Best Commercial Undercounter Ice Makers for Restaurants

In a busy restaurant, every step counts. The time it takes for a server to walk from a table to the kitchen for an ice refill adds up, impacting table turnover and customer satisfaction. An efficient workflow is not a luxury; it's essential for profitability. Placing equipment strategically is one of the most effective ways to eliminate wasted motion. A commercial undercounter ice maker is a perfect example of this principle in action. By installing a compact, high-efficiency unit directly at the beverage station or behind the bar, you give your staff instant access to ice, speeding up service.

Why Your Restaurant Needs a Commercial Undercounter Ice Maker

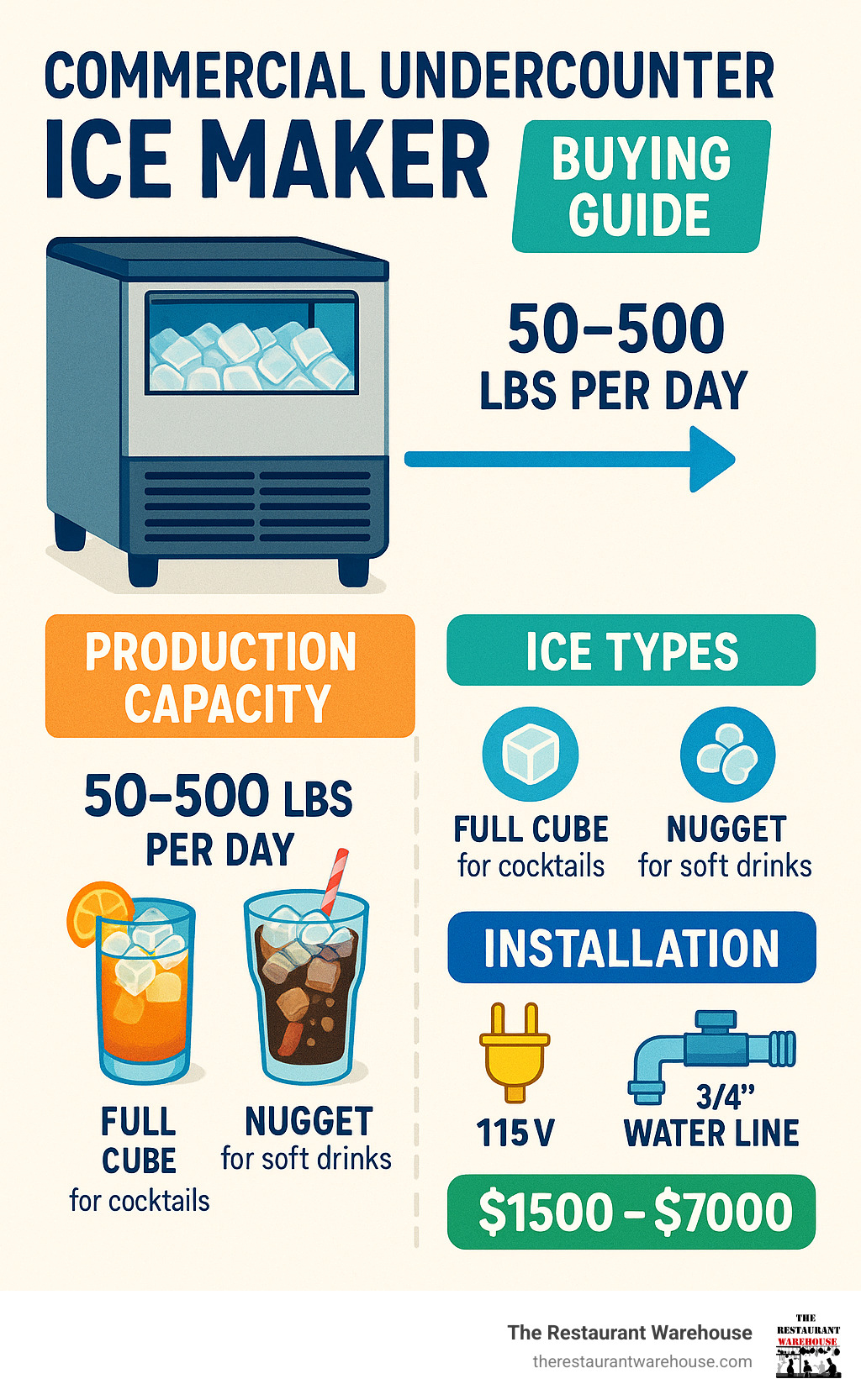

A commercial undercounter ice maker is a compact, self-contained ice production unit designed to fit beneath counters or in tight spaces where traditional floor-standing models won't work. These space-saving workhorses produce between 50-500 pounds of ice per day while storing 25-90 pounds in built-in bins.

Quick Answer for Buyers: - Best for small spaces: Bars, cafes, food trucks, small restaurants - Production range: 50-500 lbs ice per 24 hours - Ice types: Full cube, half dice, nugget, flake, gourmet - Price range: $1,500-$7,000 - Key features: Built-in storage, front ventilation, 115V plug-and-play

Restaurant owners love undercounter units because they deliver ice right where it's needed most - behind the bar, at prep stations, or in server areas. Unlike bulky modular systems, these compact machines require minimal floor space and often need just a water line and standard electrical outlet.

The 2025 models bring exciting upgrades: Energy Star ratings that cut operating costs, smart diagnostics that prevent downtime, and eco-friendly refrigerants. Modern units now offer models producing up to 40 pounds more ice daily than previous generations.

Whether you're opening a craft cocktail bar or upgrading your cafe's beverage station, choosing the right undercounter ice maker means matching production capacity to peak demand, selecting the ideal ice type for your menu, and ensuring proper installation for years of reliable service.

Commercial undercounter ice maker vocab explained: - commercial ice machine not making ice - ice machine cleaning

The Basics of Undercounter Ice Makers

Let's explore what makes a commercial undercounter ice maker such a game-changer for busy restaurants and bars. These clever little machines pack serious ice-making power into surprisingly tight spaces - some models are just 14 inches wide, yet still churn out hundreds of pounds of ice daily.

Think of them as the Swiss Army knife of ice equipment. Unlike those massive modular systems that dominate your kitchen floor, undercounter units tuck neatly beneath counters while delivering everything you need: ice production, storage, and easy access all in one compact package.

The real beauty lies in their self-contained design. No need to coordinate separate ice makers, storage bins, and complex plumbing runs. Everything happens inside one unit that plugs into a standard 115V outlet and connects to your water line.

When it comes to ice types, you've got options. Full-cube ice works perfectly for cocktails and premium beverages, while half-dice handles everything from soda fountains to food displays. Want something special? Gourmet ice creates crystal-clear cubes that won't dilute expensive spirits, nugget ice gives customers that satisfying chewable texture, and flake ice keeps seafood displays looking fresh.

Production capacity typically ranges from 50-500 pounds per 24 hours, depending on your needs and budget. Most units earn Energy Star ratings for efficiency and carry NSF certification for food safety. Don't forget about noise level - newer models run surprisingly quietly, so they won't disrupt your dining room atmosphere.

Commercial vs. Residential Models

It might be tempting to grab a cheaper residential undercounter ice maker, but it's a classic case of "you get what you pay for." Commercial models are engineered for the relentless pace of a foodservice environment. They are built with durable materials to withstand constant use and can produce anywhere from 50 to over 500 pounds of ice daily, ensuring you never run out during a dinner rush. Residential units, on the other hand, are designed for occasional use, producing a fraction of that amount and would quickly fail under the pressure of a busy bar or café. Investing in proper restaurant equipment from the start saves you from costly replacements and service interruptions down the line.

How Do These Ice Makers Actually Work?

The ice-making magic starts when water flows over a chilled evaporator plate. As eco-friendly refrigerant R-290 circulates through the system, it pulls heat from the water, causing it to freeze into your chosen cube shape.

Here's where it gets interesting: during the cube harvest cycle, the system briefly reverses direction, warming the evaporator just enough to release the finished ice into the storage bin below. It's like giving the evaporator a gentle shake to drop the cubes.

Most units use air-cooled condensers to handle heat rejection - much simpler than water-cooled systems that need additional plumbing. When it comes to drainage, you'll choose between gravity drain systems (which need a floor drain within 6 feet) or pump drain models that can push water uphill to distant drains.

The whole process repeats automatically until the bin fills up, then the machine takes a well-deserved break until you need more ice.

The Biggest Benefits for Your Business

Space saving tops every restaurant owner's wish list, and undercounter units deliver in spades. These machines fit where floor-standing models simply can't - behind bars, under prep counters, even in food trucks where every inch counts.

Quick access means your bartenders and servers aren't hiking across the kitchen for ice during the dinner rush. Having ice right at the point of use dramatically improves workflow and keeps customers happy.

Less heat in your kitchen is always welcome. Unlike massive ice machines that dump serious thermal load into your space, undercounter units with front ventilation keep things cool. Your HVAC system will thank you, and your kitchen staff will stay more comfortable.

Front ventilation also means easier installation - no need to worry about side clearances for airflow. Just slide the unit into place and you're ready to go.

Mobility gives you flexibility. Many undercounter units can move with you if you relocate or redesign your space. Try doing that with a built-in modular system.

Built-in storage eliminates the need for separate ice bins, simplifying your equipment footprint while maintaining that ideal 2:1 storage-to-production ratio that keeps ice available when you need it most.

How to Choose the Best Undercounter Ice Maker

Shopping for a commercial undercounter ice maker in 2025 means navigating better technology, smarter features, and more options than ever before. The good news? Prices remain reasonable, with solid entry-level units starting around $1,500 and premium high-capacity models topping out near $7,000. For buyers balancing startup costs with performance, financing your ice equipment can help spread the investment over time while securing the production capacity you need today.

Here's what catches many buyers off-guard: ice production ratings use two different temperature conditions. You'll see a higher number for 70°F air/50°F water (ideal lab conditions) and a lower number for 90°F air/70°F water (real commercial kitchen conditions). Always plan around that second, more realistic number - your kitchen probably runs closer to 90°F during busy service than the perfect 70°F.

Smart buyers focus on the certifications that matter: NSF ensures your ice meets sanitation standards, ETL covers electrical safety, and Energy Star ratings help slash operating costs. These aren't just stickers - they're your protection against health department issues and surprise electric bills.

Most commercial undercounter ice makers follow a simple 2:1 storage-to-production ratio. A machine producing 200 pounds daily typically stores about 100 pounds. This ratio works well for steady service, but consider your peak demand patterns when sizing up.

Installation stays refreshingly simple with most units requiring just a 3/4-inch water supply and standard 115V electrical outlet. Higher-capacity models might need 208V power, but the majority plug into regular commercial outlets.

Exploring Top Brands and Price Points

Once you start looking at specific models, you'll notice a few key brands and a pretty wide price range. Don't let the options overwhelm you. Understanding who the major players are and what drives the cost will make your decision much easier. It’s all about finding that sweet spot between a brand you can trust and a price that fits your budget, ensuring you get a machine that will work hard for your business for years to come.

Leading Brands in the Industry

When you begin to shop for restaurant equipment, you'll quickly see a few names that consistently stand out in the world of commercial ice. Brands like Hoshizaki, Manitowoc, and Scotsman are widely recognized for their performance, durability, and innovative features. These are the industry workhorses, found in busy kitchens and bars across the country for good reason—they are built to last. While these premium brands often come with a higher price tag, they set the standard for what a reliable commercial ice machine can do. Knowing these benchmarks helps you evaluate all your options and understand what to look for in terms of quality and functionality, no matter which brand you ultimately choose.

What to Expect for Pricing

The investment for a commercial undercounter ice maker typically falls between $1,500 and $7,000. What causes such a big gap? The main factors are ice production capacity, the type of ice it makes, and advanced features like smart diagnostics. You might see cheaper units on consumer websites, but it's critical to distinguish between residential models and true commercial equipment. Commercial machines are NSF-certified for food safety and built with heavy-duty components to withstand the demands of a restaurant environment. For business owners managing upfront costs, restaurant equipment financing is a practical path that allows you to get the durable, high-capacity machine you need now without straining your capital.

What Size Ice Maker Do You Really Need?

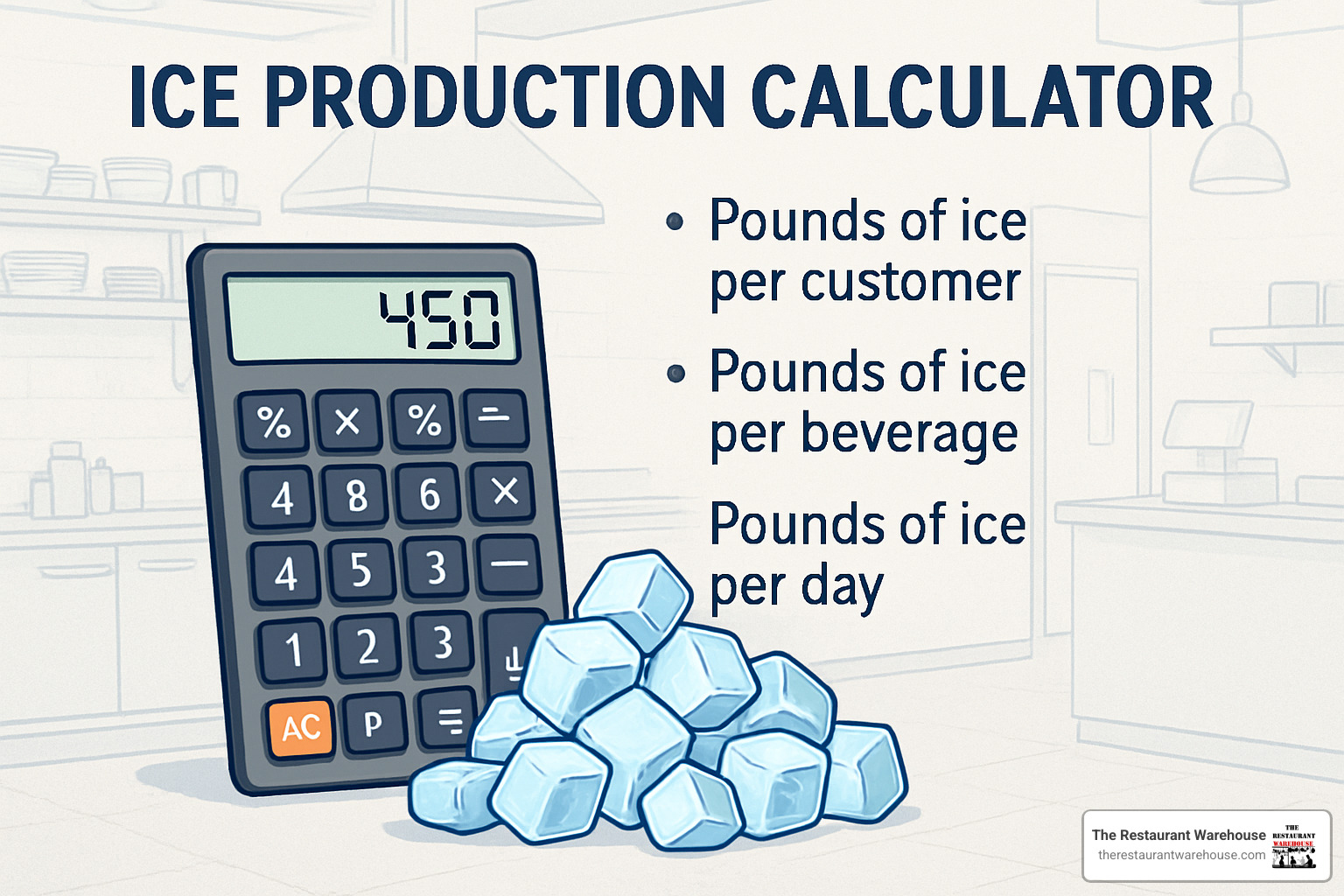

Getting the size right saves money and prevents those awkward moments when you run out of ice during the dinner rush. The math isn't complicated, but it's crucial.

Start with your patron count during peak hours, not average daily traffic. Restaurants typically need 1.5 pounds of ice per customer, while bars and cocktail lounges require up to 3 pounds per patron due to drink-heavy service. Coffee shops and cafes usually fall somewhere between with lighter ice needs.

Don't forget the 20% growth buffer - it accounts for busier-than-expected nights, seasonal variations, and business growth. Summer months can easily double ice consumption, especially if you add frozen drinks to the menu or expand outdoor seating.

Your service style matters too. Fast-casual spots with lots of fountain drinks need steady production throughout operating hours. Fine dining restaurants might see concentrated peak-hour demand during specific service windows, requiring higher production capacity even if daily totals seem manageable.

Think seasonally and plan for your busiest periods, not your average Tuesday afternoon. That extra capacity pays for itself the first time you avoid disappointed customers during a heat wave.

Choosing Your Ice: From Cubes to Nuggets

The shape of your ice affects everything from drink quality to customer satisfaction. Choose wrong, and even perfect production capacity won't save your beverage program.

Full cubes melt slowly and look professional, making them perfect for cocktails and premium spirits where dilution control matters. These crystal-clear cubes maintain drink integrity longer and create that satisfying clink in glassware that customers associate with quality.

Half dice offers the best versatility for mixed beverage programs. These cubes cool drinks effectively while fitting easily into narrow glassware. Most restaurants choose half dice as their all-purpose ice since it works well for both soda fountain drinks and simple cocktails.

Nugget ice has become incredibly popular for its soft, chewable texture that customers love in soft drinks and blended beverages. Healthcare facilities particularly appreciate nugget ice since it's easier for patients to chew and swallow. The downside? It melts faster than solid cubes.

Flake ice excels at seafood display and salad bar applications where you need ice that conforms to irregular shapes. It's not ideal for beverages but keeps food products properly chilled and attractively presented.

Gourmet cubes represent the premium option with crystal-clear appearance and nearly 100% ice-to-water ratio. These slow-melting cubes are perfect for upscale establishments serving premium spirits where presentation and minimal dilution matter most.

Beyond the Cube: Crescent, Bullet, and Specialty Ice

While cubes and nuggets get most of the attention, a few other specialty shapes can really define your beverage service. Crescent ice, with its unique half-moon form, is a fantastic all-rounder. It stacks neatly in a glass, which prevents splashing when you pour drinks, and it provides excellent cooling for soft drinks and cocktails without watering them down too quickly. Then there's bullet ice, a small, cylindrical option with a hollow center. This shape is a favorite in fast-paced bars and cafes because it cools beverages rapidly and has a soft, chewable texture that customers enjoy. For establishments focused on high-end presentation, gourmet ice remains the gold standard. These crystal-clear, slow-melting cubes ensure that premium spirits are chilled perfectly while maintaining their full flavor profile. Choosing the right ice shape is a small detail that makes a big impact on the customer experience, and having the right restaurant equipment to produce it is key.

Key Features That Make a Difference

Once you've determined the size and ice type you need, it's time to look at the features that separate a good ice maker from a great one. These details impact everything from your utility bills to your daily workflow and maintenance schedule. Understanding the core differences in how these machines operate will help you select a unit that not only fits your space but also supports your business operations efficiently. Choosing the right features from the start prevents headaches down the road and ensures you get the best return on your investment. Let's break down the most important options you'll encounter when you shop for restaurant equipment.

Air-Cooled vs. Water-Cooled Systems

You can choose between ice makers that use air or water to cool their internal components. Air-cooled systems are the most common choice for undercounter models because they are generally more affordable and easier to install. They use a fan to pull in ambient air and blow it across the condenser coils to dissipate heat. The main consideration is that they require adequate clearance for airflow and will release some warm air into your kitchen. Water-cooled systems, on the other hand, use a continuous flow of water to cool the condenser. They are highly efficient in very hot kitchens and operate more quietly, but they significantly increase water consumption and utility costs, making them a less common choice for smaller establishments.

Built-In or Freestanding?

The beauty of an undercounter ice maker is its ability to save precious floor space. Most of these machines are designed for built-in installation, meaning they can fit snugly under a standard 34-inch-high counter. To make this possible, they feature front-facing vents for air intake and exhaust, so you don't need to leave clearance on the sides or back. This design is perfect for creating a seamless look in your bar or prep station. While they are designed to be built-in, they can also function as freestanding units if needed. This flexibility allows you to place your ice source exactly where your staff needs it most, improving efficiency during busy service hours and keeping your operation running smoothly.

Helpful Features for Daily Use

Modern ice makers come with features designed to make your life easier. Many machines now offer a self-cleaning or auto-clean function, which is a lifesaver for busy kitchens. This feature automates the descaling and sanitizing process, reducing manual labor and ensuring your ice is always clean and safe. Another useful tool is a 24-hour timer, which lets you schedule ice production to align with your operating hours, saving both energy and water. Look for models with durable stainless steel exteriors, as these machines are built to withstand the daily demands of a commercial environment. Quiet operation is also a key feature, especially if the unit will be located near customer seating, ensuring it doesn't disrupt the dining experience.

Our Top Picks for Lighter Use (Under 150 lbs/Day)

Smaller operations like compact bars, cafés, and office pantries don't need massive ice production - they need reliable, space-efficient units that deliver quality ice without breaking the budget.

The gourmet cube focus makes sense at this capacity level since these establishments often prioritize beverage quality over sheer volume. Crystal-clear cubes create a premium impression that justifies higher drink prices and builds customer loyalty.

Units in this range typically feature gravity drainage, which simplifies installation since you don't need drain pumps - just a floor drain within 6 feet. Many offer reversible doors for flexible placement in tight spaces, and some even carry outdoor installation approvals for patio bars.

Storage bins typically hold 25-40 pounds, perfect for operations that use ice steadily throughout the day rather than in huge bursts. The compact footprint means these units fit where larger machines simply won't work.

Digital controllers on better models provide real-time diagnostics and allow operators to adjust cube thickness for customized sizes - a feature that used to be exclusive to much more expensive units.

Best Mid-Range Workhorses (150-300 lbs/Day)

This sweet spot serves most restaurants, hotel pantries, and busy bars that need serious ice production without the space requirements of modular systems. These are the workhorses that handle diverse beverage programs day after day.

Half-dice versatility shines in this category since these operations typically serve everything from craft cocktails to soft drinks to iced coffee. The medium-sized cubes work well across different beverage types without requiring multiple ice machines.

Storage bins scale up to 75-80 pounds, maintaining proper storage ratios while reducing the frequency of ice harvesting during busy periods. Forward-sliding bins on premium models provide easy access to refrigeration components for faster maintenance.

More robust compressors and improved diagnostics become standard features at this level. Digital controllers display production stages and alert operators to maintenance needs, reducing unexpected downtime during crucial service periods.

Some models in this range include intelligent features like growth inhibitors that extend cleaning intervals and predictive diagnostics that warn about potential issues before they cause problems.

High-Capacity Picks for Busy Kitchens (300+ lbs/Day)

When space is limited but ice demand is massive, high-capacity undercounter units deliver modular-system performance in compact footprints. These powerhouses serve banquet halls, nightclubs, and high-volume restaurants where running out of ice means lost revenue.

Twin evaporators and heavy-duty compressors push production to 500+ pounds daily in some commercial models. These units often require 208V power instead of standard 115V outlets, and they need improved ventilation compared to smaller models.

Advanced features become standard: multiple ice size settings, predictive diagnostics, and automatic cleaning cycles. Some models include remote monitoring capabilities that alert managers to maintenance needs via smartphone apps.

Storage bins hold 75-90 pounds to maintain proper ratios, but high-capacity production means more frequent harvesting during peak periods. Consider your workflow patterns carefully when positioning these units - staff will be accessing them frequently during busy service.

For detailed specifications on high-capacity models, check the comprehensive E-Document Catalog for detailed specs covering electrical requirements, dimensions, and performance data.

The investment in high-capacity commercial undercounter ice makers pays off quickly in operations where ice shortage creates immediate problems. Better to have too much capacity than to disappoint customers during your busiest periods.

Installation and Care for Your Ice Maker

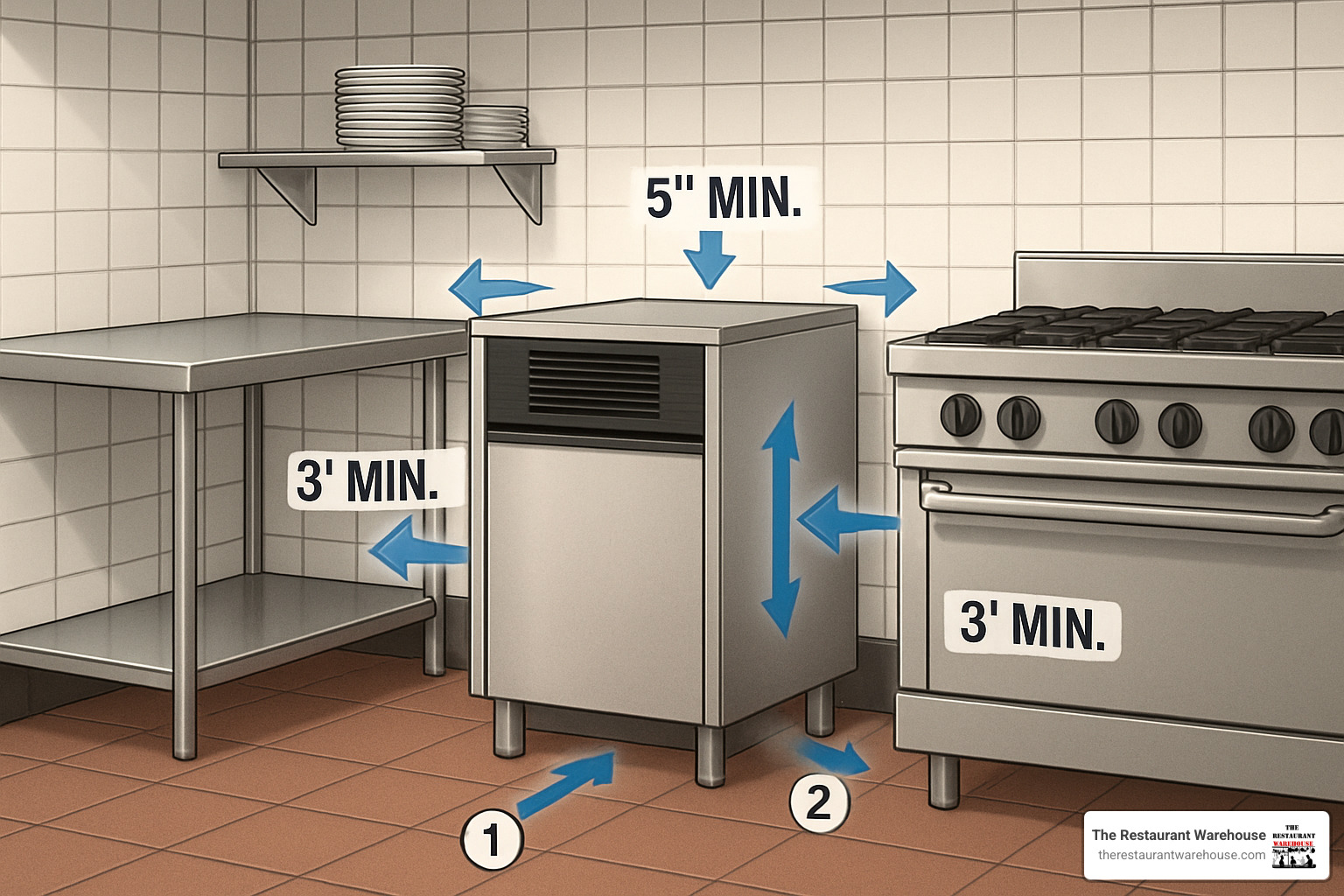

Proper installation determines whether your commercial undercounter ice maker delivers years of reliable service or becomes a maintenance headache. Most units require a 3/4-inch water supply line, dedicated 115V GFCI outlet, and floor drain within 6 feet for gravity drainage models.

Ventilation is critical - maintain at least 6 inches clearance on sides and rear for air-cooled models. Front-venting units offer more flexibility but still need adequate airflow to prevent overheating. Ambient temperatures should stay between 45-100°F for optimal performance.

Water quality dramatically impacts ice quality and equipment lifespan. Install inline water filters to remove chlorine, sediment, and minerals that cause scale buildup. Many models include pre-drilled mounting points specifically for filter installation.

For comprehensive installation guidance, check our detailed Atosa Under Counter Ice Machine Installation guide covering electrical, plumbing, and ventilation requirements.

Getting Drainage Right

Gravity Drains and Pump Drain Options

Let's talk about one of the most important, yet often overlooked, parts of setting up your ice maker: drainage. Getting this right from the start saves you from future headaches like leaks or water damage. The most common setup is a gravity drain, which is exactly what it sounds like. It uses the simple force of gravity to pull meltwater from the ice bin down into a nearby floor drain. For this to work, your installation spot must be located within about six feet of a floor drain, and the drain line needs a consistent downward slope. It’s a simple, reliable, and cost-effective system that works beautifully when your kitchen layout cooperates.

But what if your ideal spot for the ice maker is nowhere near a floor drain? That’s where a pump drain model comes to the rescue. These units have a small internal pump that actively pushes the wastewater out, giving you incredible flexibility to install your ice maker almost anywhere. The pump can push water uphill or across longer distances to connect to a standpipe or sink drain, which is a lifesaver in older buildings or tight layouts where adding a new floor drain isn't practical. When you shop for restaurant equipment, you'll notice drainage type is a key specification, and choosing a pump model can solve a lot of logistical challenges.

Your Simple Cleaning and Maintenance Schedule

Consistent cleaning prevents the bacterial growth and mineral buildup that destroy ice quality and shorten equipment life. Daily tasks include wiping down exterior surfaces and checking for unusual noises or error codes on digital displays.

Weekly cleaning involves sanitizing the ice storage bin and wiping door gaskets with approved sanitizing solutions. Remove any ice buildup around the evaporator and check that the air filter isn't clogged with lint or grease.

Quarterly deep cleaning requires descaling the water system and sanitizing all food-zone surfaces. Modern units feature automatic cleaning cycles that guide operators through the process via LED indicators.

For specific cleaning products and procedures, our comprehensive guide Crystal Clear Ice Awaits: Best Ice Machine Cleaning Solutions Reviewed covers approved cleaners and step-by-step sanitization protocols.

Common Problems and How to Fix Them

Most commercial undercounter ice maker problems stem from simple issues that operators can resolve quickly. No-ice alarms often indicate water supply problems - check that the water valve is fully open and the supply line isn't kinked or frozen.

Low-water errors typically point to clogged water filters or insufficient water pressure. Most units require 10-113 PSI water pressure for proper operation. Replace filters according to manufacturer schedules, typically every 6 months in high-usage applications.

Dirty condensers cause overheating and reduced ice production. Clean the condenser coils monthly using a soft brush and vacuum to remove dust, lint, and grease buildup. This simple maintenance task can restore full production capacity.

Bridging cubes (ice clumping together) usually result from high ambient temperatures or insufficient cleaning. Ensure proper ventilation and increase cleaning frequency during hot weather or high-usage periods.

For comprehensive troubleshooting guidance, our detailed guide Troubleshooting Tips for a Commercial Ice Machine Not Making Ice covers common problems and solutions.

How to Make Your Ice Maker Last Longer

Smart operation practices extend equipment life while reducing operating costs. Use delay cycles during off-peak hours to reduce wear on compressors and save energy. Most modern units allow programming ice production around your service schedule.

LED diagnostics provide early warning of potential problems. Pay attention to error codes and unusual sounds - addressing minor issues quickly prevents major repairs later. Modern units display production stages and maintenance alerts through universally recognizable icons.

Keep ambient temperatures below 90°F whenever possible. Every 10-degree increase in ambient temperature can reduce ice production by 10-15%. Ensure adequate ventilation and consider additional exhaust fans in hot kitchens.

Schedule filter replacements based on water quality and usage volume rather than just time intervals. Hard water areas may require monthly filter changes, while soft water locations might extend to quarterly replacements. Track ice quality and production rates to optimize filter schedules.

Smart Shopping for Your Ice Maker

Using Customer Reviews to Guide Your Choice

Before you commit to a specific ice maker, spend some time with customer reviews. Marketplaces like Amazon offer a massive selection, giving you a broad look at what’s available. Reading through feedback from other restaurant and bar owners provides invaluable insight into how a machine performs in a real-world commercial environment. Look for comments on long-term reliability, actual ice production versus advertised specs, and noise levels during operation. Many undercounter ice machines are made of durable stainless steel and can be installed as built-in or freestanding units, and reviews can tell you how easy the installation process really was for other buyers.

How to Find a Great Deal

Finding the right ice maker is a balance between price and performance. Prices for undercounter models can range from a few hundred dollars to over $2,500, so there’s a machine for nearly every budget. A higher price tag doesn't always equal better value, as some popular commercial models online receive thousands of positive reviews while costing significantly less than premium brands. At The Restaurant Warehouse, we focus on sourcing high-quality, dependable restaurant equipment that performs without forcing you to overspend. If you're managing startup costs, you can also finance your ice equipment to get the machine you need now and pay for it over time.

Checking Availability and Finding Support

A great price on an ice maker doesn't mean much if the unit is back-ordered for months or if you can't get help when you need it. Before you buy, confirm that the model you want is in stock and check the estimated shipping times. A reliable supplier will be transparent about availability and provide excellent customer support. Look for a company with a solid warranty and a knowledgeable team that can answer your questions about everything from installation to maintenance. This post-purchase support is crucial for keeping your operations running smoothly and protecting your investment for years to come.

Stocking Up on Essential Accessories

Your new ice maker is the main event, but don't forget the supporting cast of essential accessories. To keep your machine running efficiently and your ice clean, you'll need a few key items from the start. Stock up on NSF-approved ice scoops to ensure sanitary handling, along with designated ice buckets for transport. A high-quality water filter is non-negotiable; it will improve the taste and clarity of your ice while preventing mineral buildup that can damage your machine. Finally, be sure to have the right ice machine cleaning and sanitizing solutions on hand to follow a regular maintenance schedule.

Frequently Asked Questions about Commercial Undercounter Ice Makers

Getting the right commercial undercounter ice maker means asking the right questions before you buy. These are the questions we hear most from restaurant owners, and frankly, they're the same ones we asked when we started helping foodservice operators find the perfect ice solutions.

What Certifications Should I Look For?

NSF certification should top your must-have list - it's the gold standard for commercial food service sanitation. When health inspectors visit your restaurant, they'll look for this certification to ensure your ice maker meets strict hygiene standards for water contact surfaces and ice storage areas.

ETL listing covers the electrical safety side, ensuring your unit won't become a fire hazard or electrocution risk. This certification is particularly important since ice makers combine water and electricity in ways that demand careful engineering and testing.

Energy Star qualification might seem optional, but it's actually a smart financial move. These units use 15-20% less energy than standard models, which translates to real savings on your monthly utility bills. Over a unit's 7-10 year lifespan, those savings often pay for the slightly higher upfront cost.

AHRI certification provides the verified capacity ratings you need for accurate sizing. This independent testing at standard conditions (90°F air/70°F water) lets you compare apples-to-apples performance between different manufacturers. Without AHRI certification, you're essentially guessing at actual production capacity.

How Much Ice Will My Restaurant Use?

The math starts simple but gets interesting when you factor in your specific operation. Seating capacity times 1.5 pounds works for most restaurants, while bars need closer to 3 pounds per patron due to cocktail service and the fact that people tend to drink more when they're socializing.

Coffee shops and cafes typically need much less - about 0.5-1 pound per customer since most drinks use minimal ice. But if you're planning to add blended drinks or cold brew programs, bump that number up significantly.

Here's where the 20% safety buffer becomes crucial. Summer heat waves, unexpected private parties, or a viral social media post about your signature cocktail can double your normal ice demand overnight. Better to have extra capacity than to run out during your busiest service.

Track your actual usage for a few weeks if possible. Many operators find their calculated needs don't match reality - sometimes they need more ice than expected, sometimes less. Real-world data beats theoretical calculations every time.

Do I Need a Floor Drain for Installation?

Absolutely, but you'll need a pump-drain model instead of the standard gravity-drain units. These models include built-in pumps that push water upward to sinks or other drainage points, giving you much more flexibility in placement.

Pump-drain models cost slightly more upfront - typically $200-400 extra - but they open up installation possibilities in locations where floor drains simply don't exist. The pumps handle about 1 GPM flow rates and can push water up to 6 feet vertically or 50 feet horizontally.

Check your local plumbing codes first though. Some jurisdictions require direct floor drainage for commercial ice equipment as a safety measure. Your local health department can clarify what's allowed in your area before you make equipment decisions.

The pump systems are generally reliable, but they do add one more component that could potentially need service down the road. Still, for many operators, the installation flexibility makes pump-drain models the only practical choice.

Making the Right Choice for Your Business

Selecting the perfect commercial undercounter ice maker for your restaurant doesn't have to feel overwhelming. The 2025 models bring exciting improvements - eco-friendly R-290 refrigerants that protect the environment while Energy Star ratings slash your monthly electric bills.

The secret to success lies in right-size selection. We've seen too many restaurant owners make costly mistakes - choosing units too small leaves customers waiting for drinks during the dinner rush, while oversized machines gobble up precious counter space and energy. Our experience shows that mid-range units producing 150-300 pounds daily hit the sweet spot for most restaurants, delivering reliable capacity without breaking the budget.

Proactive maintenance separates the operators who enjoy years of trouble-free service from those dealing with emergency repair calls during Saturday night service. The good news? Today's smart ice makers practically maintain themselves with automatic cleaning cycles and diagnostic alerts that tell you exactly what needs attention.

Modern units with LED diagnostics take the guesswork out of maintenance. When the Manitowoc NEO series displays a cleaning reminder, you know it's time to descale - no more wondering if that strange noise means trouble. This predictive approach prevents small issues from becoming expensive headaches.

At The Restaurant Warehouse, we know that every ice cube matters to your operation's success. Whether you're crafting artisanal cocktails that demand crystal-clear gourmet cubes or serving hundreds of soft drinks with perfect half-dice ice, we've got you covered.

Our wholesale pricing cuts out the retail markup that makes quality equipment feel out of reach. Why pay dealer commissions when you can get the same premium ice makers at prices that make sense for your bottom line? From compact 50-pound units perfect for coffee shops to high-capacity workhorses cranking out 500 pounds daily, our inventory serves operations of every size.

Ready to upgrade your ice game? Our team understands the unique challenges facing today's foodservice operators. We're here to help you choose the right unit, steer installation requirements, and keep your operation running smoothly for years to come.

For more insights on choosing and maintaining commercial ice equipment, explore our comprehensive Ice Maker resource center covering everything from sizing calculations to troubleshooting tips.

Key Takeaways

- Size for Your Busiest Day, Not Your Average One: Plan for peak demand by using the 1.5 lbs of ice per restaurant guest or 3 lbs per bar patron rule, and always add a 20% buffer. This ensures you won't run out of ice during a surprise rush or a summer heatwave.

- Choose an Ice Shape That Complements Your Drinks: The right ice improves your beverage program. Use slow-melting full or gourmet cubes to protect the integrity of cocktails and spirits, and select versatile half-dice or chewable nugget ice for soft drinks and casual beverages.

- Focus on a Flawless Setup for Long-Term Reliability: Your ice maker's lifespan depends on its installation. Confirm you have the correct drainage (gravity or pump), proper ventilation for airflow, and a high-quality water filter to prevent scale buildup and ensure consistent performance from day one.

Related Articles

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment