Freeze Frame – Best Food Service Ice Makers to Keep Your Customers Cool

The Business of Ice: Why Food Service Ice Makers Matter

Food service ice makers are essential equipment for restaurants, bars, cafes, and any establishment serving cold beverages or requiring ice for food display and preservation.

Quick Answer: Best Food Service Ice Makers by Type * Modular (High Volume): Commercial Indigo Series, Professional Elevation Series * Undercounter (Space-Saving): Premium KM Series, Commercial NEO Series * Countertop (Convenience): Professional E7 Series, Commercial CNF Series * Dispensers (Self-Service): Professional Pearl Ice Dispensers, Commercial Symphony Series * Energy-Efficient: ENERGY STAR®-certified models can save up to 15% on energy costs

Ice is much more than frozen water in the food service industry—it's a critical operational component that directly impacts customer satisfaction, food safety, and your bottom line. Whether you're chilling drinks at a busy bar, displaying fresh seafood, or serving healthcare patients, having the right ice machine ensures your business never misses a beat when customers want to cool down.

Commercial ice makers can produce anywhere from 100 pounds to over 2,000 pounds of ice per day, depending on the model. Finding the perfect balance between your peak demand, available space, and budget is crucial for operational efficiency.

"Nothing is more frustrating than running out of ice during your busiest service period," notes a veteran restaurant owner with 20 years in the business. "The right commercial ice maker becomes the unsung hero of your operation."

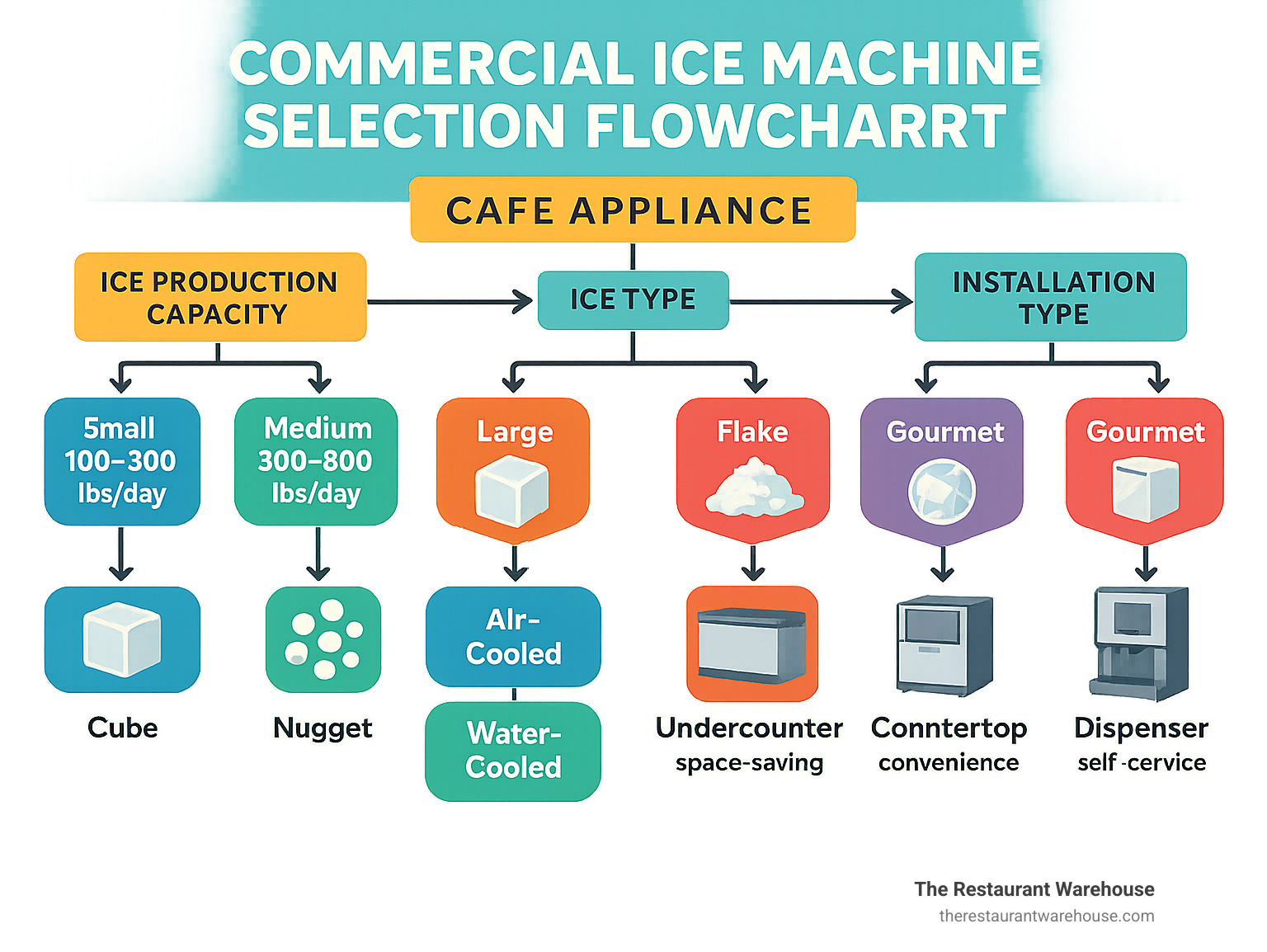

Understanding your specific needs is the first step in selecting the ideal ice machine. Do you need crystal-clear cubes for premium cocktails, soft chewable nuggets for healthcare applications, or flake ice for food displays? Each type serves a distinct purpose in the food service ecosystem.

In this comprehensive guide, we'll help you steer commercial ice makers to find the perfect match for your establishment—one that keeps both your customers and your profit margins cool.

Understanding Food Service Ice Makers

Food service ice makers are the unsung heroes of the restaurant world – powerful commercial machines built to handle the non-stop demands of busy kitchens, bars, hotels, and healthcare facilities. Unlike the ice maker in your home refrigerator, these workhorses are engineered for reliability and volume, producing ice consistently hour after hour while meeting strict health regulations.

When you invest in a quality commercial ice machine, you're getting more than just frozen water. You're securing a critical tool that improves your beverages, maintains food freshness, and keeps up with your busiest rush periods without breaking a sweat. The best food service ice makers produce crystal-clear, taste-neutral ice that complements your carefully crafted drinks rather than diluting their flavors.

Modern commercial ice machines operate through an ingenious continuous cycle: water flows over a freezing evaporator plate, forms ice of the perfect thickness, and then a harvest cycle releases that ice into a storage bin – ready for your staff to scoop and serve. This automated process ensures you're never caught without ice during crucial service times.

Why Food Service Ice Makers Are Essential

Beyond simply chilling drinks, food service ice makers are fundamental to successful operations for several important reasons:

Food safety depends on proper temperature control – ice maintains the ideal temperature for perishable items on buffet lines and seafood displays, extending shelf life while preserving visual appeal. Health departments actually classify commercial ice as a food product, making purpose-built machines with antimicrobial components essential for meeting health code requirements.

"Ice is one of the most overlooked profit drivers in food service," notes an experienced restaurant consultant. "The right machine pays for itself through improved beverage quality, reduced waste, and eliminated emergency ice runs."

The quality of your ice directly impacts customer experience too. Clear, perfectly formed ice lifts the perceived value of your drinks and reflects your commitment to quality. And operationally speaking, running out of ice during a busy service period can bring everything to a grinding halt – especially at the bar where nearly every order requires it.

Perhaps most compelling for your bottom line: producing ice in-house is dramatically more economical than purchasing bagged ice, especially if you serve hundreds of drinks daily.

How Food Service Ice Makers Boost Efficiency

A properly sized food service ice maker creates workflow magic throughout your operation:

Smart placement of your ice machines can significantly reduce staff movement and improve service speed. Imagine having undercounter units right at your bar stations instead of sending bartenders to a distant storage room during a Friday night rush.

The labor savings alone can justify the investment – no more assigning staff to manually fill ice bins or make emergency runs to the store when supplies run low. Meanwhile, the consistency of machine-produced ice ensures uniform drink recipes and presentation that customers come to expect.

Modern food service ice makers also help manage resources more effectively. With proper planning, you'll produce only what you need, reducing both energy waste from overproduction and profit loss from melting. Many newer models even include programmable functions that pause production during off-hours, reducing utility costs without sacrificing availability during service times.

When chosen wisely, your ice maker becomes more than equipment – it becomes an integral part of your kitchen's workflow, quietly supporting operations while your team focuses on creating exceptional dining experiences that keep customers coming back.

Types & Uses: Matching the Right Machine to Your Menu

Selecting the appropriate food service ice maker is a bit like finding the perfect pair of shoes – it needs to fit your space, handle your workload, and complement your style. Let's walk through the main types of ice machines and help you find your perfect match:

Modular vs. Undercounter vs. Countertop

Think of modular ice machines as the workhorses of the ice world. These separate ice-making heads sit proudly atop storage bins, churning out an impressive 250-2,000+ pounds of ice daily. They're the go-to choice for busy hotels, hospitals, and large restaurants where ice demand never seems to end. The Professional Elevation Series Modular Cube Ice Maker, for instance, can produce about 800 pounds of ice every 24 hours – enough to keep a hotel banquet operation running smoothly all day long. The trade-off? They need more space and make a bit more noise, but their production capacity makes them worth every square inch.

Tucked neatly beneath your bar or prep counter, undercounter ice machines offer the perfect balance of convenience and capacity. Producing between 50-350 pounds daily, these units are ideal for bars, coffee shops, and smaller restaurants. Picture your bartenders seamlessly reaching down for fresh ice without missing a beat in their cocktail preparation. The Commercial UYF-0310A Neo® undercounter model, for example, produces up to 290 pounds of ice daily with 119 pounds of storage – perfect for keeping drinks flowing during happy hour. Just keep in mind they do generate heat in confined spaces, so proper ventilation is key.

For the smallest spaces with modest ice needs, countertop ice machines offer a practical solution. These compact units (producing 15-200 pounds daily) sit comfortably on countertops or shelves, making them perfect for coffee shops, office breakrooms, or healthcare stations. The Commercial CNF0201A-L countertop nugget ice maker exemplifies this category – small in size but mighty in convenience for self-service areas.

| Machine Type | Width Range | Depth Range | Height Range | Typical Production |

|---|---|---|---|---|

| Modular | 22"-48" | 24"-34" | 21"-31" (head only) | 250-2,000+ lbs/day |

| Undercounter | 15"-30" | 24"-28" | 33"-38" | 50-350 lbs/day |

| Countertop | 14"-17" | 17"-24" | 20"-35" | 15-200 lbs/day |

Dispensers & Specialty Units

Beyond the standard configurations, the ice machine world offers some fascinating specialists that solve unique challenges in food service.

Ice and water dispensers combine two essential services in one sleek package. With production capacities of 125-500 pounds daily, these units are particularly valuable in healthcare settings where touchless operation reduces cross-contamination concerns. They're also perfect for hotel corridors and self-service areas where guests can help themselves to both ice and water without staff assistance.

When hotel guests head out for ice, they're interacting with hotel ice dispensers – machines specifically designed for high-traffic, self-service environments. These durable units (producing 300-1,000+ pounds daily) often include bag fillers and are built to withstand constant use. Just remember, with many hands using these machines, regular sanitizing is non-negotiable.

For the craft cocktail bar looking to lift their ice game, specialty ice makers create those perfect spheres, crystal-clear cubes, and artisanal blocks that transform ordinary drinks into Instagram-worthy creations. While they typically produce less volume, the premium presentation and slower melting rates can set your establishment apart from competitors.

Got an outdoor bar or kitchen? Outdoor-rated units feature weatherproof controls and corrosion-resistant components to handle sun, rain, and everything in between. They're perfect for pool areas and outdoor dining spaces, though they may need some extra TLC during winter months in colder climates.

For those specifically focusing on bar operations, our Bar Ice Machines Guide offers deeper insights into creating the perfect ice program for your cocktail service.

The right food service ice maker isn't just equipment – it's an investment in your operation's efficiency and your customers' satisfaction. At The Restaurant Warehouse, we're happy to help you steer these choices to find the perfect match for your menu and space.

Capacity, Ice Shapes & Selection Calculator

Let's talk about one of the most important decisions you'll make when choosing your food service ice maker: how much ice you actually need. Getting this right means never running out during your Friday night rush—but also not wasting energy producing ice that just melts away.

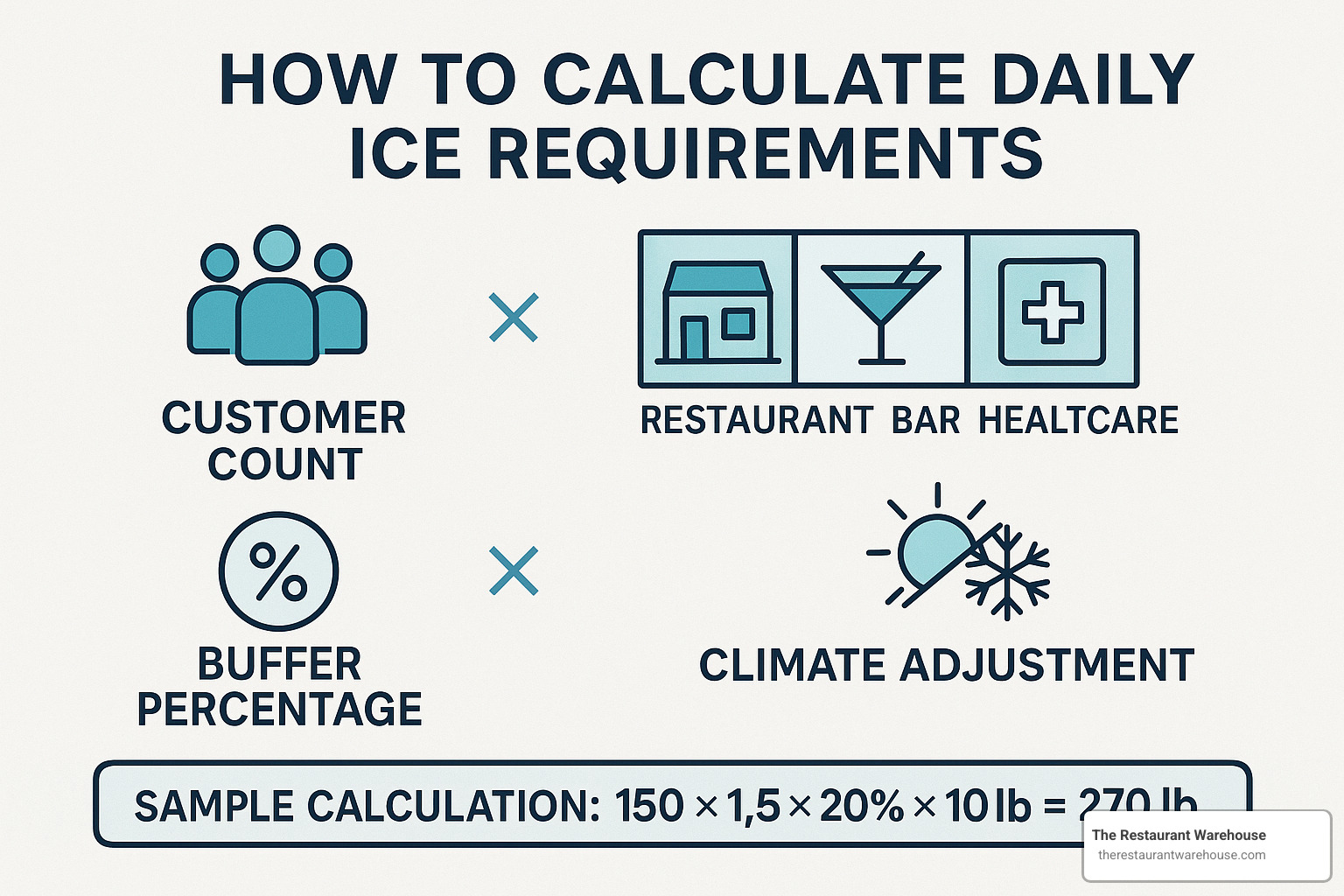

Daily Demand Formula

Figuring out your ice needs isn't just guesswork. Here's a practical approach that restaurant owners have relied on for years:

Start with your busiest day—that Saturday when every table is full and the bar is three-deep. Count those customers and multiply based on your service style. A full-service restaurant typically needs about 1.5 pounds per customer, while a cocktail bar might require double that at 3 pounds per guest. Quick-service spots can get by with less (about 0.7 pounds per customer), while healthcare facilities need around 2 pounds per patient.

"I learned the hard way that running out of ice on a hot summer day is a disaster you can't recover from," shares a seasoned restaurant owner. "Now I always build in a buffer—it's cheaper than disappointing customers."

If you're serving specialty drinks like frozen margaritas or blended daiquiris, add another 50% to your calculations. And don't forget about climate—if you're in Miami or Phoenix, you'll need 20-30% more ice than the same restaurant in Chicago during winter months.

Sample Calculation: For a full-service restaurant serving 200 customers on its busiest day: * 200 customers × 1.5 lbs = 300 lbs base requirement * Add 20% buffer: 300 × 1.2 = 360 lbs daily capacity needed

Manufacturer ratings assume perfect conditions (70°F air/50°F water). When your kitchen heats up to 90°F, that 800-pound machine might only give you 645 pounds. Similarly, your storage bin should hold at least 20% of your daily needs to handle those inevitable rush periods.

Ice Shape Applications

Ice isn't just ice—the shape matters tremendously depending on what you're serving.

Cube Ice is the classic workhorse. Hard, clear, and slow-melting, these cubes are perfect for mixed drinks and spirits on the rocks. They look attractive in the glass and minimize dilution, preserving the flavor of premium spirits. Available in various sizes from full cubes (1¼") down to half dice (⅞" × ⅞"), they're the standard choice for most bars and restaurants.

Flake Ice feels like fresh snow—soft, moldable, and quick to cool. It's ideal for food displays, especially seafood, because it molds gently around delicate items without bruising them. Seafood counters love flake ice because it creates beautiful presentations while keeping products at the perfect temperature. The downside? It melts quicker than cubes.

Nugget Ice (sometimes called "pearl ice") has developed an almost cult-like following. These chewable, soft pieces absorb flavors and are incredibly popular in soft drinks. They're perfect for healthcare settings where patients might need to chew ice, and quick-service restaurants love how they efficiently displace liquid in drinks. Just be aware they tend to melt faster than traditional cubes.

Gourmet Ice makes a statement. These oversized, often crystal-clear cubes or spheres are the hallmark of craft cocktail programs and high-end spirits service. They melt extraordinarily slowly, maintaining drink integrity while creating an impressive visual presentation. The trade-off is lower production capacity and higher cost per pound.

Micro Chewblet ice takes the nugget concept even smaller, creating tiny, highly chewable pieces that cool drinks rapidly and are especially popular in healthcare settings where ease of consumption matters.

For an even deeper dive into matching ice types to your specific restaurant needs, check out our Ice Machine Restaurant Guide.

The science behind ice safety is well-documented. According to research shared by WebMD's food safety section, proper ice handling is crucial for preventing contamination and foodborne illness—something every food service professional should take seriously.

Choosing the right capacity and ice shape isn't just about operations—it directly impacts your guests' experience and your bottom line. The perfect food service ice maker matches your volume needs while producing the ideal ice type for your specific menu offerings.

Features, Cooling Methods & Buying Checklist

Choosing the right food service ice maker isn't just about capacity and shape—it's also about the features that will keep your machine running efficiently for years to come. Let's explore what makes today's ice machines smarter, cleaner, and more efficient than ever before.

Energy Efficiency & Certification

Nobody wants to watch their profits melt away through high utility bills. That's why energy efficiency should be at the top of your ice maker shopping list:

ENERGY STAR® certification is more than just a sticker—it's a promise that your machine uses about 15% less energy and 10% less water than standard models. Over the 7-10 year lifespan of a commercial ice maker, these savings add up dramatically. A typical 100-pound daily production machine consumes around 10 kWh of electricity each day—which means efficient models can save you hundreds each year.

"I was skeptical about paying more upfront for an energy-efficient model," shares one café owner, "but the utility rebate covered part of the difference, and my electric bill dropped noticeably the first month."

Many utility companies offer substantial rebates for ENERGY STAR®-certified equipment, sometimes covering $200-500 of your purchase price. When you calculate the return on investment, most energy-efficient models pay for their premium price within 1-3 years, then continue saving you money for the rest of their service life.

When it comes to cooling methods, you have three main options, each with distinct advantages:

Air-cooled machines are the workhorses of the industry, using air to remove heat from the refrigeration system. They're popular because they use less water, cost less to operate, and install more easily. The trade-off? They need good ventilation space (usually 6-12 inches on all sides) and will add some heat to your kitchen environment. These are ideal for most standard installations where you have decent airflow and moderate kitchen temperatures.

Water-cooled systems shine in hot environments where air-cooling efficiency drops off. They run quieter and maintain consistent production regardless of kitchen temperature. The downside is higher water consumption—some models use up to 100 gallons to produce 100 pounds of ice. In areas with water restrictions or high water costs, this can be a deal-breaker. However, in extremely hot kitchens, the production consistency might be worth the extra utility expense.

Remote-cooled units offer the best of both worlds by placing the heat-generating condenser away from the ice-making unit, often outdoors. This keeps your kitchen cooler and quieter while improving energy efficiency. The installation is more complex and costs more initially, but for large operations where heat and noise reduction matter, the benefits often justify the investment.

Cleaning & Antimicrobial Tech

Ice is food—a fact that health inspectors take very seriously. Modern food service ice makers now include impressive technologies to keep your ice pure and your maintenance schedule manageable:

Antimicrobial components infused with compounds like AlphaSan® help fight bacteria, mold, and slime between cleanings. These additives are molded directly into food-zone plastics and gaskets, providing continuous protection.

Self-cleaning cycles have revolutionized ice machine maintenance. With the push of a button, these systems run through cleaning and sanitizing routines that once required hours of manual labor. While they don't eliminate the need for periodic deep cleaning, they significantly extend the time between service sessions.

Built-in filtration systems serve double duty by improving ice taste and clarity while reducing scale buildup on critical components. A good filtration system can extend the time between descaling services by 50% or more in hard water areas.

Some manufacturers have developed proprietary technologies that use UV light to continuously battle yeast and bacterial growth in the food zone. These innovations can dramatically reduce the biofilm that makes ice machines notorious maintenance challenges.

Smart ice makers now include service indicators that take the guesswork out of maintenance timing. Instead of arbitrary cleaning schedules, these systems monitor actual usage and alert staff when cleaning or filter changes are needed.

Despite these impressive technologies, regular cleaning remains essential for food safety and machine longevity. For step-by-step guidance on keeping your ice pristine, check out our detailed guide on Crystal Clear Ice Awaits.

When evaluating features, the best ice maker isn't necessarily the one with the most bells and whistles—it's the one that reliably meets your specific needs while keeping operating costs manageable. For science-backed information on energy-efficient appliances, the ENERGY STAR® website offers comprehensive research and savings calculators.

Installation, Maintenance & Troubleshooting Tips

Proper installation and maintenance are crucial for ensuring the longevity and efficiency of your food service ice maker.

Site Requirements for a Smooth Install

Before your shiny new ice machine starts churning out those perfect cubes, you'll need to make sure its new home is properly prepared. Think of it as setting up a comfortable living space for your hardworking kitchen companion.

First, find a level surface for your machine. This isn't just being picky—ice makers need to be perfectly level to function properly and drain correctly. It's like trying to sleep on a tilted bed; nobody's happy and things start sliding where they shouldn't.

Your ice machine also needs room to breathe. Most manufacturers recommend at least 6-8 inches of clearance on both sides for air-cooled models, about 12 inches at the top for proper ventilation, and 6 inches at the back for connections. Cramping your ice maker's style with insufficient space is a recipe for overheating and reduced performance.

When it comes to power, don't cut corners. Food service ice makers typically require a dedicated circuit (usually 15-20 amp), with the proper voltage for your model. Think of sharing circuits like sharing a milkshake—someone's bound to come up short. Your machine needs its own electrical "milkshake" to run properly.

Water is obviously crucial for making ice, and your supply needs to be up to par. You'll want clean, filtered water with at least 20 psi of pressure (though 40-80 psi is ideal), and water temperatures between 40°F-90°F. Your water line should be either 3/8" or 1/2" depending on your machine's specifications.

Don't forget about where all that melted ice will go. Proper drainage options include a floor drain within 6 feet of the unit, a wall drain with the proper air gap, or a drain pump for locations where gravity drainage isn't possible. Without good drainage, you're essentially creating an indoor swimming pool nobody asked for.

The room temperature where your ice machine lives matters too. Most are designed to work in environments between 50°F-100°F, but keep in mind that as the temperature rises, ice production falls. A machine working in a hot kitchen is like trying to make snowballs in summer—possible, but not very efficient.

Finally, invest in a quality water filtration system. This isn't just a nice-to-have; it's essential for removing sediment and contaminants, reducing scale buildup, improving ice clarity and taste, and extending your machine's life. Think of it as sunscreen for your ice maker—preventative protection that pays off in the long run.

For complex installations, we strongly recommend professional installation services. The upfront cost saves money in the long run by preventing warranty issues and ensuring optimal performance from day one.

Cleaning Schedule & Pro Tips

Let's be honest—cleaning your ice machine isn't the most exciting task on your to-do list, but it's among the most important for food service ice makers. A dirty ice machine is like a dirty kitchen—it affects everything you serve and can potentially make people sick.

Every 3-6 months, your machine needs a complete cleaning and sanitizing treatment. If your establishment deals with yeast-heavy environments like bakeries or breweries, you'll need to clean even more frequently. Those microscopic yeast particles are like uninvited party guests that move in and refuse to leave.

Monthly maintenance should include checking or replacing your water filter. Weekly, give the exterior a good wipe-down and clean that bin where all your ice hangs out. Daily—yes, daily—clean your ice scoop and store it somewhere sanitary outside the bin. That scoop touches hands and then touches ice, making it a potential germ highway.

When it's time for that deep clean, follow these professional steps:

First, power down and unplug your machine—safety first! Remove all ice from the bin (perfect excuse for a staff margarita party). Apply a nickel-safe ice machine cleaner to the water system, then run the cleaning cycle or manually circulate the cleaner. Scrub removable components with a soft brush—think of it as giving your machine a gentle spa treatment. Rinse thoroughly with clean water, apply a food-grade sanitizer, rinse again, and let everything air dry before reassembling and restarting.

Pro tip: Keep a maintenance log to track cleaning dates and filter changes. It's like a baby book for your ice maker, but instead of first steps, you're recording "first cleaned the condenser coils."

Only use manufacturer-approved cleaners that are nickel-safe for machines with nickel-plated evaporators. Using the wrong cleaner is like washing your car with dish soap—it might seem fine at first, but you're causing damage.

For air-cooled machines, remove and clean the air filter monthly. And consider a maintenance contract for regular professional servicing—sometimes it's worth paying the experts, especially when health codes are involved.

For specific guidance on maintaining commercial ice machines, check out our detailed maintenance guides on our website.

Quick Fixes When Ice Runs Dry

It's Saturday night, your bar is packed, and suddenly you're out of ice. Before you panic (or call for expensive emergency service), try these troubleshooting steps.

First, check your water supply. Make sure the water supply valve is fully open—sometimes they get accidentally bumped or turned. Verify you have adequate water pressure (at least 20 psi) and inspect your water filter. A clogged filter is like trying to breathe through a straw—not enough gets through.

Next, examine the air flow around your machine. Dusty or obstructed condenser coils are a common culprit, like trying to cool your house with a blanket over the air conditioner. Ensure there's proper clearance around the machine and check the ambient temperature—remember, hot rooms mean less ice.

Take a look at the bin and controls. Sometimes the bin thermostat falsely thinks the bin is full and shuts down production. It's like your refrigerator light sensor getting covered—the machine thinks it's done its job when it hasn't. Make sure the bin switch is functioning properly and verify the machine isn't in delay mode.

When in doubt, try the universal tech support solution: turn it off and back on again. Power down the machine for about 5 minutes, restart, and observe the cycle. While you're at it, check for error codes on digital displays—they're like your machine's way of telling you what hurts.

If your ice production has been gradually declining, scale buildup may be restricting water flow. A quick acid wash may restore performance, like unclogging arteries for better blood flow.

Keep an eye on your energy usage too. A typical food service ice maker producing 100 pounds of ice daily consumes around 10 kWh of electricity. If your energy costs have increased without more ice to show for it, you might have an efficiency problem that needs professional attention.

A well-maintained ice machine is a reliable partner in your food service operation—treat it right, and it'll keep your beverages cold and your customers happy for years to come.

Frequently Asked Questions about Food Service Ice Makers

How much ice should my restaurant produce daily?

Let's talk ice quantities - one of the most common questions we hear from restaurant owners! The truth is, your daily ice needs depend on your specific operation:

For a typical full-service restaurant, plan for about 1.5 pounds of ice per customer. If you're running a busy bar, that jumps to around 3 pounds per customer since nearly every order requires ice.

Your menu style dramatically affects these numbers too. If you're serving lots of iced coffees, blended drinks, or displaying seafood on ice beds, you'll need to bump those estimates up significantly.

Don't forget about climate! In hot locations (looking at you, Florida and Texas), expect to use 20-30% more ice as drinks are served colder and ice melts faster.

Always calculate based on your busiest day, not your average. A typical 100-seat restaurant might need 150-300 pounds daily, while a cocktail bar of the same size could easily require 500+ pounds or more.

My best advice? Use the formula we detailed in our capacity section and then add that 20% buffer. It's always better to have a little extra ice than to run out during your Saturday night rush!

Which ice shape works best for cocktails, smoothies, or displays?

Ice shape isn't just about aesthetics - it dramatically impacts both function and customer experience. Here's what works best for different applications:

For premium cocktails, large clear cubes or spheres are the gold standard. They melt slowly, minimizing dilution while creating that upscale presentation that justifies higher drink prices. For standard mixed drinks, half-dice or full cube ice provides the perfect balance of cooling and controlled dilution.

When making smoothies and blended beverages, nugget or pearl ice creates the smoothest texture while being gentler on your blender motors. Flake ice blends beautifully but tends to create a slightly waterier final product. Many operations use standard cube ice with powerful blenders for consistent results.

Food displays really benefit from flake ice. It molds perfectly around seafood and produce without causing bruising, while maintaining even cold temperatures. When flake ice isn't available, crushed cube ice can work in a pinch, though it doesn't conform as nicely.

For healthcare settings, those soft, chewable nugget or chewblet ice types are ideal for patient hydration and therapeutic use. Many patients find them easier and more comfortable to consume, especially those with dental concerns or difficulty swallowing.

How often should a commercial ice maker be cleaned?

Cleaning your food service ice maker isn't just about health codes - it directly impacts your ice quality, machine efficiency, and equipment lifespan!

For a full deep cleaning and sanitizing, plan on every 3-6 months depending on your water quality and usage patterns. If you're operating in a bakery, brewery, or anywhere with high yeast in the air, you'll need to clean monthly as these environments accelerate biofilm growth.

Your water filters need changing every 3-6 months (or according to your specific manufacturer's guidelines). The ice bin itself should get a weekly wipe-down with proper sanitizer solution, while external surfaces need daily attention with mild detergent.

If you have an air-cooled machine, don't forget that air filter! A monthly cleaning prevents dust buildup that can seriously reduce your machine's efficiency and lifespan.

How do you know when it's time to clean? Watch for decreased ice production, cloudy or strange-tasting ice, visible scale buildup, or ice cubes that look smaller or malformed compared to normal.

One crucial tip: always follow the manufacturer's guidelines for cleaning products. Using the wrong chemicals can damage internal components and potentially void your warranty. Most manufacturers recommend nickel-safe cleaners for machines with nickel-plated evaporators.

Clean ice isn't just about health and safety - it's about delivering the best possible product to your customers while protecting your equipment investment!

Conclusion

Choosing the right food service ice maker isn't just a purchasing decision—it's an investment in your daily operations, customer satisfaction, and financial health. When you find that perfect ice machine that matches your specific needs, it becomes an unsung hero in your kitchen ecosystem.

Think about what we've covered and how it applies to your unique situation:

First, capacity matters enormously. Those busy Friday nights when everyone wants iced drinks at once? That's when having that extra 20% buffer we recommended really pays off. Nothing frustrates customers (or staff) more than running out of ice during a rush.

The type of ice you choose speaks volumes about your establishment. Those crystal-clear cubes in a premium whiskey create an experience worth returning for, while the moldable flake ice keeping your seafood display fresh helps maintain food quality and visual appeal.

When considering cooling options, while air-cooled machines are generally more economical for most situations, that busy kitchen that runs hot all summer might benefit from a water-cooled unit that maintains consistent production regardless of ambient temperature.

Energy efficiency isn't just good for the planet—it's good for your wallet. Those ENERGY STAR®-certified models might cost a bit more upfront, but the 15% energy savings and 10% water reduction add up significantly over the machine's lifetime. Many restaurant owners find these units pay for themselves through utility savings alone.

And please, don't overlook regular maintenance. Even the best ice machine needs consistent care. A simple cleaning schedule prevents those emergency service calls that always seem to happen during your busiest weekend.

At The Restaurant Warehouse, we understand that every food service operation has its own rhythm and requirements. That's why we've carefully curated a selection of commercial ice machines at wholesale prices that deliver real value without compromise.

Our direct-to-consumer approach eliminates those painful retail markups and commission structures that drive up equipment costs unnecessarily. We believe quality ice equipment shouldn't require inflated pricing—your margins are tight enough already.

Whether you're launching a new café, upgrading your bar's ice program, or replacing aging equipment in your established restaurant, our team is ready to help you steer the options without the sales pressure.

For more detailed information about our complete range of ice makers and accessories, check out our ice maker options page or reach out to our team with your questions.

The right food service ice maker does more than just freeze water—it improves your beverages, preserves your food, improves your operational flow, and ultimately contributes to those positive customer experiences that build loyalty and drive your business forward. One perfect cube, nugget, or flake at a time.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment