The Ultimate 4-Door Pizza Prep Table Buying Guide

Is your Friday night rush more chaos than controlled speed? When staff are bumping elbows, running to the walk-in for more cheese, and struggling for a clear spot to work, your equipment is the bottleneck. A smaller prep table that worked for your grand opening can quickly become the main obstacle to growth. This is where upgrading to a 4-door pizza prep table changes the game entirely. It’s not just about adding more refrigerated space; it’s about redesigning your entire workflow. This guide will show you how this single piece of equipment can eliminate kitchen traffic jams and streamline your process from dough to door.

Why Your Pizzeria Needs a 4-Door Pizza Prep Table

A 4 door pizza prep table is essential for any serious pizzeria looking to maximize efficiency. These commercial-grade units combine massive refrigerated storage with an expansive workspace, allowing multiple chefs to work simultaneously while keeping ingredients perfectly chilled and organized.

Top 4-Door Pizza Prep Table Features:

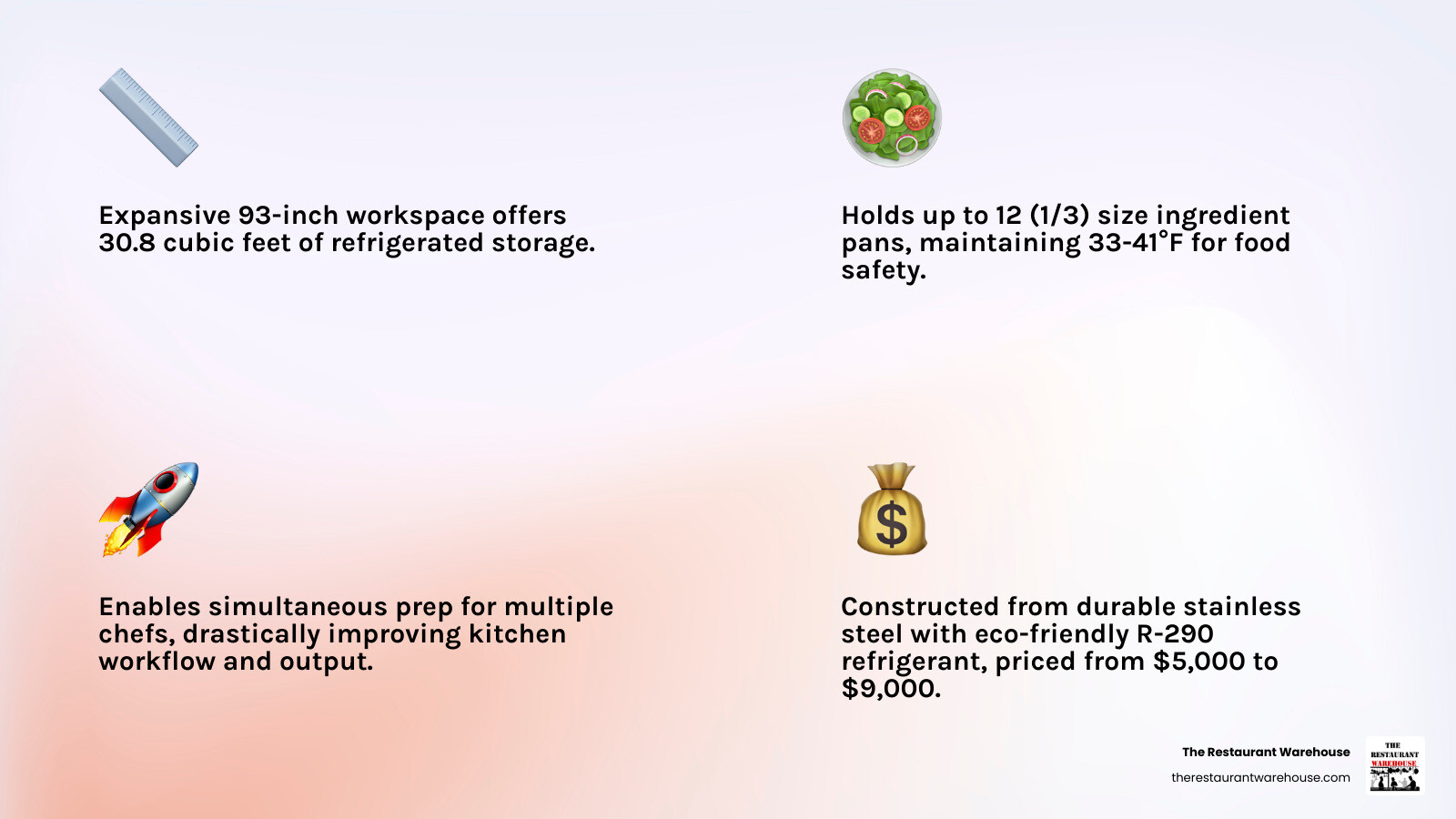

- Capacity: 30.8 cubic feet of refrigerated storage

- Workspace: 93-inch width provides ample prep space

- Pan Capacity: Holds up to 12 (1/3) size ingredient pans

- Temperature Range: Maintains 33°F to 41°F for food safety

- Price Range: $5,000 to $9,000 depending on features

- Construction: Durable stainless steel interior and exterior

During peak hours, having enough cold storage and prep space is critical for service speed. Traditional 2-door models often can't handle the ingredient volume that busy restaurants demand.

Upgrading to a 4-door model fundamentally changes your kitchen workflow. It allows multiple staff members to prep simultaneously without crowding, keeps ingredients organized and accessible, and reduces time-wasting trips to walk-in coolers.

Features like eco-friendly R-290 refrigerant, heavy-duty casters for mobility, and digital temperature controls ensure food safety and compliance. The investment pays off quickly through faster order fulfillment and reduced labor costs.

How a 4-Door Table Transforms a Busy Kitchen

For a busy pizzeria, a 4 door pizza prep table is a secret weapon. It doesn't just add storage; it reshapes how your team operates when orders start flying in. Imagine a busy Friday night. Instead of staff dancing around a small table, a 4-door unit provides ample space for everyone to work efficiently.

The maximum storage capacity is impressive, with around 30.8 cubic feet of refrigerated space. This is enough to stock for your busiest nights without constant trips back to the walk-in cooler.

What really makes the difference is the expansive workspace. At around 93 inches wide, these tables allow you to set up a pizza assembly line. Your dough stretcher can work on one end, another person can add sauce and cheese in the middle, and a third can put on the finishing touches.

This workflow optimization creates a system where everyone has a defined role, which also helps reduce cross-contamination. When ingredients stay at the perfect temperature and your team works in a smooth rhythm, every pizza comes out with perfect consistency. That's the kind of high-volume capacity that builds customer loyalty.

A 4 door pizza prep table naturally creates multiple prep stations, making your process smarter and faster. During peak hours, you'll wonder how you ever managed without one.

Streamline Your Workflow and Increase Output

When you upgrade to a 4 door pizza prep table, your entire kitchen rhythm changes for the better. Simultaneous prep becomes your new reality. Multiple team members can work side by side, one stretching dough, another adding sauce, and a third handling specialty toppings.

You'll notice reduced staff movement immediately. With everything stored in the refrigerated base and top rail pans, your team stays put and productive, eliminating sprints to the walk-in.

The ergonomic design is crucial during long, busy shifts. When your staff can reach everything without stretching or bending, they stay comfortable and focused, which means they work faster and make fewer mistakes.

This setup creates an assembly line workflow. With excellent ingredient accessibility, no one is ever hunting for the pepperoni or waiting for someone else to move. The result is faster order fulfillment that keeps your customers happy and your kitchen running smoothly.

Why Go Bigger? 4-Door vs. 2- and 3-Door Tables

Smaller prep tables are fine for small operations, but they become a bottleneck that holds back growing pizzerias. A 4 door pizza prep table is in a different class of equipment.

The expanded refrigerated storage is a key difference. A 4-door unit offers around 30.8 cubic feet, compared to a 2-door's 22 cubic feet. That extra space means you can store more backup ingredients for busy nights.

Greater pan capacity is another major upgrade. A 4 door pizza prep table accommodates 12 (1/3) size pans, compared to a 2-door's typical nine. This means more standard and specialty toppings are always within arm's reach.

The larger cutting board, at 93 inches wide, is transformative. It provides room to prep multiple orders at once, a significant upgrade from the 46 to 72 inches of smaller tables.

Supporting multiple chefs becomes natural rather than a juggling act. Two or three people can work comfortably, turning pizza making into a true team effort.

Think of it as future-proofing your kitchen. As your business grows, you'll have the capacity to handle increased demand. That's the kind of investment value that pays dividends for years.

Key Features to Look for in a 4-Door Pizza Prep Table

When you invest in a 4 door pizza prep table, understanding the specifications is your roadmap to a smart purchase. These are precision-engineered workhorses designed to transform your kitchen's productivity.

Every detail matters. The stainless steel construction isn't just for looks; it's for durability. The cutting board material must withstand constant use, and the pan capacity determines your topping variety. The refrigerated base design—whether you choose doors or drawers—will shape how your staff accesses ingredients. Heavy-duty casters provide mobility for cleaning, and digital temperature controls are your insurance policy for food safety. Each component works together, so understanding them helps you choose a unit that will serve your kitchen for years.

Finding the Right Size and Capacity for Your Space

Let's talk numbers. A 4 door pizza prep table is typically 93 inches wide—that's nearly eight feet of continuous workspace. This allows multiple team members to prep pizzas simultaneously without playing bumper cars.

The work surface height usually sits around 35 1/4 inches, an ergonomic design that prevents staff from hunching over during long dinner rushes. Happy backs mean happier, more productive employees.

Next is the 30.8 cubic feet of refrigerated storage space. That's enough room to store backup cheese, extra sauce, and plenty of dough without playing refrigerator Tetris. You'll spend less time restocking and more time serving customers.

The top rail accommodates 12 (1/3) size pans, which are designed specifically for pizza operations. You can keep generous portions of all your toppings chilled and accessible. Each shelf inside the refrigerated base typically supports up to 90 pounds, so you can store heavy sauce buckets and cheese blocks without worry.

More Than Just Large: A Look at Size Variety

The most striking feature of a 4-door pizza prep table is its sheer size. At 93 inches wide, you get nearly eight feet of uninterrupted workspace. This isn't just about having more room; it's about creating a more efficient system. This expansive surface allows multiple team members to prep pizzas at the same time without playing bumper cars in the middle of a dinner rush. One person can be stretching dough at one end while another is saucing and cheesing in the middle. This kind of parallel workflow is impossible on smaller tables and is a key factor in getting orders out the door faster. It transforms a chaotic process into a streamlined assembly line, making it one of the most valuable pieces of restaurant equipment you can own.

Matching Storage Capacity to Your Needs

Underneath that massive workspace lies the second major advantage: storage. A 4-door model offers an impressive 30.8 cubic feet of refrigerated space. Think about what that means on your busiest night. You can stock enough backup dough, cheese, and sauce to get through the peak hours without sending someone on constant trips to the walk-in cooler. This not only saves precious time but also reduces the risk of temperature fluctuations that can affect food quality. Having everything you need stored directly below your prep area keeps your ingredients perfectly chilled and within reach, ensuring your team can maintain its rhythm without interruption. It’s a simple change that has a huge impact on your kitchen’s overall efficiency and output.

Flexible Pan Configurations for Toppings

The top rail of a 4-door pizza prep table is designed for maximum variety and accessibility. It typically accommodates 12 (1/3) size pans, which is a significant step up from the nine pans you might find on a 2-door model. This extra capacity means you can offer a wider range of standard and specialty toppings without cluttering your workspace. From pepperoni and mushrooms to artichoke hearts and feta cheese, every ingredient has its designated spot, chilled and ready to go. This organization keeps everything within arm's reach, allowing your pizza makers to build custom orders quickly and accurately. It’s this level of ingredient accessibility that helps you serve customers faster and maintain consistent quality with every pie.

What Materials Make a Prep Table Last?

In the restaurant world, equipment either survives or becomes expensive scrap metal. The construction of your 4 door pizza prep table determines which category it falls into.

304 stainless steel and 430 stainless steel are your best friends. The 304 grade is often used for interiors where food contact happens, as it's the champion of corrosion resistance. The 430 stainless steel typically handles exterior duties, providing a clean, easy-to-wipe finish.

NSF certification is non-negotiable. This isn't just a sticker; it's your guarantee that the equipment meets strict public health standards, which health inspectors love to see.

Heavy-duty casters are game-changers. Look for 5-inch diameter wheels with locking mechanisms that let you easily move the table for deep cleaning, then lock it firmly in place.

Polyurethane insulation, usually around 2 3/8 inches thick, works with magnetic door gaskets to create an airtight seal. This system maintains consistent temperatures while keeping energy costs reasonable.

Removable cutting boards are essential for sanitation. When you can easily remove and sanitize cutting surfaces, you're protecting your reputation and your customers. Quality units use materials that resist scoring and staining.

Interior and Exterior Material Combinations

When you're looking at a prep table, the type of stainless steel used is a big deal. Think of it like this: 304-grade stainless steel is the hero of the interior. It's what comes into contact with your food, and its high resistance to corrosion means it can handle acidic sauces and constant moisture without breaking a sweat. For the exterior, you'll often find 430-grade stainless steel, which provides a durable, polished finish that's simple to wipe down after a chaotic shift. Also, keep an eye out for that NSF certification. It’s not just a sticker; it’s proof that the unit meets strict public health standards, which is exactly what you want when the health inspector stops by. This combination of materials ensures your restaurant equipment is built to last from the inside out.

Caster Sizes and Kitchen Mobility

Mobility might not be the first thing you think of, but it’s a feature that makes a huge difference in daily operations. Heavy-duty casters, especially 5-inch wheels with locking brakes, are essential. They allow your team to easily roll the entire unit out of the way for thorough floor cleaning—a task that’s nearly impossible with a stationary table. Once cleaning is done, the locking mechanism keeps the table securely in place, so it won’t shift during a busy service. This simple feature not only simplifies sanitation but also improves kitchen flexibility. Investing in equipment that makes your kitchen easier to manage is always a smart move, and options like equipment financing can make these upgrades more accessible.

Keeping Your Prep Table Running Smoothly

The heart of any refrigerated prep table is its refrigeration system. For a 4 door pizza prep table, this system is critical for maintaining food safety and ingredient freshness, even with frequent opening of doors during peak hours.

Modern refrigeration systems also focus on eco-friendliness and energy efficiency. But even the best system requires proper care. Routine cleaning and maintenance are investments in the longevity and reliable performance of your equipment. Neglecting these can lead to costly breakdowns and compromised food safety. Understanding what’s “under the hood” will help you keep your prep table running smoothly for years.

How Refrigeration Systems Keep Ingredients Fresh

The magic behind keeping ingredients fresh in a 4 door pizza prep table is its advanced refrigeration. Many modern units use R-290 hydrocarbon refrigerant, a highly efficient and eco-friendly choice with a very low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP).

The system maintains a consistent temperature range, typically between 33°F and 41°F (1°C to 5°C). This precise control is crucial for food safety. It's achieved through forced-air systems that circulate cold air evenly throughout the cabinet and the top ingredient rail.

Many high-quality models feature integrated condensate evaporators, which eliminate the need for a drain line and simplify installation. Digital controllers with LED temperature displays are standard, allowing for precise adjustments and easy monitoring. Some units even have automatic defrost cycles to prevent ice buildup.

When looking at models, we recommend diving into their technical specifications.

Dual Temperature Controls for Precision Cooling

One of the most valuable features you'll find on premium 4-door pizza prep tables is dual temperature control. This isn't just a fancy add-on; it's a practical tool for maintaining food quality. This feature allows you to set separate temperatures for the top ingredient rail and the main refrigerated cabinet. Think about it: your toppings in the rail are constantly exposed to the kitchen's ambient heat, while the dough and cheese in the base stay protected. With dual controls, you can keep the rail extra chilly to ensure food safety without freezing the sensitive ingredients stored below. This level of precision gives you complete command over your inventory, reducing waste and ensuring every pizza starts with perfectly chilled components.

Specialized Cooling Systems for the Ingredient Rail

The ingredient rail is the hardest-working part of your prep table, and it needs a dedicated cooling system to match. Many high-end models use a specialized "cold-wall" system that surrounds the ingredient pans with consistent, even cold. This is a significant step up from systems that just blow air up from the bottom. A cold-wall design creates a protective barrier of cold air, ensuring that every topping—from the pepperoni on top to the mushrooms at the bottom of the pan—stays at a safe and consistent temperature. This is crucial for food safety, especially during a relentless dinner rush when the insulated lid is open for long stretches. It’s a feature that directly protects both your ingredients and your reputation.

Energy-Saving Features to Reduce Costs

A large piece of restaurant equipment doesn't have to come with a massive utility bill. Manufacturers understand that energy efficiency is key to a healthy bottom line. Many 4-door pizza prep tables include smart features designed to save you money. For instance, some models allow you to turn off the ingredient rail's refrigeration system independently overnight, which can cut energy consumption significantly. Additionally, the widespread use of eco-friendly R290 refrigerant not only reduces your environmental impact but is also more energy-efficient than older refrigerants. These thoughtful design elements mean your investment works to lower your operating costs from day one, proving that high capacity and efficiency can go hand in hand.

A Simple Maintenance Checklist

Maintaining your 4 door pizza prep table isn't complicated, but it is essential for reliability, efficiency, and longevity. Regular equipment maintenance is crucial for keeping your kitchen operational.

Here’s an essential maintenance checklist:

- Daily: At the end of each shift, remove all food pans and the cutting board. Wipe down all surfaces with a mild, food-safe cleaner, paying special attention to the top rail.

-

Weekly:

- Inspect door and lid gaskets for any tears or cracks. Damaged gaskets leak cold air and increase energy consumption. Replace them promptly.

- Thoroughly clean the pan rail area to prevent food buildup.

- Deep clean or sanitize your cutting board. If it's reversible, flip it to extend its life.

-

Monthly/Quarterly:

- Clean the condenser coils. This is the most critical task. Dust and grease buildup reduces cooling efficiency and can lead to compressor failure. Use a stiff brush or vacuum to gently remove it.

- Check digital temperature logs to ensure consistency.

- Ensure the condensate drain pan and line (if applicable) are clean and free of clogs.

- Annually: Schedule professional servicing. A certified technician can check refrigerant levels, inspect electrical components, and catch potential issues before they become major problems.

Knowing common replacement parts like gaskets, divider bars, fan motors, and casters can also save you time. Following these steps will maximize the lifespan of your 4 door pizza prep table.

Features That Simplify Cleaning

Let's be real: cleaning is a constant in any kitchen, and smart design can make it much less of a headache. When you're looking at a 4 door pizza prep table, features that simplify cleaning are non-negotiable. Removable cutting boards are a perfect example. Being able to take them off for a thorough scrub-down is critical for sanitation and protecting your customers. Some of the best models also have a sealed pan rail with a dedicated port for easy cleaning, which prevents sauce and cheese from getting into hard-to-reach crevices. Another great feature is an accessible compressor area that opens up, allowing your team to keep the unit's mechanical heart free of dust and grime. These thoughtful details in well-designed equipment don't just save time; they make it easier to maintain high hygiene standards, which is always a win.

Long-Term Durability: Coils and Defrost Systems

The long-term health of your prep table depends on its coils and defrost system. Think of the condenser coils as the lungs of the refrigerator; if they get clogged with dust and grease, the whole system has to work harder, leading to higher energy bills and potential breakdowns. Regular cleaning is a must. Many modern units also feature an automatic defrost system, which is a lifesaver. It prevents ice from building up on the evaporator coils, ensuring the unit runs efficiently without you having to manually defrost it. Another feature that adds to durability and convenience is an integrated condensate evaporator. This system evaporates excess water, so you don't need a floor drain, simplifying installation. Taking care of these components is the best way to protect your equipment and ensure it remains a smart investment for years to come.

Choosing the Best 4-Door Pizza Prep Table

When you're ready to invest in a premium 4 door pizza prep table, you're getting a sophisticated workstation engineered for the most demanding pizza operations.

The beauty of top-tier models lies in their flexible configurations. Many combine traditional swing doors with pull-out drawers, giving you the best of both worlds. Side-mount compressors are another hallmark of quality, often providing easier maintenance access. Look for heavy-duty drawers with full-extension slides that glide smoothly even when fully loaded. Insulated lids for the ingredient rail are a simple feature that reduces energy costs and keeps ingredients fresher. For the ultimate in function, some premium models feature granite work surfaces, which stay naturally cool and are incredibly durable.

Popular Brands and Warranty Considerations

When you're investing in a cornerstone piece of equipment like a 4-door pizza prep table, the brand name matters. Look for manufacturers with a proven track record for durability and performance, such as Beverage-Air or Hoshizaki. These brands are known for using high-quality materials like stainless steel for both the interior and exterior, which ensures your table can handle the demands of a busy kitchen and is easy to clean. A reliable brand often means fewer headaches and a longer lifespan for your equipment.

Just as important as the brand is the warranty that comes with it. Think of the warranty as your insurance policy. Most manufacturers offer coverage for parts and labor, but the duration can vary. Pay close attention to the compressor warranty, which is often covered for a longer period—sometimes up to five years—because it's such a critical component. Before you buy, always read the fine print to understand exactly what's covered. A strong warranty reflects a company's confidence in its product and is a key part of any smart restaurant equipment financing decision.

Premium Features: Are They Worth It?

Premium 4 door pizza prep tables go beyond just size. Massive 119-inch models represent the pinnacle of design, changing your prep line into a true production center. The refrigeration technology is also superior, with improved pan cooling systems that use specialized airflow to ensure every pan maintains perfect temperature consistency.

Deep cutting boards, often 30 inches or more, provide extra real estate for assembling multiple or large specialty pizzas. Self-closing doors with magnetic gaskets create an airtight seal every time, preventing energy loss from doors left ajar. The heavy-duty construction in premium models includes reinforced frames and industrial-grade components built to last for decades. Finally, advanced temperature controls offer precision digital displays, programmable settings, and even alarm systems to alert you to fluctuations, providing extra peace of mind about food safety.

Advanced Door Features for Convenience

The best prep tables have features that solve real-world kitchen problems. Look for self-closing doors that swing shut on their own, which is a lifesaver when your hands are full. Many premium models also include a stay-open feature, where the doors will hold their position at a 120-degree angle, making it easy to load and unload bulk ingredients without the door getting in your way. Another huge plus is the door design itself. Some units allow you to reverse the door swing to better fit your kitchen's layout. For cleaning, snap-in magnetic gaskets are a must-have. They create a perfect seal but can be removed in seconds for thorough sanitation, preventing mold and grime buildup.

Customization Options: From Locks to Lids

A great 4 door pizza prep table can be tailored to your exact needs. You can often choose from various upgrades to create the perfect workstation. For instance, you might opt for a full stainless steel interior for maximum durability or select clear lids for the ingredient rail to quickly check stock levels. Many manufacturers offer different door and drawer combinations, allowing you to store dough boxes in drawers and bulk items behind doors. You can also add extra shelves for better organization, door locks to secure valuable ingredients overnight, or an external thermometer for at-a-glance temperature checks. Even the cutting board can be customized, with options for different materials to suit your preferences.

Specialized Installation for Unique Kitchens

Not every kitchen is a standard, level space, and top-tier equipment manufacturers understand that. That’s why you’ll find specialized installation options to adapt your prep table to unique environments. If your floor is uneven, you can often choose different leg or caster sizes to get the work surface perfectly level. For restaurants in earthquake-prone regions, seismic or flanged legs are available to securely anchor the unit to the floor, ensuring safety and stability. These thoughtful options demonstrate a commitment to quality and practicality, ensuring your investment works perfectly in your specific space. When planning a major kitchen upgrade, exploring financing options can help you get all the custom features you need.

Doors vs. Drawers: Which Is Right for You?

The integration of drawers alongside doors in a 4 door pizza prep table creates a more intelligent, organized workspace. Ingredient organization becomes effortless, with dedicated drawers for different cheeses or toppings. This eliminates digging through stacked containers during a rush.

The quick access that drawers provide is invaluable. A single pull reveals exactly what you need, making the prep process faster. This also helps with portion control, as you can store pre-portioned containers to improve consistency and manage food costs.

A significant advantage is reduced cold air loss. Opening a small drawer exposes less of the interior to warm air than opening a full door, saving energy. From an ergonomic perspective, drawers are easier on staff, reducing the strain of bending and reaching. Models with 4 drawers and 1 door have become popular because they offer a perfect balance of organized access and bulk storage.

Understanding the Cost and Long-Term Value

Investing in a 4 door pizza prep table is a significant decision, with a price range of $5,000 to $9,000. However, this isn't just an expense; it's one of the smartest investments for your pizza operation.

The long-term ROI becomes clear when you consider the labor savings. A more efficient team can increase output during peak hours, serving more customers and generating more revenue. Reduced food waste is another major cost saver, as superior, organized refrigeration keeps ingredients fresher for longer.

When making a comparison to smaller units, the value proposition is even clearer. A 2-door model costs less upfront but can become a bottleneck as your business grows. The incremental cost of a 4-door unit often prevents these expensive problems.

Warranty considerations protect your investment. Quality units come with solid coverage, typically one to two years on parts and labor, with extended compressor warranties of three to five years. When you factor in faster service, happier customers, and reduced waste, the initial investment is a smart move for long-term success.

A Realistic Look at the Price Range

When you start shopping for a 4-door pizza prep table, you'll see prices that range from around $1,400 to well over $18,000. That's a huge gap, so what gives? The cost really comes down to the brand, materials, and extra features. Entry-level models can get the job done, but many pizzerias find the sweet spot in the $5,000 to $9,000 range for a durable, high-performance unit that will last. The higher end of the spectrum is typically reserved for premium brands with specialized features like granite tops or advanced cooling systems. It's important to remember that this is a major piece of equipment, and managing the cost is key. Exploring restaurant equipment financing can make a top-quality table much more accessible for your budget.

Frequently Asked Questions about 4-Door Pizza Prep Tables

When you're considering investing in a 4 door pizza prep table, it's natural to have questions. After all, this is a significant purchase that will impact your kitchen's daily operations. Let's address the most common concerns we hear from pizzeria owners.

What's the Main Advantage for a Busy Pizzeria?

The game-changing advantage of a 4 door pizza prep table is the massive increase in both refrigerated storage and immediate workspace. A 93-inch workspace allows multiple chefs to work simultaneously in a parallel workflow, which is simply impossible with smaller prep tables.

The large refrigerated storage capacity means you're not constantly sending staff to the walk-in cooler for backup ingredients. Everything you need is right there, chilled and organized, which eliminates frustrating bottlenecks during peak business hours. This expanded capacity can turn kitchen chaos into smooth service and significantly increase your pizzeria's output.

How Much Topping Storage Can You Expect?

Most standard 4 door pizza prep table units are designed to hold twelve 1/3-size food pans in the top refrigerated rail. This provides enough space for all your essential toppings, from different cheeses and meats to a full range of vegetables.

The 1/3-size pans are larger than the pans you'd find on sandwich prep tables, so you can store more of each high-volume ingredient like mozzarella or pepperoni. While some premium models offer more capacity, twelve pans has proven to be the sweet spot for most pizzerias, providing enough variety without making organization difficult.

Choosing Between Drawers and Doors for Refrigeration

This depends on your kitchen's specific workflow, but there are clear advantages to each option.

Traditional doors are fantastic for bulk storage. If you're storing large dough trays, gallon containers of sauce, or bulk cheese blocks, doors give you the flexible space and access you need.

Drawers, on the other hand, are organizational powerhouses. They're perfect for pre-portioned ingredients and items you need to access frequently. When you pull out a drawer, everything is right there at eye level, and you lose less cold air compared to opening a full door. The ergonomic benefits also reduce staff fatigue.

Many high-end 4 door pizza prep table models offer hybrid configurations—perhaps four drawers combined with one door. This gives you the best of both worlds: organized, easy-access storage for your most-used ingredients, plus flexible bulk storage for larger items. The key is to think about your specific workflow and ingredient storage needs.

Equipping Your Pizzeria for Success

In a busy pizzeria, every piece of equipment needs to earn its keep. A 4 door pizza prep table doesn't just earn its keep—it transforms how your entire operation runs, especially during those intense dinner rushes.

We've covered the generous 93-inch workspace that lets multiple team members work side by side, the impressive 30.8 cubic feet of refrigerated storage, and the 12 (1/3) ingredient pans that keep toppings at your fingertips. These features are the foundation of a kitchen that can handle high volume.

The advanced refrigeration systems using eco-friendly R-290 refrigerant maintain critical temperatures between 33°F and 41°F, ensuring food safety. Meanwhile, the durable stainless steel construction, heavy-duty casters, and precise digital controls mean this investment will serve you reliably for years.

The bottom-line impact is clear. When your team can work more efficiently, you see a real return on investment through labor savings, reduced food waste, and the confidence to handle your busiest nights without breaking a sweat.

The price range of $5,000 to $9,000 might seem significant, but when you consider how a 4 door pizza prep table streamlines your workflow and boosts your capacity, it's an investment that pays for itself through improved efficiency. You're not just buying refrigeration; you're buying the ability to serve more customers faster and more consistently.

At The Restaurant Warehouse, we've seen how the right equipment can make or break a kitchen's success. We are passionate about helping foodservice operations thrive by providing high-quality, affordable solutions. Our commitment to avoiding high commissions and retail overhead means you get wholesale pricing on equipment that's built to last.

Your pizzeria deserves equipment that works as hard as you do. Find the perfect pizza prep table for your kitchen and take the next step toward changing your operation into the efficient, profitable business you've always envisioned. Because when you're equipped for success, success has a way of finding you.

Key Takeaways

- Create an Efficient Assembly Line: The expansive 93-inch workspace on a 4-door prep table allows multiple chefs to work together without crowding, transforming your kitchen's workflow and increasing your order capacity.

- Eliminate Mid-Rush Restocking: With over 30 cubic feet of refrigerated storage and 12 topping pans, all your ingredients stay chilled and accessible, ending time-wasting trips to the walk-in cooler.

- Choose Equipment That Grows With You: A 4-door table is a strategic investment in your pizzeria's future. Its capacity to handle high volume saves on labor and reduces food waste, directly contributing to your long-term success.

Related Articles

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment