What Is Induction Ready Cookware Explained

So, what exactly is "induction-ready" cookware? At its core, it's any pot or pan built with a magnetic material in its base. This is the secret ingredient that lets it connect with an induction cooktop.

The easiest way to check? Just grab a simple refrigerator magnet. If it sticks firmly to the bottom of your pan, you’re good to go.

What's the Big Deal with Induction Cookware?

Unlike a traditional stove that has to heat up a burner first, induction technology works by creating a direct magnetic field that turns the cookware itself into the source of heat. Think of it less like putting a pot on a fire and more like the pot becoming the fire.

This simple principle is a game-changer for professional kitchens, bringing some serious benefits to the table:

- Speed: Water boils significantly faster, which is a massive win for shaving down prep times during a busy service.

- Efficiency: Up to 90% of the energy is transferred directly into the food, which means less wasted heat and lower utility bills.

- Safety: The cooktop surface stays remarkably cool to the touch. This drastically cuts down the risk of accidental burns in a fast-paced kitchen.

- Precision: Temperature adjustments are instant and incredibly accurate, giving your chefs a level of control that gas or electric ranges just can't match.

We're seeing a huge shift in the industry because of these advantages. The global induction cookware market was valued at USD 2.39 billion and is expected to more than double by 2033. This isn't just a passing trend; it shows that efficiency and performance are top priorities.

In fact, over 60% of new kitchenware buyers now say induction compatibility is a key factor in their decision. As more chefs and operators experience the benefits, understanding what makes cookware "induction ready" becomes essential for outfitting a modern, high-performing kitchen. You can dive deeper into the numbers by checking out these induction cookware market trends.

How Induction Cooking Works at a Glance

To put it all together, here's a quick look at the core ideas behind induction technology and why they matter in a real-world kitchen setting.

| Feature | How It Works | Why It Matters to You |

|---|---|---|

| Magnetic Field | An electromagnetic coil under the cooktop creates a magnetic field. | This is what generates the heat, but only in the pot. The cooktop itself stays cool. |

| Magnetic Cookware | The magnetic base of the pan completes the circuit, creating electrical currents. | No magnetic pan? No heat. This is the key safety and efficiency feature. |

| Direct Heating | These currents turn the pan itself into the heat source, cooking food directly. | Faster heating, pinpoint temperature control, and less wasted energy heating the air. |

Understanding this simple science is the first step in seeing why so many kitchens are making the switch. It’s all about working smarter, faster, and safer.

The Science of Induction Cooking Made Simple

Ever wondered how an induction cooktop works its magic without a single flame or a glowing-hot burner? It feels a bit like science fiction, but the technology is surprisingly straightforward. Think of it like a wireless phone charger, but instead of just transferring power, it uses magnetism to create heat.

Beneath the sleek, smooth glass surface of every induction cooktop lies a coil of tightly wound copper wire. When you power it on, this coil generates a high-frequency, alternating magnetic field. By itself, this field is just potential energy—it doesn't produce any heat. It's just waiting for a pan to complete the circuit.

The Pan Becomes the Burner

This is where your induction ready cookware steps in. The moment you place a pot or pan with a magnetic base on the cooktop, it enters that magnetic field and sparks an incredible reaction.

This interaction creates an electrical current (often called an "eddy current") that swirls directly within the metal base of the pan itself. The pan's natural resistance to this current is what generates instant, powerful heat. In other words, the cooktop isn't getting hot and then warming up the pan; the magnetic field turns the pan itself into the source of the heat.

The real magic of induction is that it heats the cookware directly, not the cooktop. This is why the surface stays cool to the touch, which dramatically cuts down on wasted energy and creates a much safer kitchen.

The Efficiency Game-Changer

This direct heating method is fundamentally different from traditional gas or electric stoves. Those methods are indirect—they waste a ton of energy just heating the surrounding air or the burner itself long before your pan even gets hot.

With induction, up to 90% of the energy is channeled straight into the pot. This is why water boils so much faster and temperature adjustments are incredibly responsive. Understanding this simple science is the key to seeing why a commercial induction cooktop can completely change a kitchen's speed and efficiency. It’s not just a different kind of stove; it’s a smarter way to cook.

Choosing The Best Materials For Your Cooktop

When it comes to induction cooking, not all pots and pans are created equal. The material your cookware is made from is the single most important factor that determines whether it will work with this tech. Once you get a handle on the differences, you can choose pieces based on how they’ll actually perform on the line, not just because they have a compatibility symbol on the box.

The secret is all in the magnetic properties. Induction cooktops create a magnetic field to generate heat, so your cookware has to be made from a ferromagnetic metal—basically, anything that contains iron and can hold a magnetic field.

A simple way to think about it is this: ferromagnetic materials complete the electrical circuit with the cooktop. Without that magnetic connection, no heat is generated, no matter how high you crank the power.

This is why some of the most trusted, heavy-duty materials you already see in professional kitchens are naturally perfect for induction.

Top Performing Induction Materials

Cast iron is a classic top performer. Its high iron content makes it incredibly magnetic, and its sheer density gives it awesome heat retention—perfect for getting a hard sear on a steak or holding a steady temperature for delicate sauces.

Stainless steel is another kitchen workhorse, but there’s a small catch. For it to work with induction, it needs to be bonded with a magnetic base layer. The good news is that most high-quality, multi-ply stainless steel cookware built for pro use now includes this feature, making it one of the most versatile options out there.

The market for induction-ready cookware is booming, which shows a major shift in both commercial and home kitchens toward more efficient and safer cooking. Valued at about USD 2.54 billion, this segment is only expected to grow as more chefs get on board with induction. You can dig into more data on this trend by reading the full induction cookware market report.

Materials That Don't Make The Cut

On the flip side, some popular cookware materials just won't work on their own. Pure aluminum, copper, and glass aren't magnetic, so they can't complete the circuit needed for induction heating to kick in.

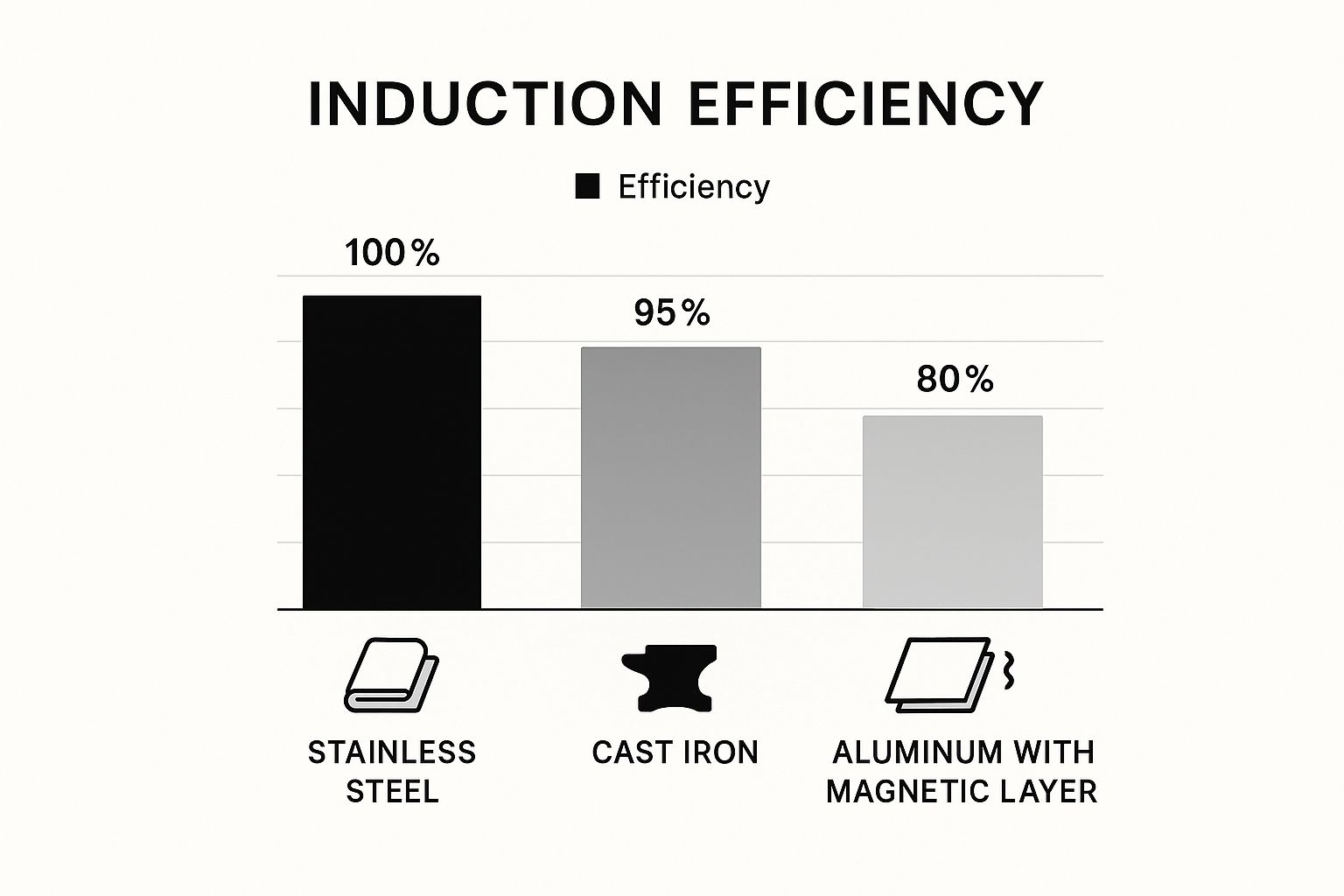

This infographic gives you a quick visual on the energy efficiency of common induction-ready materials.

As you can see, high-quality stainless steel and cast iron give you the most direct and efficient energy transfer, making sure your cookware heats up fast and evenly every time.

Induction Cookware Material Comparison Guide

To make things even clearer, here’s a quick-glance table breaking down the most common materials. Think of this as your cheat sheet for choosing the right tool for the job.

| Material | Induction Performance | Strengths | Weaknesses |

|---|---|---|---|

| Cast Iron | Excellent | Unbeatable heat retention, naturally non-stick when seasoned, very durable. | Heavy, can be brittle, requires seasoning to prevent rust, heats up slowly. |

| Magnetic Stainless Steel | Very Good | Non-reactive, durable, easy to clean, and resists corrosion. | Heat distribution can be uneven unless it has an aluminum or copper core. |

| Enameled Cast Iron | Excellent | All the benefits of cast iron but with an easy-to-clean, non-reactive surface. | Enamel can chip or crack if dropped or exposed to thermal shock. |

| Carbon Steel | Excellent | Heats up faster than cast iron, lightweight, and develops a non-stick patina. | Requires seasoning, can rust if not cared for properly. |

Ultimately, your choice depends on what you’re cooking. For searing and slow cooking, cast iron is king. For all-around versatility and easy maintenance, a multi-ply magnetic stainless steel pan is hard to beat.

How to Test Your Cookware for Induction Compatibility

So, you're thinking about making the switch to induction, but you're not sure if your current pots and pans will make the cut. Before you go all-in on new equipment, it's a smart move to check what you've already got. The good news is, you don't need any special tools for this.

There are a couple of quick, foolproof tests you can do in seconds. These simple checks can save your restaurant a good amount of time and money.

The Magnet Test

The easiest way to know for sure is the magnet test. Just grab any regular refrigerator magnet and hold it up to the bottom of a pot or pan.

If that magnet sticks on tight, you're in business. That means the cookware is ferromagnetic and will work perfectly on an induction cooktop. If it falls right off or the pull feels really weak, it doesn't have the right magnetic stuff and won't heat up. It’s a simple test that gives you an immediate answer.

Check for the Induction Symbol

Another surefire method is to look for the official induction symbol right on the cookware itself. To take out all the guesswork, manufacturers often stamp this little icon directly onto the bottom of their induction-ready pots and pans.

The symbol usually looks like a coil of wire in a zig-zag pattern. Finding this mark is a clear confirmation that your pan was designed to work with the magnetic fields of induction burners.

With these two tests, you can quickly audit your entire kitchen inventory. Knowing which pieces are compatible helps you make smarter purchasing decisions, whether you're just upgrading a single station or outfitting a whole new kitchen. For a deeper dive into the equipment itself, check out our complete commercial induction burners guide to find the right fit for your operation.

Real-World Benefits of Switching to Induction

So, beyond all the science, what’s the real-world payoff when you bring induction-ready cookware into your professional kitchen? Switching from old-school gas or electric isn’t just about a fancy new gadget; it delivers immediate, practical wins that you’ll see in your ticket times, your staff’s safety, and your utility bills.

It all starts with incredible energy efficiency. Induction is a direct-to-pan technology, meaning nearly all the power goes straight into the cookware. Almost no heat is wasted escaping into your kitchen, which makes for a much cooler, more comfortable line for your team.

Faster Cooking and Precision Control

Speed is the other huge game-changer here. Because the pot or pan is the heat source, water boils in a fraction of the time it takes on a gas or electric range. This lets your crew turn tickets faster during a slammed service, pushing more plates out the door. A faster kitchen is a more profitable one.

That direct heating also gives your chefs an almost unbelievable level of temperature control. Adjustments are instant. You can go from a hard boil to a delicate simmer in seconds.

This kind of responsiveness is a chef’s dream. It gives you the power to nail a tricky sauce or get the perfect sear with a level of precision that traditional burners just can’t touch. No more frustrating lag time waiting for a burner to cool down.

Enhanced Safety and Lower Costs

Finally, induction creates a much safer cooking environment. With no open flames and a cooktop that stays cool to the touch, you drastically cut down the risk of accidental burns. In a fast-paced, crowded commercial kitchen, that’s a massive advantage.

This efficiency also translates directly into savings. Induction stoves can convert up to 90% of their energy into heat for the pan. Compare that to about 74% for electric and a dismal 40% for gas. When you look at induction cookware market trends, it's clear the industry is taking notice of these benefits.

Pairing the right equipment with your cookware is key to getting the most out of your kitchen's performance and spending. To explore the best options for your restaurant, our comprehensive induction range guide has all the details you need.

What to Look for When Buying Induction Cookware

So you're ready to invest in some new cookware for your induction setup? Awesome. But before you start buying, know this: beyond just looking for that little compatibility symbol, a few key details separate the good pans from the great ones. Getting the construction and design right will guarantee you get top performance and the kind of durability a busy kitchen demands.

First things first, flip that pan over and look at the base. For an induction cooktop to work its magic, the bottom of your induction ready cookware must be perfectly flat. I mean, perfectly. Even a minor warp or a slight curve will kill your efficiency because it reduces the contact with the cooktop's magnetic field. That means slower cooking and annoying hot spots.

A truly flat base ensures a solid, consistent connection, letting the pan soak up energy evenly across its entire surface. This is what you need for that perfect sear or a steady, even simmer.

Construction and Pan Dimensions

Next up, let's talk construction. A simple cast iron skillet is just one solid layer of magnetic metal, and it works great. But when you get into high-performance stainless steel, you'll often see multi-ply construction. This is where manufacturers sandwich a layer of a super-conductive metal, like aluminum or copper, between layers of tough stainless steel.

This layered approach, often called "cladding," is the best of both worlds. It gives you the magnetic properties you need for induction, plus the superior heat distribution of copper or aluminum. It means heat travels quickly and evenly up the sides of the pan, not just across the bottom.

Finally, think about the pan's size and weight. You want the diameter of the pan to be a close match for the induction burner you'll use it on. A pan that’s way too small or too big for the burner ring will heat up inefficiently and just waste energy.

And don't forget the feel of it. Look for cookware that has a balanced weight—heavy enough to sit flat and hold heat well, but not so clunky that it’s a pain for your chefs to handle during a fast-paced service. Nailing these details ensures your investment really pays off in performance and longevity.

Common Questions About Induction Cookware

Even after you've got the basics down, a few practical questions always pop up when making the switch to induction. It's totally normal. Let's clear the air on some common uncertainties so you can start cooking with confidence.

One of the first things chefs ask is whether their new induction pans can pull double duty on other cooktops. The answer is a big yes. Since induction-ready cookware is simply any pot or pan with a flat, magnetic base, it works perfectly on your traditional gas and electric stoves. This makes it a smart, flexible investment for any professional kitchen.

Another frequent concern is about scratching that sleek glass top. Will your heavy-duty pans damage it? While the glass is tough, it's not invincible. The best practice is to always lift your pots and pans instead of sliding them across the surface. Keeping both the cooktop and the pan bottoms clean and free of grit also goes a long way in keeping everything looking pristine.

Addressing Common Noises and Concerns

You might also notice a faint buzzing or humming sound when you're cooking, especially on higher power settings. Don't worry, that's completely normal. That sound is just the magnetic field interacting with the layers of metal in your cookware—it's the sound of science at work.

The industry is taking notice. Market projections show the commercial induction cooktop market is expected to jump from USD 13,320.7 million to over USD 23,990.2 million by 2035. That's a huge indicator of its growing importance in professional kitchens everywhere. This isn't just a passing trend; it's a fundamental shift in how modern restaurants are being run. Learn more about this commercial kitchen trend.

Once you understand these minor quirks, you can fully embrace induction cooking, knowing you’ve chosen an efficient, safe, and powerful system for your kitchen.

At The Restaurant Warehouse, we provide the high-performance induction equipment and cookware your kitchen needs to stay ahead. Explore our full catalog and equip your operation for success at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney used to work at Amazon.com and started The Restaurant Warehouse. He has more than 10 years of experience in restaurant equipment and supplies. He graduated from the University of Washington in 1993. He earned a BA in business and marketing. He also played linebacker for the Huskies football team. He helps restaurants find equipment at a fair price and offers financing options. You can connect with Sean on LinkedIn or Facebook.

Leave a comment