Cool Deals on Commercial Ice Makers for Sale

Finding the Right Commercial Ice Maker for Your Business

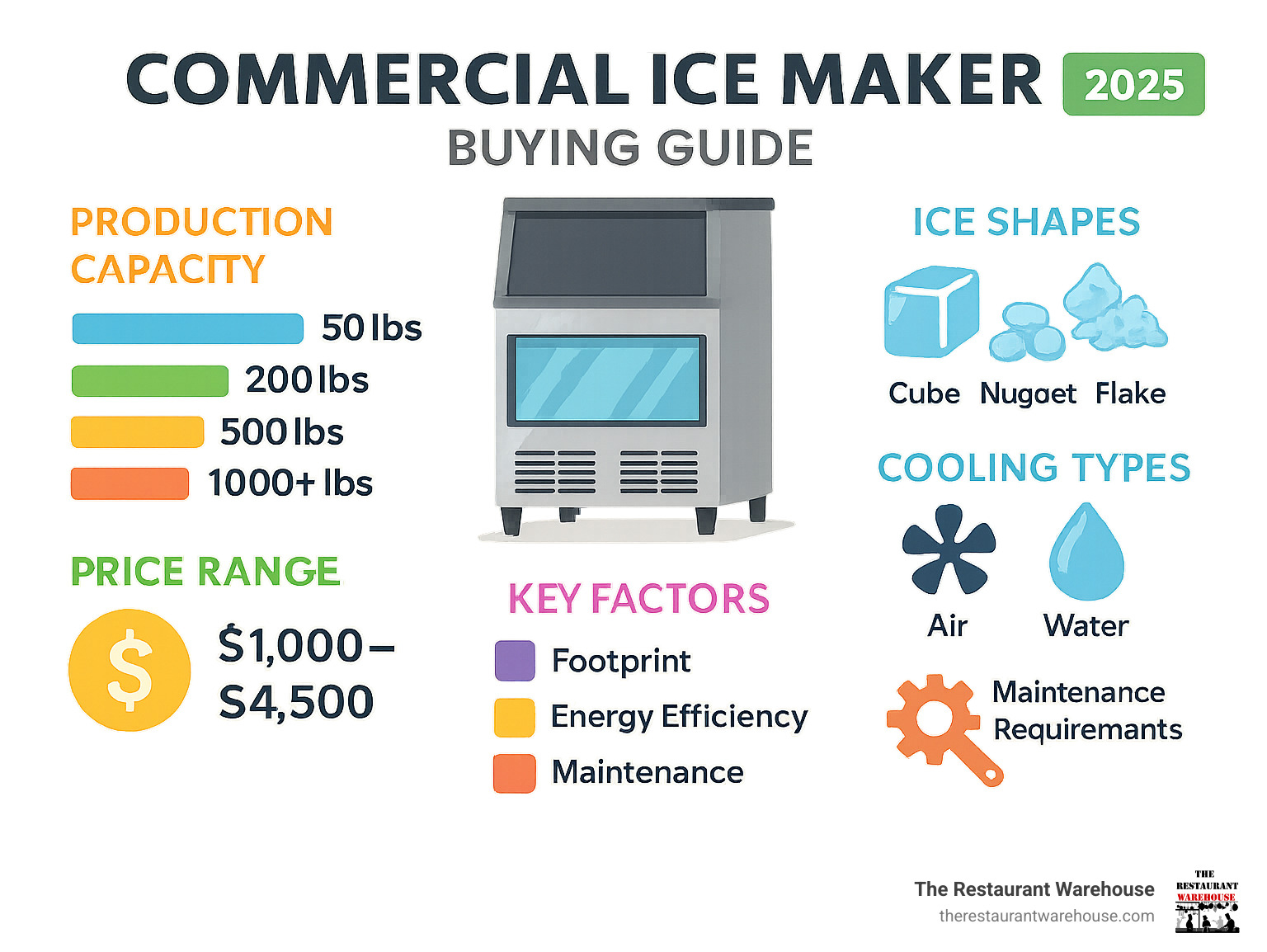

Commercial ice makers for sale range from $1,000 to $4,500 depending on capacity and features. Whether you need 100 pounds per day for a small café or 1,000+ pounds for a busy restaurant, here's what you need to know:

Quick Buying Guide:

- Small operations (50-200 lbs/day): Undercounter units with built-in storage

- Medium volume (300-500 lbs/day): Modular heads with separate bins

- High volume (500-1,000+ lbs/day): Commercial-grade modular systems

- Price range: $1,000-$4,500 based on capacity and cooling type

- Key factors: Daily production, ice shape, air vs water-cooled, footprint

The ice machine industry offers everything from compact undercounter models producing 100 pounds daily to massive modular systems cranking out over 1,000 pounds per day. Air-cooled units work great in most kitchens, while water-cooled models handle hot environments better.

Ice shape matters too. Large cubes work best for cocktails because they melt slower. Nugget ice is perfect for drinks that need chewable ice. Flake ice works well for food displays and cooling.

Most commercial ice makers need cleaning every 3-6 months according to FDA guidelines. Treat ice like food - because that's exactly what it is.

Commercial ice makers for sale terms to know:

Why Capacity, Ice Type & Footprint Matter

Let's be honest - buying the wrong ice maker is an expensive mistake that haunts restaurants for years. When you're shopping for commercial ice makers for sale, three things will make or break your decision: how much ice you actually need, what shape works for your customers, and where the heck you'll fit the thing.

Production capacity isn't just a number on a spec sheet. It's measured in pounds per 24 hours under perfect conditions - 70°F air temperature and 50°F water temperature. But here's the kicker: most businesses completely underestimate their peak demand. That busy Saturday night when everyone wants drinks? Your ice maker better keep up.

A small café might cruise along fine with 100 pounds daily, but a busy bar can blow through 400+ pounds during a weekend rush. The difference between having enough ice and running out at 9 PM on Saturday night is the difference between happy customers and angry ones.

| Business Type | Daily Ice Needs | Recommended Capacity |

|---|---|---|

| Small café/coffee shop | 50-150 lbs | 200 lb capacity |

| Restaurant (50 seats) | 200-400 lbs | 500 lb capacity |

| Bar/nightclub | 300-800 lbs | 1000+ lb capacity |

| Hotel (100 rooms) | 400-600 lbs | 750 lb capacity |

| Supermarket deli | 200-500 lbs | 600 lb capacity |

Matching Production to Peak Demand

Here's where most people mess up big time: they calculate their average daily needs instead of planning for their busiest day. Your ice maker doesn't care that Tuesday is slow - it needs to handle Friday night when everyone shows up at once.

Storage bins are just as important as production capacity. Picture this: your machine cranks out 500 pounds daily, but the storage bin only holds 200 pounds. If you're serving 300 pounds during a 4-hour dinner rush, you're looking at a lot of disappointed customers and frazzled staff.

Those 70/50°F ratings tell you what to expect under ideal conditions. But your kitchen isn't a laboratory. When temperatures hit 90°F or higher, production drops by 10-20%. That's why understanding your environment matters. Water-cooled units handle heat better, while air-cooled models need proper ventilation to maintain their rated capacity.

Choosing the Right Ice Shape

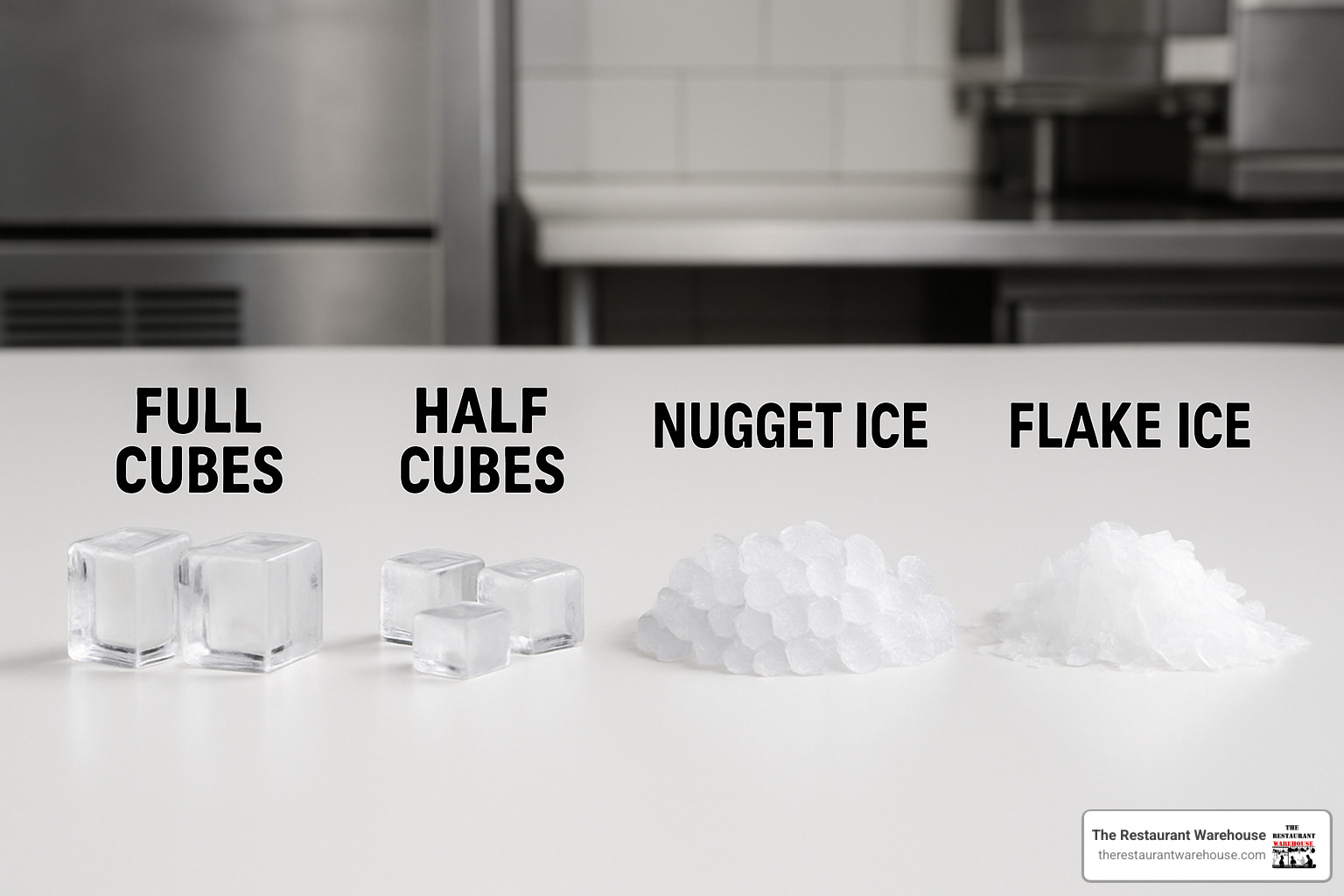

Ice isn't just ice - your customers definitely notice the difference. Full cubes (sometimes called dice cubes) are the gold standard for cocktails because they have less surface area and melt slower. Less melting means less dilution, and your customers will taste the difference in their premium drinks.

Nugget ice is the crowd favorite for soft drinks and healthcare settings. It's chewable, blends perfectly in smoothies, and many customers specifically ask for it. Some people are absolutely obsessed with nugget ice - and they'll choose your business because of it.

Flake ice works like a charm for food displays, salad bars, and seafood counters. It molds around products and provides excellent cooling coverage. You'll see it in grocery stores and buffets because it keeps food at safe temperatures while looking professional.

Half cubes split the difference - they cool drinks faster than full cubes but don't dilute as quickly as flake ice. They're perfect for high-volume beverage service where speed matters.

Cooling Options Explained

Air-cooled condensers work just like your home refrigerator - they blow hot air away from the condenser coils. They're cheaper upfront and easier to install. Just remember to leave adequate space: usually 6 inches on the sides and 12 inches on top. Skimp on ventilation, and your ice production plummets.

Water-cooled systems use water instead of air to cool the condenser. They're champions in hot kitchens, enclosed spaces, or anywhere with poor ventilation. The trade-off? Your water bill goes up - expect to use 15-30 gallons of condenser water for every 100 pounds of ice produced.

Remote condensers separate the hot condenser from the ice-making unit entirely. They're perfect for tight spaces or when you want to keep excess heat out of your kitchen. Installation costs more upfront, but the improved energy efficiency and kitchen comfort often make it worthwhile.

ENERGY STAR certified models can save you hundreds of dollars annually in utility costs. When you're running an ice maker 24/7, those savings add up fast.

Top Commercial Ice Makers for Sale: Our 2024 Roundup

After testing dozens of units and talking to hundreds of restaurant owners, we've narrowed down the best commercial ice makers for sale that actually deliver what they promise. Real-world performance matters more than spec sheets - and these machines prove it every day in busy kitchens.

Here's what we looked for: machines that hit their production numbers even in hot kitchens, stay clean with minimal fuss, and keep running year after year. We also factored in energy costs, warranty coverage, and how easy they are to service. Nobody wants to call a repair tech every few months.

The sweet spot for most businesses falls into three categories: compact undercounter units for smaller operations, modular powerhouses for high-volume needs, and specialty vending solutions for entrepreneurs looking at passive income opportunities.

Best Undercounter Commercial Ice Makers for Sale

Undercounter units solve the space puzzle beautifully. They slide right under your standard 34-36 inch counter and include built-in storage bins. Perfect when you need ice close to the action but don't have room for a full-size machine.

Our top pick produces 155 pounds daily with a 39-pound built-in storage bin. The LCD control panel lets you adjust ice thickness - thicker cubes for cocktails, thinner for faster production. It cranks out 511 ice cubes every 8-15 minutes, which means you're never waiting around during busy periods.

The auto-clean cycle runs at the touch of a button. No mixing chemicals or complicated procedures. The built-in water filter handles most water quality issues, and the thickened insulation keeps energy costs reasonable.

For smaller operations, the 100-pound daily unit fits even tighter spaces. Its 33-pound storage capacity works great for coffee shops and small bars. The R290 refrigerant runs more efficiently than older systems, and at 350W power consumption, it won't spike your electric bill.

Both units produce those perfect 0.9" x 0.9" cubes that bartenders love. Large enough to minimize dilution, small enough to fill glasses quickly.

High-Volume Commercial Ice Makers for Sale

When you need serious ice production, modular systems deliver. These separate the ice-making head from storage, letting you match production capacity with storage needs perfectly.

The 1000-pound daily champion handles the busiest restaurants and bars without breaking a sweat. At 5.8 kWh per 100 pounds of ice, it's surprisingly efficient for its size. The automatic cleaning cycle keeps maintenance simple, and the CFC-free refrigerant meets all current environmental standards.

This unit needs 16 gallons of water per 100 pounds of ice - pretty standard for air-cooled systems. You'll need a separate storage bin, but that flexibility lets you size storage for your specific needs.

For enclosed kitchens or hot climates, the 500-pound water-cooled unit maintains consistent production even when kitchen temperatures soar. Water-cooled systems use more water overall (you need condenser water plus ice-making water), but they handle heat much better than air-cooled units.

The 350-pound all-in-one unit bridges the gap nicely. It includes a 300-pound storage bin in a compact 22-inch width. Perfect when you need modular-level production but want the simplicity of a single unit.

Specialty & Vending Ice Solutions

Ice vending represents a completely different business model. Instead of making ice for your own operation, you're selling premium ice to customers 24/7. These machines connect directly to water and electricity - no restocking, no employee management.

The Ice House handles serious traffic with 6,500 pounds of storage capacity. One location generated over $4,000 in a single weekend. These machines accept cash, credit cards, Apple Pay, and Google Wallet. They're built for high-traffic spots like convenience stores and busy intersections.

Mid-capacity kiosks store 2,400-3,000 pounds of ice - about five times what most competitors offer. They work great at campgrounds, car washes, and retail locations where people need ice regularly but not constantly.

Compact vending units fit smaller locations while still offering double the capacity of most alternatives. They're perfect for franchises looking to replace traditional bunker ice with automated premium ice sales.

The beauty of ice vending is the passive income potential. Once installed, these machines operate independently while generating revenue around the clock. Remote management systems let you monitor performance and troubleshoot issues without site visits.

Maintenance & Cleaning: Protect Your Investment

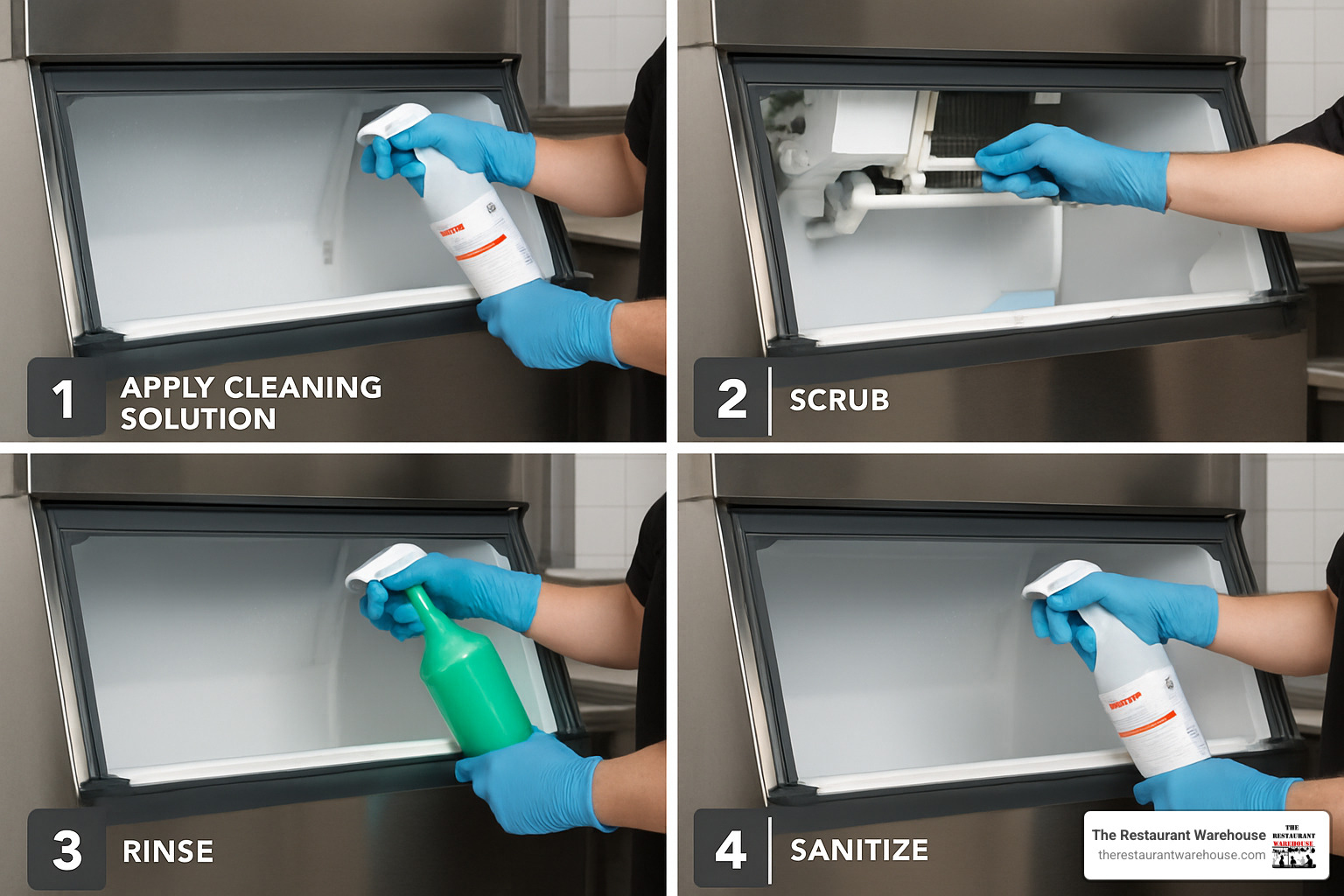

Here's the truth about commercial ice makers for sale: they're only as good as how well you maintain them. The FDA treats ice like food - because that's exactly what it is. Your customers are eating what comes out of your machine.

Most ice machines need cleaning every 3-6 months minimum. In busy restaurants or areas with hard water, bump that up to monthly cleanings. Ignore this schedule, and you'll watch your expensive investment turn into a bacteria-growing science project.

Your ice machine will tell you when something's wrong. Cloudy or weird-tasting ice is the first warning sign. If your machine starts making less ice than usual or making strange noises, it's crying for help. When you see visible scale buildup or slimy surfaces inside the machine, you've waited too long.

Think of ice machine maintenance like changing the oil in your car. Skip it, and you'll pay way more later when the whole system breaks down during your busiest weekend.

Common Mistakes & How to Avoid Them

Water filters get forgotten more than anything else. Replace them every 6 months minimum - every 3 months if you have hard water. A $30 filter replacement beats a $500 repair bill when mineral buildup destroys your evaporator plates.

Scale buildup sneaks up on everyone. Those white, chalky deposits from hard water coat everything inside your machine. They make your ice maker work harder and produce less ice. Use proper descaling solutions designed for ice machines - never grab random cleaners from under the sink.

Skipping professional maintenance is like ignoring that weird noise your car makes. Annual service catches small problems before they become expensive disasters. It's way cheaper than emergency repairs when your ice maker dies during a heat wave.

The biggest mistake? Using household cleaners on your ice machine. They leave residues that contaminate your ice and make customers sick. Only use NSF-approved ice machine cleaners that are designed for food contact surfaces.

Quick 6-Step Cleaning Checklist

Power everything off first. Turn off the ice machine and shut off the water supply. Never clean electrical equipment while it's running - that's how people get hurt.

Empty the machine completely. Remove all ice and drain every drop of water. Leftover water dilutes your cleaning solution and makes the whole process pointless.

Mix your cleaning solution using three parts water to one part ice machine cleaner. Follow the manufacturer's mixing instructions exactly - stronger isn't better, it's just wasteful and potentially dangerous.

Scrub with a soft cloth to avoid scratching surfaces. Pay extra attention to the evaporator plates and water lines where buildup hides. These areas directly touch your ice, so they need to be spotless.

Let everything air dry completely before restarting the machine. Moisture trapped in the system creates perfect conditions for bacteria growth.

Always discard the first batch of ice after cleaning. It might contain traces of cleaning solution. Test the second batch to make sure everything tastes normal.

Schedule your cleaning during slow periods - the whole process takes 2-4 hours depending on your machine size. Your customers will appreciate the crystal-clear ice, and your machine will thank you with years of reliable service.

Cost, ROI & Energy Efficiency Breakdown

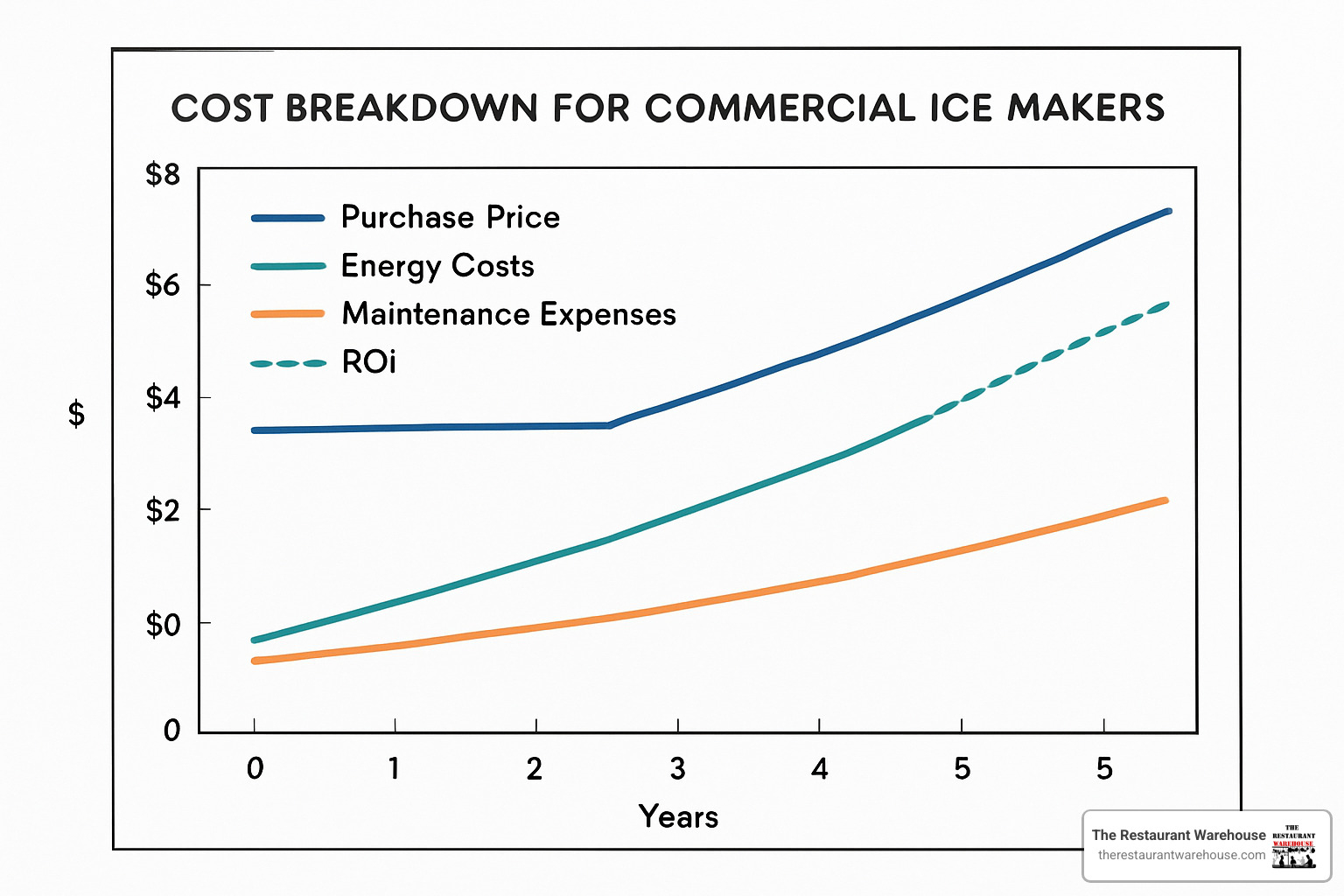

Let's talk real numbers. Commercial ice makers for sale aren't just an expense - they're an investment that pays for itself faster than you might expect.

Upfront costs vary dramatically based on what you need. Undercounter units handling 50-200 pounds daily run $1,000-$2,500. Step up to mid-volume modular systems producing 300-500 pounds daily, and you're looking at $2,000-$3,500. High-volume workhorses cranking out 500-1,000+ pounds daily cost $3,000-$4,500. Specialty vending machines jump to $15,000-$25,000+, but they're a completely different business model.

Here's where it gets interesting: the sticker price is just the beginning. Energy efficiency makes or breaks your long-term costs. Efficient units sip 4-5 kWh per 100 pounds of ice. Average machines gulp 6-7 kWh. Older or poorly designed units can waste 8-10 kWh for the same ice production.

At typical commercial electricity rates of $0.12 per kWh, an efficient 500-pound-daily machine costs about $1.50 in electricity each day. An energy hog costs $3.00+ daily. That difference - $550 extra per year - adds up fast.

Water costs depend on your cooling choice. Air-cooled units use 15-25 gallons per 100 pounds of ice. Water-cooled systems need the same amount of drinking water plus 100-150 gallons for condenser cooling. At $0.005 per gallon, water costs range from $0.75 to $8.75 per 100 pounds of ice produced.

Calculating Total Cost of Ownership

Smart buyers look beyond the purchase price. Here's what a 500-pound-daily machine really costs over five years:

The purchase price starts at $3,000. Energy costs over five years hit $2,737 for efficient units versus $5,475 for energy wasters. Water costs add $1,370 for air-cooled models or $4,380 for water-cooled systems. Maintenance and cleaning runs about $1,500 over five years.

Total five-year cost: $8,607 for an efficient air-cooled unit versus $14,355 for an inefficient water-cooled model. That's nearly $6,000 difference for the exact same ice production.

ENERGY STAR certified equipment cuts these costs another 15-20% while reducing your environmental footprint. The savings compound year after year.

Real-World ROI Scenarios

The payback numbers will shock you. Cocktail bars buying ice from suppliers pay about $0.50 per pound. A machine producing 400 pounds daily saves $200 compared to buying ice. At that rate, a $3,000 machine pays for itself in 15-20 days.

Hotels see different benefits. Reliable ice access improves guest satisfaction scores. No more staff time hauling bagged ice to upper floors. Fewer complaints mean better online reviews and higher occupancy rates. The ROI shows up in guest retention and premium room rates.

Ice vending businesses represent pure passive income potential. One successful location generated over $4,000 in a single weekend. High-traffic Ice House units serve 50,000+ customer visits annually. With proper location selection, payback periods run 12-24 months, then it's profit from there.

The math is simple: ice machines don't just save money - they make money. Whether you're eliminating supplier costs, improving customer satisfaction, or creating new revenue streams, the investment pays dividends for years.

Frequently Asked Questions about Commercial Ice Makers

Let's tackle the most common questions we hear from restaurant owners, bar managers, and food service operators looking at commercial ice makers for sale.

How Much Do Commercial Ice Makers Cost?

The honest answer? It depends on what you need, but most businesses spend between $1,000 and $4,500 for a quality commercial ice maker.

Small undercounter units that produce 50-150 pounds daily typically run $1,000-$2,000. These work great for coffee shops, small bars, or restaurants that don't go through massive amounts of ice.

Medium capacity modular systems producing 300-500 pounds daily cost $2,000-$3,500. This sweet spot works for most restaurants and busy bars.

High-volume powerhouses cranking out 500-1,000+ pounds daily run $3,000-$4,500. If you're running a nightclub, large restaurant, or hotel, this is your territory.

Here's what catches people off guard: water-cooled units add $300-$800 to air-cooled prices. Installation costs another $200-$800 depending on how complex your setup gets.

Don't forget about storage bins if you're buying a modular unit. The ice-making head and storage bin are sold separately, and bins add $400-$1,200 to your total investment. Yeah, it adds up - but so does running out of ice on a busy Saturday night.

How Often Should I Clean My Ice Machine?

Here's the rule that keeps health inspectors happy: clean your ice machine every 3-6 months minimum. The FDA treats ice like food because that's exactly what it is.

But real-world cleaning schedules depend on your specific situation. Clean monthly if you're dealing with hard water, running the machine constantly, or working in a hot, humid kitchen. Those conditions create the perfect storm for buildup and contamination.

Clean every 3 months if you have moderate water hardness and regular usage. This covers most restaurant situations.

Clean every 6 months only if you have soft water, excellent filtration, and light usage. Honestly, this is pretty rare in commercial settings.

The warning signs are obvious once you know what to look for. Cloudy ice, weird tastes, reduced production, or visible buildup inside the machine all scream "clean me now." Don't wait for your health inspector to point it out.

Which Ice Shape Is Best for Cocktails?

Full cubes win for cocktails - no contest. Large cubes have less surface area exposed to the liquid, so they melt slower and don't water down premium spirits.

Your bartenders will thank you for full cubes when they're making whiskey cocktails, old fashioneds, or any drink where dilution matters. The ice looks professional in the glass too.

Half cubes work as a compromise option. They cool drinks faster than full cubes but still provide decent dilution control. They're fine for mixed drinks and sodas where you want quick cooling.

Nugget ice has a cult following among customers who love the chewable texture. It's perfect for soft drinks, healthcare settings, and frozen drinks. But it melts fast, so skip it for premium cocktails.

Flake ice belongs in your seafood display or salad bar, not in beverages. It's great for food presentation but terrible for drinks.

If you're running a serious cocktail program, invest in a full-cube machine. The difference shows up in every glass, and customers notice quality even when they can't put their finger on exactly why one drink tastes better than another.

Conclusion

Choosing the right commercial ice makers for sale isn't just about finding the cheapest option - it's about understanding your business and making a smart investment that pays off for years.

We've walked through everything from calculating your peak demand (remember, size for your busiest Saturday night, not your quiet Tuesday afternoon) to understanding why full cubes make cocktails taste better. The math is pretty straightforward: a properly sized ice machine typically pays for itself within weeks when you compare it to buying bagged ice.

Here's what really matters: Don't get stuck with an undersized machine that can't keep up during rush periods. Factor in those energy costs - an efficient unit can save you $500+ every year compared to an older, power-hungry model. And please, don't skip the cleaning schedule. Ice is food, and your customers deserve clean, fresh-tasting ice every time.

Water-cooled units handle hot kitchens like champs but will cost more to operate. Air-cooled models work great in most situations and keep operating costs down. If you're serious about cocktails, invest in a machine that makes full cubes - your bartenders will thank you, and your customers will notice the difference.

The biggest mistake we see? Businesses that buy based on price alone, then spend years dealing with breakdowns, high energy bills, and frustrated staff. A quality ice machine from a reliable supplier is one of those purchases that makes your daily operations smoother.

At The Restaurant Warehouse, we skip the high commissions and retail markup that drive up prices elsewhere. Our team actually understands foodservice operations - we're not just selling equipment, we're helping you solve problems and run a better business.

Whether you need a compact undercounter unit for your coffee shop or a high-volume modular system that can handle your restaurant's dinner rush, we have the expertise to match you with the right machine and the inventory to get it to you quickly.

Ready to stop running out of ice during your busiest times? More info about ice makers or reach out to our team. We'll help you figure out exactly what capacity and features make sense for your specific operation - no sales pressure, just straight answers from people who understand the restaurant business.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment