What is a grease interceptor? Essential guide for kitchens

Think of a grease interceptor as the unsung hero of your commercial kitchen’s plumbing. It’s essentially a large, specialized tank—your first line of defense—designed to catch fats, oils, and grease (FOG) before they have any chance of escaping into the city sewer system. For any foodservice business, this piece of equipment isn't just helpful; it's absolutely crucial for preventing costly blockages and staying on the right side of environmental regulations.

Your Kitchen's Unsung Hero

So, what is a grease interceptor, really? At its core, it’s a passive but powerful device, usually a large concrete or fiberglass tank buried underground, that works around the clock to separate harmful FOG from your kitchen’s wastewater. Every time a pot washer blasts a greasy pan or a dishwasher runs a cycle, all that dirty water flows directly into the interceptor first.

This isn't just a suggestion; for most foodservice operations, it's a mandatory requirement. Without one, the sheer volume of FOG a restaurant produces would quickly cool and solidify inside municipal sewer lines, creating catastrophic blockages infamously known as "fatbergs." These clogs cause nasty sewer backups, pollute the environment, and lead to massive repair bills and steep fines for businesses that don't comply.

To give you a quick rundown, here are the essential details every restaurant owner should know.

Grease Interceptor Quick Facts for Restaurant Owners

| Aspect | Description |

|---|---|

| Primary Function | To trap and separate fats, oils, and grease (FOG) from kitchen wastewater. |

| Typical Location | Usually a large tank installed underground, outside the restaurant. |

| Why It's Required | Prevents FOG from clogging public sewer lines and causing environmental damage. |

| Who Needs One | Virtually all commercial foodservice establishments, including restaurants, cafeterias, and caterers. |

| Consequences of Not Having One | Severe plumbing blockages ("fatbergs"), hefty municipal fines, and potential business closure. |

This table covers the basics, but understanding the interceptor's role is key to appreciating why it's such a critical part of your operation.

The Role of an Interceptor

A grease interceptor is much more than just a tank; it’s a core part of your risk management strategy. Its job is straightforward but absolutely vital for your daily operations:

- Preventing Plumbing Disasters: It’s the gatekeeper that stops grease from ever reaching the main sewer lines, protecting both your internal plumbing and the public infrastructure from clogs.

- Ensuring Regulatory Compliance: Cities and towns have very strict rules about FOG discharge. A properly maintained interceptor keeps you in compliance and shields you from fines that can easily run into the thousands of dollars per violation.

- Promoting Environmental Responsibility: By capturing FOG right at the source, your kitchen does its part to prevent pollution of local waterways and contributes to the community's environmental health.

Interestingly, the idea behind this essential equipment isn't new. The grease interceptor industry actually has deep historical roots stretching back about 140 years, with the first official patent filed by Nathaniel T. Whiting way back in 1884. This innovation came about during an era when FOG buildup was already creating major headaches in city sewage systems, though formal sizing rules weren't put in place until World War II. You can learn more about the history of FOG management and how it evolved into the regulated systems we have today.

A well-maintained grease interceptor is an investment in operational continuity. It quietly works 24/7 to prevent the kind of plumbing emergencies that can shut down a restaurant without warning.

Ultimately, understanding what a grease interceptor does is fundamental for any foodservice professional. It is the single most important tool for managing the unavoidable byproduct of a busy kitchen, safeguarding your business from financial penalties and operational chaos.

How a Grease Interceptor Separates FOG From Water

Ever notice how a bottle of oil and vinegar salad dressing separates into layers after it sits for a moment? The lighter oil always floats right to the top. A grease interceptor works on that exact same principle—gravity—just on a much bigger scale to protect your pipes and the city's sewer lines.

It’s a surprisingly straightforward process. There are no complex machines or chemicals involved, just clever design that uses basic physics to passively filter your kitchen's wastewater 24/7. The whole system is built around one key idea: slowing down the water long enough for everything to separate naturally.

The Journey of Wastewater Through an Interceptor

When greasy water from a three-compartment sink or a pre-rinse station flows into the interceptor, its journey to becoming cleaner begins. The entire device is engineered to create a calm, controlled environment where that separation can happen.

- Slowing the Flow: The wastewater first runs into an inlet baffle. This internal wall immediately slows the water down, reducing turbulence so it doesn't stir up everything already inside the tank.

- Allowing Time for Separation: Once the water is calm, gravity gets to work. The interceptor is big enough to hold the wastewater for a specific amount of time, known as retention time. This pause is the most critical step.

- Separating by Density: During this quiet period, the natural layering happens. Fats, oils, and grease (FOG)—which are all lighter than water—float to the surface, forming what’s often called a "grease mat." At the same time, heavier food solids sink to the bottom, creating a layer of sludge.

- Exiting Cleaner Water: With the FOG trapped at the top and solids at the bottom, the cleaner water in the middle is now free to flow under an outlet baffle and out of the tank into the sewer system. That outlet baffle is crucial; it acts like a dam, making sure none of the floating surface grease can escape with the water.

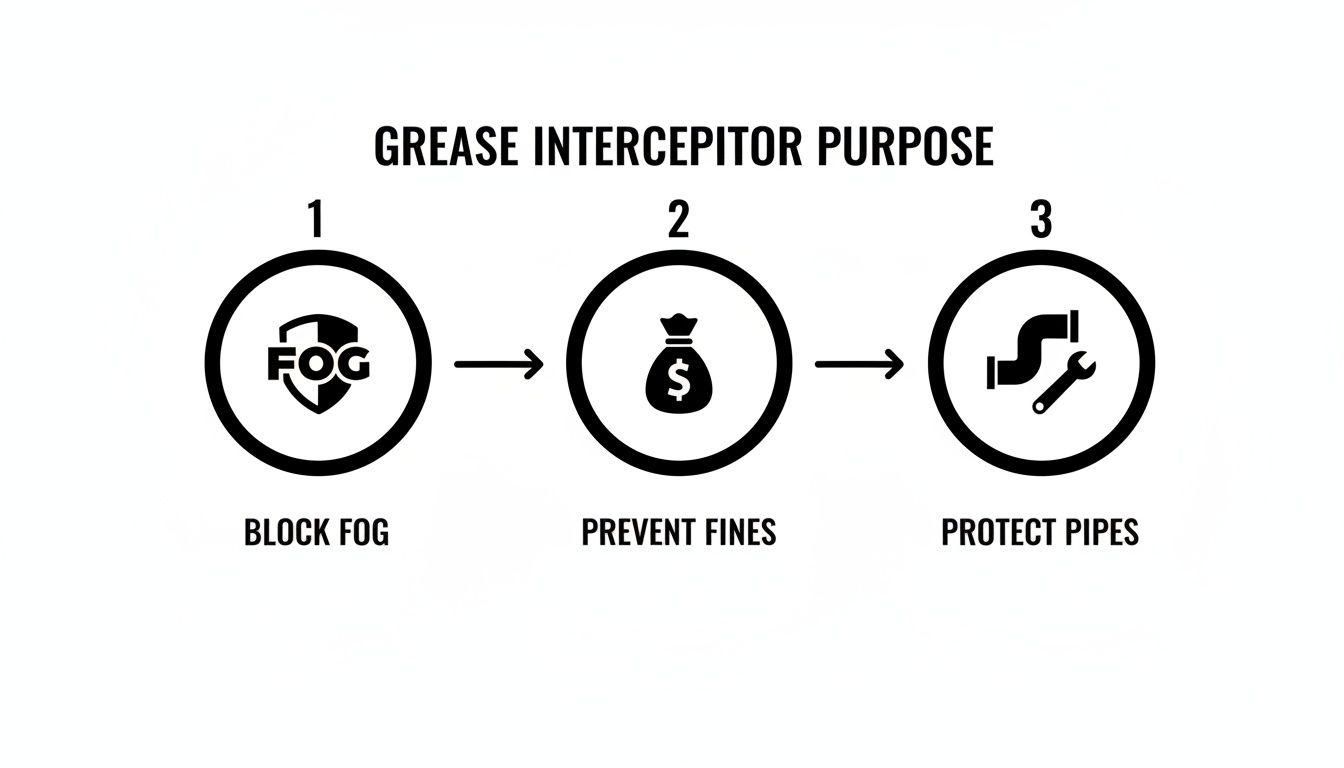

This diagram breaks down exactly what the interceptor is accomplishing—blocking FOG, helping you avoid costly fines, and protecting your plumbing.

It’s pretty clear this isn't just a piece of plumbing; it's a vital risk management tool for any foodservice business.

The Critical Role of Retention Time

The whole concept of retention time is the secret sauce to making an interceptor work. The long-standing rule of thumb in the industry is that you need about a 30-minute retention time for gravity to do its job properly. This standard is what drives the sizing of these units—an interceptor has to be large enough to hold the peak flow of wastewater for half an hour to give that FOG a chance to rise.

An interceptor’s performance isn’t about high-tech filters; it’s about providing a big enough, calm enough space for gravity to work. If there isn't enough retention time, wastewater just rushes through, taking the FOG right along with it and defeating the whole purpose of the system.

But here’s the catch: if an interceptor gets too full of trapped grease and solids, its liquid capacity shrinks, which dramatically cuts down the actual retention time. When the water volume gets too low, wastewater can "short-circuit," flowing straight from the inlet to the outlet without ever separating.

This is exactly why following a strict maintenance schedule, like the "25% Rule"—which calls for pumping the tank once it's a quarter full of FOG and solids—is non-negotiable. It’s the only way to keep the system working as it was designed.

Grease Interceptor vs Grease Trap: Understanding The Difference

In the world of commercial kitchens, you'll hear the terms "grease trap" and "grease interceptor" thrown around, often as if they mean the same thing. They don't. While both are designed to wrangle fats, oils, and grease (FOG), they are fundamentally different tools built for entirely different scales of operation.

Getting this distinction right is critical. It's the key to choosing the right system for your kitchen, staying compliant with local codes, and avoiding the kind of catastrophic plumbing bills that can ruin your month.

Here's an easy way to think about it: it's like comparing a small fire extinguisher to a full-building sprinkler system. Both put out fires, but you wouldn’t bet your entire business on a handheld extinguisher. In the same way, a grease trap is a small, point-of-use solution, while a grease interceptor is a comprehensive, facility-wide system.

The Small but Mighty Grease Trap

A grease trap is the smaller of the two, usually a compact steel or plastic box installed indoors. You'll typically find them tucked directly under a 3-compartment sink or sitting next to a dishwasher. Their job is simple: catch FOG from a specific fixture before it ever gets a chance to enter your main plumbing lines.

Here are the key things to know about grease traps:

- Location: Almost always found indoors, right at the point of use (like under a sink).

- Size: They have a small capacity, holding anywhere from 10 to 100 gallons of wastewater.

- Flow Rate: Measured in gallons per minute (GPM), typically handling between 20 to 50 GPM.

- Ideal User: Best suited for very low-volume operations like a small coffee shop, deli, or juice bar.

Because they’re so small, grease traps fill up fast and need frequent cleaning—often weekly, or in some cases, even daily. If you neglect them, they get overwhelmed and stop working. For a closer look, you can learn more about how to choose the right grease trap for your restaurant in our guide.

The Heavy-Duty Grease Interceptor

Now, let's talk about the big guns. A grease interceptor is a heavy-duty, high-capacity system built for the real-world demands of a full-service restaurant, hotel, or large commercial kitchen. These are almost always massive tanks made of concrete, fiberglass, or steel that are installed outside and buried underground.

A grease interceptor serves the entire kitchen's drainage system, not just one sink. It's the central hub for FOG management, capable of handling thousands of gallons of wastewater every single day.

This massive scale is what truly sets it apart. An interceptor’s huge volume gives wastewater a much longer time to sit (this is called retention time), allowing gravity to separate out the FOG far more effectively than a small trap ever could. As a result, they need to be pumped out much less often, usually every 30 to 90 days, depending on how much FOG you produce and what your local regulations require.

At a Glance: Comparing the Two Systems

Let's put them side-by-side. Seeing the differences clearly shows why each system has such a distinct role. Installing the wrong one isn't just a mistake; it's a recipe for immediate compliance failures and serious operational headaches.

To make it simple, here’s a quick comparison of the two.

Grease Interceptor vs Grease Trap Comparison

| Feature | Grease Interceptor (Large Capacity) | Grease Trap (Small Capacity) |

|---|---|---|

| Typical Location | Outside, buried underground | Indoors, under a sink or on the floor |

| Capacity | 500 - 5,000+ gallons | 10 - 100 gallons |

| Flow Rate Rating | Sized by total liquid capacity (gallons) | Sized by flow rate (gallons per minute) |

| Material | Concrete, fiberglass, or steel | Steel, plastic, or cast iron |

| Maintenance Frequency | Every 30-90 days (pumped by professionals) | Every 1-7 days (cleaned by kitchen staff) |

| Best For | High-volume restaurants, cafeterias, hotels | Small cafes, delis, low-FOG operations |

Ultimately, the choice between a trap and an interceptor isn't about preference—it's dictated by your kitchen's output and local health codes. A busy restaurant simply produces way too much FOG for a small trap to handle, making a large-capacity grease interceptor a non-negotiable requirement for staying in business and protecting the city's sewers.

How to Choose the Right Grease Interceptor

Picking the right grease interceptor is one of those behind-the-scenes decisions that can make or break your kitchen's workflow. This isn't just about ticking a box for the health inspector; it’s a critical choice that hits your operational efficiency, your budget, and your ability to stay on the right side of local environmental codes. An undersized unit is a recipe for backups and fines, while an oversized one is just wasted cash.

Getting it right starts with understanding what you're actually working with. Each type of interceptor is built for different scenarios, and knowing their strengths and weaknesses is the first step to finding the perfect fit for your kitchen's specific needs.

Understanding the Three Main Types of Interceptors

Your options typically fall into three main buckets. Each has its own way of working, its own maintenance demands, and its own ideal home.

-

Gravity Grease Interceptors (GGIs): These are the old-school workhorses. Think big, in-ground tanks usually made of concrete, fiberglass, or steel. They rely on sheer size and a long retention time—the amount of time wastewater sits in the tank—to let FOG naturally float to the top. They're best suited for high-volume spots like large restaurants, hospitals, and school cafeterias.

-

Hydromechanical Grease Interceptors (HGIs): These are the smaller, smarter cousins. HGIs use internal baffles and flow controls to separate FOG more efficiently in a much smaller footprint. Often made of steel or plastic, they are a fantastic solution for kitchens with space constraints or lower FOG output, like a small café or deli.

-

Automatic Grease Removal Units (AGRUs): These are the high-tech option. AGRUs are active systems that don't just separate FOG—they automatically skim it off the surface into a separate collection bin. This cuts down on the need for frequent professional pumping, but it does mean more daily upkeep from your staff and a higher upfront investment.

Choosing between these often comes down to a trade-off: upfront cost versus available space and long-term maintenance. A big gravity unit costs a lot to install but has less frequent service calls, while an AGRU costs more to buy but simplifies the daily chore of managing FOG.

The Critical Process of Sizing Your Interceptor

Once you have an idea of the type you need, the next step is the most important one: sizing it correctly. An improperly sized grease interceptor is pretty much useless. This isn't a guessing game; it's a specific calculation based on your kitchen's wastewater output and local rules.

The most common way to size an interceptor is by calculating Drainage Fixture Units (DFUs). Every plumbing fixture in your kitchen that produces greasy wastewater—from your three-compartment sinks and dishwashers to your floor drains and mop sinks—is assigned a DFU value by the plumbing code. You add up all those values to get a total wastewater load.

From there, your local plumbing code will give you a formula or a chart to turn that total DFU value into a required interceptor capacity, usually measured in gallons. For example, a kitchen with a total of 35 DFUs might require a 1,000-gallon gravity interceptor. These calculations are all designed to ensure the interceptor provides enough retention time for FOG to separate properly, even during your busiest dinner rush. For a deeper dive into these calculations, check out our comprehensive guide on grease trap sizing.

Why Professional Consultation Is Non-Negotiable

While it’s great to understand the basics, this is definitely not a DIY project. The formulas can get complicated, and your local city or county often has unique requirements or additions to the standard plumbing codes. This is where you absolutely need to bring in the pros.

You should always consult with:

- A Licensed Plumber: They live and breathe the local code and can accurately calculate your DFU load.

- Your Local Municipality: The public works or water department will tell you their specific sizing rules and which interceptor models are approved for use.

- An Equipment Supplier: Experts can help you compare the real-world costs, benefits, and long-term maintenance needs of different brands and types.

Industry-wide performance standards, like those from ASME, require a minimum of 90% FOG removal from wastewater. The modern hydromechanical grease interceptors developed between 2006 and 2018 are a huge leap forward from older gravity systems. Getting a handle on these regulatory demands is crucial, as compliance costs can vary wildly. The market for these units is growing, driven by stricter environmental rules and a greater awareness among restaurant owners about keeping FOG out of city sewers.

Making a mistake at this stage can lead to thousands of dollars down the drain, failed inspections, and frustrating operational headaches. Getting it right from the start by relying on professional expertise is the smartest financial decision you can make.

Keeping Your Grease Interceptor in Check: Maintenance and Compliance

Putting in a grease interceptor is just the start. Think of it less like a one-time install and more like hiring a full-time guard for your plumbing. Consistent, professional maintenance is what keeps that guard on duty. Skipping out on it isn't a minor slip-up; it's practically inviting operational disasters, environmental fines, and costs that can make your head spin.

It's a common mistake to see maintenance as just another expense. A much smarter way to look at it is as an investment in keeping your doors open. A properly serviced interceptor is your best defense against the kind of sewer backups that shut down a kitchen for days. It keeps you on the right side of the law and proves you’re a responsible business in your community.

This proactive approach is what keeps your kitchen humming and your bank account safe from emergencies. Trust me, the alternative is way more expensive.

Living by the Critical 25% Rule

In our industry, there's a golden rule for grease interceptor care: the "25% Rule." It's simple but absolutely critical. Your interceptor needs to be pumped and cleaned out the moment the floating FOG and the settled solids at the bottom add up to 25% of the tank's total liquid depth.

Why 25%? Because once you hit that mark, the interceptor's ability to do its job plummets. The tank gets too full of gunk, which means there's less water in it. This drastically cuts down the time wastewater spends inside, allowing grease and oil to zip right through the unit and straight into the city sewer—which is the exact problem it’s supposed to prevent.

Following the 25% Rule isn't just a good idea; in most places, it's the law. Health inspectors and city officials use this benchmark to see if you're compliant.

Sticking to this rule ensures your interceptor always has the capacity to work correctly, keeping your plumbing safe and the regulators happy.

The High Cost of Neglect

Putting off maintenance can set off a chain reaction of problems that are far worse than a simple clogged pipe. The risks of a poorly maintained grease interceptor are serious enough to threaten your entire business.

Here’s what you’re risking:

- Massive Municipal Fines: We're not talking about a slap on the wrist. Cities can hit you with fines that run into the tens of thousands of dollars for FOG discharge violations. These are often daily fines, so the bill can skyrocket in no time.

- Forced Kitchen Shutdowns: A sewer backup from a full interceptor will shut your restaurant down, period. The lost revenue, on top of the emergency plumbing bills, can be absolutely devastating.

- Serious Legal Liability: If your grease discharge causes a major sewer overflow for the city, your business could be on the hook for the environmental cleanup costs and property damage. That can easily lead to lawsuits.

These aren't just hypotheticals; they happen all the time. For more tips on keeping your whole operation up to code, check out our guide on cleaning restaurant equipment.

Your Best Defense: Meticulous Service Logs

When it comes to compliance, it’s not just about doing the right thing—it’s about proving you did it. Health inspectors and city agents need to see detailed records to verify your grease interceptor is being serviced properly. Keeping organized service logs isn't optional.

Every time your interceptor is serviced, your log needs to capture the essentials:

- Date of Service: When exactly was it pumped?

- Service Provider: Which company did the work?

- Volume Removed: How many gallons of FOG and solids were taken out?

- Unit's Condition: Did the technician note any damage or potential issues?

- Manifest or Receipt: You absolutely need the official paperwork from the service company.

This log is your proof of compliance. When an inspector shows up, having a complete and organized record is your best defense against fines and shows you’re a responsible operator.

The rules we follow today didn't just appear overnight; they've evolved as our understanding of environmental protection grew. While early laws date back to 1948, it was the landmark Clean Water Act of 1972 that really changed the game for commercial kitchens. This act gave the EPA the authority to set the wastewater standards that shape how foodservice businesses must manage their FOG output. You can learn more about the history and evolution of grease interceptors to get the full picture on these crucial regulations.

Equip Your Kitchen for FOG Management Success

When it comes down to it, truly understanding what is a grease interceptor is one of the fundamentals of running a successful kitchen. This isn't just another box to check off your equipment list; it’s the silent guardian of your plumbing, your budget, and even your community’s infrastructure. A correctly sized and well-maintained unit is the unsung hero of any compliant, efficient foodservice operation.

From stopping catastrophic sewer backups in their tracks to shielding your business from steep municipal fines, its role is completely non-negotiable. Ignoring this system is a direct threat to your kitchen's stability, while investing in its proper care is really an investment in your long-term success.

Your Partner in Compliance and Efficiency

Navigating the maze of local codes, sizing formulas, and pump-out schedules can feel pretty overwhelming. That’s where having a reliable partner makes all the difference. At The Restaurant Warehouse, we do more than just sell equipment; we help you build a successful kitchen from the ground up.

We offer expert guidance to help you select the perfect grease interceptor for your specific needs, making sure you get it right the first time. Our inventory is stocked with trusted, high-performance brands designed to deliver dependable FOG management day in and day out. For total FOG management, it helps to understand all the tools involved, which can even include knowing about Choosing and Using a Cordless Grease Gun.

Investing in the right infrastructure is crucial, but it shouldn't drain your capital. A well-equipped kitchen is a profitable kitchen.

We firmly believe that a tight budget shouldn't ever compromise your ability to run a safe and efficient business. That's why we offer a range of flexible financing and lease-to-own solutions that are tailored to the realities of the foodservice industry. These programs are designed to help you get the essential gear your business needs to thrive, all while protecting your cash flow for day-to-day operations.

Let us help you build a compliant, efficient, and successful kitchen.

Got Questions? We’ve Got Answers.

Alright, so you get the basics of what a grease interceptor does. But what does owning one actually look like day-to-day? We hear the same practical, real-world questions all the time from operators just like you.

Knowing the real costs, what to look for when things go wrong, and why some jobs just aren't DIY is what protects your business in the long run. Let's get straight to the answers you need.

What Are the Realistic Costs for Installation and Maintenance?

This is usually the first question on everyone's mind, and for good reason. The financial side of things can vary a lot, but you absolutely need to budget for both the upfront installation and the regular upkeep.

- Installation Costs: Getting a new, in-ground gravity grease interceptor installed is a significant project. You can expect it to range anywhere from $5,000 to over $25,000. The final number really depends on the size of the unit, the material (concrete is common), local labor rates, and how complex the digging and plumbing work turns out to be.

- Maintenance Costs: Think of professional pumping as a recurring operational expense, just like utilities. Each service call will likely run between $250 and $750, depending on your interceptor's size and where you're located. For most busy restaurants, you'll need this done every 30 to 90 days to stay on the right side of the law.

It helps to reframe these expenses. They aren't just costs—they're insurance against a much bigger financial nightmare. The price tag for a single emergency sewer backup or one hefty fine from the city can easily wipe out an entire year's worth of maintenance fees.

What Are the Signs My Interceptor Needs Service?

Don't worry, your grease interceptor won't just fail without warning. It will give you some pretty clear signals when it's getting full and needs to be pumped out. Ignoring these red flags is a fast track to a backup that could shut your whole kitchen down.

Keep an eye (and nose) out for these tell-tale signs:

- Foul Odors: This is the classic sign. If you notice a strong, nasty smell coming from your drains or from the ground outside where the interceptor is buried, it’s a dead giveaway. That's usually hydrogen sulfide gas building up from all the grease and food solids breaking down in the tank.

- Slow Draining Fixtures: Are your three-compartment sinks, floor drains, or dishwashers taking forever to drain? That’s a huge indicator that the interceptor is full, and the wastewater has nowhere else to go.

- Gurgling Drains: If your drains sound like they're burping, that's another bad sign. Those gurgling noises mean air is getting trapped in the pipes by a blockage downstream—and that blockage is almost certainly inside your interceptor.

Why Is Professional Installation So Important?

Look, I get the temptation to DIY some projects to save a few bucks. But installing a grease interceptor is one area where you absolutely cannot cut corners. Trying to do it yourself or hiring a random, unqualified contractor is just asking for a world of expensive problems down the road.

Professional installation isn't just a suggestion; it's non-negotiable for a few key reasons:

- Regulatory Compliance: A licensed plumber knows the local plumbing codes and city regulations inside and out. They'll make sure the installation is done by the book so you can pass your inspections without any trouble.

- Proper Sizing and Placement: An expert will do the math to size the unit correctly based on your kitchen's output. More importantly, they'll install it with the exact right slope and connections needed for gravity to do its job effectively.

- Long-Term Functionality: Getting it right the first time prevents a ton of future headaches like leaks, chronic blockages, and even structural failure. A professional job saves you thousands in repairs you'd otherwise be facing.

Ready to equip your kitchen for success? The Restaurant Warehouse is your partner in building a compliant and efficient operation with a wide selection of essential equipment and flexible financing options. Explore our solutions at https://therestaurantwarehouse.com.

About The Author

Sean Kearney

Sean Kearney is the Founder of The Restaurant Warehouse, with 15 years of experience in the restaurant equipment industry and more than 30 years in ecommerce, beginning with Amazon.com. As an equipment distributor and supplier, Sean helps restaurant owners make confident purchasing decisions through clear pricing, practical guidance, and a more transparent online buying experience.

Connect with Sean on LinkedIn, Instagram, YouTube, or Facebook.

Leave a comment