Food Truck Appliances 101: A Complete Guide

Your food truck is more than just a vehicle; it's a high-performance restaurant squeezed onto a chassis. While your passion for food is the fuel, the engine is a well-planned kitchen. Every decision matters, but none more so than selecting the right food truck appliances. This isn't just about cooking—it's about creating a seamless workflow that can handle the rush. The right equipment ensures you meet safety codes, maximize your limited space, and serve customers quickly. Get this part right, and you're building a foundation for a profitable, smooth-running business.

This isn't just about what you cook. It's about how efficiently and safely you can pull it off in a space that’s usually only 120 to 200 square feet.

Every single piece of equipment has to earn its spot. It needs to contribute to your menu while working within the tight constraints of space, power, and ventilation. The choices you make right now will directly shape your workflow, your speed of service, and ultimately, your profits.

The Rise of the Food Truck: A Growing Opportunity

If you're thinking about launching a food truck, you're tapping into one of the most dynamic sectors of the foodservice industry. It's more than just a trend; it's a fundamental shift in how people dine, offering a massive opportunity for entrepreneurs who are ready to hit the road. This mobile food movement is gaining serious momentum, and understanding the "why" behind its growth is the first step toward building your own successful business on wheels.

Understanding the Industry Growth

The numbers speak for themselves. The food truck industry is expanding at an impressive rate, growing much faster than traditional brick-and-mortar restaurants. This boom isn't just a fluke; it's fueled by what modern customers crave: unique food experiences, convenience, and the chance to support local entrepreneurs. People love the variety and accessibility that food trucks offer, from gourmet tacos to artisanal ice cream, all served up with a personal touch. This creates fertile ground for new business owners to enter the market with a creative concept and a lower barrier to entry compared to a full-scale restaurant.

This rapid growth means there's a real opportunity, but success hinges on setting up your mobile kitchen for peak performance. A food truck isn't just a smaller version of a restaurant kitchen; it's a unique environment that demands specialized, compact, and powerful food truck equipment. Every appliance, from the griddle to the under-counter refrigerator, has to work hard in a tight space. Outfitting your truck is a significant investment, but smart planning and options like equipment financing can make it manageable, allowing you to get the high-quality gear you need to compete from day one.

Beyond the cooking equipment, your success is built on a foundation of food safety and cleanliness. In such a compact workspace, efficiency is everything. You need surfaces that are easy to sanitize and refrigeration that holds temperature reliably, even on a hot day. Investing in dependable commercial refrigerators and freezers isn't just about keeping ingredients fresh; it's about protecting your customers and your reputation. When you prioritize high standards from the start, you build trust and create a smooth workflow that allows your culinary skills to shine.

Designing Your Food Truck Kitchen

A strategic mix of gear is absolutely essential for meeting health codes, keeping your workflow smooth, and making sure every customer leaves happy. To give you a clear picture, we can break down all the essential appliances for a food truck into four main groups: cooking, refrigeration, preparation, and sanitation. A killer kitchen setup combines compact, powerful equipment from each category to create a mobile restaurant that’s both functional and code-compliant.

Here's a quick look at how these categories function inside your truck.

Planning Your Kitchen Layout for Efficiency

Think of your kitchen workflow as a carefully choreographed dance—every step matters in a tight space. Your layout isn't just about fitting everything in; it's about creating a logical, efficient path for every order. Let your menu be your guide. The appliances you rely on most, like your griddle for burgers, should be front and center and easy to access. You can strategically mix and match smaller countertop units with larger equipment to optimize the space. Investing in high-quality, durable pieces for your signature items is always a smart move, as it means fewer service interruptions. Also, consider your power sources. Using propane for cooking equipment like deep fryers can help you manage energy consumption and keep your operation profitable on the go.

What Appliances Does a Food Truck Need?

| Appliance Category | Primary Function | Key Considerations |

|---|---|---|

| Cooking Equipment | Brings your menu to life. | Power source (gas/electric), BTU/kW output, ventilation needs, footprint. |

| Refrigeration Systems | Keeps ingredients fresh and safe. | Undercounter vs. full-size, energy efficiency, temperature consistency. |

| Preparation Stations | Streamlines assembly and workflow. | Work surface area, integrated cold storage, easy-to-clean materials. |

| Sanitation & Dishwashing | Ensures health code compliance. | Sink compartment requirements, hot water capacity, separate handwashing. |

Let's dig a little deeper into what each of these pillars of a mobile kitchen really involves.

Must-Have Food Truck Appliance Categories

- Cooking Equipment: This is where the magic happens. We're talking about the workhorses like commercial griddles, deep fryers, charbroilers, and convection ovens that have to deliver consistent results, rush after rush.

- Refrigeration Systems: Keeping ingredients fresh and food-safe is completely non-negotiable. Undercounter refrigerators and freezers are the industry standard here, maximizing that precious floor space.

- Preparation Stations: Fast service starts with efficient prep. This group includes stainless steel worktables, sandwich/salad prep tables, and all the smallwares that make your process seamless.

- Sanitation and Dishwashing: Health inspectors live here. A three-compartment sink, a totally separate handwashing station, and a reliable hot water heater are mandatory for passing inspection.

A common mistake new owners make is underestimating how all the appliances affect each other. For instance, a powerful gas griddle requires an equally powerful ventilation hood and fire suppression system, which in turn spikes your overall power demand.

Choosing the right appliances for your food truck from day one prevents expensive retrofits and operational nightmares down the road. Understanding how these pieces fit together is the first step toward a successful launch.

To see how these components come together visually, explore our detailed guide on creating an effective food truck layout. This foundational checklist helps you make smart investments that align your equipment with your culinary concept from the get-go.

Creating Your Food Truck Appliance Budget

The appliances you choose are the single biggest equipment investment you'll make, pretty much the heart and soul of your mobile kitchen. Getting your truck outfitted is a huge financial step, so wrapping your head around the costs and having a smart financing strategy is absolutely critical for a strong start.

Think of your appliance budget as the concrete foundation of your business plan. The choices you make here don’t just hit your startup costs; they directly shape your daily efficiency, what you can realistically put on your menu, and your long-term profits. Getting this right from day one saves you from a world of hurt—like costly replacements and service shutdowns—down the road.

What Are the Biggest Equipment Expenses?

When you’re trying to budget for appliances for a food truck, it helps to think in categories. This way, you're less likely to forget something essential, and you get a much clearer picture of where your money is actually going.

- Cooking Lineup: This is where your money-makers live—things like commercial griddles, deep fryers, and charbroilers. A quality 36-inch flat-top griddle can run anywhere from $2,000 to $6,000, while a dependable countertop deep fryer often lands between $1,500 and $4,000.

- Refrigeration Units: Food safety is totally non-negotiable. Undercounter refrigerators and freezers are the champs for saving space, typically costing $2,500 to $6,000. A combination sandwich prep table, which does double duty as a workstation, usually falls in the $1,500 to $3,000 range.

- Safety and Sanitation Systems: This covers your ventilation hood, fire suppression system, and sink setup. A proper hood and fire safety system can add $5,000 to $15,000 to your budget, but they are legally required to operate. No shortcuts here.

These numbers really show why planning is everything. The initial sticker shock for durable, professional-grade gear can be real, but you're not just buying equipment; you're investing in reliability and compliance.

The True Cost of Outfitting Your Truck

Let’s be real: commercial kitchen equipment is the largest single expense for new food truck owners. In fact, industry reports show that appliances and the truck build-out typically eat up 35% to 50% of your total startup cash, with most folks spending between $25,000 and $75,000. This big number is driven by the need to meet health codes and stand out in a crowded market. If you want to dig deeper, you can explore in-depth market reports about the food truck sector.

Remember, the initial price tag is only part of the story. Cheaper, residential-grade equipment might save money upfront but often fails under commercial demands, leading to higher repair costs, lost sales during downtime, and potential safety hazards.

Putting your money into quality, NSF-certified commercial appliances ensures they can handle the grind of a busy service and meet the strict rules set by health departments. It's strategic spending that paves the way for a business that lasts.

Cooking and Ventilation

This is where your menu comes alive. The cooking line is the heart of your food truck, featuring the workhorses that have to perform consistently during every rush. This includes equipment like commercial griddles, charbroilers, and deep fryers. But a powerful appliance is only half the story. A common mistake new owners make is forgetting how these pieces affect each other. For example, a high-output gas griddle demands an equally powerful ventilation hood and fire suppression system, which in turn increases your overall power needs. Planning these systems together is essential for a safe and functional kitchen.

Refrigeration and Prep

Keeping ingredients fresh and food-safe is absolutely non-negotiable. In the tight quarters of a food truck, undercounter refrigerators and freezers are the industry standard because they maximize precious floor space while keeping everything perfectly chilled. Fast service starts with an efficient prep area, so these cold storage units are often paired with stainless steel worktables or combination sandwich/salad prep tables. This setup creates a seamless workflow, allowing you to assemble orders quickly and keep the line moving without compromising on quality or safety.

Sinks and Sanitation

This is the area that health inspectors focus on the most, and for good reason. There is no room for cutting corners here. To pass inspection and operate legally, your truck must have a specific setup: a three-compartment sink for washing, rinsing, and sanitizing, a completely separate handwashing station, and a reliable hot water heater. This isn't just about ticking boxes on a checklist; it's about preventing cross-contamination and ensuring the health of your customers. Investing in the right sanitation equipment is a foundational part of building a trustworthy business.

Power and Safety Systems

While not as glamorous as the cooking line, your power and safety systems are the backbone of your entire operation. This includes your ventilation hood, fire suppression system, and the generator or shore power connection that runs it all. These systems are not optional—they are legally required to operate and can represent a significant part of your budget, often costing between $5,000 and $15,000. Because this is a major investment, exploring restaurant equipment financing can make it more manageable. Opting for quality, NSF-certified appliances ensures they meet health codes and can handle the daily grind of a busy service.

New vs. Used Equipment: Making the Right Choice

Deciding between new and used equipment is one of the most significant financial choices you'll make for your food truck. New appliances offer undeniable peace of mind. They come straight from the factory with a full warranty, the latest energy-efficient technology, and the assurance that you are the first person to put them to the test. This reliability is a massive advantage in a fast-paced mobile kitchen, where a single equipment failure during a lunch rush can cost you hundreds in sales. Investing in new, top-tier restaurant equipment is an investment in consistency and your business's reputation from day one.

On the other hand, used equipment offers a much lower upfront cost, which can be incredibly tempting when you're working with a tight startup budget. Buying used can free up capital for other essentials like marketing or initial inventory. However, this path comes with its own risks. Used appliances rarely include a warranty, meaning you're fully responsible for any repairs. You don't know the equipment's history, and a hidden issue could lead to unexpected downtime and costly service calls. While the initial savings are attractive, it's crucial to weigh that against the potential for future headaches and expenses.

A smart approach is often a hybrid one. Prioritize buying new for your most critical, high-usage items—like your primary deep fryer or main refrigerator—that would cripple your operation if they failed. For less essential pieces, like storage racks or a secondary prep table, a well-inspected used item might be a perfectly sensible way to save money. If your budget feels stretched, remember that restaurant equipment financing can make brand-new, reliable gear more accessible, allowing you to get the best of both worlds without draining your startup funds.

Smart Ways to Finance Your Equipment

Funding a full set of commercial appliances without completely wiping out your working capital is a classic challenge. The good news is, you've got options to get the gear you need without skimping on quality.

- Equipment Financing: This is a loan made specifically for buying business equipment. The appliance itself acts as the collateral, which often makes it easier to get than a traditional bank loan.

- Lease-to-Own Programs: Leasing lets you use brand-new equipment for a fixed monthly payment. When the term is up, you usually have the option to buy the appliance for a set price.

- Business Lines of Credit: A line of credit gives you flexibility. You can draw funds as you need them to buy different pieces of equipment from various vendors over time.

Companies like The Restaurant Warehouse specialize in these kinds of financial solutions, helping entrepreneurs manage those big upfront costs and keep cash flowing. By looking into these options, you can equip your food truck with durable, high-performance appliances that set you up for success right from the get-go.

Selecting the Right Cooking Equipment

Your cooking appliances are the beating heart of your food truck. This is where your menu stops being an idea and becomes a reality, especially when you're slammed during a lunch rush.

Picking the right gear isn’t just about buying shiny stainless steel. It’s a strategic choice that defines how fast you can work, how consistent your food is, and whether you can actually pull off your culinary vision. Think of each piece of equipment as a specialist on your team. You need to match the right tool to the right job, every time.

Let Your Menu Guide Your Appliance Choices

The smartest food truck owners build their equipment list directly from their menu. You wouldn't install a massive deep fryer if you're selling fresh-pressed juices, right? It sounds obvious, but it’s the most critical first step.

Let's break it down with some real-world examples:

- For Smash Burgers and Breakfast Tacos: The undisputed champion here is the flat-top griddle. Its huge, evenly-heated surface is a master of multitasking—searing patties, toasting buns, and scrambling eggs all at once. A solid 36-inch griddle is one of the most versatile appliances for a food truck you can get.

- For Authentic BBQ and Grilled Skewers: If your whole brand is built on that smoky, flame-kissed flavor, a charbroiler is an absolute must. It delivers those beautiful grill marks and a deep, savory taste that a griddle just can't touch.

- For Crispy Fries and Golden Onion Rings: A reliable commercial deep fryer is your best friend. Countertop models are perfect for squeezing into tight spaces, and a double-basket fryer can be a total lifesaver for keeping up with high-volume orders.

- For Gourmet Sandwiches and Pizza: A compact convection oven or a speedy conveyor oven makes quick work of everything from melting cheese perfectly to baking flatbreads evenly.

Your menu is your blueprint. Every single item should point directly to a specific piece of cooking equipment. If there's a mismatch, you're setting yourself up for slow service and unhappy customers.

When you're figuring out the best equipment, you can pull some great ideas from a broader guide on how to choose the right appliances for your kitchen renovation, since the core ideas of matching function to your needs are the same.

Gas or Electric: Which Is Right for Your Truck?

Once you know what gear you need, you have to decide how you're going to power it. This is a huge decision that depends on your truck’s power setup, your cooking style, and even the rules at different venues.

Propane (Gas) Appliances

Gas is the old-school powerhouse of food truck kitchens. Many chefs swear by it for its raw, responsive heat.

- Pros: You get instant, intense heat that’s perfect for searing and cooking fast. Gas equipment often packs more of a punch (higher BTUs) and gives chefs that hands-on, immediate temperature control they love.

- Cons: This requires a professionally installed propane system, which means dealing with tank refills and a serious ventilation and fire suppression system. Plus, some cities or event organizers have strict rules about using propane.

Electric Appliances

Electric gear, especially induction, is becoming more popular because it’s so efficient and safe.

- Pros: Electric appliances don't throw off as much ambient heat, which helps keep your truck from turning into a sauna. They're often easier to clean and much safer without an open flame. Induction cooking, in particular, is incredibly fast and efficient.

- Cons: High-wattage electric appliances are absolute power hogs that will put a massive strain on your generator. If your generator isn’t up to the task, you’ll be tripping breakers all day, shutting down your entire line. You must calculate your total electrical load before you commit.

Most seasoned operators land on a hybrid approach, pairing the brute force of a gas griddle with an efficient electric fryer or food warmer. This balanced strategy helps you manage your power load while still giving you the best of both worlds. Make this choice carefully—it will define your reality on the truck every single day.

Keeping Food Hot: Warming and Holding Equipment

Cooking the food is only half the job. The real challenge during a chaotic lunch rush is keeping everything at that perfect, just-served temperature without sacrificing quality. This is where warming and holding equipment becomes your secret weapon. These appliances are designed to maintain food at safe, consistent temperatures, ensuring that the last customer in a long line gets a meal that’s just as hot and delicious as the first. Getting this part of your setup right is key to managing workflow, passing health inspections, and keeping your customers happy.

Fry Dump Stations

If your menu features anything crispy and golden, a fry dump station is a non-negotiable part of your line. This piece of equipment, often a simple station with an overhead heat lamp, provides a dedicated space to hold freshly fried foods. It keeps items like french fries, onion rings, and chicken tenders perfectly hot and crispy, preventing them from turning into a soggy mess while you assemble the rest of an order. For any truck running a commercial deep fryer, this station is essential for batch cooking during peak hours, which drastically cuts down your ticket times and keeps the line moving.

Soup Kettles and Warmers

For trucks serving chilis, soups, stews, or even nacho cheese, a soup kettle or warmer is an absolute must. These countertop units are designed to hold large batches of liquid-based foods at a consistent and safe temperature for extended periods. This is critical for food safety, as it keeps your product out of the temperature "danger zone" where bacteria can grow. Using warming and holding equipment correctly is a simple way to prevent people from getting sick and avoid any issues during a health inspection, all while ensuring your signature soup is ready to serve the moment a customer orders it.

Heated Display Cases

A heated display case serves two brilliant functions at once: it keeps food warm and actively merchandises it for you. If you offer grab-and-go items like hot pretzels, empanadas, or pizza slices, placing them in an attractive, well-lit display case can seriously drive impulse buys. Customers waiting to order can see the delicious options available, often adding an extra item to their meal. It’s a smart way to present your food professionally while ensuring every bite is perfectly warm and ready to eat, turning your waiting line into a sales opportunity.

Insulated Food Carriers

Insulated food carriers are the unsung heroes of any food truck that preps food off-site or offers catering services. These heavy-duty containers are designed to keep hot food hot and cold food cold for hours without any electricity. This is essential for safely transporting pans of ingredients from your commissary kitchen to the truck or for delivering a large catering order across town. Investing in high-quality, durable carriers is a critical step in maintaining food safety and quality from the moment it leaves your kitchen to the moment it's served, protecting both your customers and your reputation.

Making the Most of Your Space: Refrigeration & Prep

In a food truck, every single square inch is prime real estate. Once you've locked in your core cooking equipment, your next big challenge is designing a refrigeration and prep area that's both ridiculously efficient and incredibly compact. This is about more than just keeping food cold; it's about engineering a seamless workflow where every ingredient is fresh, safe, and exactly where it needs to be when the rush hits.

Just think of your refrigeration and prep stations as mission control for your service. A clunky, disorganized setup will create bottlenecks, slow down your ticket times, and can even flirt with food safety issues. The real key is to choose smart, multi-functional appliances for food truck kitchens that accomplish more in less space.

Why Undercounter Refrigeration Is a Game-Changer

For any food truck operator, vertical space is a luxury, but your horizontal floor space is pure gold. This is exactly why undercounter refrigerators and freezers are the undisputed champions of the mobile kitchen world. By tucking your cold storage right underneath your countertops, you reclaim valuable floor area that would otherwise be eaten up by a bulky, full-size unit.

These compact powerhouses are built specifically for the chaos of a commercial kitchen. They give you precise temperature control, tough stainless steel construction, and the efficiency you need to run off a generator without constantly tripping the breaker. Their low profile keeps your precious counter space free for plating and prep, which keeps the kitchen's flow open and uncluttered. If you want to dive deeper into picking the right unit, check out our complete guide on choosing a commercial refrigerator.

This intense focus on compact, high-efficiency equipment is a major force in the food truck market. With the industry projected to grow at a rate of 6-7% annually, manufacturers are stepping up with innovative, space-saving designs. In the real world, successful operators prioritize low-profile refrigeration and multi-function cooking gear to fit within tight vehicle footprints and strict power limits. In fact, case studies show that around 70–85% of modern trucks use energy-saving tech like LED lighting or inverter compressors to cut down on fuel costs and stay within their generator's capacity. You can find more insights on these market trends and their impact on food truck equipment.

Work Smart: Combining Prep and Cold Storage

Ready to take space-saving to the next level? The ultimate food truck weapon is the sandwich/salad prep table. This brilliant piece of equipment merges three essential functions into one tidy footprint:

- Refrigerated Base: An undercounter refrigerator or freezer to store your backup ingredients.

- Chilled Ingredient Rail: A set of refrigerated wells on top for holding chopped veggies, sauces, and proteins, all within arm's reach.

- Cutting Board/Work Surface: A dedicated, food-safe prep area right in front of the ingredient rail.

This single unit completely revolutionizes your prep line. Instead of running back and forth between a separate fridge and a worktable, your team can stand in one spot to assemble sandwiches, salads, tacos, or bowls with incredible speed. It’s a workflow game-changer in a box.

By consolidating refrigeration, storage, and prep into one station, you not only save space but also drastically reduce the number of steps your team takes per order. In the world of food trucks, fewer steps mean faster service and more sales.

When you're trying to squeeze every bit of utility out of your limited space, choosing between different types of compact appliances can feel like a high-stakes game of Tetris. The table below compares some common choices, highlighting how food-truck-specific alternatives can be a smarter play.

Top Space-Saving Appliances for Your Truck

| Appliance Type | Traditional Choice | Food Truck Alternative | Key Benefit |

|---|---|---|---|

| Refrigeration | Full-Size Reach-In Refrigerator | Undercounter Refrigerator/Freezer | Frees up floor space and preserves countertop area for prep work. |

| Prep Station | Separate work table + refrigerator | Sandwich/Salad Prep Table | Consolidates three functions into one unit, streamlining workflow. |

| Cooking | Standalone Griddle and Burners | Combination Griddle/Range Unit | Combines multiple cooking methods in one footprint, saving space. |

| Slicing | 12" Heavy-Duty Slicer | Compact 9-10" Slicer | Delivers commercial performance with a smaller, more storable design. |

As you can see, the theme is consolidation. Every piece of equipment that can pull double or triple duty is a huge win, helping you build a more functional and less cluttered kitchen.

Must-Have Prep Tools for a Small Kitchen

Beyond the major appliances, your smaller prep tools also need to be selected with a mobile kitchen in mind. You need commercial-grade durability without the bulky size of traditional restaurant equipment.

- Commercial Food Processors: A powerful but compact food processor can handle everything from chopping vegetables for salsa to mixing dough for bao buns, saving you hours of manual labor. Look for models with a smaller base but a high-horsepower motor.

- Heavy-Duty Slicers: If you’re serving up deli sandwiches or charcuterie, a commercial slicer is non-negotiable. Go for a model with a smaller blade (9-10 inches) that can be stored easily but is still tough enough to handle high-volume use.

By thoughtfully selecting each piece of your refrigeration and prep equipment, you create a workspace that is both highly functional and ergonomic. This strategic approach ensures your kitchen isn't just equipped to cook—it's truly optimized for speed, safety, and profitability on the go.

Cookware Essentials

Your griddle and fryer might be the stars of the show, but your pots, pans, and utensils are the hardworking crew that makes every performance possible. This isn't the place for your home kitchen gear. You need heavy-bottomed stainless steel saucepans that heat evenly, non-stick skillets that can handle hundreds of flips a day, and durable metal spatulas and tongs that won't bend under pressure. These are the tools you'll have in your hand for every single order, and their quality directly impacts your speed and consistency. Investing in a solid set of commercial-grade cookware ensures you can deliver those perfect results, rush after rush, without worrying about your equipment failing you.

Knives, Cutting Boards, and Storage

A sharp, reliable knife is a chef's best friend, especially in a tight space where efficiency is everything. You don't need a massive block; a core set of a chef's knife, a paring knife, and a serrated knife will handle most tasks. Pair them with color-coded cutting boards—this is a non-negotiable for health inspectors and a simple way to prevent cross-contamination between raw meats and fresh vegetables. When it comes to storage, think smart and compact. A magnetic knife strip mounted on a wall is a classic space-saver that keeps your most important tools within easy reach. It’s all about choosing items with commercial-grade durability that don't come with the bulky footprint of traditional restaurant setups.

Thermometers, Mixers, and Blenders

Food safety is your top priority, and a good thermometer is your number one tool for guaranteeing it. An instant-read digital thermometer is absolutely essential for checking that every piece of chicken or beef patty has reached its safe internal temperature before it goes out the window. Beyond safety, think about labor-saving prep tools. A powerful but compact food processor can whip up sauces, salsas, and slaws in seconds, saving you valuable time. An immersion blender is another fantastic space-saver, letting you blend soups and sauces directly in the pot. These small appliances have to earn their spot on your counter, so look for models that offer maximum power in a minimal footprint.

Don't Forget Power and Ventilation

That shiny new griddle looks incredible, but without the right power and ventilation, it’s just an expensive paperweight. These behind-the-scenes systems are the absolute heart and lungs of your food truck. They dictate which appliances you can run, keep your crew safe, and make sure you pass those critical health and fire inspections.

It's easy to get caught up in the excitement of picking out cooking gear, but your electrical and air systems are what make everything else work. If you underestimate their importance, you’re setting yourself up for a generator that quits mid-rush, a dangerously smoky kitchen, or a quick shutdown from an inspector.

How Much Power Do You Really Need?

Think of your generator as the heart of your operation, pumping electricity to every single appliance. If that heart isn't strong enough for the demand, the whole system fails. That’s why you absolutely have to calculate your total power needs before you even start looking at generators.

The process is pretty straightforward: just add up the power requirements for everything you’ll be plugging in. This isn’t just your big cooking equipment; it’s your refrigerators, lights, water pump, and even your POS system.

Here's a simple way to break it down:

- List Every Single Appliance: Make a complete list of all equipment that needs electricity.

- Find the Wattage: Check the manufacturer's label on each piece for its power draw in watts (W) or kilowatts (kW). If it only lists amps and volts, you can find the watts by multiplying them (Amps x Volts = Watts).

- Add It All Up: Sum the wattage for every appliance to get your total running watts.

- Factor in the Startup Surge: Anything with a motor, like a fridge, needs a big jolt of power to get started. Find the highest starting wattage among your appliances and add that to your total running watts. This final number is the absolute minimum your generator must produce.

Always add a 20% buffer to your final calculation. This gives you a safety margin, stops you from redlining the generator, and leaves a little room for any equipment you might add later on.

Choosing one of the best portable generators for mobile units is a make-or-break decision for any food truck owner. Understanding your power needs is the first step. To help you nail this choice, we’ve put together a complete guide on how to select the https://therestaurantwarehouse.com/blogs/restaurant-equipment/best-food-truck-generator for your setup.

Power Estimates by Truck Type

To see how this plays out in the real world, let's look at the power demands for a few common food truck concepts. While your exact numbers will vary based on the specific models you choose, these estimates offer a reliable starting point. Your menu is the biggest factor; a simple coffee truck has a much smaller electrical footprint than a mobile kitchen running multiple electric fryers.

- Coffee & Pastry Truck (Low Power): An espresso machine, grinder, and a small refrigerator will put you in the 4,000–5,500 watt range, including your safety buffer.

- Taco or Sandwich Truck (Medium Power): If you're using a gas griddle but electric refrigeration and food warmers, your needs will likely land between 6,000–8,000 watts, especially once you factor in the exhaust hood's startup surge.

- Burger & Fry Truck (High Power): This is a power-heavy setup. An electric deep fryer, several undercounter refrigerators, and a high-CFM hood fan can easily push your requirements to 10,000–12,000 watts or even higher.

Staying Safe and Legal with Proper Ventilation

Ventilation isn't just about keeping things comfortable; it's a critical safety requirement that inspectors take very seriously. A commercial-grade ventilation hood is required by law for any food truck that uses equipment producing grease-laden vapors—think griddles, fryers, or charbroilers.

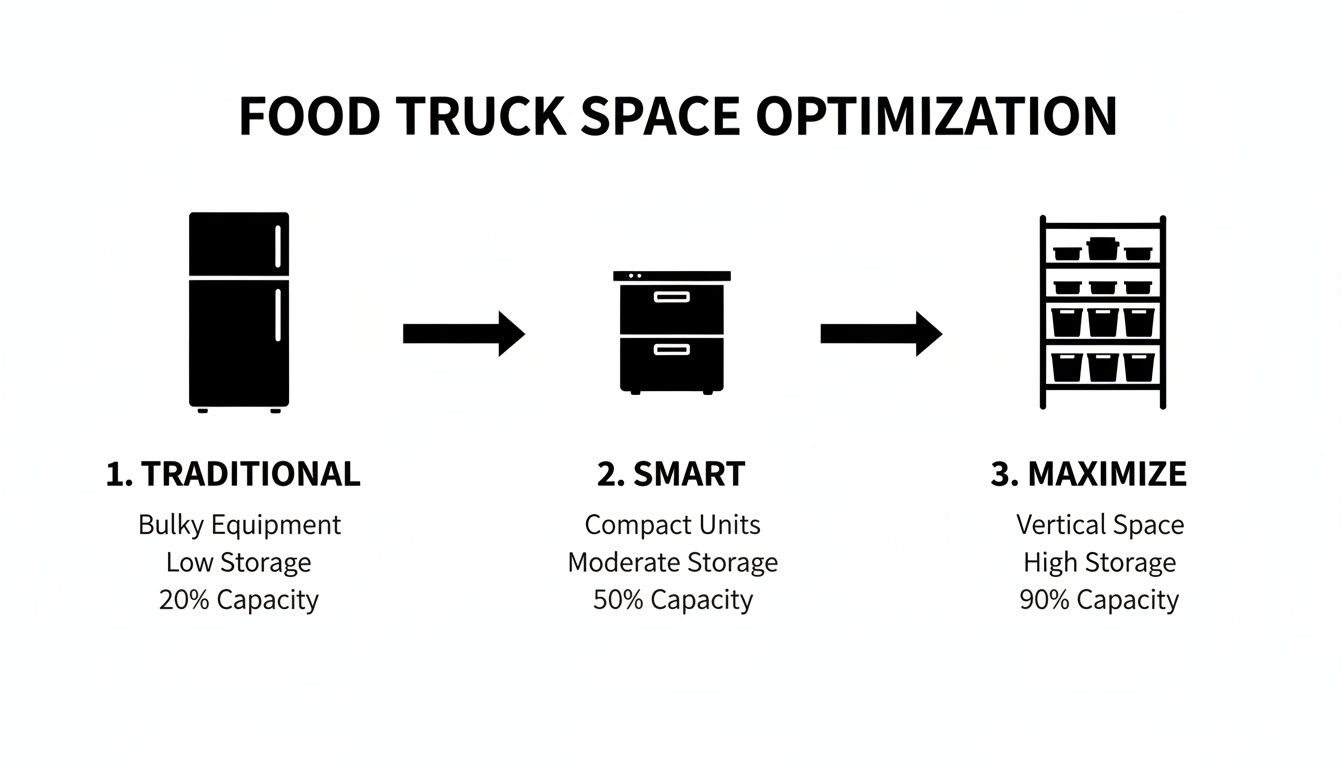

This diagram shows how smart equipment choices can transform the tight quarters of a food truck kitchen.

You can see the shift from inefficient, bulky appliances to compact, multi-functional units that make the most of every single inch.

A proper ventilation system does three crucial jobs:

- Pulls Out Smoke and Heat: It yanks hot, smoky air out of the kitchen, making it a much safer and more bearable place for your team to work.

- Traps Grease: Baffle filters inside the hood catch grease particles, preventing them from building up in the exhaust duct and becoming a massive fire hazard.

- Includes Fire Suppression: Modern hoods come with an integrated fire suppression system. This system is designed to automatically blast fire-retardant chemicals if a flare-up occurs—a feature the fire marshal will absolutely insist on.

Your ventilation system has to be powerful enough for your entire cooking line. Its capacity is measured in Cubic Feet per Minute (CFM), and the CFM you need is tied directly to the type and size of your cooking equipment. Skimping on your ventilation is one of the fastest ways to fail an inspection and keep your truck parked. Investing in the right power and ventilation from day one ensures your mobile kitchen is safe, legal, and ready to perform under pressure.

Passing Inspection: Your Sanitation Checklist

Let's be honest: passing a health inspection isn't just a goal, it's the absolute baseline for keeping your food truck doors open. Inspectors are known for taking a close look at mobile kitchens, which means your sanitation setup has to be more than just good—it needs to be perfect. Think of this gear as the foundation of your entire operation; it's what allows you to operate cleanly, safely, and legally.

Your sanitation station is often the very first thing an inspector will want to see. It’s all built around a couple of key components that work together to stamp out cross-contamination and keep hygiene front and center.

Getting Your Sink Setup Right

Every single food truck needs a very specific sink arrangement to meet health codes. This isn't a friendly suggestion—it's a hard-and-fast rule in just about every city and state.

- The Three-Compartment Sink: This is your dishwashing workhorse. Each basin has a specific job: one for washing with hot, soapy water, the second for a clean water rinse, and the third for a final dip in a sanitizing solution.

- A Dedicated Hand-Washing Sink: You absolutely must have a separate, smaller sink used only for washing hands. It needs its own hot and cold running water, soap, and paper towels, and it has to be super easy for your crew to get to at all times.

One of the quickest ways to fail an inspection is a problem with your water system. Just having the sinks isn't enough. You have to prove they can deliver hot water on demand, which for handwashing is typically at least 100°F.

Water Tanks and Plumbing Basics

To make your sinks work and keep the health department happy, you need a reliable water system humming in the background. This comes down to two crucial pieces of equipment.

A commercial water heater is non-negotiable for providing the constant stream of hot water that inspectors require. You’ll also need a solid water pump to keep steady pressure flowing to all your sinks, ensuring you have a strong stream for everything from washing hands to rinsing dishes. Without both, your truck is dead in the water.

Don't Forget These Food Safety Tools

Beyond the sinks, a few other pieces of support equipment are critical for keeping your food safe and your workspace in order. This is the stuff that prevents temperature issues and keeps things tidy—two things inspectors absolutely love to see.

Key support items include NSF-certified food warmers and holding cabinets. These are designed to keep your cooked food safely above the 140°F "danger zone," which stops bacteria from growing while you're serving customers. On top of that, smart storage like stainless steel wall shelves and dunnage racks gets ingredients off the floor and your kitchen organized. This not only prevents contamination but also makes cleaning way easier. Getting your truck outfitted with this gear is your best bet for building a kitchen that an inspector will walk into and approve without a second thought.

Class K Fire Extinguishers

A standard fire extinguisher won't work on a grease fire; in fact, it can make things dangerously worse. That's why a Class K fire extinguisher is an absolute, non-negotiable piece of safety equipment for any food truck. These are specifically designed to put out fires started by cooking oils and fats, which are common when you're running commercial deep fryers or griddles. The fire marshal will look for this immediately during an inspection. Think of it as the first line of defense, working alongside the automated fire suppression system that should be built into your ventilation hood. Having the right extinguisher on hand is a critical, legally required step to protect your crew, your customers, and your investment.

First-Aid Kits and Alarms

In the fast-paced, tight quarters of a food truck, minor cuts and burns are practically a given. A fully stocked, commercial-grade first-aid kit is essential for handling these small injuries quickly so your team can get back to work safely. Beyond immediate injuries, you also need to protect against invisible threats. Smoke and carbon monoxide (CO) detectors are mandatory. Because you're working in a small, enclosed space with fuel-burning appliances and a generator, the risk of CO buildup is serious. Make sure your staff knows where these safety items are and what the emergency plan is. Having the right gear is one thing; knowing how to use it is another.

Anti-Fatigue and Wet Area Floor Mats

This is one of those small investments that pays off in both safety and staff morale. Food truck floors inevitably get wet and greasy, creating a serious slip-and-fall hazard. High-quality, wet-area floor mats provide crucial traction to keep everyone on their feet. But they do more than just prevent accidents. Standing on a hard metal floor for ten hours is exhausting and tough on your back and joints. Anti-fatigue mats provide cushioning that reduces physical strain, keeping your team more comfortable, focused, and productive throughout a long shift. It’s a simple way to show you care about your crew's well-being while making the kitchen a safer place to work.

Beyond the Appliances: Essential Day-to-Day Supplies

Once your major appliances are installed, it's time to focus on the smaller, everyday items that keep your food truck operating smoothly. A strategic mix of gear is absolutely essential for meeting health codes, keeping your workflow smooth, and making sure every customer leaves happy. These day-to-day supplies are the connective tissue of your mobile kitchen, turning your high-powered equipment into a fully functional service line. Without them, even the best-equipped truck will grind to a halt during a rush, so planning for these items is just as important as choosing your griddle or fryer.

Serving and Dispensing Equipment

Serving equipment is all about speed, consistency, and safety. This category includes everything you use to get your finished product into a customer's hands. Think insulated beverage dispensers to keep drinks at the perfect temperature, condiment pumps for consistent portioning, and insulated food carriers to hold hot items safely. These tools are designed to streamline your service window, reduce waste, and ensure every order goes out looking and tasting exactly as it should. Investing in quality serving gear helps your team work faster and more efficiently, which is critical when you have a long line of hungry customers waiting.

Disposable Serving Supplies

Because your customers are almost always eating on the go, you need a solid stock of disposable items. This is a significant and recurring expense, so it's important to plan for it. Your list will include essentials like food containers (clamshells, bowls, or trays), plastic or compostable cutlery, napkins, and cups for both hot and cold drinks. The key is to choose products that are sturdy enough to hold your food without leaking or falling apart. The quality of your disposables directly reflects on your brand, so this isn't the place to cut corners too much.

Marketing with Custom Branded Supplies

Don't just think of your disposable items as containers; see them as tiny, mobile billboards for your business. Custom branded supplies not only enhance your food truck's visibility but also create a memorable experience for your customers. Getting your logo printed on cups, napkins, or sandwich wrappers is a relatively low-cost marketing strategy that reinforces your brand identity with every single sale. When a customer walks away carrying a cup with your logo on it, they're advertising your truck to everyone they pass, helping you build recognition and attract new business.

Janitorial and Cleaning Supplies

Your sanitation station is often the very first thing an inspector will want to see, so your cleaning supply inventory has to be on point. This goes far beyond a bottle of soap. You'll need commercial-grade sanitizers and degreasers, heavy-duty trash cans with tight-fitting lids, and a constant supply of liners. Don't forget color-coded cutting boards to prevent cross-contamination, food-safe cleaning cloths, and a well-stocked first-aid kit. Keeping these items organized and readily accessible is fundamental to maintaining a clean, safe, and inspection-ready kitchen at all times.

Keeping Your Kitchen Running: Maintenance and Upkeep

Your food truck is a complex machine, and just like any vehicle, it needs regular care to perform at its best. Proactive maintenance isn't just about fixing things when they break; it's about preventing those breakdowns from ever happening. A well-maintained kitchen runs more efficiently, uses less energy, and is far less likely to suffer a catastrophic failure during your busiest service. Establishing a routine for upkeep protects your investment and ensures your business can operate reliably day in and day out, keeping you on the road and making money.

The Importance of a Regular Maintenance Schedule

Choosing the right restaurant equipment for your food truck from day one prevents expensive retrofits and operational nightmares down the road. That same foresight should apply to its care. Create a simple checklist for daily, weekly, and monthly maintenance tasks. Daily tasks might include wiping down all surfaces and cleaning fryer oil. Weekly, you could focus on deep cleaning your freezers and checking refrigerator seals. Monthly, you might inspect hoses and clean ventilation hood filters. This consistent attention helps you catch small issues before they become major, costly problems that could shut you down for days.

Got Questions About Food Truck Appliances? Let's Clear a Few Things Up.

Stepping into the world of mobile kitchens is exciting, but it definitely brings up a lot of questions, especially when it comes to the gear. Getting straightforward answers is the key to making smart buys and dodging the rookie mistakes that can stall a new food truck before it even hits the street.

My goal here is to cut through the confusion and give you some real-world clarity on outfitting a small but mighty kitchen. We’ll tackle everything from the money talk to the must-have legal stuff, so you can build out your truck with confidence the first time around.

Can I Just Use Regular Home Appliances in My Food Truck?

This is easily one of the first questions people ask, and the answer is a hard no. I get it—it seems like a genius way to save a chunk of change. But residential appliances are just not built for the grind of a commercial kitchen. They don't have the muscle, the durability, or the precise temperature control you need when you're cranking out orders.

More importantly, they are not NSF-certified, which is a deal-breaker for pretty much every health department out there. Using home equipment is a surefire way to fail your health inspection. It also creates a serious fire risk that could easily void your insurance policy. Always, always invest in commercial-grade appliances for a food truck.

"The single biggest mistake I see new operators make is trying to cut corners with non-commercial gear. It breaks down faster, can't keep up with demand, and ultimately costs them more in lost revenue and replacement fees than if they had just bought the right equipment from the start."

How Much Do Food Truck Appliances Really Cost?

Budgeting for your equipment is a huge step. While the numbers can move around, a realistic budget for a full set of new, essential appliances—think cooking, refrigeration, and sanitation—is usually somewhere between $25,000 and $75,000. This range covers the main workhorses that are the backbone of your entire operation.

- Cooking Line: Griddles, fryers, and ovens can run you $2,000 to $8,000 per unit.

- Refrigeration: Undercounter units and prep tables typically land between $2,500 and $6,000.

- Ventilation & Safety: A code-compliant hood and fire suppression system can add another $5,000 to $15,000.

Just remember, you're not just buying equipment; you're investing in reliability and the ability to legally operate.

What Is the One Appliance I Absolutely Can't Live Without?

If you had to pick just one MVP for a food truck, it would almost always be the commercial flat-top griddle. I say this because its huge, even cooking surface lets you do so many things at once. You can be searing burgers, toasting buns, cooking eggs, and sautéing veggies all at the same time.

Its incredible versatility makes it the ultimate space and time-saver in a tiny kitchen. In the food truck game, that kind of multi-functionality directly translates to speed and profit.

Ready to build your mobile kitchen with reliable, code-compliant equipment? The Restaurant Warehouse offers a massive selection of commercial appliances perfect for any food truck concept, along with flexible financing options to get you started. Explore our inventory and get a free quote today at https://therestaurantwarehouse.com.

Key Takeaways

- Your Menu is Your Equipment Blueprint: Start with your menu to select only the essential appliances you'll actually use. This approach prevents you from buying unnecessary equipment and ensures your layout is perfectly optimized for the dishes you'll be making day in and day out.

- Choose Appliances That Do Double Duty: In a tight mobile kitchen, opt for multi-functional equipment like undercounter refrigerators and combination prep tables. This strategy consolidates your workflow, reduces the steps your team takes per order, and keeps your limited space open and efficient.

- Invest in Commercial-Grade Systems for Compliance: Using residential appliances is a non-starter; they won't pass health inspections and aren't built for the demand. Invest in NSF-certified commercial equipment, proper ventilation, and the required sink setup from day one to operate legally and build a reliable business.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment