aluminum, copper, and glass cookware will not work. You must verify that your existing pan inventory is compatible or budget for new cookware.

- Higher Initial Cost: Induction ranges typically have a higher upfront purchase price compared to gas or electric models of similar size and power.

- Learning Curve: The lack of a visual flame and the sheer speed of heating can require a brief adjustment period for chefs accustomed to traditional gas ranges.

- Best For: Precision-focused tasks, energy-conscious operations, open or demonstration kitchens, and any environment where safety and a cool kitchen are top priorities.

If you're comparing fuel options for multiple locations or a new build-out, you can schedule a strategy call with The Restaurant Warehouse to review your utility availability, codes, and long-term operating costs before purchasing.

Choosing the Right Commercial Countertop Range for Your Business

Selecting the perfect commercial countertop range is not merely a purchasing decision; it's a strategic investment in your kitchen's productivity and your menu's potential. A thorough assessment of your available space, menu requirements, and operational workflow is essential to choosing a unit that will enhance efficiency and deliver a strong return on investment for years to come.

Sizing Your Range: Burners and Footprint

The physical size and burner configuration of your range are the most fundamental considerations, as they must align with your physical layout and production volume.

-

Number of Burners: Choose a configuration based on the complexity and volume of your menu.

- 2-Burner Models: Typically 12 inches wide, these are ideal for small cafes, food trucks, or as a specialized auxiliary station in a larger kitchen. They are perfect for soup-and-sandwich concepts, small-plate menus, finishing stations, or a limited hot line that only requires one or two active pans at a time.

- 4-Burner Models: A highly versatile choice for most medium-sized operations, these units are typically 24 inches wide. They provide enough capacity to support multiple pans at once, allowing a single cook to manage a sauté pan, a sauce pot, a stock pot, and perhaps a backup holding pan simultaneously.

- 6-Burner Models: These high-capacity units, typically 36 inches wide or more, are essential for busy, high-volume kitchens. They are suited for restaurants with extensive menus that require simultaneous searing, boiling, blanching, simmering, and complex sauce work during peak service.

- Unit Dimensions and Clearances: Commercial countertop ranges come in a vast array of widths, from a compact 12 inches to an expansive 72 inches. Before purchasing, meticulously measure your available counter space. Crucially, you must also account for the manufacturer's specified safety clearances—usually a minimum of 4-6 inches on the sides and back—to prevent fire hazards and ensure proper ventilation. Factor in any adjacent appliances, side splash guards, or prep areas to ensure a safe and functional fit.

- Step-Up Design: For high-volume kitchens, consider models that feature raised rear burners. This ergonomic design elevates the back row of burners, improving a chef's access to pots and pans without having to reach over hot front burners. This small design feature can significantly enhance workflow efficiency and reduce the risk of burns and spills during a hectic service.

Decoding Power: Matching BTU and Wattage to Your Menu

Matching the power output of the range to the specific demands of your menu is absolutely critical for achieving desired culinary results and maintaining ticket times.

- BTU (British Thermal Units) for Gas: Higher BTU ratings translate directly to faster heating and quicker recovery times after cold food is added to a pan. Burners typically range from a standard 15,000 BTUs/hr to a high-performance 35,000 BTUs/hr. If your menu is heavy on items that require a hard sear (steaks, scallops), flash sautéing, or boiling large pots of water for pasta or stocks, you must opt for higher BTU burners to keep up with demand.

- Wattage for Electric/Induction: For electric and induction ranges, power is measured in watts. As with BTUs, higher wattage means faster, more robust performance. Light-duty units may be around 1,800W, suitable for light simmering or front-of-house cooking. Heavy-duty models can exceed 4,200W per burner, providing the power needed for demanding back-of-house production lines. Don't underestimate your power needs; an underpowered unit will lead to slow service and inconsistent food quality.

- Matching Power to Menu and Technique: Go beyond the numbers and analyze your cooking processes. Do you need intense, roaring heat for quick searing, or do you require gentle, consistent, low heat for delicate sauces and braises? Do your cooks often work with cold proteins directly from the refrigerator (requiring high recovery power), or do they primarily work with prepped, room-temperature ingredients? A steakhouse has vastly different power needs than a small cafe. Your menu and production style are the ultimate guides to determining the right power level.

Material and Construction: Built to Withstand the Rush

The longevity and reliability of your commercial countertop range are directly dependent on its build quality and the materials used in its construction.

- Stainless Steel Body: Grade 430 stainless steel is the industry standard for the exterior body of professional cooking appliances. It offers an excellent balance of corrosion resistance, durability against dents and scratches, and is easy to keep clean and hygienic to meet health code standards.

- Cast Iron Components: For gas models, heavy-duty cast iron grates and burners are non-negotiable. Cast iron provides exceptional heat retention and distribution, creating a stable, even-heating surface that can handle the weight and thermal shock of heavy commercial pots and pans without warping or cracking.

- Engineered for Durability: Look for signs of quality engineering. Commercial ranges should be built for extreme resilience with reinforced frames, fully welded seams (which are stronger and more sanitary than spot-welded seams), and high-quality internal components. Features like corrosion-resistant coatings on internal parts and durable metal control knobs (as opposed to plastic) extend the unit's lifespan and make long-term maintenance easier.

Optimizing for Workflow, Staff, and Menu Evolution

Beyond the technical specifications, you must consider how your commercial countertop range will integrate into the dynamic, real-world environment of your kitchen.

- Line Layout and Ergonomics: Think about the physical flow of your cook line. Will cooks be passing hot pans over each other? A step-up configuration or a staggered burner layout can reduce collisions and improve safety. Consider the placement of the range in relation to refrigeration, prep tables, and the service window to minimize unnecessary steps and create a more efficient workflow.

- Staff Skill Level and Training: The choice of fuel type can be influenced by your team's experience. Highly skilled sauté cooks can harness the full potential of powerful, responsive gas units. For kitchens with less experienced staff or high turnover, the precise temperature settings of an induction range or the steady heat of an electric model can reduce food waste from burning and lead to more consistent results.

- Menu Evolution and Future Growth: Your menu is not static. If you anticipate adding more sautéed items, vegetarian options that require dedicated pan space, or global cuisines that rely on high-heat wok-style cooking, choose a configuration and power level that provides room to grow. Investing in a slightly larger or more powerful unit now can save you the cost and hassle of needing to upgrade again in a year.

To compare specifications quickly, you can view The Restaurant Warehouse commercial countertop range collection and filter by size, fuel type, and power rating, then use this section as a checklist while you shop.

Installation, Maintenance, and Safety for Peak Performance

Proper installation, diligent maintenance, and strict adherence to safety standards are not optional—they are paramount for the longevity and performance of your commercial countertop range. Following these best practices ensures your appliance operates efficiently, lasts longer, minimizes the risk of accidents, and complies with all local health and fire regulations.

Proper Installation and Ventilation

Correct installation from day one is the foundation for safe and effective operation. Rushing this step can lead to poor performance and serious safety hazards.

- Leveling and Placement: Your range must be placed on a stable, non-combustible surface. Use the adjustable legs to ensure the unit is perfectly level. An unlevel surface can cause uneven cooking, lead to dangerous grease pooling, and create a risk of pots and pans sliding off. Always maintain the manufacturer-specified clearance from walls and other combustible surfaces (typically 4-6 inches on sides and back) and consult your local fire codes for any additional requirements.

- Utility Connections: All utility connections must be performed by a qualified professional. For gas models, this means a licensed plumber or gas fitter must connect the unit to the gas line (often a 3/4" NPT inlet) and install the required pressure regulator. For electric and induction units, a licensed electrician must verify the required voltage (120V vs. 240V) and amperage, ensuring your electrical system can safely support the load. Use only properly rated cords, receptacles, and disconnect switches as specified by the manufacturer and local electrical codes.

- Ventilation: High-heat commercial cooking produces a significant amount of heat, steam, grease-laden vapors, and, in the case of gas, combustion byproducts. Your kitchen must have adequate ventilation, typically a Type I commercial hood system, to handle this additional load. This is crucial for maintaining proper air quality, preventing grease buildup (a major fire hazard), and ensuring a safe, comfortable working environment for your staff. Local health and building departments often reference standards and guidelines similar to those discussed in educational resources from institutions like Iowa State University Extension, so checking with your AHJ is a mandatory step.

Cleaning and Maintenance Best Practices

Regular, systematic cleaning is the single most important factor in extending the life of your commercial countertop range and upholding critical food safety standards.

| Task | Frequency | Details |

|---|---|---|

| Daily | After Each Service | - Turn off the unit and allow it to cool. Wipe down all stainless steel surfaces with a clean, damp cloth and a mild, food-safe detergent. |

- Remove heavy cast iron grates and burner heads (if applicable). Scrape off any large food debris and wash them in a 3-compartment sink or as per your standard procedures. Allow them to dry completely before replacing.

- Empty, wash, and sanitize the full-width crumb trays or waste trays. This prevents pest attraction and fire hazards.

- For induction ranges, wipe the glass-ceramic surface with a non-abrasive cleaner after it has cooled completely. | | Weekly | Once a Week | - Perform a more thorough cleaning of all surfaces, including under the grates and around the burner assemblies. Use a degreaser if necessary.

- For gas models, use a stiff wire brush or a paperclip to carefully clear any debris from the burner ports to ensure an even, blue flame.

- Inspect gas pilot lights (if applicable) to ensure they are lit and the flame is a steady blue color.

- Remove and clean control knobs and the surrounding panel to remove grease buildup. | | Monthly/Quarterly | As Needed | - Deep clean all removable parts by soaking them in a commercial-grade degreaser solution.

- Conduct a thorough visual inspection of gas lines, fittings, and electrical cords for any signs of wear, cracking, or damage. Report any issues to a service professional immediately.

- Check that the adjustable legs are still tight and the unit remains stable and level.

- Schedule professional servicing annually to have a technician inspect internal components, calibrate controls, check gas pressures, and ensure optimal, safe performance. |

Always document your cleaning schedule and keep logs. This practice is invaluable for satisfying health inspectors and for internal quality control.

Troubleshooting Common Issues

- Uneven Heating (Gas): This is often caused by clogged burner ports. Turn off the gas, let the unit cool, and clean the ports with a stiff brush or paperclip. If the flame is yellow or orange instead of blue, it may indicate an improper air-to-gas mixture, which requires a professional technician to adjust.

- Pilot Light Won't Stay Lit (Gas): The thermocouple may be dirty or faulty. Gently clean the tip of the thermocouple with a soft cloth. If it still won't stay lit, the thermocouple likely needs to be replaced by a professional.

- Unit Won't Turn On (Electric/Induction): First, check that the unit is properly plugged in and that the circuit breaker has not been tripped. For high-voltage units, ensure the disconnect switch is in the 'on' position. If these steps don't work, there may be an internal electrical issue requiring a service call.

- Induction Burner Flashing/Beeping: This usually indicates one of two things: either there is no pan on the burner, or the pan is not induction-compatible. Ensure you are using a ferromagnetic pan (a magnet will stick to the bottom).

Essential Safety Standards and Certifications

In the commercial foodservice industry, safety certifications are non-negotiable. They are your proof of compliance and your protection against liability.

- NSF and ETL Sanitation Marks: An NSF or ETL Sanitation certification mark signifies that the appliance meets rigorous standards for public health and safety. It verifies that the unit is designed and constructed with materials and methods that make it easy to clean and minimize the risk of food contamination.

- Electrical and Gas Safety: Look for ETL, UL, or CSA marks, which indicate that the product has been independently tested and evaluated to meet applicable safety standards for electrical or gas-fired appliances.

- Importance for Health Inspections: In the United States, health departments almost universally require certified appliances for commercial use. Using non-certified (e.g., residential) units can result in immediate failure of a health inspection, fines, or even operational shutdowns. These certifications protect your customers, your staff, and your business.

If you're unsure whether a specific model meets your local code requirements, reach out to The Restaurant Warehouse for guidance before purchasing. Sharing your jurisdiction and concept will help us point you to compliant options and provide the documentation your inspector may request.

Conclusion

Choosing a commercial countertop range is a critical strategic decision for any modern foodservice business. By thoroughly understanding the distinct advantages of gas, electric, and induction models, and by carefully considering crucial factors like size, power (BTU/watts), construction quality, and workflow integration, you can select a unit that not only meets your current needs but also boosts your kitchen's long-term performance and profitability.

Remember that the purchase is only the beginning. Proper professional installation, diligent routine maintenance, and unwavering adherence to safety standards like NSF and ETL are essential for ensuring longevity, compliance, and peak operational efficiency. Documented cleaning routines, professionally verified utility connections, and adequate ventilation plans all contribute to smoother health inspections and fewer unexpected disruptions during peak service.

The right commercial countertop range is a powerful investment in your operation's efficiency and success. It empowers you to maximize valuable kitchen space, expand and improve your menu, and deliver consistent, high-quality food—whether you're operating a food truck in Seattle, a bustling cafe in Washington, a large-scale campus dining hall, or a high-volume urban bistro.

At The Restaurant Warehouse, we are committed to supplying professional cooking appliances at lower prices. By operating with a lean model that avoids high retail overhead, we can offer affordable, wholesale-style pricing without ever sacrificing the quality and durability your professional kitchen demands. Equipping your kitchen with the right tools is a direct investment in your future success.

Take the time to assess your unique needs, use the detailed insights from this guide, and choose a commercial countertop range that will serve as a reliable workhorse for your business for years to come. When you’re ready to move from research to action, you can:

- Browse our complete commercial countertop range selection online

- Contact us to book a strategy call to review specific models, lead times, and financing options before you buy

A thoughtful, well-informed purchase today will directly translate into faster ticket times, smoother service, a more capable culinary team, and a more flexible and profitable menu tomorrow.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment