How to Choose the Perfect Commercial Refrigerator for Your Restaurant

Of all the equipment in your kitchen, nothing works harder than your commercial refrigerator. It’s the silent MVP, running 24/7 to protect thousands of dollars in inventory and ensure every dish starts with safe, quality ingredients. But choosing the wrong one is an expensive mistake that can disrupt your entire operation. Think sky-high energy bills, spoiled food, and frustrating workflow interruptions. This guide is your roadmap to avoiding those costly pitfalls, ensuring your investment becomes a reliable workhorse—not a source of constant stress and financial drain.

Making the right choice here isn't just about picking a box that keeps things cold. It's a fundamental business decision that directly impacts your food safety, daily workflow, and, ultimately, your bottom line.

Why Your Refrigerator is Your Kitchen's MVP

Think about it: choosing the right refrigerator is a decision that sets the tone for your entire operation. A well-chosen unit can streamline prep, prevent costly food waste, and keep you on the right side of the health inspector. The wrong one? It can become a constant source of stress, inefficiency, and financial loss.

This choice is only getting more important. The global commercial refrigeration market, already valued at over USD 44 billion, is projected to rocket to nearly USD 80 billion by 2034. That explosive growth, detailed in this commercial refrigeration equipment market report, shows just how essential these workhorses are to our industry. Making an informed choice now means you're investing in a durable asset that will serve you faithfully for years.

How to Choose a Refrigerator for Your Business Model

The first step is to be honest about your kitchen's reality. There’s no single “best” refrigerator—the perfect unit for a bustling hotel kitchen would be total overkill for a small coffee shop. It all starts with matching the type of refrigerator to your specific operational needs. Let's break down the main players.

A Quick Guide to Commercial Refrigerator Types

To help you get a quick sense of your options, here's a simple breakdown of the most common refrigerator types. This table will help you start thinking about which unit best fits your kitchen's size and the demands of your menu.

| Refrigerator Type | Best For | Typical Kitchen Size | Key Feature |

|---|---|---|---|

| Reach-In Refrigerator | Daily line prep, easy access | Small to Large | Versatility; solid or glass doors |

| Walk-In Cooler | Bulk ingredient storage | Medium to Large | Maximum storage capacity |

| Undercounter Refrigerator | Specific workstations | Small to Medium | Space-saving; fits under counters |

| Refrigerated Prep Table | Sandwich/salad/pizza assembly | Small to Large | Combines storage with a workspace |

Each of these types fills a very specific role, and understanding that role is key to designing an efficient kitchen.

Reach-In Refrigerators: These are the versatile workhorses you’ll find in almost every professional kitchen. Available with one, two, or even three doors, they offer quick access to ingredients you need throughout the day. A solid-door model is fantastic for back-of-house storage, as it offers better insulation and efficiency.

Walk-In Coolers: If you're running a high-volume operation—think large restaurants, hotels, or catering companies—a walk-in isn't a luxury; it's a necessity. It gives you the space for bulk storage, allowing you to take advantage of wholesale pricing on everything from produce to proteins.

Undercounter Refrigerators: These compact units are absolute lifesavers for maximizing space. They slide neatly under prep tables or service counters, putting crucial ingredients right at a specific workstation, like a salad or sandwich station.

Refrigerated Prep Tables: Combining refrigerated storage with a food-safe work surface, these units are all about efficiency. They are indispensable for assembling pizzas, salads, and sandwiches, keeping every necessary ingredient perfectly chilled and within arm’s reach.

Your choice of refrigerator literally shapes your kitchen's entire workflow. A well-placed undercounter unit can shave precious minutes off prep time, while a properly organized walk-in prevents inventory waste and keeps food costs in check. You’re not just buying a box; you’re designing a system.

Understanding Door Styles

The doors on your refrigerator do more than just open and close—they directly influence your kitchen's workflow. You can find commercial refrigerators with one, two, three, or even four doors, and choosing between glass and solid styles is a key decision. Glass doors are fantastic for busy prep lines because they let your team see inventory at a glance, minimizing the time the door is open. Solid doors, however, provide better insulation, making them a more energy-efficient choice for back-of-house storage where contents aren't needed as frequently. Beyond that, consider the door mechanism itself. Classic swing doors are common, but sliding doors can be a lifesaver in narrow aisles, while drawers in undercounter units offer incredible organization for specific workstations.

Exploring Interior Materials

When you look inside a commercial refrigerator, you'll almost always find one material: stainless steel. It's the industry standard for a very good reason. A professional kitchen is a demanding environment, and stainless steel is built to withstand the daily abuse, resisting the dents, scratches, and rust that come from constant use. More importantly, its non-porous surface is simple to clean and sanitize, which is absolutely critical for meeting health codes and ensuring food safety. While other materials exist, choosing a unit with a high-quality stainless steel interior is a smart investment in durability, ensuring your restaurant equipment will hold up for years while maintaining a hygienic space for your ingredients.

Factoring in Space and Long-Term Energy Costs

Beyond just the type of unit, you have to think about its physical and financial footprint. Let's be clear: a commercial refrigerator is a major energy consumer, and that consumption can vary wildly depending on the model you choose.

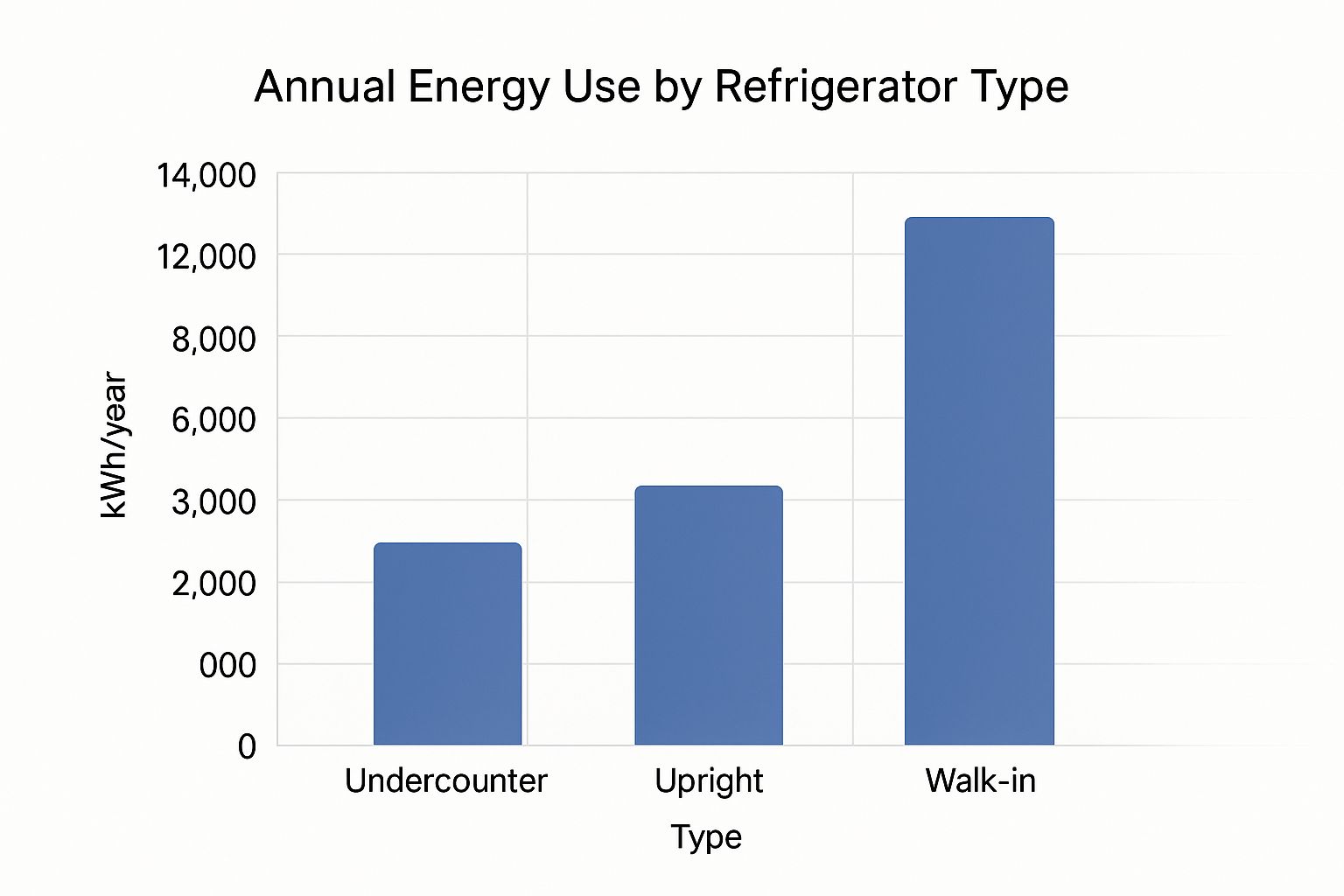

This chart gives you a pretty clear picture of the typical annual energy usage for different refrigerator types.

As you can see, a walk-in cooler can easily use more than three times the energy of a standard upright reach-in. That’s a significant operational expense you absolutely need to plan for.

Getting this first step right—aligning the refrigerator type with your specific business model—sets the stage for operational success. This isn't just another purchase; it's a strategic investment in the efficiency, safety, and profitability of your business.

Gauging Real-World Energy Use

Those energy charts are a great starting point, but let's talk about what those numbers mean for your actual utility bill. A single commercial refrigerator can consume up to 17,000 kilowatt-hours (kWh) of electricity per year. If you're looking at a commercial freezer, that number can jump to a staggering 38,000 kWh annually. This isn't a minor detail—it's a major operational expense that shows up on your books every single month. When you invest in a modern, energy-efficient refrigerator, you're not just buying an appliance; you're making a long-term financial decision that directly impacts your profitability by lowering those persistent energy costs.

How Location and Condition Impact Efficiency

A refrigerator's performance isn't just about its specs; it's heavily influenced by its environment and upkeep. Where you place the unit matters immensely. Setting up your fridge next to a heat-generating appliance like a deep fryer or an oven forces the compressor to work much harder, driving up your energy consumption. The age and condition of the unit are also critical. Older refrigerators are simply less efficient than newer models, which benefit from better insulation and components. Simple, routine maintenance—like cleaning the condenser coils and checking that door seals are tight—is one of the most effective ways to ensure your equipment runs efficiently and lasts longer, saving you from costly repairs and high utility bills.

Choosing a Commercial Refrigerator for Your Real-World Kitchen

Alright, we’ve covered the basic types of commercial refrigerators. Now, let’s get to the real art of picking the right one: matching a unit to the specific rhythm and demands of your kitchen. A refrigerator isn't just a box that keeps things cold; it's a strategic partner in your daily grind. Its real value is measured by how seamlessly it fits into your unique workflow.

The needs of a chaotic school cafeteria are a world away from those of a sleek, front-of-house bar. One needs massive capacity and has to be tough enough to handle constant opening and closing. The other is all about good looks and a compact design that saves precious space. This is where thinking through real-world scenarios is crucial to making a smart investment.

Walk Through These Scenarios Before You Buy

Let's ground this in some practical examples. Picture a busy convenience store. For this business, a glass-door merchandiser isn't just a nice-to-have—it's essential. These units turn your cold storage into a billboard, encouraging impulse buys and letting customers grab a drink or snack without needing any help. The visual appeal directly fuels sales.

Now, contrast that with the back-of-house at a fine dining spot. Here, a solid-door reach-in is the clear winner. Its job is to protect expensive, delicate ingredients, not show them off. Those solid doors provide better insulation, which means better energy efficiency and more stable internal temperatures—absolutely critical for food safety and quality, far away from the customer's view.

The right commercial refrigerator should feel like a natural extension of your workflow, not another obstacle your team has to work around. The goal is to pick a unit that truly supports your menu, your staff, and your style of service.

Matching the Refrigerator's Design to Your Daily Workflow

The commercial refrigeration market is incredibly diverse, with specialized units built for just about every niche you can imagine. And it's a growing market, driven by the specific needs of retail and food service businesses all over the world. The equipment landscape includes everything from display cases and walk-ins to beverage coolers and reach-ins, with supermarkets and restaurant chains being major drivers of demand. You can dig deeper into these global commercial refrigeration market trends to see how different applications are shaping the equipment we buy. This level of specialization is a huge advantage for operators who know exactly what they need.

Think about these very different kitchen environments:

The Food Truck: Space is everything. Undercounter and worktop refrigerators are non-negotiable here. They cleverly combine cold storage with valuable prep surfaces, maximizing every single square inch of a tight kitchen. A low-profile unit makes it possible to pump out orders efficiently from a tiny footprint.

The Busy Bar: Speed and easy access are the name of the game. Bartenders need refrigerated storage for garnishes, juices, and bottled drinks right at their station. A back-bar cooler with glass doors lets them spot what they need in a flash and restock on the fly, keeping service flowing smoothly during peak hours.

The High-Volume Pizzeria: This kind of operation demands a specialized refrigerated prep table. These units are designed with insulated lids and pans to hold dozens of toppings at safe temperatures, located just below the pizza assembly line. This whole setup is built for speed and consistency, which is vital for a business churning out hundreds of pies.

Features That Make a Difference

Once you’ve settled on the right type of refrigerator for your space, it’s time to look at the specific features that separate a good unit from a great one. These details aren't just minor upgrades; they have a real impact on your daily operations, energy bills, and the overall lifespan of your equipment. A commercial refrigerator is a major energy consumer, with some models using up to 17,000 kilowatt-hours annually. That’s why energy-saving features like high-quality insulation, efficient compressors, and bright LED lighting are so critical. They directly translate to lower utility costs over the life of the unit, making them a wise investment for any budget-conscious operator browsing for new refrigerators.

Think about the flow of your kitchen during the busiest part of the day. Features that streamline your staff's work can make a huge difference. Self-closing doors are fantastic when a chef’s hands are full, preventing energy waste and keeping temperatures stable. Precise digital temperature controls remove the guesswork from food safety, while see-through glass doors allow for quick inventory checks without letting all the cold air out. Even something as simple as having casters (wheels) makes cleaning underneath and behind the unit much easier, which is a huge plus for maintenance and sanitation. These thoughtful design elements are what make a refrigerator a seamless part of your kitchen’s workflow.

A professional kitchen is a demanding environment, so your equipment has to be tough. Look for durable stainless steel construction that can withstand the daily grind of a busy service. Many modern units also come with practical features like locking doors to secure your valuable inventory overnight and reversible door hinges that give you more flexibility with placement. Because consistent maintenance is the key to longevity, choose a model with easily accessible condenser coils for routine cleaning. Investing in a durable, easy-to-maintain unit protects your purchase for years to come. High-quality equipment is more accessible than you might think, and options like restaurant equipment financing can help you get the features you need without a massive upfront cost.

Setting Yourself Up for Long-Term Success

The commercial refrigerator you choose sends ripples across your entire business. It affects everything from your energy bills and your staff's efficiency to the complexity of the menu you can offer.

A unit that’s too small will force you to over-stock it, which blocks airflow and can lead to food spoilage. A unit that’s too big is just wasting valuable kitchen real estate and burning through unnecessary energy.

Ultimately, the best decision comes from a clear-eyed look at your day-to-day reality. Get honest about your customer volume, your menu’s storage demands, and the physical layout of your kitchen. When you align your purchase with these core operational factors, you ensure your new refrigerator will be a productive and profitable asset for years—not a source of constant headaches.

Choosing a Supplier You Can Trust

Your equipment is only as good as the supplier standing behind it. A great refrigerator from a questionable seller can quickly turn into a nightmare if something goes wrong, which is why choosing a reliable supplier is just as important as picking the right model. Look for a company that prioritizes quality and customer service, not just a quick sale. Before you commit, do your homework. Read customer reviews, get a clear understanding of the warranty options, and ask about their process for ongoing support. A trustworthy partner will be transparent about these details and help you feel confident in your purchase. Finding a supplier who understands the financial realities of the foodservice industry is also a huge plus. A good partner knows every dollar counts and can offer solutions like restaurant equipment financing to make essential investments more manageable for your business.

Popular Brands on the Market

As you browse for the perfect unit, you’ll start to see a few brand names pop up again and again. In the world of commercial refrigeration, companies like True Manufacturing have built a reputation for being incredibly durable, though they often come with a premium price tag. On the other hand, you have brands that have become extremely popular by delivering exceptional value and reliable performance without the high cost. Atosa is a perfect example of a brand that hits this sweet spot, making it a favorite for new and established restaurants alike. Focusing on brands known for quality and efficiency is a smart way to narrow down your options. At The Restaurant Warehouse, we carry an extensive selection of Atosa refrigerators and freezers because we believe in their ability to stand up to the demands of a busy kitchen while offering incredible value.

How to Read a Commercial Refrigerator Spec Sheet Like a Pro

Let's be honest, technical spec sheets can look like a foreign language. They’re packed with jargon and numbers that make your eyes glaze over. But here’s the thing: this is where the real story of a commercial refrigerator is hiding.

Learning to translate these specs is the single best way to know you’re buying the right unit, not just hoping you are. It’s the difference between buying on price alone and making a smart investment for your kitchen's future. These sheets hold all the secrets to a unit's power, durability, and true long-term cost.

Top Mount vs. Bottom Mount: Which Compressor Is Best?

One of the first things you'll see on a spec sheet is the compressor location. This isn't just some minor design detail; it has a huge impact on how the refrigerator will actually perform in your specific kitchen.

A top-mount compressor sits at the very top of the unit. This is a great setup for kitchens that are relatively cool and don't have a lot of grease or flour dust in the air. Since heat rises, the compressor isn't sucking in the hottest air in the kitchen. It also stays clear of floor debris, which means the condenser coils usually need less frequent cleaning.

On the other hand, a bottom-mount compressor is a real workhorse in very hot kitchens. Because it pulls in cooler air from near the floor, it can operate more efficiently when your kitchen's ambient temperature is high. The trade-off? Its location means it will inevitably suck in more dust, flour, and grease from the floor, demanding a more rigorous cleaning schedule to prevent clogs and overheating.

Here's a quick way to think about it:

- Go for a Top-Mount if: Your kitchen has decent air conditioning, you don't do a lot of flour-based prep nearby, and you'd prefer slightly easier maintenance.

- Go for a Bottom-Mount if: Your kitchen gets hot (think temps often climbing over 85-90°F), and you want more ergonomic access to the bottom shelves. Just be ready to clean those coils more often!

Understanding Energy Efficiency for Long-Term Savings

The sticker price is only part of the story. A refrigerator's real cost reveals itself over years of energy bills, which is why understanding energy ratings is such a powerful tool for saving money.

An ENERGY STAR certified commercial refrigerator might have a higher upfront cost, but it can save you thousands over its lifespan. These units are often 20-40% more efficient than standard models, thanks to better compressors, insulation, and higher-quality parts.

When you're looking at a spec sheet, hunt for that ENERGY STAR logo. Then, find the kWh/year (kilowatt-hours per year) number. A lower number here directly translates to a lower monthly electric bill. It's that simple.

Imagine two similar reach-ins. Unit A costs $2,500 and uses 2,000 kWh/year. Unit B, an ENERGY STAR model, costs $3,000 but only uses 1,200 kWh/year. At an average electricity rate of $0.15 per kWh, Unit B saves you $120 every year. Over a ten-year lifespan, that’s $1,200 in savings—easily paying you back for the higher initial price. You’re not just buying equipment; you’re making a financial decision that benefits your bottom line for years.

How to Keep Your Refrigerator Running Efficiently

Once you've chosen the right commercial refrigerator, your work isn't over. Consistent maintenance is the key to protecting your investment and keeping energy costs under control. These units are serious power consumers, so a little upkeep goes a long way. The most important task is regularly cleaning the condenser coils. When they get clogged with dust, grease, and flour, your refrigerator has to work much harder to stay cool, which drives up your electric bill. Also, make it a habit to check the temperature settings to ensure they are correct for food safety but not colder than necessary. These simple actions don't just save you money month-to-month; they also extend the lifespan of your equipment and help you avoid the headache of an emergency repair call.

Making the Final Call on Your Commercial Refrigerator

Reading a spec sheet isn't about memorizing every term. It’s about connecting the technical data to the day-to-day reality of your kitchen. When you review a sheet, ask yourself these practical questions:

- Compressor Location: Based on my kitchen’s temperature and how clean we keep the floors, will a top-mount or bottom-mount unit perform better and be easier to maintain?

- Energy Use: What's the annual kWh consumption? How does the long-term energy cost stack up against the purchase price, especially if it’s an ENERGY STAR model?

- Dimensions & Clearance: Does it physically fit my space, including the required clearance for airflow (usually 2-3 inches on all sides)?

- Refrigerant Type: What refrigerant does it use? Is it an eco-friendly option like R290 that future-proofs my investment against changing regulations?

By focusing on these key areas, you turn a confusing page of data into a clear roadmap. You’ll be able to confidently pick a commercial refrigerator that not only meets your needs today but also serves as a reliable, cost-effective asset for your business long-term.

Balancing Budget and Capacity

It’s easy to get stuck between two extremes: buying the cheapest refrigerator to save money now, or getting the biggest one you can afford, thinking more space is always better. The smartest move is finding the sweet spot right in the middle. A unit that’s too small for your inventory leads to overstuffing, which blocks airflow and risks costly food spoilage. On the flip side, a refrigerator that’s too large is a constant drain, wasting valuable kitchen space and racking up your energy bills for capacity you don't even use. Thinking about your budget should include the long-term operating costs, not just the initial price tag. If a higher-efficiency model feels like a stretch, exploring options like restaurant equipment financing can make it possible to invest in the right-sized, energy-saving unit that will pay you back for years to come.

What to Know About Refrigerants and Regulations

The refrigerant running through your commercial refrigerator might feel like a tiny technical detail, but trust me, it carries some serious long-term weight for your finances and legal compliance. This isn't just about keeping things cold; it's about making a smart, sustainable choice that protects your investment from becoming a costly headache down the road.

The world of commercial refrigeration has been completely reshaped by environmental regulations. Not so long ago, units ran on refrigerants like CFCs and HCFCs, which were later found to be incredibly damaging to the ozone layer. Global agreements like the Montreal Protocol kicked off a mandatory phase-out, pushing the entire industry toward safer alternatives.

This ongoing shift has brought us to a critical point where the type of refrigerant in your unit matters more than ever.

What Is GWP and How Does It Future-Proof Your Purchase?

The term you absolutely need to get familiar with is Global Warming Potential (GWP). It's a simple metric that measures how much heat a gas traps in the atmosphere compared to carbon dioxide (which has a GWP of 1). The higher the GWP number, the more damaging the gas is to the environment.

Older refrigerants like R-404A have a sky-high GWP of nearly 4,000, which is why they've been a major target for regulatory phase-outs. Buying a refrigerator that uses a high-GWP refrigerant today is a risky bet. As regulations get stricter, servicing these units will become more expensive and eventually impossible, forcing you into a premature and frustratingly expensive replacement.

Choosing a refrigerator with a low-GWP refrigerant isn't just an environmental feel-good move—it's a sharp business decision. It shields you from future regulations, helps you avoid potential fines, and ensures your equipment remains viable for its full lifespan.

The Shift to Natural Refrigerants Like R-290

The industry's clear answer to this regulatory challenge has been the adoption of natural refrigerants. The one leading the charge in modern commercial refrigerators is R-290, which is essentially high-purity propane.

Now, don't let the word "propane" set off any alarms. In these sealed systems, R-290 is used in very small, safe quantities and has proven to be incredibly effective.

Here’s exactly why R-290 has become the new gold standard:

- Extremely Low GWP: R-290 has a GWP of just 3. This makes it compliant with even the most stringent current and anticipated environmental rules.

- Superior Efficiency: It's a more thermodynamically efficient refrigerant. This means units running on R-290 often use less energy to get the job done, which saves you real money on your electricity bill.

- Excellent Performance: R-290 systems often cool down faster and hold their temperature more consistently, which is a huge plus for food safety.

When you're comparing models, looking for "R-290" on the spec sheet is one of the smartest things you can do. It's a clear signal that the manufacturer has invested in modern, sustainable technology. For a deeper dive into all aspects of your purchase, check out our complete commercial refrigeration guide to ensure you're making the most informed choice.

How to Choose a Refrigerator That's Both Smart and Compliant

So, what does all this mean for you when you're shopping for a new commercial refrigerator? It means you need to look past the price tag and size and actively investigate what’s running inside.

Be ready to ask some pointed questions:

- What refrigerant type is used in this model?

- What is its Global Warming Potential (GWP)?

- Is this refrigerant subject to any upcoming phase-outs or new regulations?

Picking a unit with a low-GWP refrigerant like R-290 ensures your equipment will be a reliable partner for years to come. It's a proactive step that aligns your kitchen with both environmental responsibility and savvy financial planning, protecting your business from the hidden costs of non-compliance and outdated technology.

Protect Your Investment: Installation and Maintenance Tips

Your commercial refrigerator’s journey doesn’t end when it arrives at your loading dock. In fact, what happens next—the installation and ongoing care—is what truly determines its performance, efficiency, and lifespan. A little attention here protects your significant investment and prevents the kind of catastrophic failure that can shut down a kitchen.

Proper installation is the foundation of a long and healthy service life. Getting this right from day one prevents a host of future problems, from poor cooling performance to premature wear on critical components. It's not complicated, but it does require attention to detail.

Your Day-One Installation Checklist

Before you even plug it in, take a moment to ensure the unit is positioned correctly. This isn't just about fitting it into a space; it's about giving it the environment it needs to operate efficiently. I've seen it time and again—overlooking these initial steps is one of the most common reasons for early-life equipment problems.

Start with the basics of placement and setup:

- Ensure Adequate Ventilation: A commercial refrigerator works by pulling heat out of the cabinet and releasing it into the surrounding air via its condenser coils. If there isn't enough space for air to circulate, that heat gets trapped, forcing the compressor to work much harder. Always follow the manufacturer’s clearance guidelines, typically requiring 2-3 inches of space on the back and sides.

- Level the Unit: An unlevel refrigerator can cause some serious issues. The doors may not seal properly, leading to constant cold air leaks and condensation buildup. It can also cause lubricating oil to pool incorrectly within the compressor, leading to excessive wear. Use a level and adjust the feet or casters until the unit is perfectly stable.

- Confirm Electrical Compatibility: Check the unit's electrical requirements (voltage and amperage) on its data plate and ensure your outlet can handle the load. A dedicated circuit is almost always recommended for a commercial refrigerator to prevent power fluctuations that can damage the compressor.

A poorly installed unit is an inefficient one. A few minutes spent ensuring proper leveling and ventilation can save you hundreds of dollars in energy costs and repair bills over the life of your refrigerator.

Planning for Delivery and Logistics

Once you’ve picked your perfect unit, you need a solid plan to get it into your kitchen. This is more than just scheduling a drop-off; it’s about coordinating the entire delivery process to avoid any last-minute disasters. Before you finalize your order, walk the delivery path yourself. Measure every doorway, hallway, and tight corner from the loading dock to the final spot in your kitchen. Communicate these measurements to your supplier. It’s also crucial to inspect the refrigerator for any dings, dents, or damage *before* you sign the delivery receipt. Just as you’d insist on best practices for your food deliveries, you need to ensure this expensive asset arrives in perfect condition. Understanding how to properly handle the receiving process can help you avoid accepting damaged goods and ensure a smooth installation.

Exploring Financing Options

A high-quality commercial refrigerator is a major investment, but it shouldn't drain your capital. This is where financing becomes a powerful tool. Instead of settling for a cheaper, less efficient model that will cost you more in the long run, financing allows you to get the right equipment now. Think about it this way: the monthly energy savings from a top-tier, ENERGY STAR certified unit can often help offset the cost of your financing payment. You’re essentially letting the equipment’s efficiency pay for itself over time. Exploring restaurant equipment financing options can make a huge difference, allowing you to acquire a durable, productive asset that supports your business's growth without creating a financial strain.

Creating a Simple Long-Term Maintenance Plan

Once your refrigerator is properly installed, the focus shifts to proactive maintenance. This isn't about waiting for something to break; it's about a consistent routine that keeps the machine running in peak condition. A neglected commercial refrigerator can see its energy consumption spike by as much as 25% and is far more likely to fail during a busy service.

Your maintenance schedule should be simple, actionable, and consistent. Here are the core tasks that make the biggest difference.

The Quarterly Condenser Coil Cleaning This is the single most important maintenance task you can perform. The condenser coils are where the refrigerator sheds heat. In a busy kitchen, these coils quickly become caked with grease, dust, and flour. This buildup acts like a blanket, trapping heat and forcing the compressor to run constantly.

At a minimum, every 90 days, you should:

- Disconnect the power to the unit.

- Remove the protective grille covering the coils.

- Use a stiff-bristled brush and a vacuum to gently remove all debris from the coil fins.

- For heavy grease, a specialized coil cleaner spray may be necessary.

This simple task can prevent the vast majority of compressor failures, which is the most expensive repair a refrigerator can have. Of course, it's not just about your fridge. Ensuring all your equipment operates safely requires a robust plan. For a broader guide, this comprehensive kitchen equipment maintenance checklist provides an excellent framework for your entire setup.

Monthly Gasket Inspections and Airflow Checks The door gaskets are your primary defense against cold air loss. A torn, brittle, or loose gasket forces your unit to run overtime just to maintain its set temperature. Once a month, take a moment to inspect the entire perimeter of each door gasket for any signs of damage. A quick way to test the seal is the "dollar bill test"—close the door on a dollar bill. If you can pull it out easily, your gasket is likely weak and needs replacement.

At the same time, take a look inside. Over-stocking shelves blocks proper airflow, creating warm spots where food can spoil. Make sure there's space between products and that nothing is blocking the interior fans. For more specific guidance, you can learn more about how to properly maintain commercial refrigerators in our detailed guide. Protecting your investment is all about combining careful installation with a smart, repeatable maintenance routine.

When you're about to make a big investment in a workhorse like a commercial refrigerator, it's only natural to have a few questions. Getting straight, practical answers helps you move forward with confidence, making sure you pick, use, and maintain your unit for the long haul.

Let's dive into some of the most common questions we hear from foodservice operators just like you. This isn't about getting bogged down in technical jargon; it's about giving you straightforward info to help you run your business better.

Considering a Service Contract

While the maintenance tasks we've covered are straightforward, the reality of a busy kitchen means they can easily get overlooked. This is where a service contract can be a smart move. It puts your refrigerator's health on autopilot, ensuring that crucial jobs like cleaning condenser coils and checking temperatures happen on a consistent schedule. Think of it as proactive insurance. A contract helps you avoid the kind of catastrophic failure that can shut down your kitchen during a dinner rush, protecting the significant investment you made in your equipment.

A neglected refrigerator can use up to 25% more energy and is far more likely to need expensive emergency repairs. A service contract transforms that unpredictable risk into a manageable, budgeted expense. It’s about weighing the modest, predictable cost of regular service against the massive, unexpected cost of a major breakdown. When you're managing your budget, having predictable maintenance costs is a huge advantage, similar to how restaurant equipment financing can help manage cash flow for the initial purchase.

How Often Should I Clean My Refrigerator's Coils?

As a solid rule of thumb, plan on cleaning the condenser coils every 90 days. Honestly, this is the single most important maintenance task you can do to prevent breakdowns and keep your unit running efficiently.

But—and this is a big but—your kitchen's specific environment is the real deciding factor. If you've got a lot of airborne grease from fryers or flour dust from a bakery, you should be checking and cleaning those coils monthly. Clogged coils are the number one cause of compressor strain and, ultimately, premature failure.

What Is the Real Difference Between Top Mount and Bottom Mount?

This is a great question, and the answer comes down to your kitchen's ambient temperature and your cleaning routine.

A top-mount compressor is fantastic for cooler kitchens because it's positioned away from the floor, where it's less likely to suck in dust, debris, and mop water. It also vents hot air upwards, away from your staff, which can make the work environment a little more comfortable.

On the other hand, a bottom-mount compressor is the hero in hotter kitchens. It draws in cooler air from near the floor, helping it run more efficiently when the rest of the kitchen is cranking. The trade-off? It’s much closer to floor-level dust and grease, so it will need more frequent coil cleaning.

Key Takeaway: Go with a top-mount for cooler, cleaner environments. Opt for a bottom-mount in hotter kitchens, as long as you can commit to a more rigorous cleaning schedule. Both are excellent choices when you match them to the right conditions.

Can I Just Use a Residential Fridge in My Cafe?

I get why people ask this, but the answer is an emphatic no. Using a residential refrigerator in any commercial setting is a serious mistake, and here are the critical reasons why:

- Poor Temperature Recovery: Home fridges are not built for the constant door openings of a busy kitchen. They can't get back to a safe cold temperature quickly enough, which puts your food in the "danger zone" and is a major health code violation.

- Lack of Durability: They just aren't built with the heavy-duty parts needed to survive the grind of a professional kitchen. It will fail on you, and probably much sooner than you think.

- Voided Warranty: The second you place a residential unit in a commercial kitchen, its warranty is void. Any and all repairs will be coming straight out of your pocket.

This is one corner you absolutely cannot afford to cut. For a deeper look into selecting the right equipment, you can explore our guide on restaurant refrigeration solutions that won't leave you cold.

Layout and Material Differences

The most obvious difference between a residential and commercial refrigerator is how they’re built. A commercial unit is designed for the battlefield of a professional kitchen. Its exterior is almost always made of durable stainless steel, which is meant to withstand constant use, resist scratches, and prevent rust. Inside, you’ll find open, adjustable shelving designed for maximum storage and airflow, not the specialized crisper drawers or door bins you’re used to at home. Residential fridges, on the other hand, are built for aesthetics and convenience, using lighter materials that simply can’t hold up to the demands of a business that might serve hundreds of people a day. This focus on durability is why investing in true commercial restaurant equipment is so critical for any foodservice operation.

Repair and Service Considerations

When your home fridge breaks, you call a local appliance repair person. When a commercial refrigerator goes down, it’s a completely different ballgame. These units are complex machines that require specialized technicians who understand their powerful cooling systems and robust components. While the maintenance and repair costs for a commercial unit are higher, they are a non-negotiable part of doing business. Regular check-ups are essential to prevent catastrophic failures that could lead to thousands of dollars in spoiled inventory. This is why planning for the total cost of ownership, which can sometimes be managed with restaurant equipment financing, is a crucial step in your purchasing decision.

Using a Commercial Unit at Home: Pros and Cons

The idea of putting a commercial refrigerator in a home kitchen is tempting, especially for large families or avid home cooks who buy in bulk. The pros are clear: you get an incredible amount of storage space and a unit built to last for years under heavy use. However, the cons often outweigh the benefits for a residential setting. Commercial refrigerators are significantly louder and consume much more electricity, which will lead to a noticeable jump in your energy bills. They also lack the user-friendly features of home models, like produce drawers and condiment bins, forcing you to use separate containers for organization. While the power is appealing, these units are purpose-built for business, not for the quiet comfort of a home.

Is an ENERGY STAR Certified Refrigerator Worth the Extra Cost?

Yes, in almost every single scenario, the investment pays for itself. An ENERGY STAR certified commercial refrigerator is typically 20-40% more energy-efficient than standard models. This boost in efficiency comes from better compressors, superior insulation, and higher-quality door gaskets.

While the initial sticker price might be a bit higher, the savings on your monthly electricity bill deliver a surprisingly quick return on that investment. Over the full lifespan of the unit, these savings can easily add up to thousands of dollars, making it both a financially smart and environmentally friendly choice.

At The Restaurant Warehouse, we provide the durable, efficient, and reliable commercial refrigeration you need to run a successful kitchen. Explore our extensive selection of commercial refrigerators today.

Key Takeaways

- Match the Refrigerator to Your Kitchen’s Rhythm: The right unit should support your daily workflow, not disrupt it. Analyze whether a reach-in for quick access, a prep table for an assembly line, or an undercounter unit for a specific station will save your team the most time and effort.

- Decode the Specs for Long-Term Savings: The initial price is only part of the total cost. Look for the ENERGY STAR logo to guarantee lower monthly utility bills and confirm the unit uses a low-GWP refrigerant like R-290 to avoid expensive compliance issues down the road.

- Commit to a Simple Maintenance Routine: Proper installation and consistent care are the keys to a long service life. Ensure the unit has adequate ventilation from the start and make cleaning the condenser coils every 90 days a non-negotiable task to prevent the most common and costly breakdowns.

Related Articles

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment